Patents

Literature

36results about How to "Achieving Recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

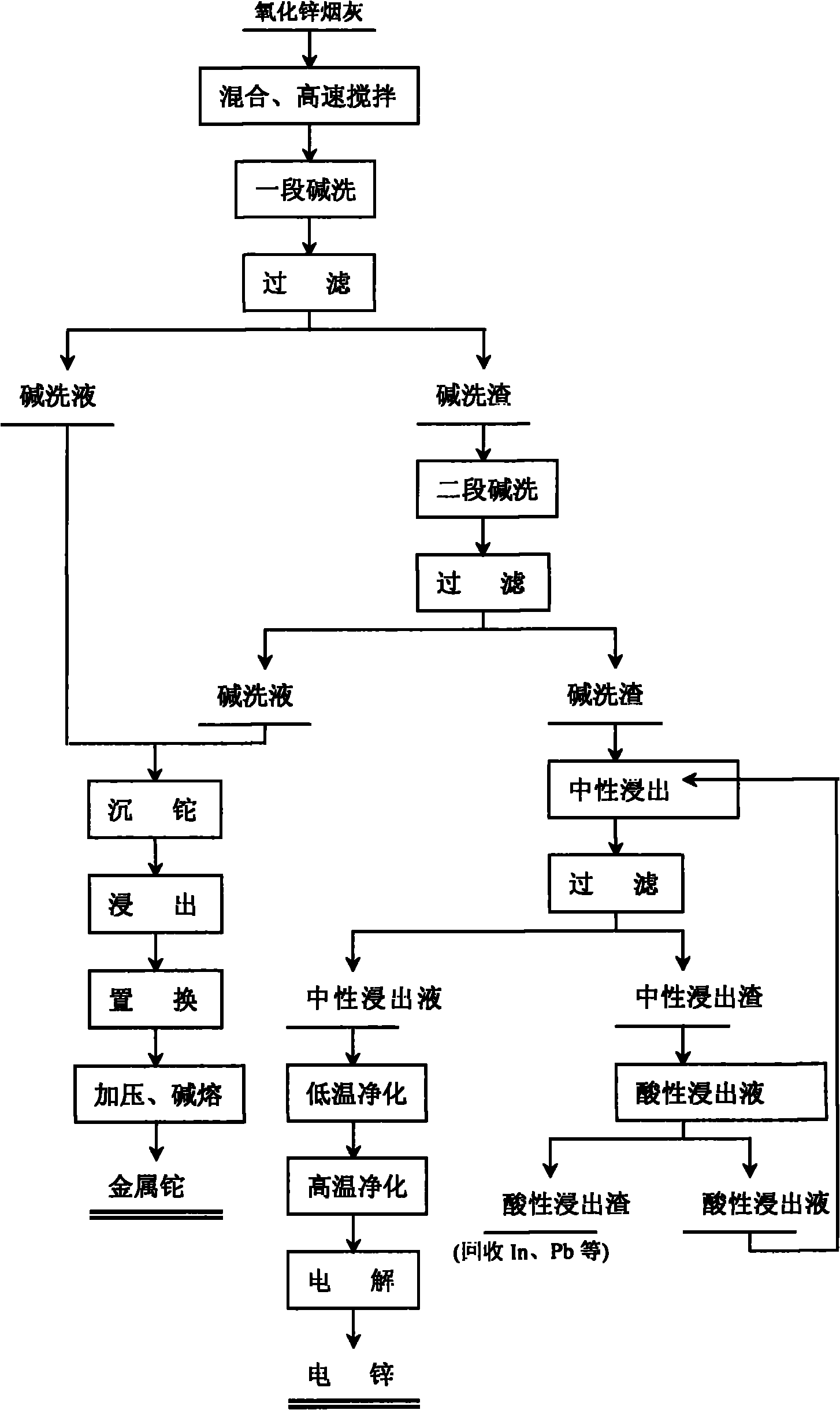

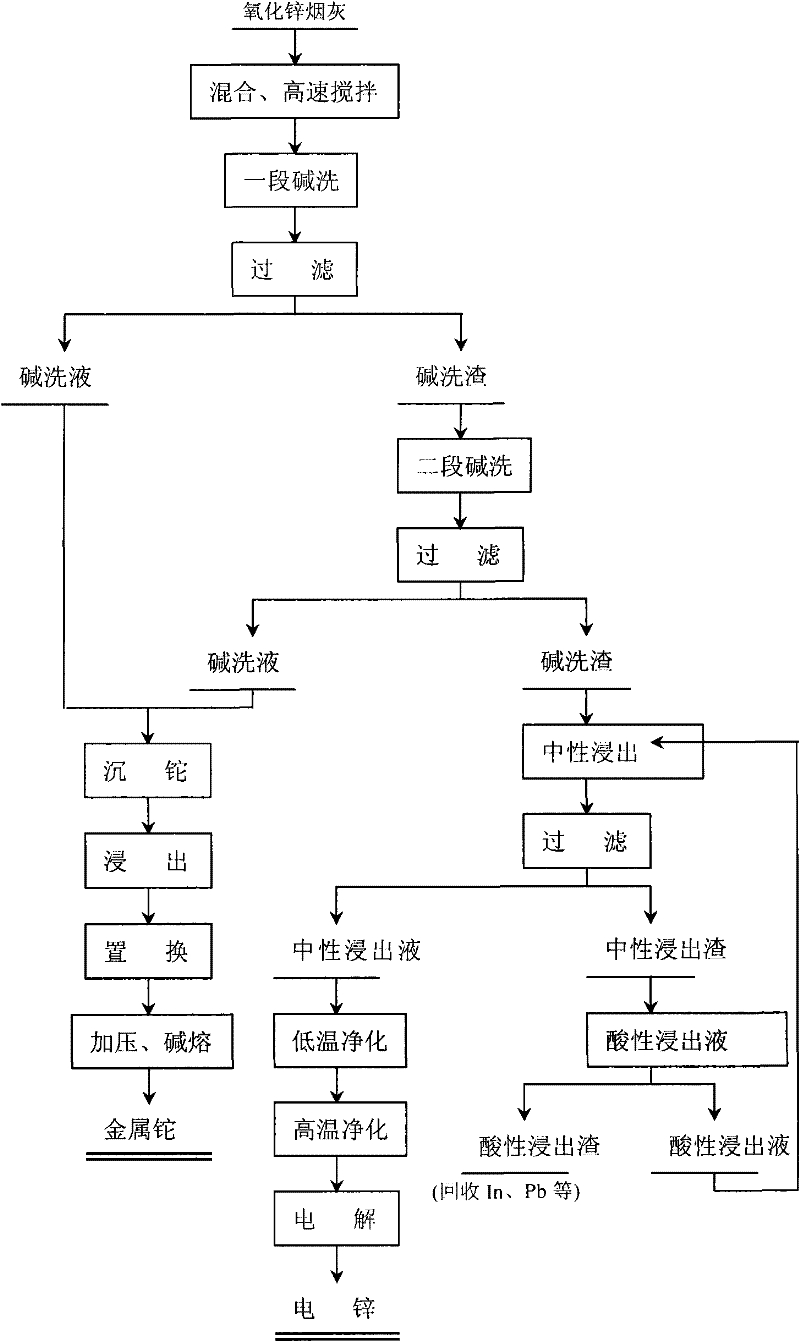

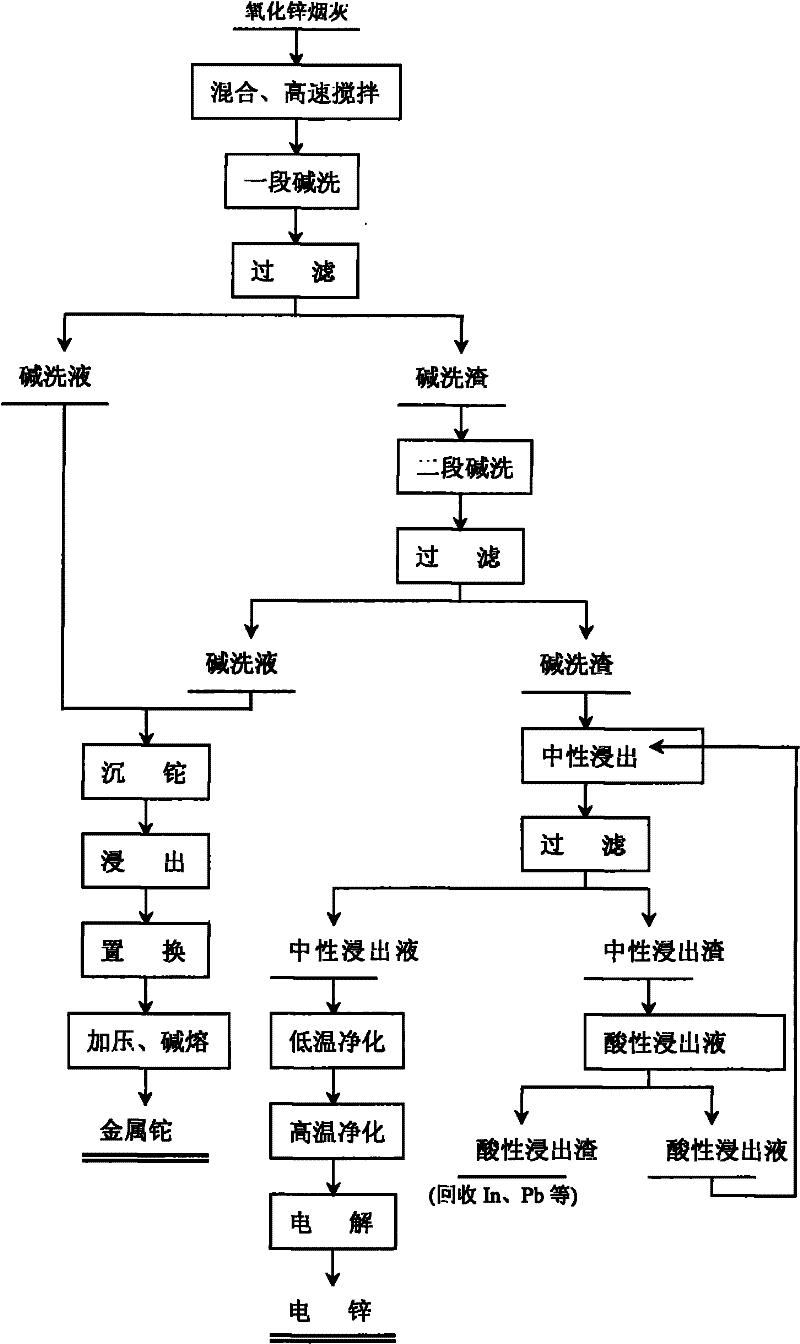

Comprehensive recovery method of zinc oxide fume dust

The invention relates to a comprehensive recovery method of zinc oxide fume dust. The method comprises the following steps: 1. performing alkali-washing on zinc oxide fume dust with Na2CO3 and NaOH in different stages: in the first stage of alkali wash, evenly mixing the zinc oxide fume dust and solid Na2CO3, adding water, stirring at high speed to dissolve the solid into solution with slag, and filtering to obtain first-stage alkali wash liquid and alkali wash slag; in the second stage of alkali wash, adding solid Na2CO3 and NaOH into the first-stage alkali wash slag, adding water, stirring to dissolve the solid, regulating the pH value, and filtering to obtain second-stage alkali wash liquid and alkali wash slag; and carrying out neutral leaching on the second-stage alkali wash slag, purifying and electrodepositing to obtain electric zinc; 2. leaching, displacing and the like to process the low temperature purified slag to obtain sponge cadmium; and 3. processing acid leached slag to obtain coarse indium, using high-temperature high-acidity leached slag as the raw material for recovering lead, and using alkali wash liquid for recovering thallium. In the invention, metals in ZnCl2, ZnF2 and PbCl2 form carbonate solid slag, chlorine and fluorine are dissolved in solution in the form of sodium salts, the slag and the liquids are respectively processed subsequently, and the products in every stage are refined processed to comprehensively recover zinc, cadmium, lead, thallium and indium.

Owner:ZHUZHOU SMELTER GRP

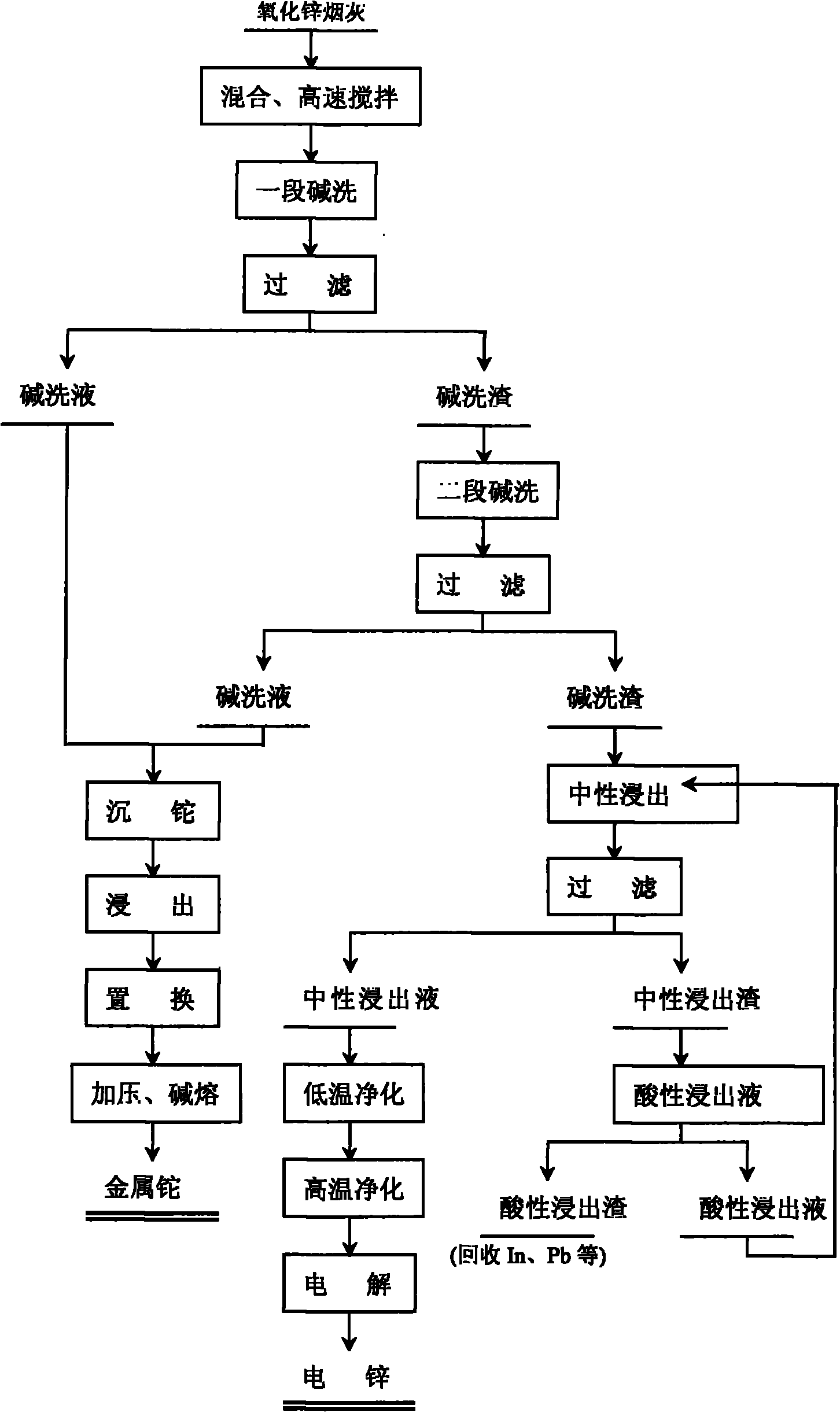

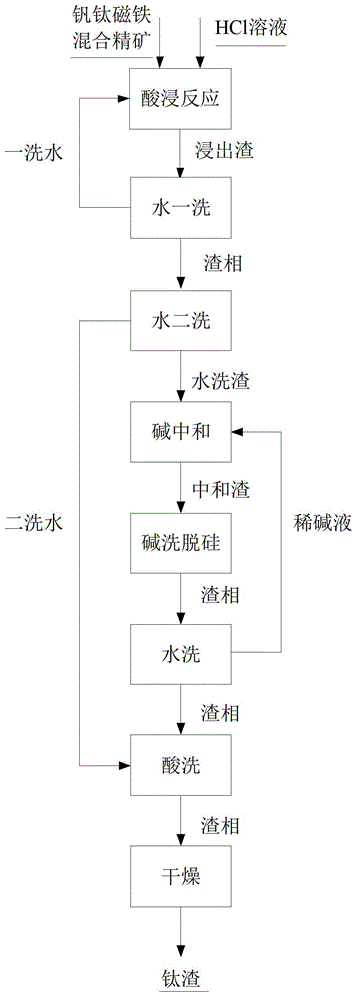

Method for preparing titanium slag by wet-processing on vanadium-titanium magnetite concentrates

ActiveCN103276204AShort processMild operating conditionsProcess efficiency improvementMagnetiteHydrometallurgy

The invention belongs to the wet-process metallurgical field and in particular relates to a method for preparing titanium slag by wet-processing on vanadium-titanium magnetite concentrates. The method for preparing titanium slag by wet-processing on vanadium-titanium magnetite concentrates comprises the following steps of: (1), mixing the vanadium-titanium magnetite concentrates with an hydrochloric acid solution to obtain intermediate sizing agent; (2), filtering the intermediate sizing agent obtained in the step (1) to obtain leaching slag and carrying out secondary water-washing on the leaching slag (3), neutralizing the water-washing slag obtained in the step (2) by using a diluted alkaline solution, and filtering the neutralized sizing agent to obtain neutralized slag; (4), mixing the neutralized slag obtained in the step (3) with a NaOH solution to carry out alkaline-washing desilicication reaction; (5), filtering the product obtained by the alkaline-washing desilicication reaction, and carrying out water-washing on the obtained alkaline-washed slag; and (6), carrying out acid-pickling on the water-washed slag obtained by the water-washing in the step (5), filtering after the acid-pickling, drying and filtering the slag to obtain the titanium slag. The method for preparing titanium slag by wet-processing on vanadium-titanium magnetite concentrates has the advantages of being short in process, gentle in operation condition, low in device investment and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

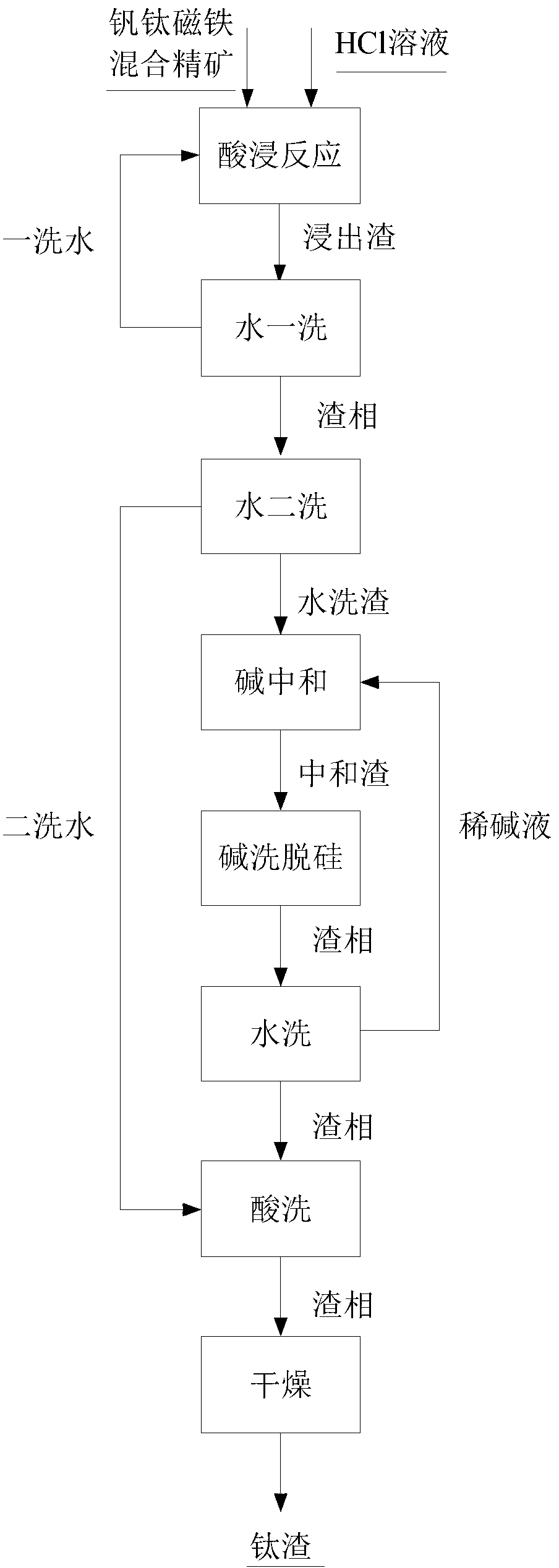

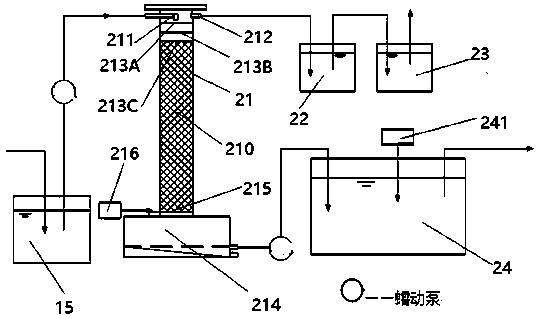

Low-energy-consumption municipal sewage nitrogen removal method based on enhanced carbon capture and anaerobic ammonia oxidation

ActiveCN106830573AEnhanced biosorption efficiencyReduce the degree of carbon oxidationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentEnergy recoveryNitrogen gas

The invention discloses a low-energy-consumption municipal sewage nitrogen removal method based on enhanced carbon capture and anaerobic ammonia oxidation. A raw water tank is a closed tank and is provided with an overflow pipe and a blow-down pipe; a bio-stabilization reactor and a biological adsorption reactor are respectively in a high DO environment and a low DO environment; the municipal sewage carbon capture is enhanced by improving the ability of adsorbing organic matters through microbes; a biological nitrogen removal reactor is sequentially divided into a low DO aerobic zone, an anoxic zone, an aerobic zone and a settling zone; a shortcut nitrification-anaerobic ammonia oxidation reaction is carried out in the low DO aerobic zone, and ammonia nitrogen is converted into nitrogen and partial nitrate nitrogen; organic matters in partial raw water serve as a carbon source, and advanced nitrogen removal is realized through the shortcut nitrification-anaerobic ammonia oxidation reaction. In order to avoid the ammonia nitrogen existing in the effluent, the aerobic zone is increased at the rear end of the anoxic zone, and the residual ammonia nitrogen in the sewage is oxidized into nitrate; and finally, the sewage is discharged through the settling zone. According to the method, the municipal sewage energy recovery efficiency can be improved, and the advanced nitrogen removal is realized.

Owner:BEIJING UNIV OF TECH

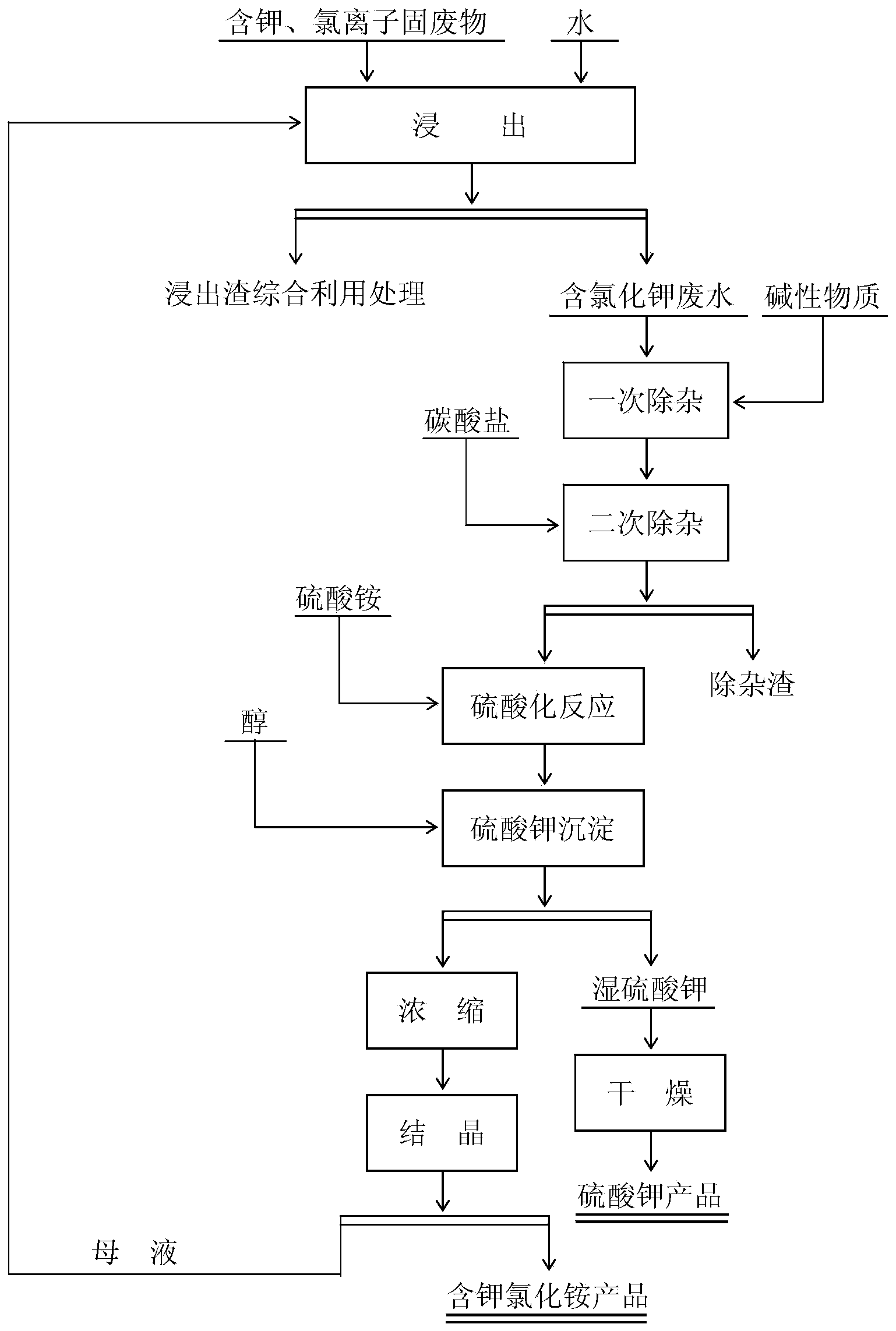

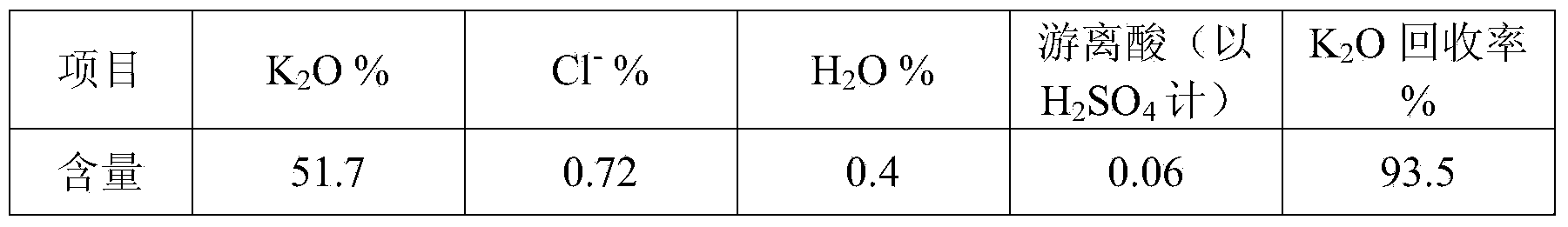

Method for producing potassium sulfate from potassium/chlorine-ion-containing solid waste

InactiveCN104261433AAchieving RecoveryImprove product qualitySulfate/bisulfate preparationAmmonium sulfateChloride potassium

The invention discloses a method for producing potassium sulfate from potassium / chlorine-ion-containing solid waste, which comprises the following steps: leaching potassium / chlorine-ion-containing solid waste with water, wherein the potassium / chlorine ions and other soluble impurity ions enter the water to form a potassium-chloride-containing mixed solution; adding an alkaline matter into the mixed solution to regulate the pH value of the solution, thereby performing primary impurity removal; adding soluble carbonate into the solution to perform secondary impurity removal; carrying out solid-liquid separation; adding ammonium sulfate into the filtrate; after the sulfating reaction, adding alcohol to precipitate potassium sulfate; after the potassium sulfate precipitation reaction, carrying out solid-liquid separation; drying the filter residue to obtain the potassium sulfate product; adding the filtrate into a concentration and crystallization device to perform concentration and crystallization, and carrying out solid-liquid separation, wherein the filter residue is the potassium-containing ammonium chloride product. By using the method, the recovery rate of K2O in the product is not less than 91% in the potassium-chloride-containing mixed solution.

Owner:XIANGTAN TIANZHI TECH

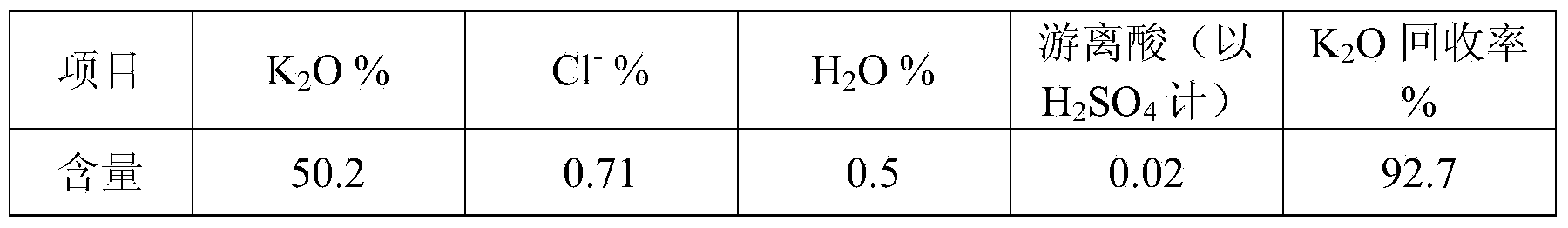

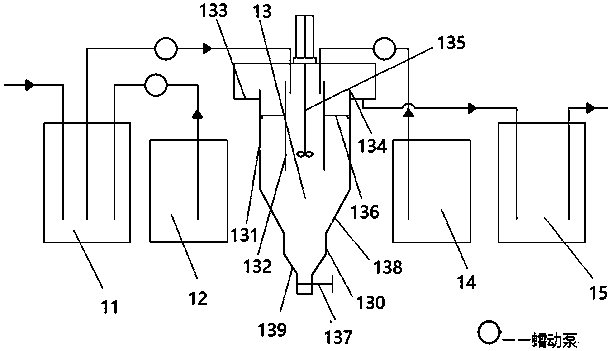

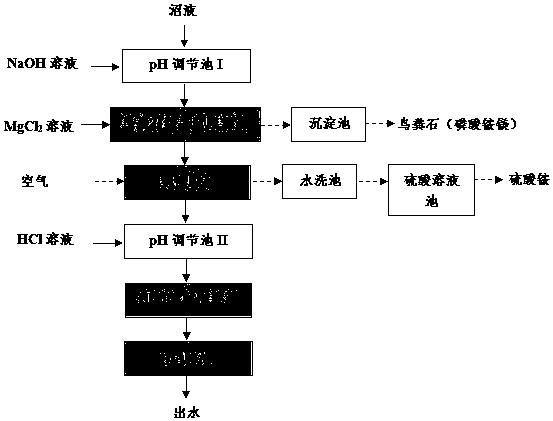

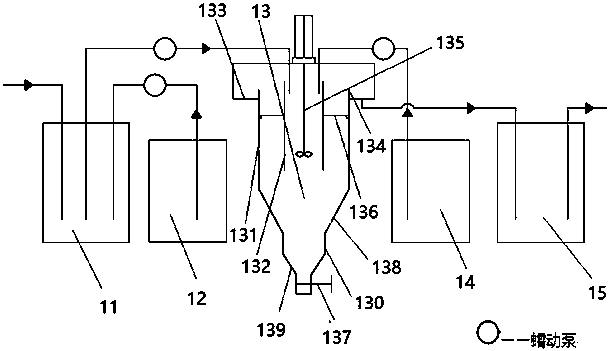

Method and device for removing and recycling nitrogen and phosphorus in biogas slurry

ActiveCN105502851ASimple processLow running costTreatment with aerobic and anaerobic processesAmmonium sulfatesAmmonium sulfateFertilizer

The invention discloses a method and device for removing and recycling nitrogen and phosphorus in biogas slurry. The combined technology of struvite crystallizing, ammonia stripping, SBBR treating and BAF treating is adopted to treat and use the biogas slurry in a resource mode, nitrogen and phosphorus in the biogas slurry are converted into struvite and ammonium sulfate capable of being used as fertilizer, while it is ensured that the treated biogas slurry reaches the emission standard of livestock and poultry industry pollutants, nitrogen and phosphorus recycling is achieved, operation cost of traditional biogas slurry treatment is effectively reduced, and the method has the advantages of being stable in treatment effect and the like. The device is designed based on the method, all parts of the device are optimized and improved, and the device can continuously and stably operate and is convenient to use and popularize.

Owner:SOUTHWEST UNIVERSITY

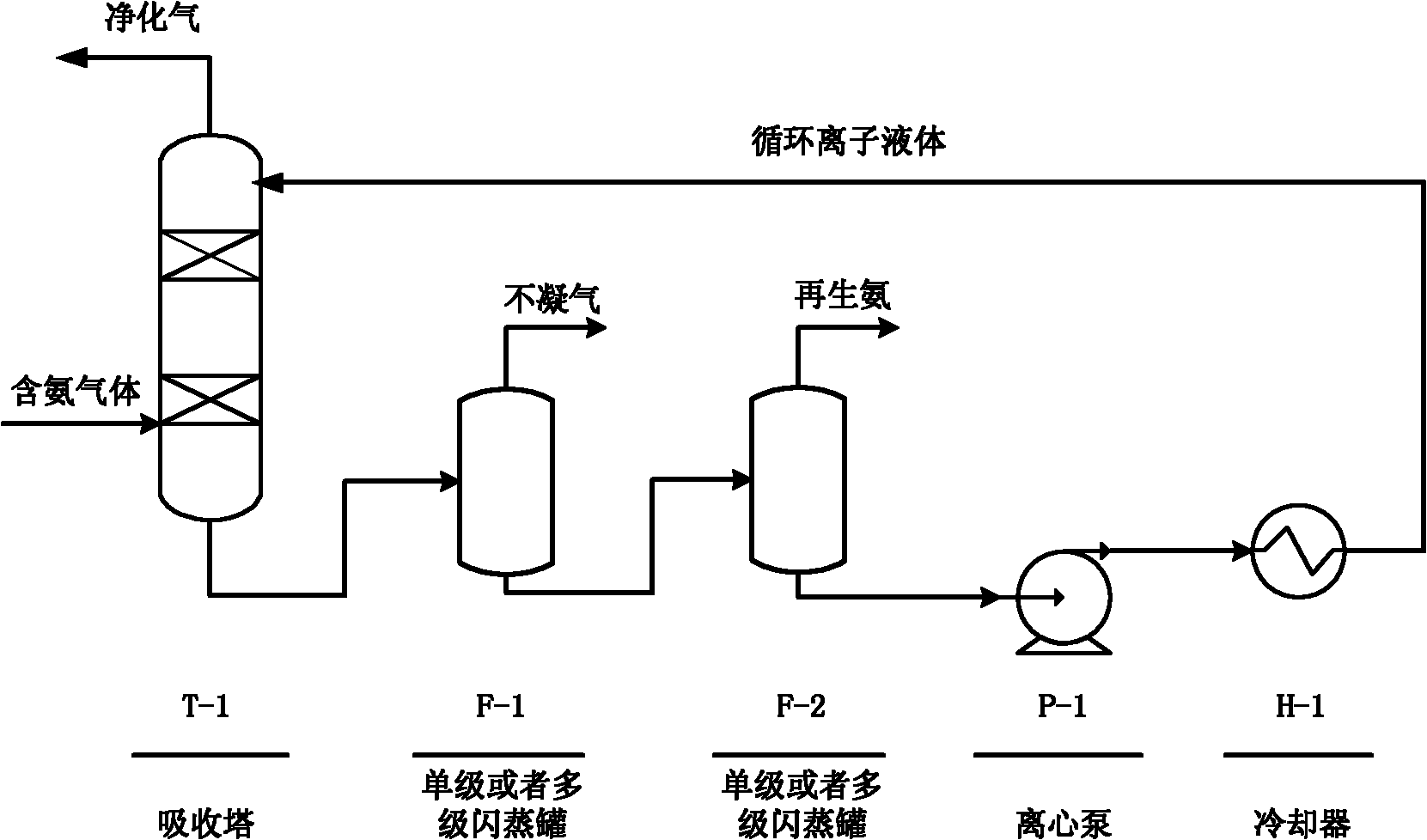

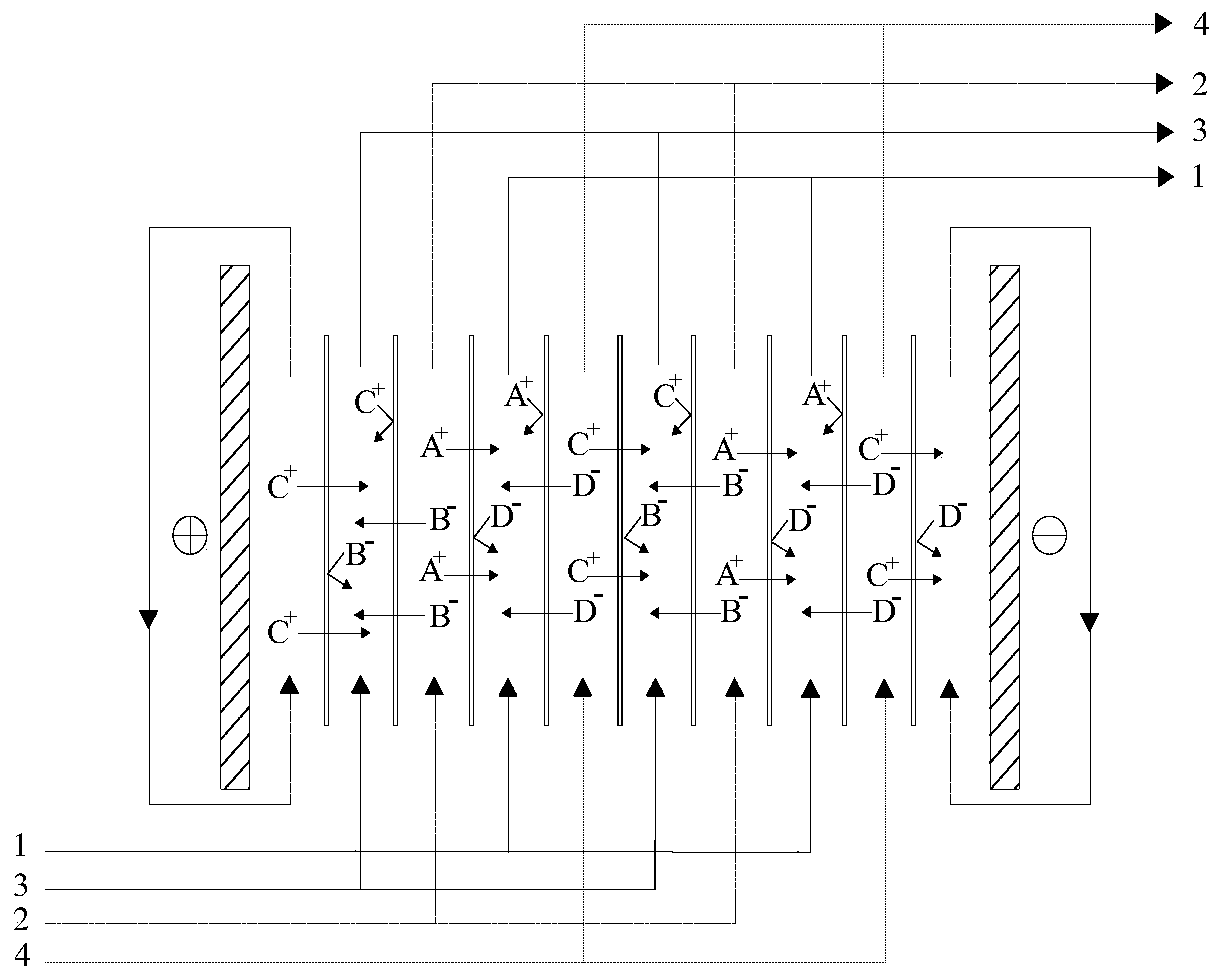

Method for recovering ammonia from ammonia-containing gas based on ionic liquid

InactiveCN102179133AAchieving RecoverySimple structureDispersed particle separationRecovery methodSingle stage

The invention relates to a method for recovering ammonia from ammonia-containing gas based on ionic liquid, which can solve the problems that a solvent is easy to volatilize, the energy consumption is high, the volume is small, wastewater is discharged and the like in the conventional method for recovering ammonia from ammonia-containing gas through water absorption. An absorption device recovers the ammonia from the ammonia-containing gas by taking the ionic liquid or a composite solvent as an absorbent; and the method comprises the following steps of: desorbing most noncondensable gas from ammonia-containing rich liquid through single stage or multiple stages of flash evaporation; and further performing flash evaporation to recover ammonia from the absorbent, and making the desorbed ionic liquid absorbent subjected to pressurization and temperature reduction enter the absorption device to circularly absorb the ammonia in the ammonia-containing gas. The recovery rate of ammonia is over 95 percent; and the process has the characteristics of environmental friendliness, low energy consumption, simple equipment, convenience of operation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

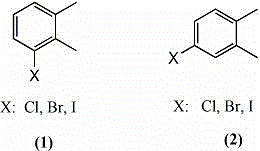

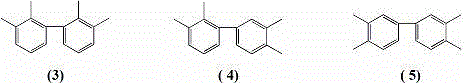

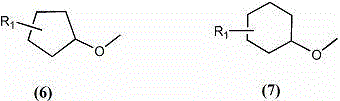

Green synthesis method of tetramethyl biphenyl isomer compounds

Owner:HARBIN INST OF TECH AT WEIHAI

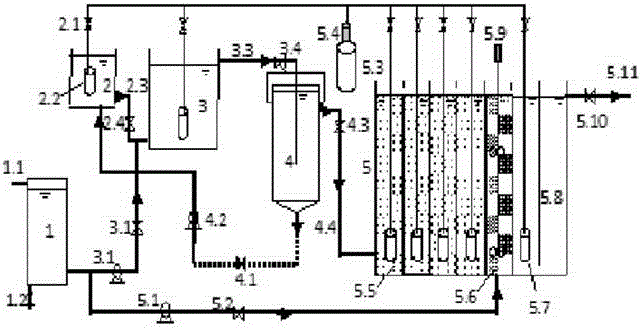

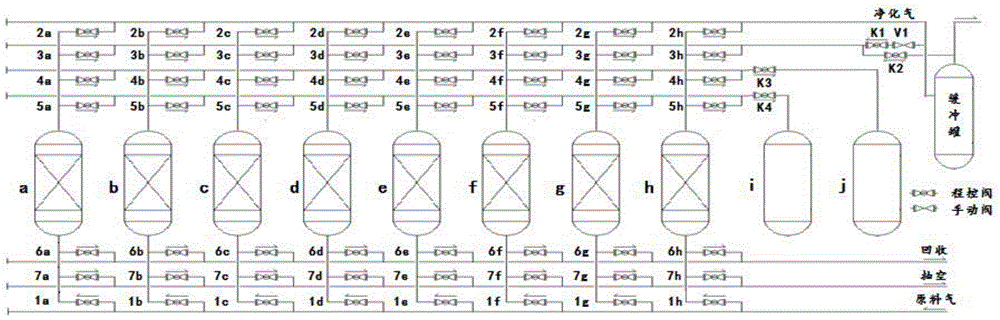

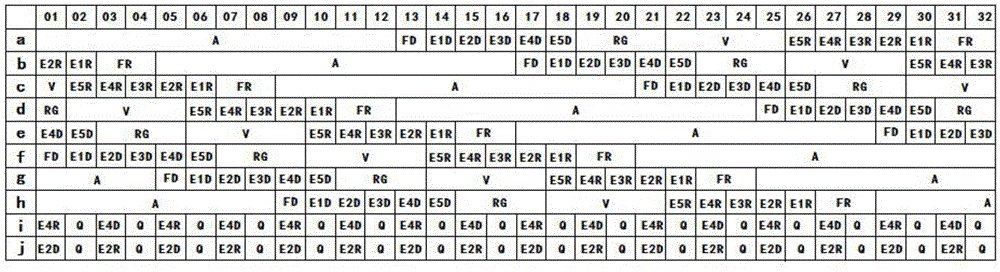

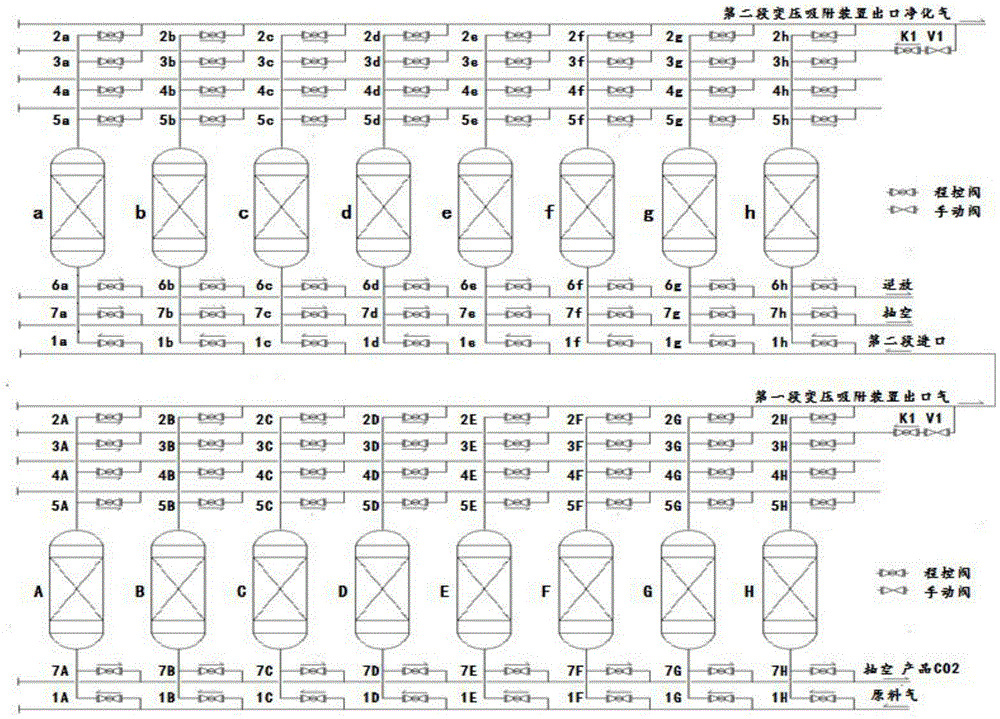

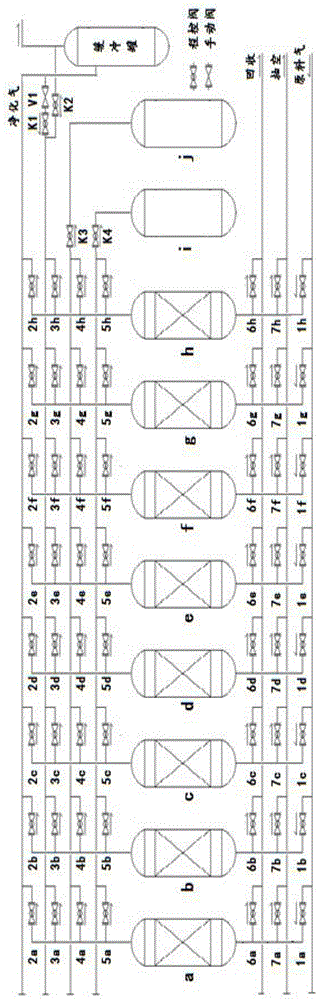

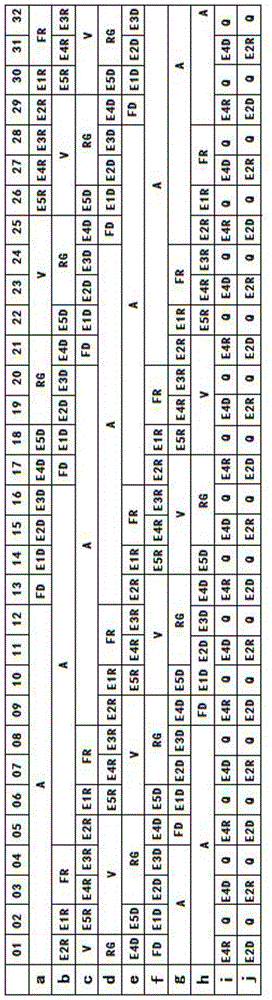

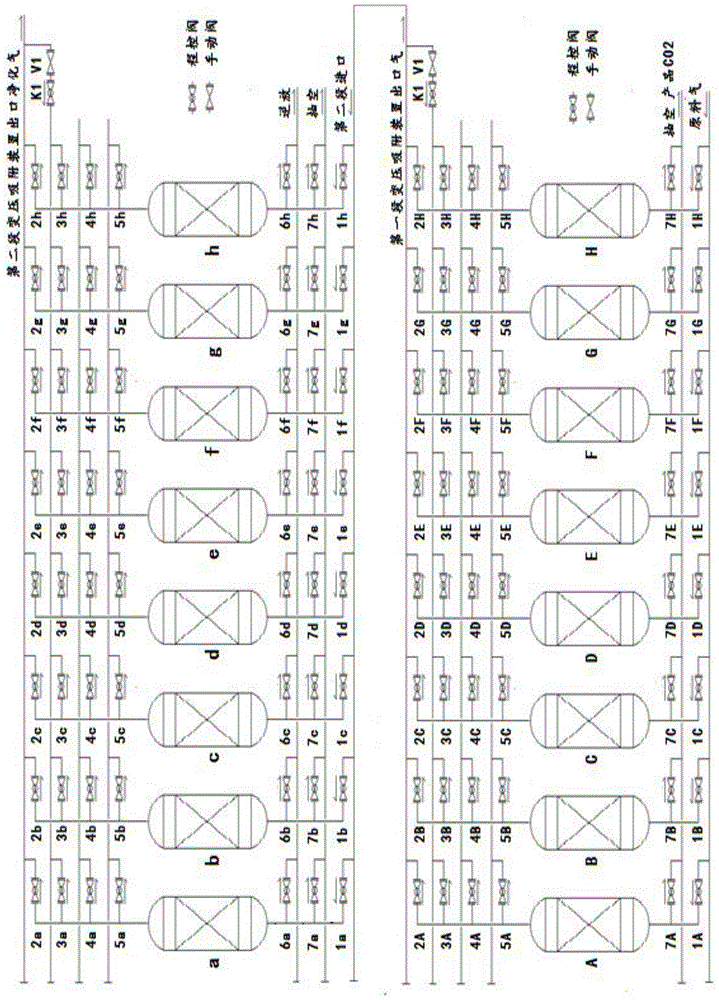

Novel saturation adsorption process of pressure swing adsorption decarburization and device thereof

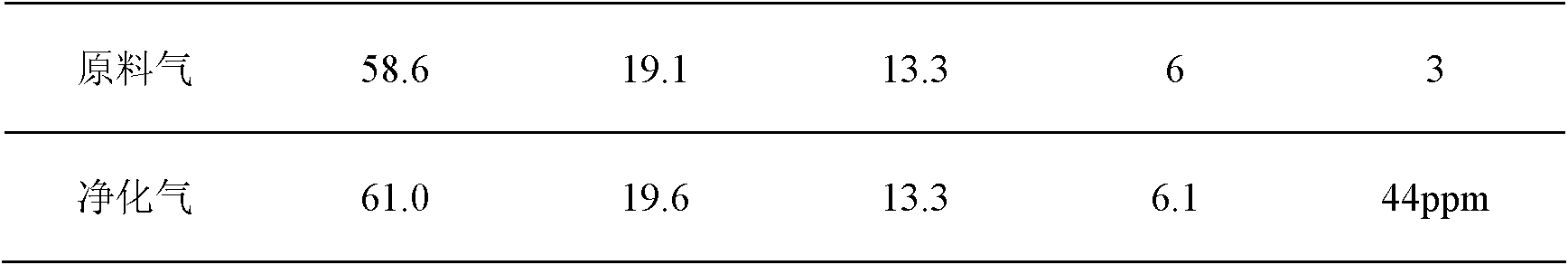

ActiveCN104128073AReduce adsorptionReduce lossesDispersed particle separationAbsorption ratioPressure rise

The invention relates to the technical field of pressure swing adsorption decarburization and discloses a novel saturation adsorption process of pressure swing adsorption decarburization and a device thereof. According to the process, CO2 gas in raw gas is adsorbed and removed by adsorbents in adsorption towers which are arranged in parallel, so as to obtain purified gas. Each circulation of the process comprises adsorption, uniform pressure drop, recycling, vacuumization, uniform pressure rise, isolation and final boosting, wherein the adsorption includes front adsorption, adsorption and back adsorption; the front adsorption specifically comprises the steps of inputting the output gas at the stage of the back adsorption of other adsorption towers and outputting the purified gas; the adsorption specifically comprises the steps of inputting the raw gas and outputting the purified gas; the back adsorption specifically comprises the step of outputting gas which exceeds the indexes of the purified gas, so as to be used as the input gas of the front adsorption or the final inflated gas of the final boosting; the final boosting comprises the step of boosting the adsorption tower by adopting the gas which exceeds the indexes of the purified gas and is output by the back adsorption of other adsorption towers. The novel saturation adsorption process has the advantages of high CO2 absorptivity, less loss of effective constituents in the gas and the like.

Owner:HUNAN THREE ARROWS AUTOMATION TECH

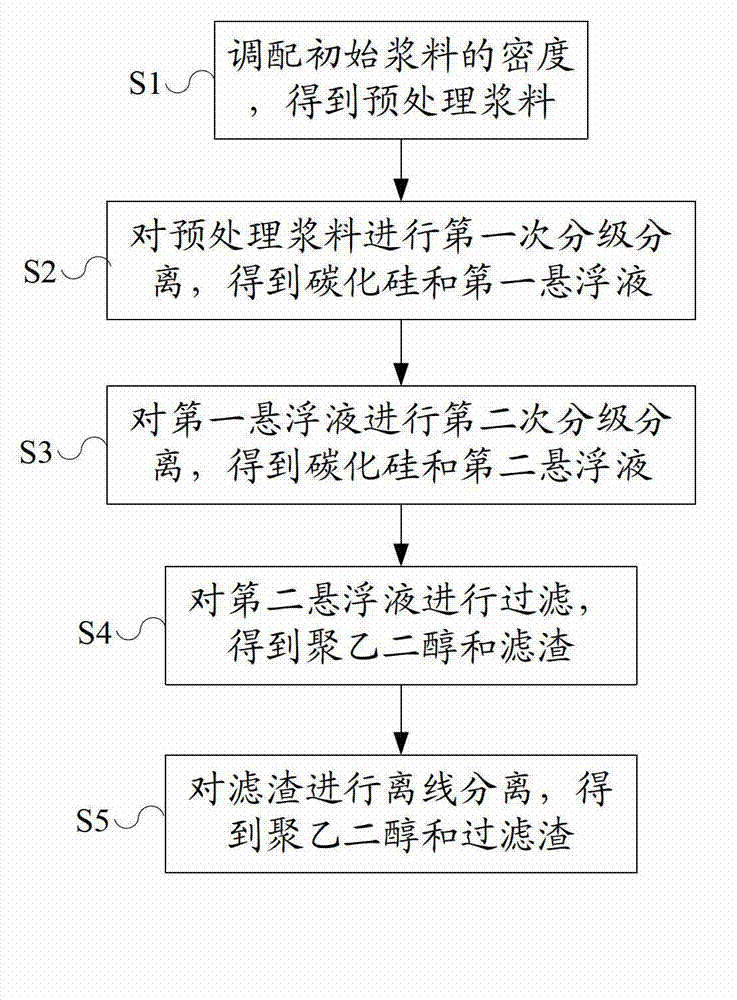

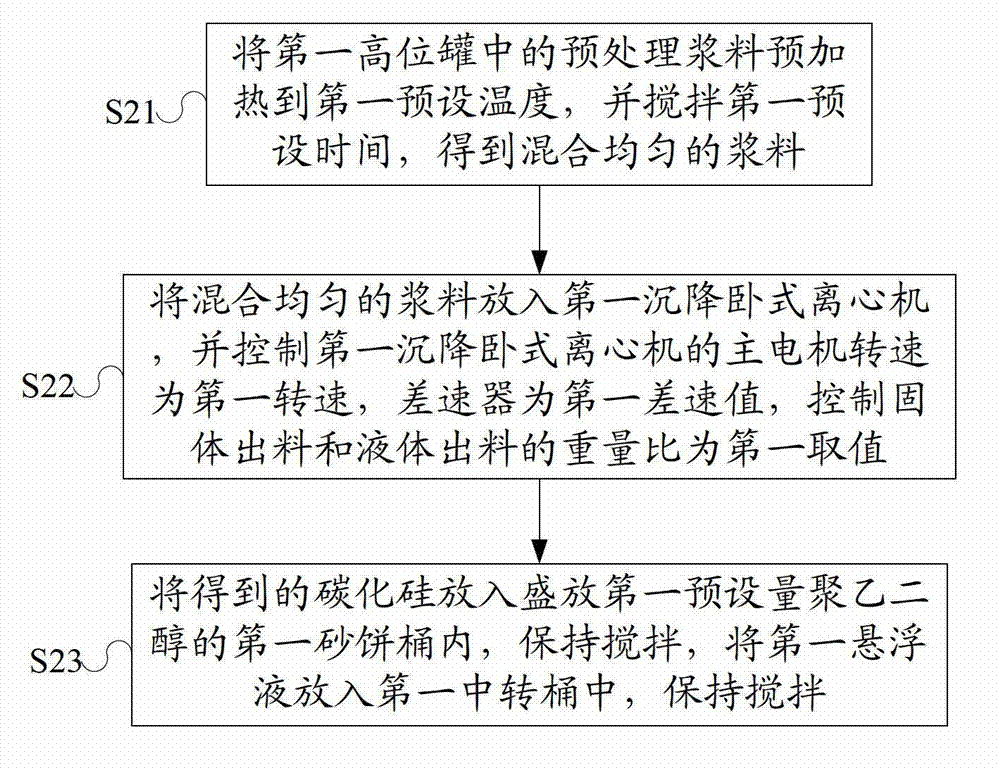

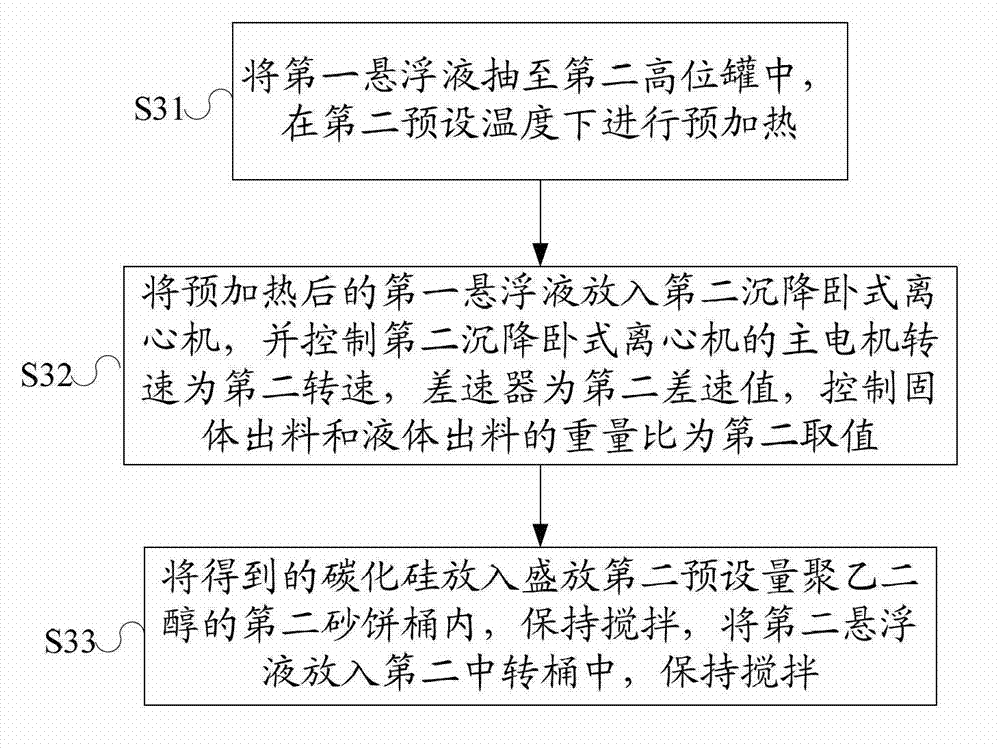

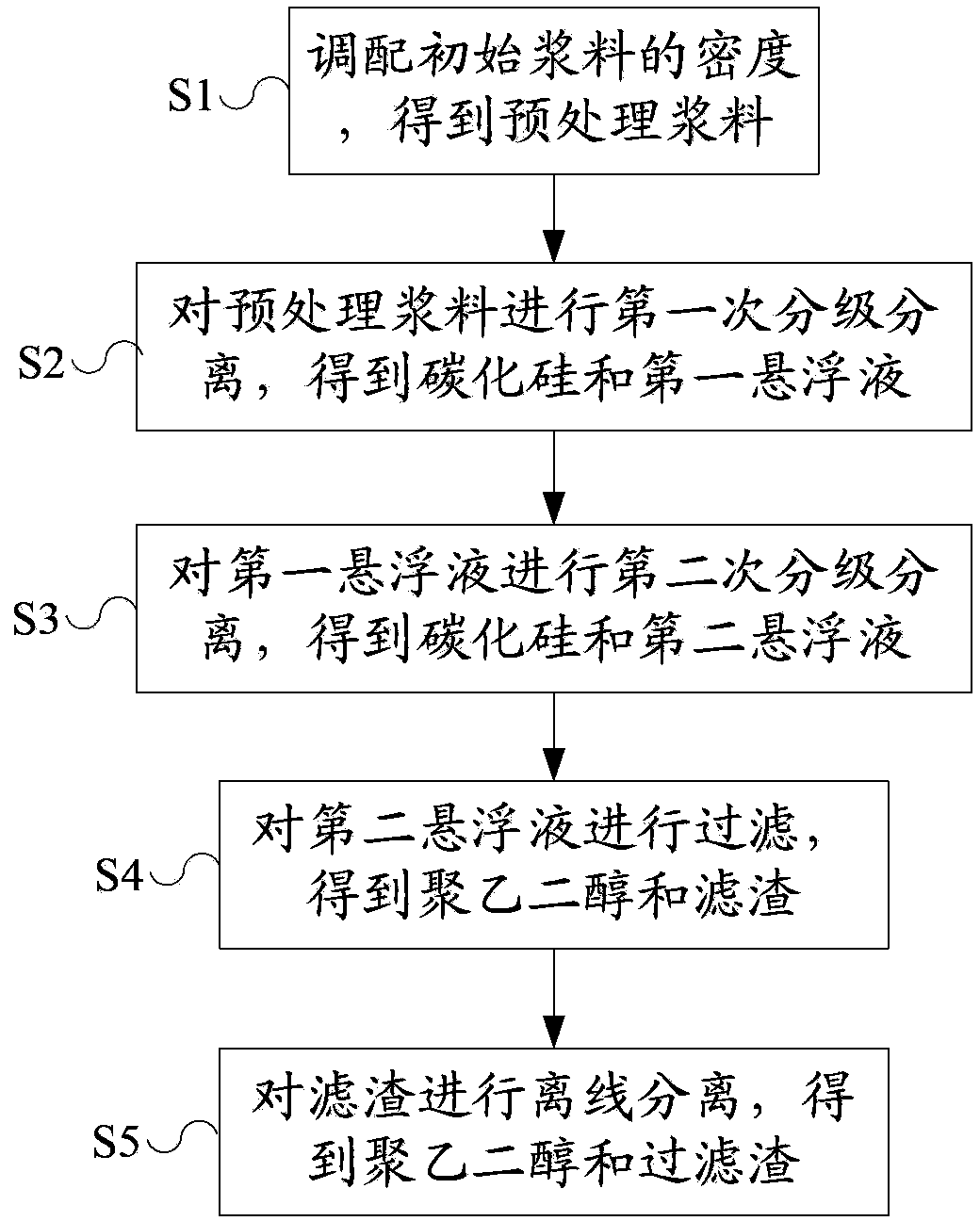

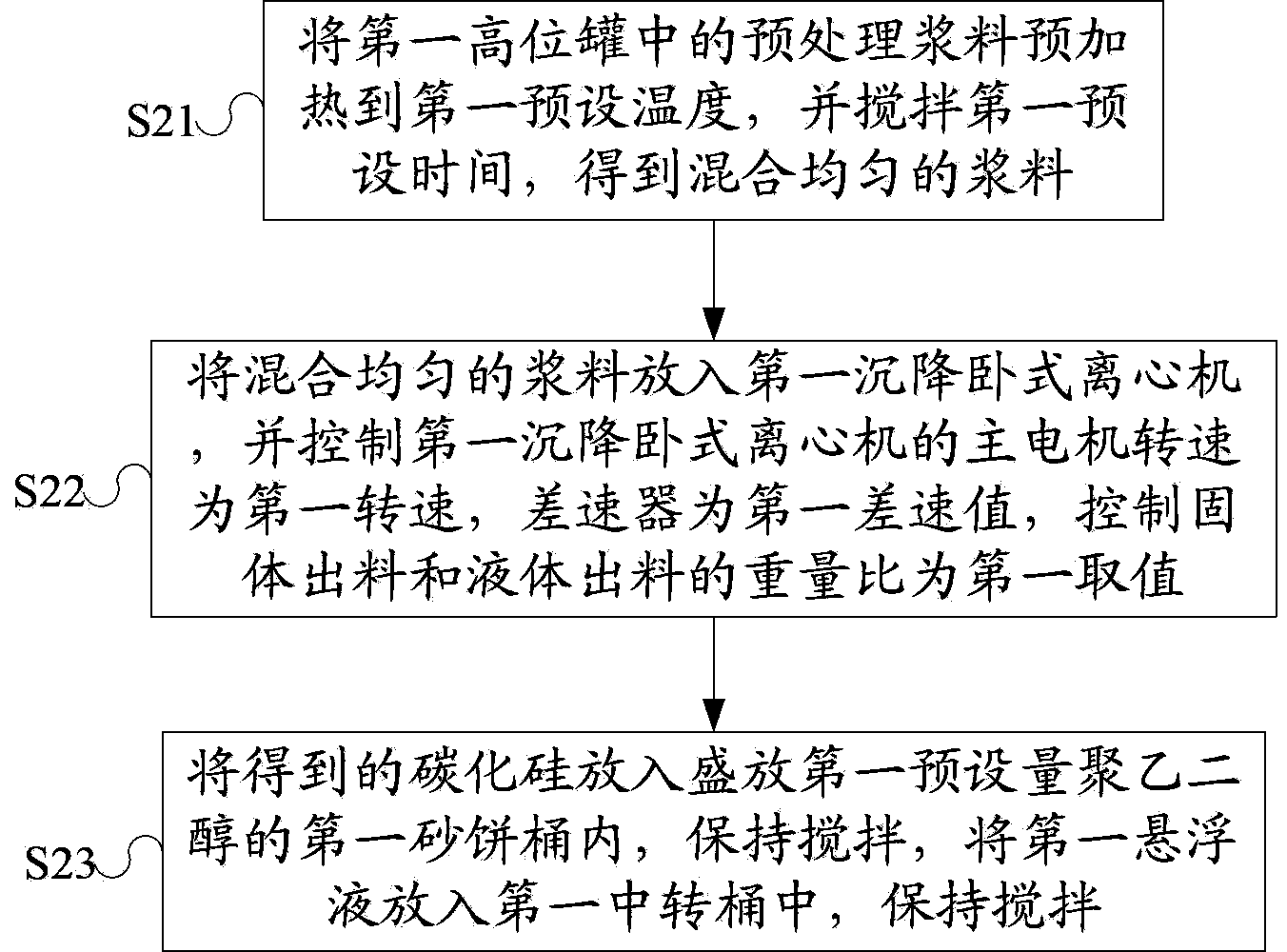

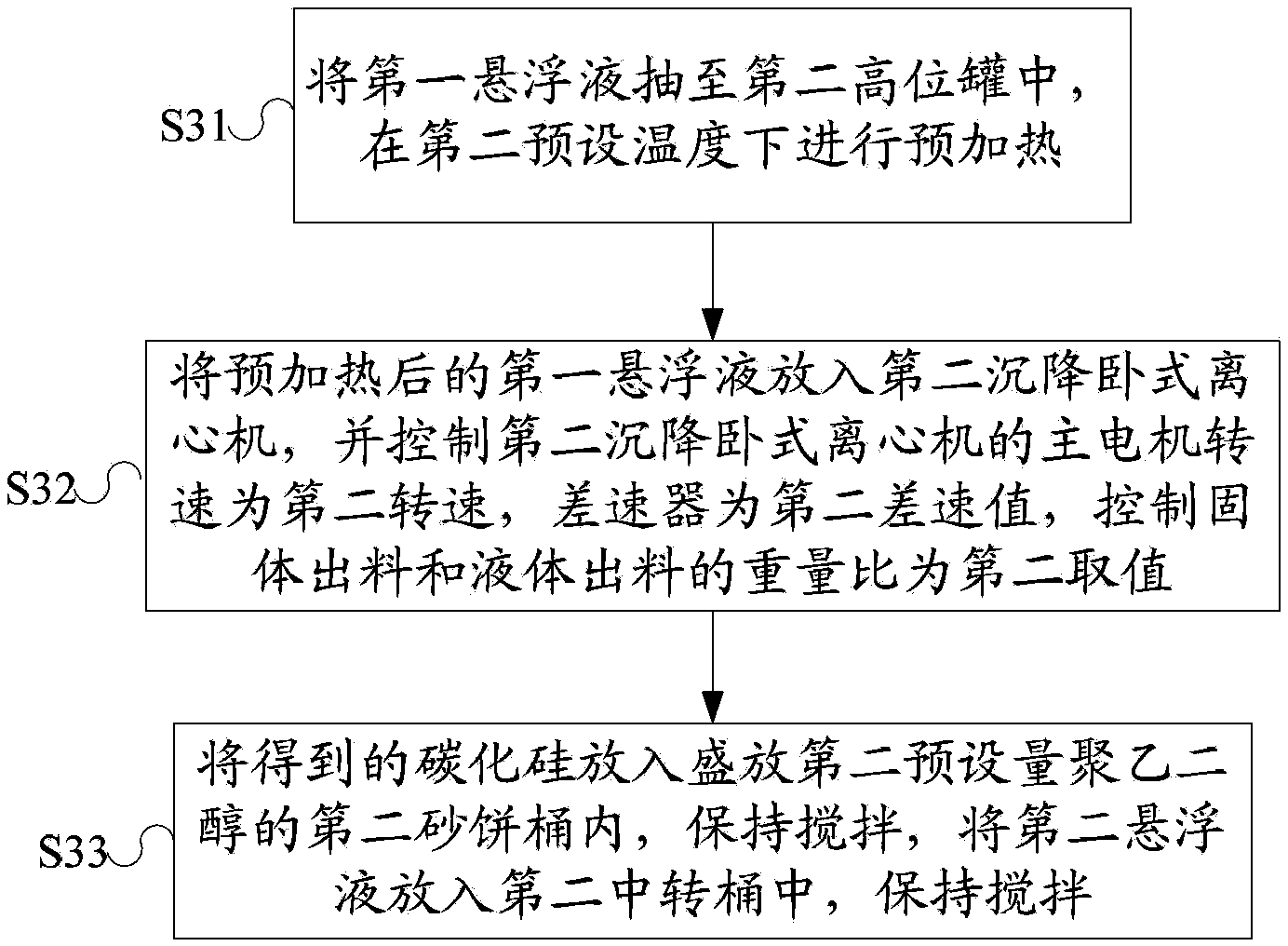

Recovery method of slurry

ActiveCN102925276AHigh recovery rateAchieve recyclingSilicon carbideLubricant compositionRecovery methodFractionation

The invention discloses a recovery method of slurry, which is used for recovering polyoxyalkylene and carborundum powder in the slurry. The recovery method comprises the following steps that the density of initial slurry is adjusted to obtain pretreated slurry; the pretreated slurry is subjected to primary fractionation to obtain carborundum and first suspension liquid; the first suspension liquid is subjected to secondary fractionation to obtain the carborundum and second suspension liquid; the second suspension liquid is filtered to obtain the polyoxyalkylene and filter residues; and the filter residues are subjected to off-line separation to obtain the polyoxyalkylene and the filter residues. According to the recovery method, as the first suspension liquid obtained after the primary fractionation is subjected to the secondary fractionation, the recovery rate of the carborundum is increased. As the second suspension liquid after the secondary fractionation is filtered, the suspension liquid is further recovered; and the filter residues after the secondary fractionation is further recovered. Therefore, with the adoption of the recovery method, the recovery rate is increased greatly.

Owner:JINKO SOLAR CO LTD

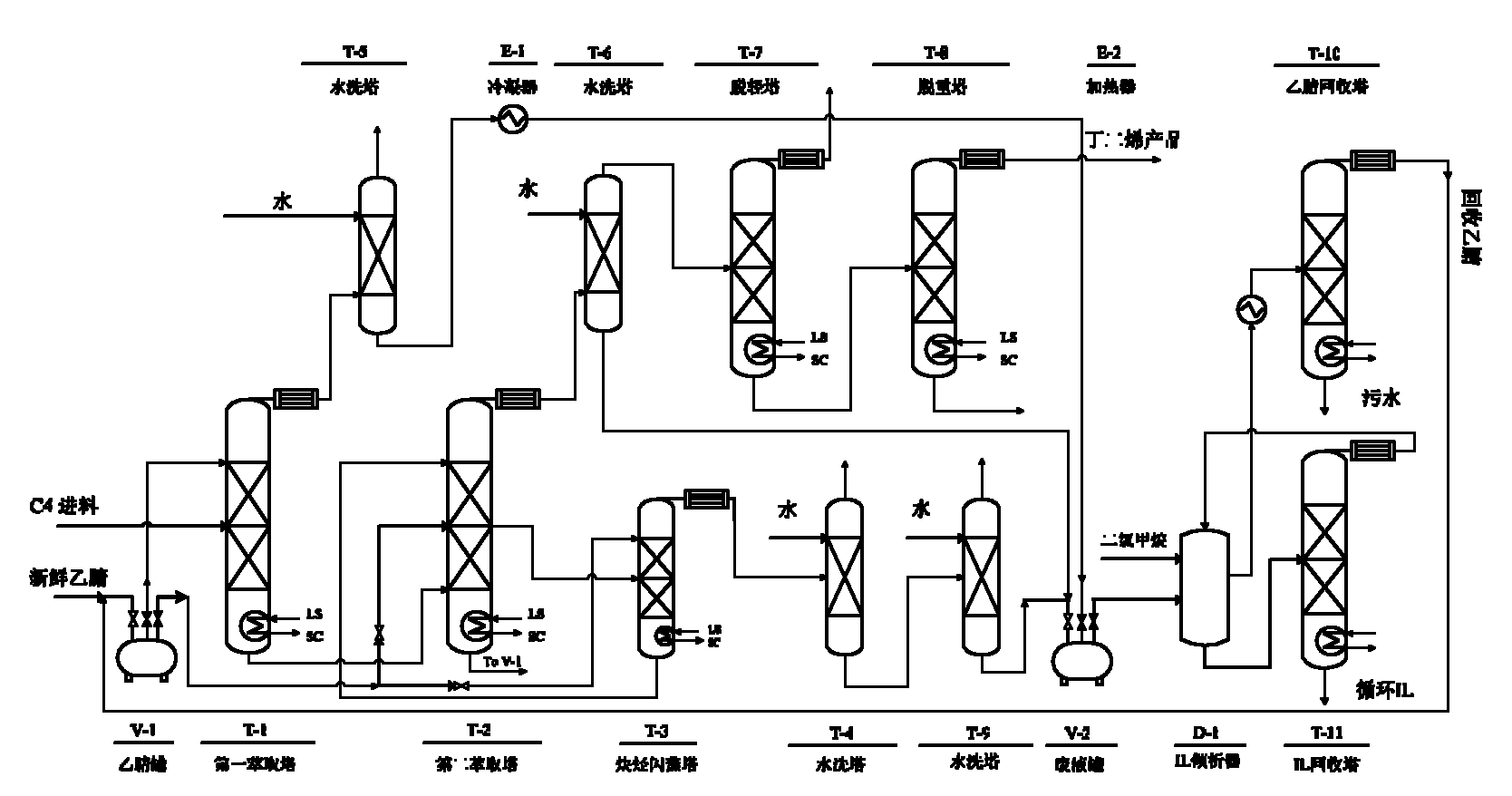

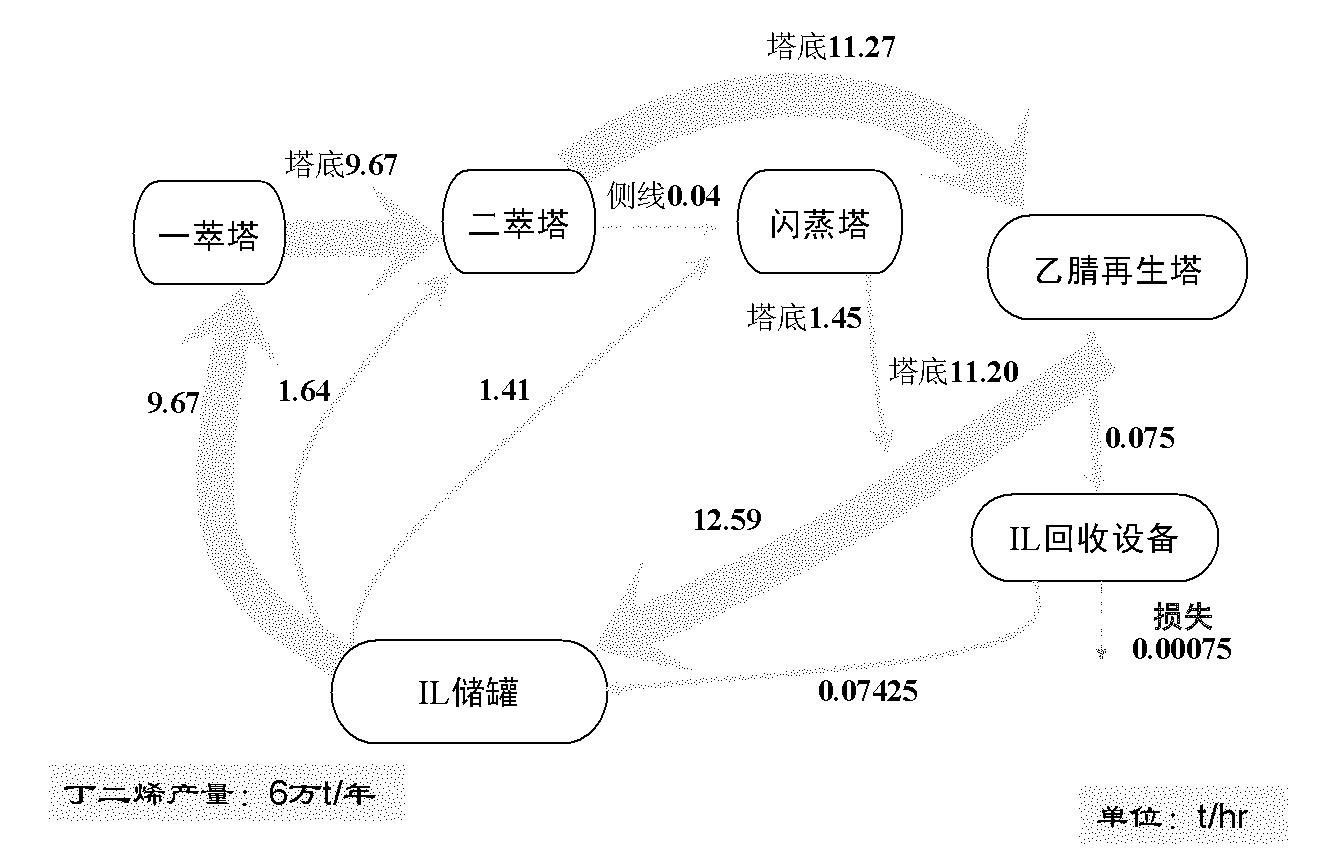

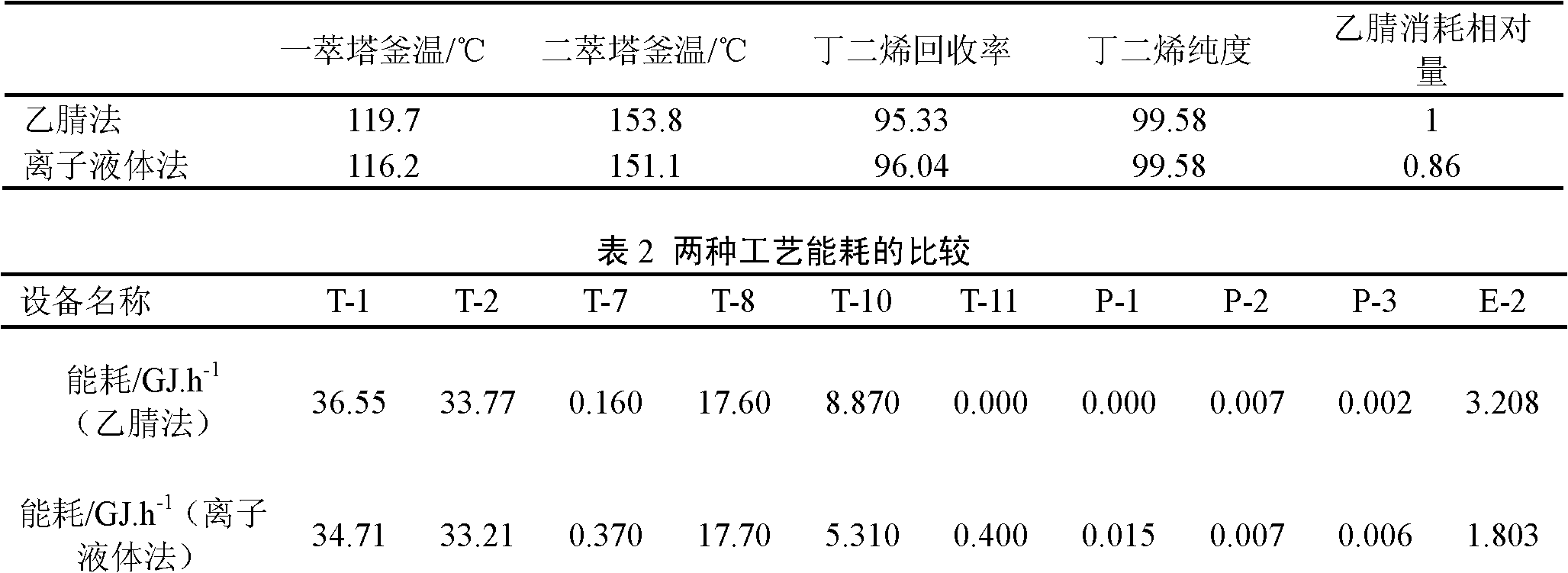

Method for producing butadiene based on ionic liquid complex solvent

InactiveCN102146012AReduce the temperatureReduce the likelihood of aggregationDistillation purification/separationBulk chemical productionButadiene DioxideExtractive distillation

The invention discloses a method for producing butadiene, and belongs to the technical field of olefin production. In order to solve uneconomical problems of high tower temperature, blockage of a tower plate due to butadiene polymerization, severe solvent loss and the like in the conventional process for extracting the butadiene through an acetonitrile method, the invention provides a new process for producing butadiene based on an ionic liquid complex solvent. By adopting technical means such as extractive distillation, common distillation and the like, a composite extractant prepared from ionic liquid, acetonitrile and water is used for separating the butadiene from other hydrocarbons in C4 fraction. Compared with the conventional acetonitrile process, the method has the advantages of obviously reducing process energy consumption, reducing butadiene polymerization, reducing consumption of acetonitrile, and improving the yield and purity of the butadiene; and the invention provides a scheme of recovering ionic liquid in industrial application, which can realize high recovery rate of the ionic liquid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

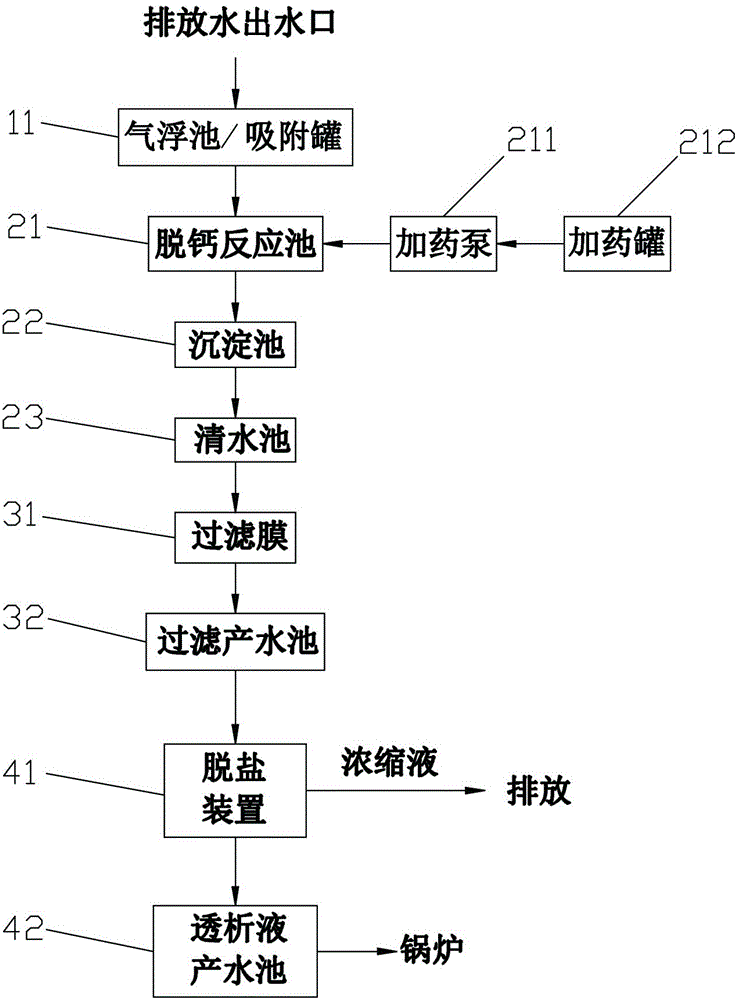

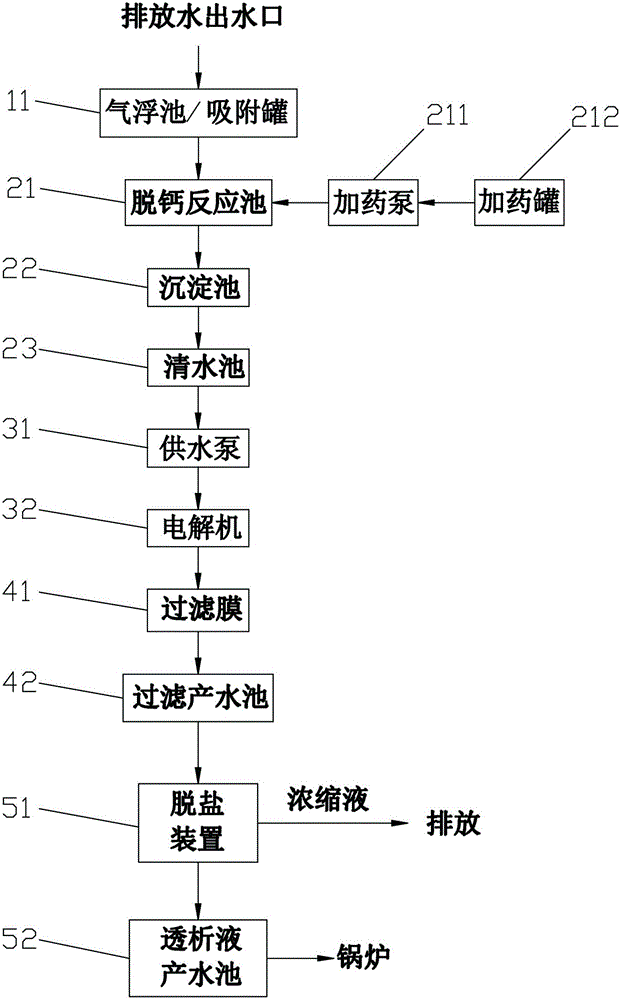

Oil-field wastewater treating and recycling device

InactiveCN105000727AEffective degreasingReduce CODcrWaste water treatment from quariesMultistage water/sewage treatmentFiltrationDesalination

An oil-field wastewater treating and recycling device comprises an oil removing system, a chemical decalcification system, a membrane filtration system and a desalting system; the oil removing system comprises an air floatation tank and an adsorption tank, the chemical decalcification system comprises a decalcification reaction tank, a sedimentation tank and a clean water tank, the membrane filtration system comprises a filtering membrane and a filtering water producing tank, the desalting system comprises a desalting device, a concentrated solution outlet of the desalting device is used for directly discharging, and a dialysis solution outlet of the desalting device is connected to a boiler. According to the device provided by the invention, through air floatation, the oil can be effectively removed, the CODcr is reduced, the calcification of the membrane is eliminated, the blockage of the membrane is avoided, the indexes, such as SS and turbidity, of waste water are reduced, the metal ions in water are removed, the salt content is reduced, and the recovery rate of 50 to 65 percent of oil-field wastewater is realized.

Owner:BOYING XIAMEN SCI & TECH

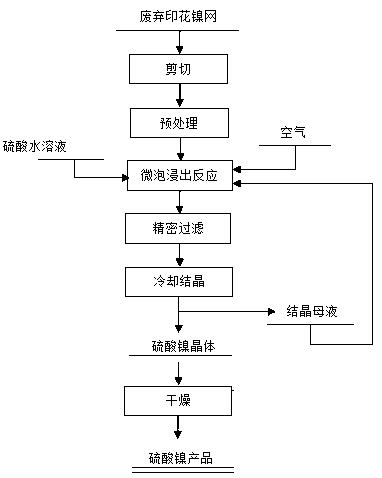

Recycling and treatment method for waste printing nickel screen

The invention discloses a recycling and treatment method for a waste printing nickel screen. The recycling and treatment method comprises the following steps: shearing the waste printing nickel screeninto fragments; after immersing the fragments in an acidic solution, taking out the fragments and putting the fragments into a micro-bubble nickel dissolving kettle containing an inorganic acid watersolution; stirring and introducing air or oxygen into the micro-bubble nickel dissolving kettle; emulsifying separated liquid through a circulating pump, a liquid-gas spraying pump and a baffling plate in sequence, and returning emulsified liquid back into the micro-bubble nickel dissolving kettle to form the circulation of the solution in the micro-bubble nickel dissolving kettle; carrying out micro-bubble leaching reaction; and after reaction is finished, carrying out filtering, pre-cooling, freezing and crystallization, solid-liquid separation and drying in sequence to obtain a nickel saltproduct. According to the recycling and treatment method, the separation of a nickel screen and a surface thin film of the waste printing nickel screen is realized through a micro-bubble nickel dissolving technology; meanwhile, high-quality nickel is recycled; in a whole system, waste residues, wastewater, waste gas and the like are not generated; and the metal recycling rate is high, the treatment cost is low and the environment-friendly meaning is obvious.

Owner:浙江科菲科技股份有限公司

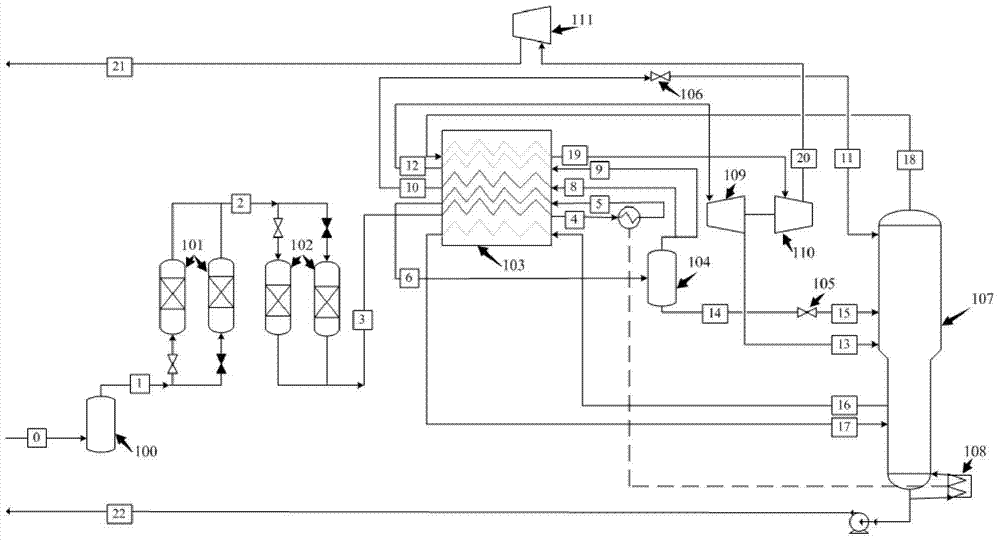

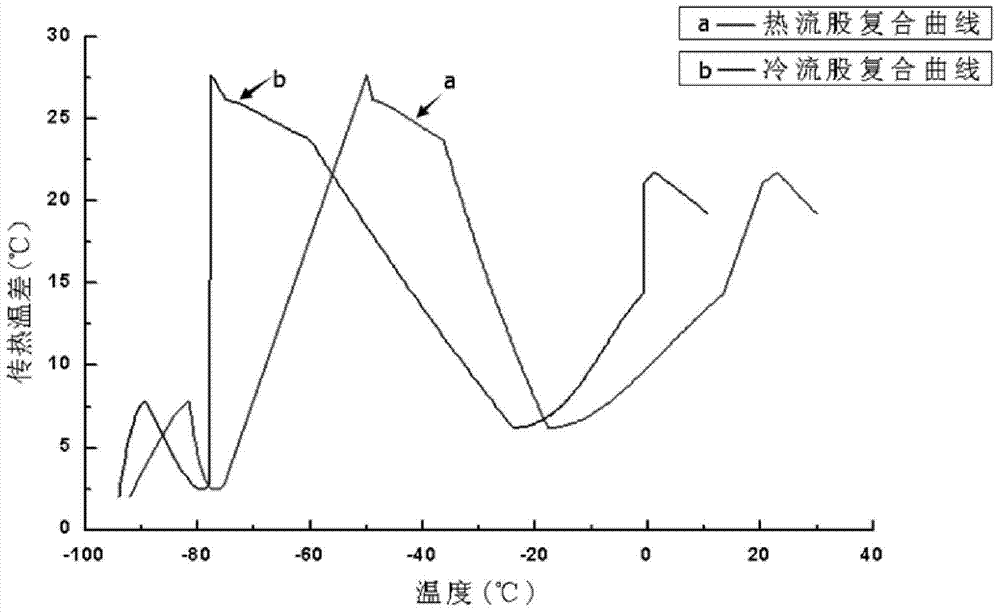

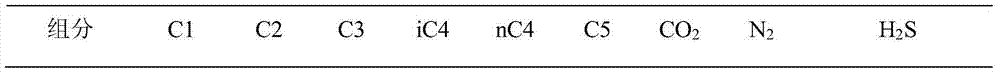

Method for efficiently recovering light hydrocarbons from pipeline natural gas by using energy integration

InactiveCN104263402AAchieve recyclingAchieving RecoveryLiquid hydrocarbon mixture recoveryHydrocarbon oils treatmentEnergy integrationTower

The invention belongs to the field of separation and recovery of natural gas light hydrocarbons, and discloses a method for efficiently recovering light hydrocarbons from pipeline natural gas by using energy integration. In the method, expansion cold production provides corresponding cold energy for the light hydrocarbon separation system, expansion pressure reduction of high-pressure pipeline natural gas is used as a cold source for providing cold quantity, and intermediate reboiling and tower bottom reboiling are performed in the demethanizer to recover the cold quantity for precooling raw gas. The method maximally recovers the cold energy inside the system by efficient energy integration, and properly matches the heat exchange of material streams of various temperature regions, thereby achieving the goals of temperature grading and cascading use. The method does not need any additional independent cold source for cold production, thereby reducing the equipment investment. The method can implement higher light hydrocarbon recovery rate and effectively recover the light hydrocarbons in pipeline natural gas.

Owner:SOUTH CHINA UNIV OF TECH

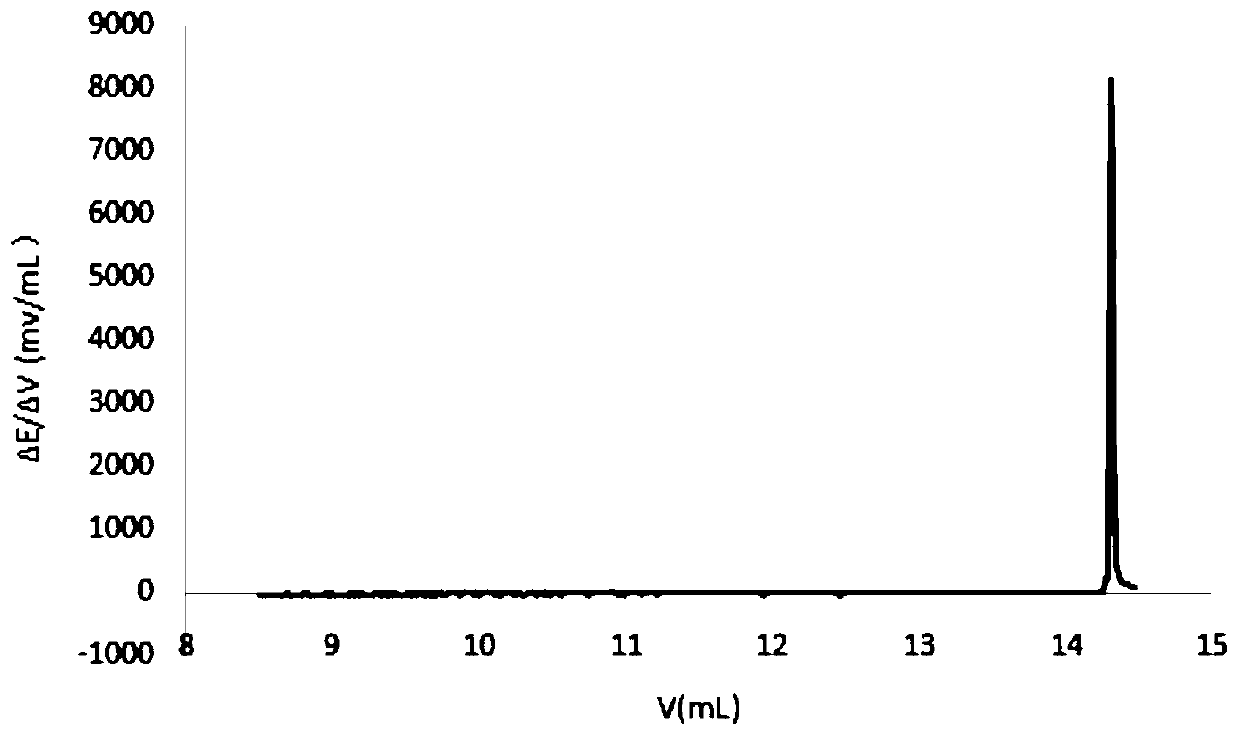

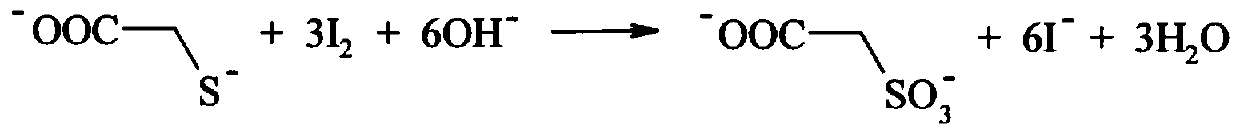

Method for rapidly determining content of mercaptoacetic acid

InactiveCN111007197AAchieving RecoveryMethod stableComponent separationChemical analysis using titrationAcetic acidPhysical chemistry

The invention provides a method for rapidly determining the content of mercaptoacetic acid. The method comprises the following steps: oxidizing sulfydryl by iodine under an alkaline condition; limiting the reaction speed through IO3<->generated by reaction; and determining the titration end point to obtain the content of mercaptoacetic acid. According to the method for rapidly determining the content of mercaptoacetic acid, the recovery rate of a mercaptoacetic acid titration method reaches 98%; meanwhile, the method is stable.

Owner:中检科健(天津)检验检测有限责任公司

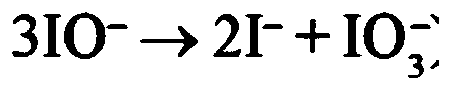

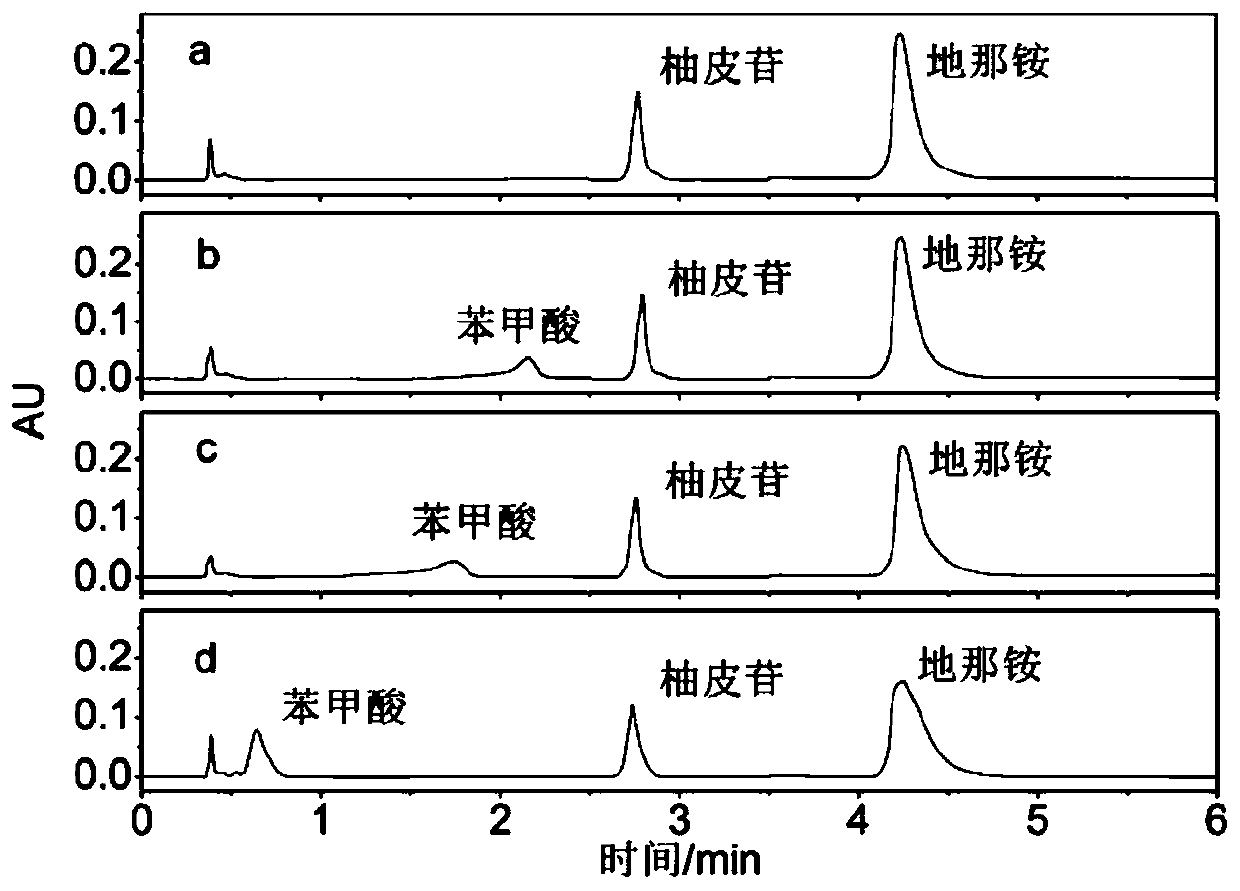

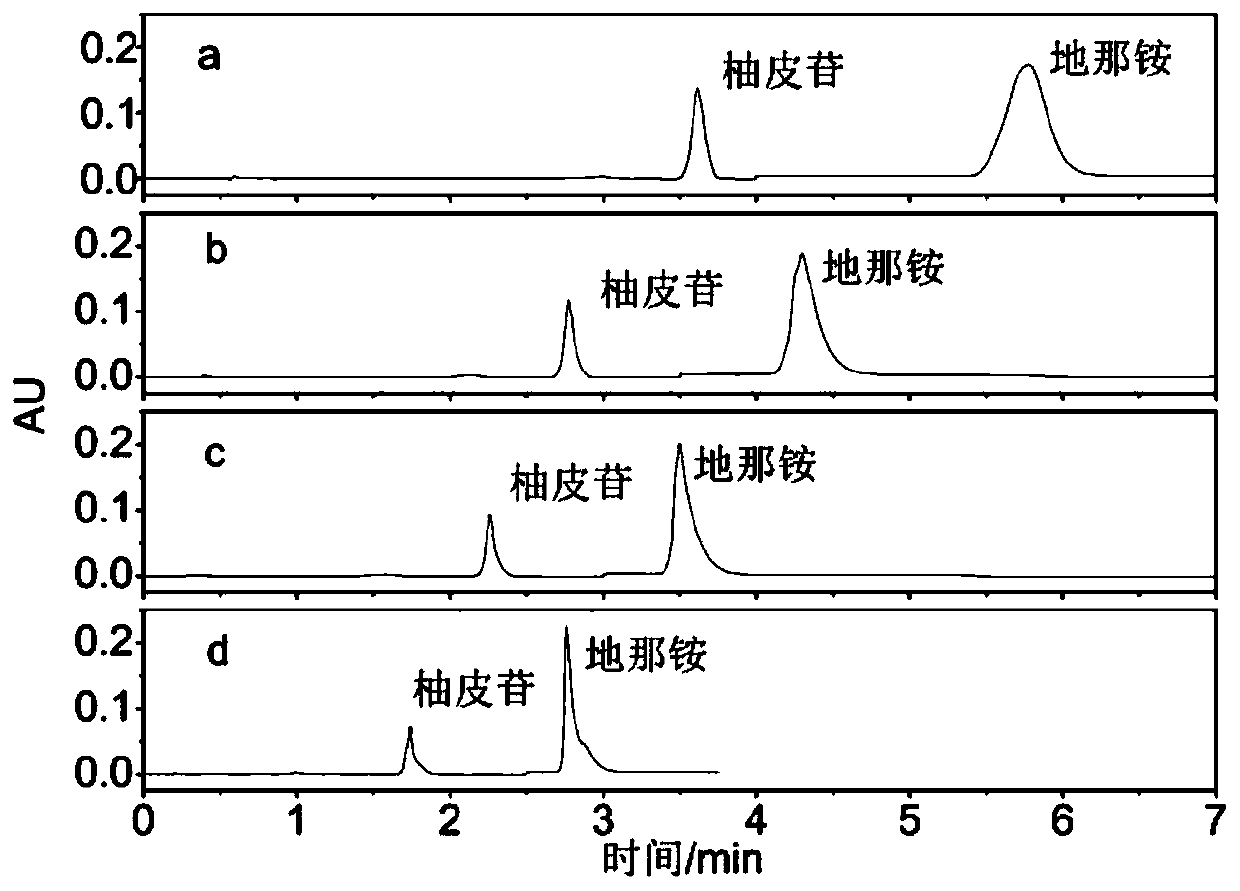

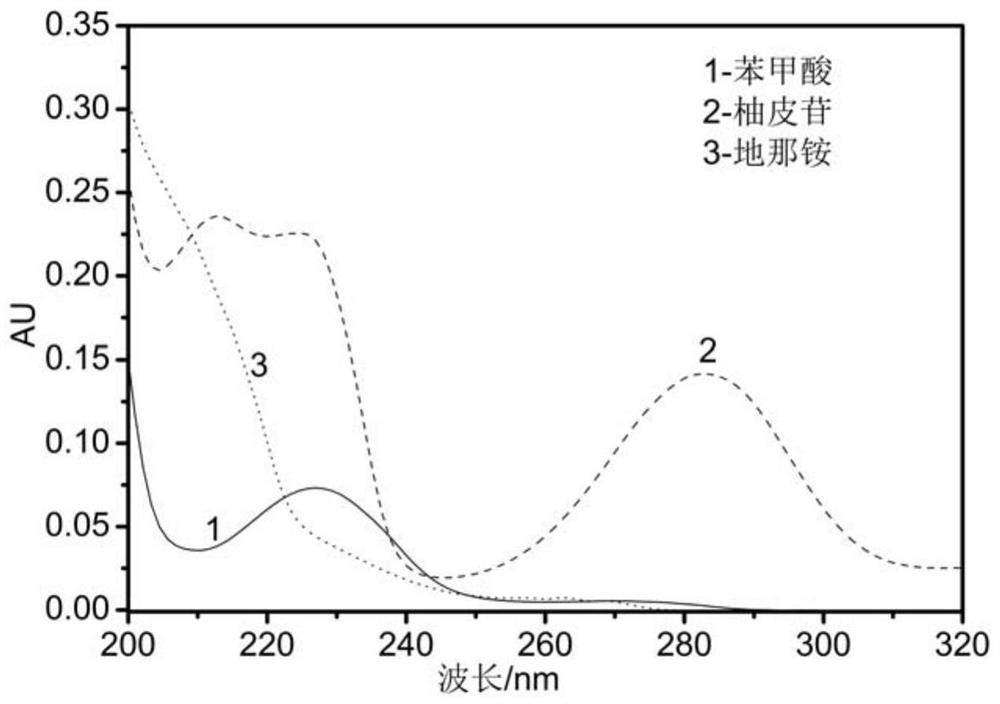

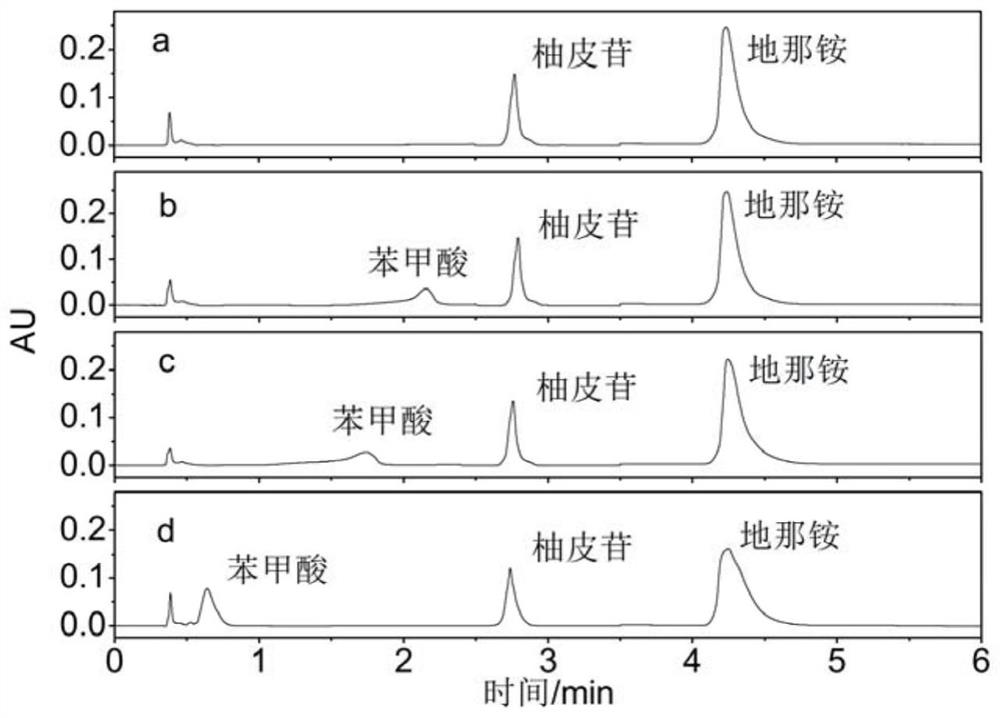

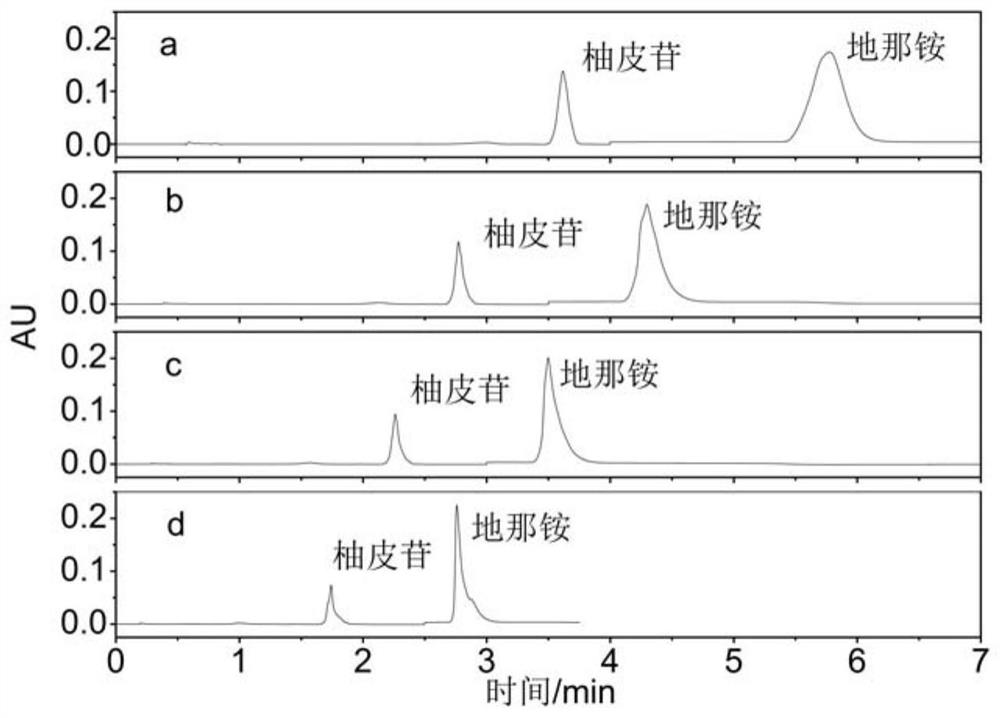

Method for determining naringin and denatonium benzoate serving as bitterants in finger painting inkpad for children by ultra-high performance liquid chromatography

The invention discloses a method for determining naringin and denatonium benzoate serving as bitterants in finger painting inkpad for children by ultra-high performance liquid chromatography. According to the method, two bitterants in a sample of the finger painting inkpad of children are extracted in an ultrasonic extracting mode by taking methyl alcohol-0.02 mol / L KH2PO4 (30:70, v / v) as a solvent; and the two bitterants are quantified through an external standard method and are analyzed through the UPLC. The linear ranges of the naringin and the denatonium benzoate are both 0.1 to 5 mg / L (R2is greater than or equal to 0.99), and the detection limits (S / N>3) are respectively 0.75 and 1.15 mg / kg. The mark recovery rate ranges of the naringin and the denatonium benzoate in the finger painting inkpad for the children at three concentration levels are 86.7 to 108.4 percent; and the relative standard deviation (RSD, n=6) is less than 5.0 percent.

Owner:上海海关机电产品检测技术中心

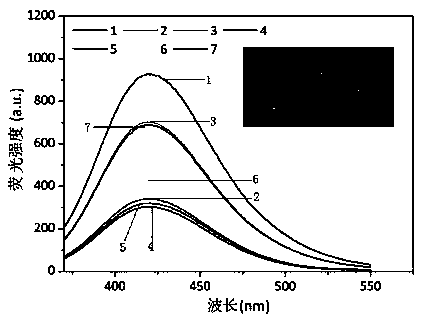

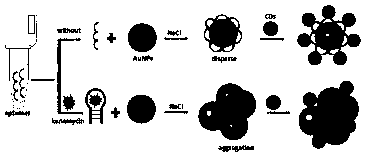

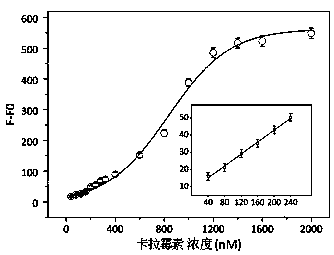

Carbon dot inner-filter effect of fluorescence-based Kanamycin detection method

InactiveCN110174389AEffective quenchingAchieving RecoveryTesting dairy productsFluorescence/phosphorescenceKanamycinLinear regression

The invention discloses a carbon dot inner-filter effect of fluorescence-based Kanamycin detection method. According to the method, to-be-detected sample solution A1 with a known Kanamycin concentration is prepared; blank control solution A2 is prepared; the A1 and the A2 are respectively scanned by using a fluorophotometer to measure fluorescence intensity corresponding to emission peaks of the solution at 430 nm, so as to obtain fluorescence emission spectrums of the solution; standard curves of variations of the Kanamycin concentration and the fluorescence intensity are drawn according to the fluorescence emission spectrums; a regression equation related to a mutual relationship between the Kanamycin concentration and the fluorescence intensity is established according to the standard curves; to-be-detected solution C with an unknown Kanamycin concentration is prepared; and the C is scanned by using the fluorophotometer to measure fluorescence intensity corresponding to an emissionpeak of the solution at 430 nm, a fluorescence intensity difference between the C and the A2 is calculated, and the difference is substituted in the linear regression equation to obtain a concentration of Kanamycin in the C. The method has the advantages of being convenient to construct, high in sensitivity and good in specificity.

Owner:GUIZHOU UNIV

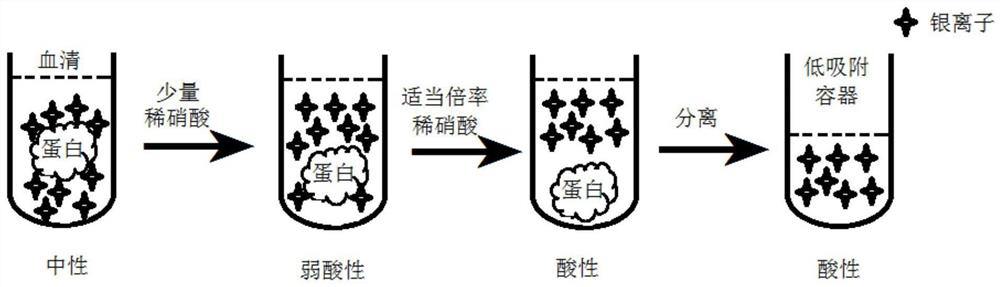

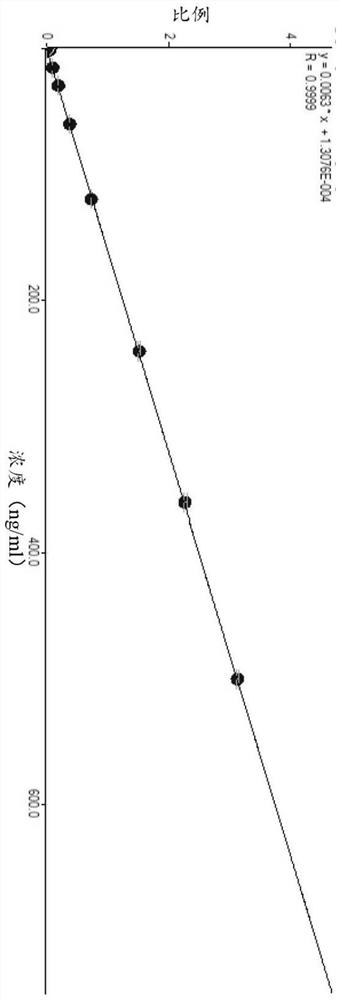

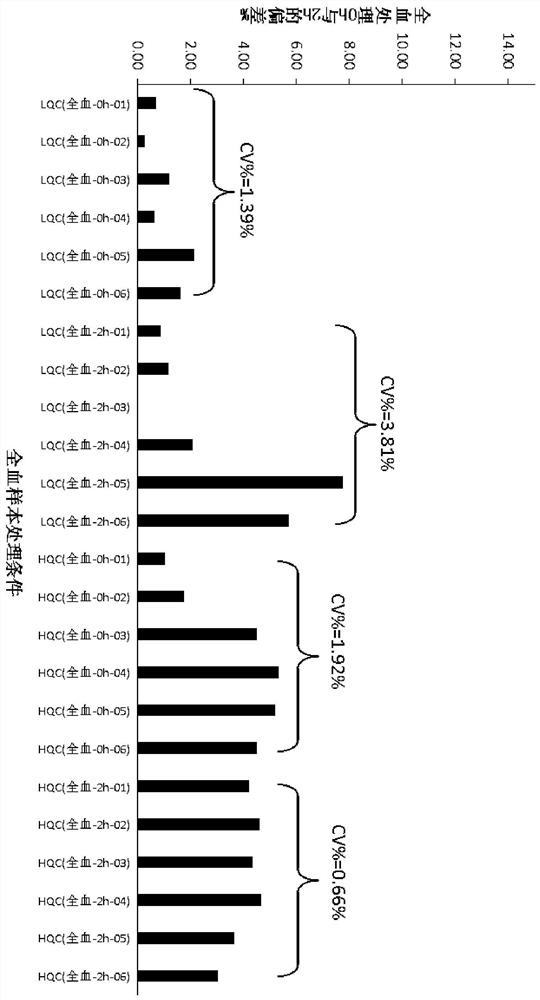

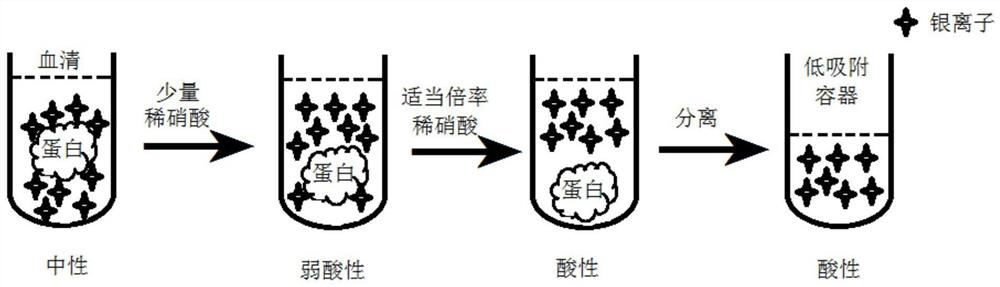

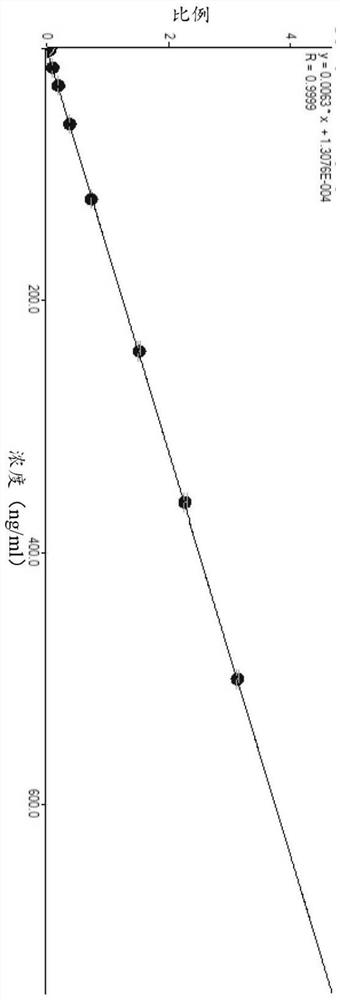

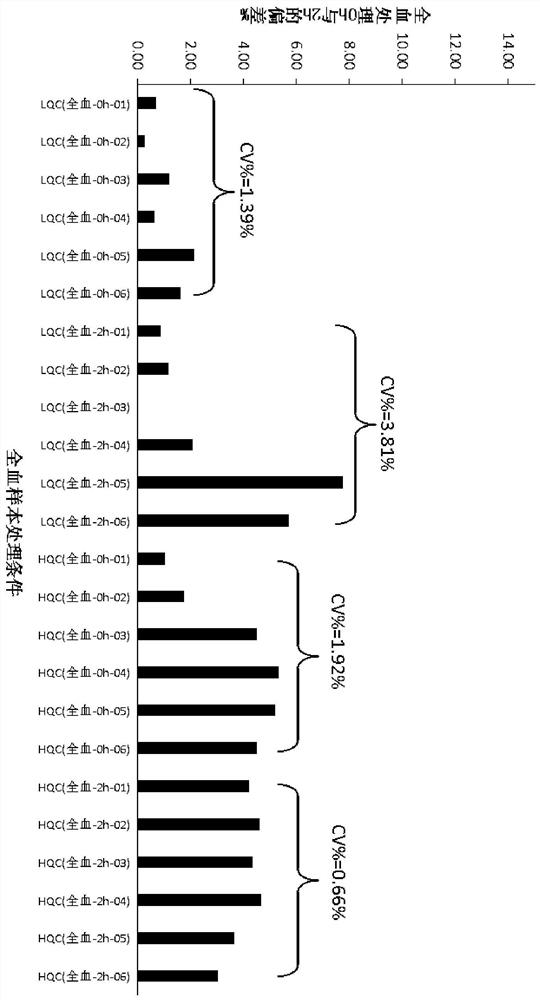

A silver ion enrichment method, quantitative kit and detection method in a protein-containing biological matrix

ActiveCN111830115BStable quantitative method parameter resultsVerify Quantitative SensitivityPreparing sample for investigationMaterial analysis by electric/magnetic meansProtein solutionBiochemistry

The invention discloses a method for enriching silver ions in a protein-containing biological matrix, a quantitative kit and a detection method. The method for enriching silver ions includes the following steps: S1. Add nitric acid solution I to the biological matrix sample to make the pH of the system Value is 4.0~6.5; S2, add nitric acid solution II, make the pH value of system 1.0~3.0; Wherein, the concentration of described nitric acid solution I and nitric acid solution II is respectively 0.5%~2.0%; The biological matrix sample The volume is larger than the volume of the nitric acid solution I; the volume of the biological matrix sample is smaller than the volume of the nitric acid solution II. The silver ion quantitative kit comprises nitric acid solution I, nitric acid solution II, protein solution, silver standard, silver quality control and indium internal standard; wherein, the concentration of nitric acid solution I and nitric acid solution II is 0.5% respectively ~2.0%.

Owner:CHANGSHA DUXACT BIOTECH CO LTD

A Saturated Adsorption Process and Device for Pressure Swing Adsorption Decarburization

The invention relates to the technical field of pressure swing adsorption decarburization and discloses a novel saturation adsorption process of pressure swing adsorption decarburization and a device thereof. According to the process, CO2 gas in raw gas is adsorbed and removed by adsorbents in adsorption towers which are arranged in parallel, so as to obtain purified gas. Each circulation of the process comprises adsorption, uniform pressure drop, recycling, vacuumization, uniform pressure rise, isolation and final boosting, wherein the adsorption includes front adsorption, adsorption and back adsorption; the front adsorption specifically comprises the steps of inputting the output gas at the stage of the back adsorption of other adsorption towers and outputting the purified gas; the adsorption specifically comprises the steps of inputting the raw gas and outputting the purified gas; the back adsorption specifically comprises the step of outputting gas which exceeds the indexes of the purified gas, so as to be used as the input gas of the front adsorption or the final inflated gas of the final boosting; the final boosting comprises the step of boosting the adsorption tower by adopting the gas which exceeds the indexes of the purified gas and is output by the back adsorption of other adsorption towers. The novel saturation adsorption process has the advantages of high CO2 absorptivity, less loss of effective constituents in the gas and the like.

Owner:HUNAN THREE ARROWS AUTOMATION TECH

Method for preparing titanium slag by wet-processing on vanadium-titanium magnetite concentrates

ActiveCN103276204BShort processMild operating conditionsProcess efficiency improvementMagnetiteHydrometallurgy

The invention belongs to the wet-process metallurgical field and in particular relates to a method for preparing titanium slag by wet-processing on vanadium-titanium magnetite concentrates. The method for preparing titanium slag by wet-processing on vanadium-titanium magnetite concentrates comprises the following steps of: (1), mixing the vanadium-titanium magnetite concentrates with an hydrochloric acid solution to obtain intermediate sizing agent; (2), filtering the intermediate sizing agent obtained in the step (1) to obtain leaching slag and carrying out secondary water-washing on the leaching slag (3), neutralizing the water-washing slag obtained in the step (2) by using a diluted alkaline solution, and filtering the neutralized sizing agent to obtain neutralized slag; (4), mixing the neutralized slag obtained in the step (3) with a NaOH solution to carry out alkaline-washing desilicication reaction; (5), filtering the product obtained by the alkaline-washing desilicication reaction, and carrying out water-washing on the obtained alkaline-washed slag; and (6), carrying out acid-pickling on the water-washed slag obtained by the water-washing in the step (5), filtering after the acid-pickling, drying and filtering the slag to obtain the titanium slag. The method for preparing titanium slag by wet-processing on vanadium-titanium magnetite concentrates has the advantages of being short in process, gentle in operation condition, low in device investment and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

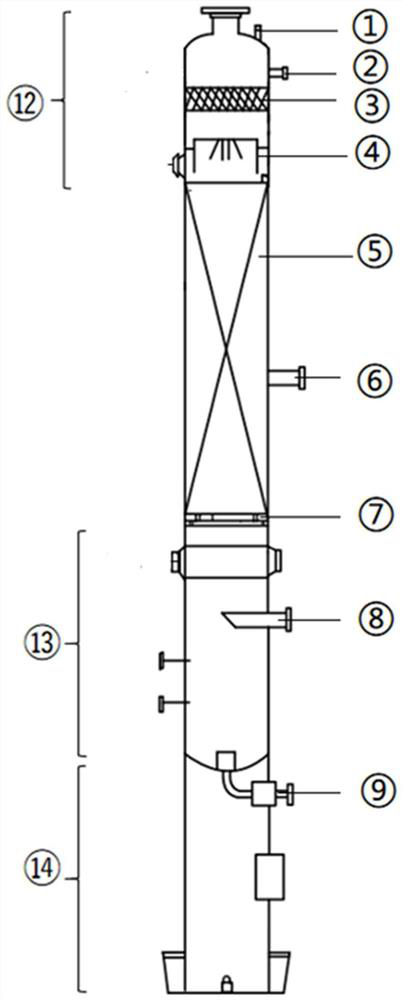

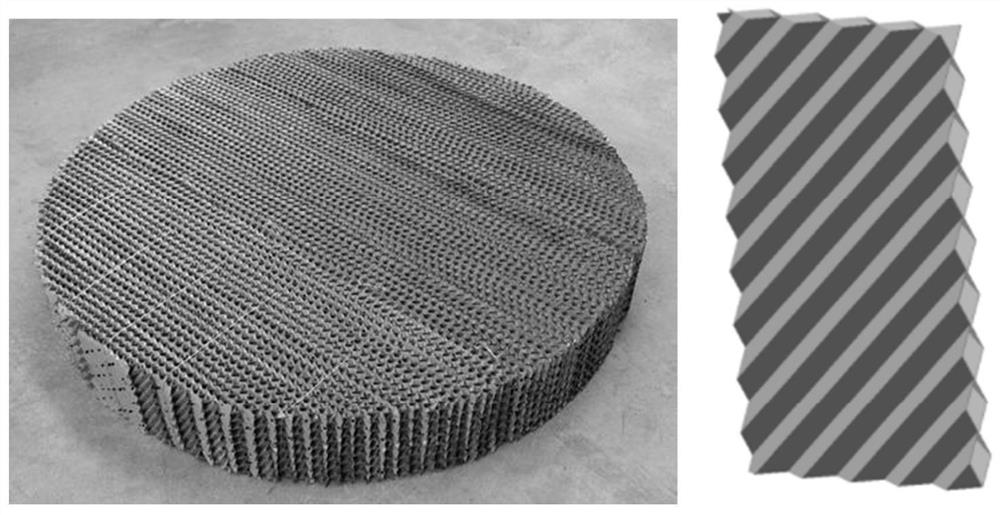

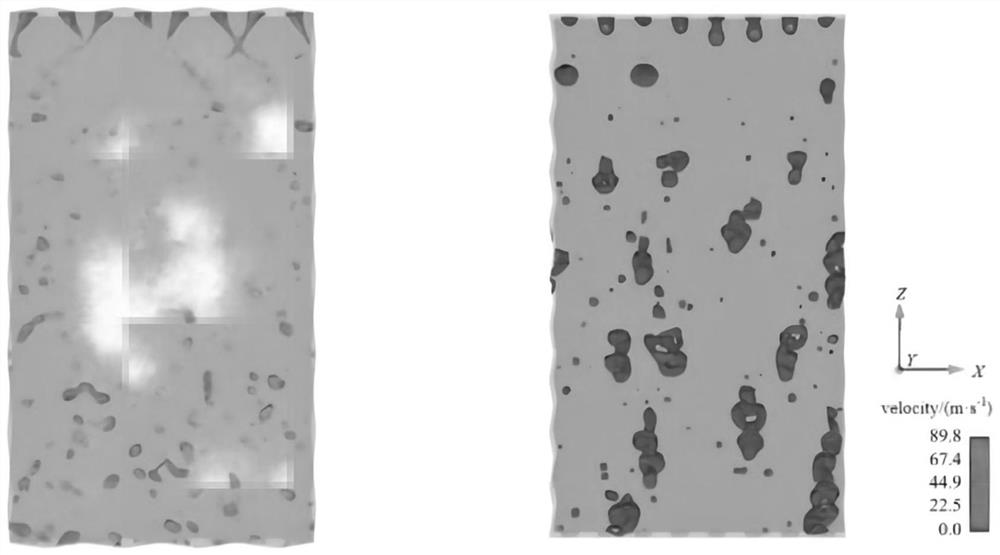

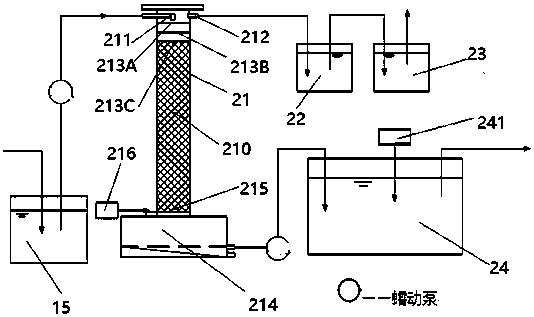

Purification packed tower and purification method of methyl trichlorosilane

PendingCN114588649AAchieving RecoveryHigh puritySilicon organic compoundsDistillation regulation/controlPurification methodsMethyltrichlorosilane

The invention relates to the field of chemical production, and discloses a packed tower for separating and purifying high-purity methyl trichlorosilane. According to the scheme, the packed tower comprises the tower body, the end socket, the connecting pipe, the packing, the skirt, the defoaming net, the feeding pipe, the liquid distributor and the packing supporting plate, and compared with a traditional plate tower, the packed tower has the advantages that the process conditions become mild and safe, meanwhile, the construction cost is reduced, the economical efficiency is high, the maintenance is easy, impurities in methyl trichlorosilane can be efficiently removed, and the production cost is reduced. The content of 3-methyl-2-pentene is lower than 0.06% wt, the purity of 2-methyl-2-pentene is lower than 0.1% wt, the requirement that the content of impurities in first-grade methyl trichlorosilane is lower than 0.1% wt in the national standard GB T 20434-2006 is met, and finally methyl trichlorosilane with the purity larger than 99.8% is obtained.

Owner:浙江中天东方氟硅材料股份有限公司

Recovery method of slurry

ActiveCN102925276BHigh recovery rateAchieve recyclingSilicon carbideLubricant compositionRecovery methodFractionation

The invention discloses a recovery method of slurry, which is used for recovering polyoxyalkylene and carborundum powder in the slurry. The recovery method comprises the following steps that the density of initial slurry is adjusted to obtain pretreated slurry; the pretreated slurry is subjected to primary fractionation to obtain carborundum and first suspension liquid; the first suspension liquid is subjected to secondary fractionation to obtain the carborundum and second suspension liquid; the second suspension liquid is filtered to obtain the polyoxyalkylene and filter residues; and the filter residues are subjected to off-line separation to obtain the polyoxyalkylene and the filter residues. According to the recovery method, as the first suspension liquid obtained after the primary fractionation is subjected to the secondary fractionation, the recovery rate of the carborundum is increased. As the second suspension liquid after the secondary fractionation is filtered, the suspension liquid is further recovered; and the filter residues after the secondary fractionation is further recovered. Therefore, with the adoption of the recovery method, the recovery rate is increased greatly.

Owner:JINKO SOLAR CO LTD

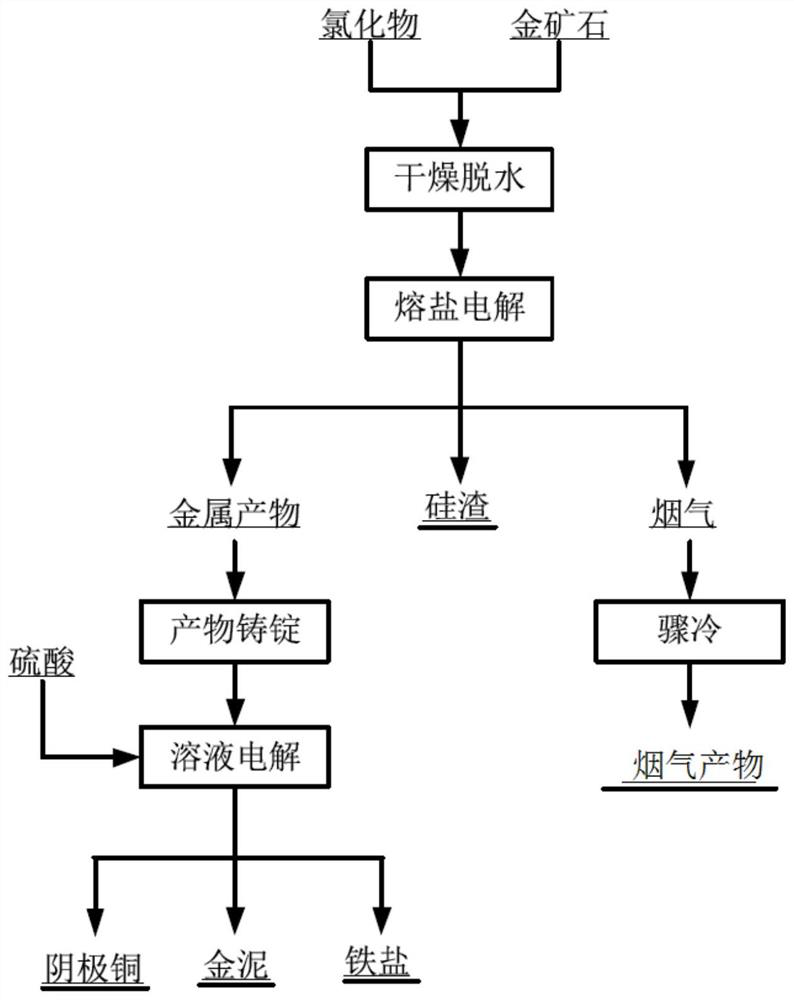

A method for enriching and extracting gold by using molten salt electrolysis

ActiveCN110863218BShort processEasy to operatePhotography auxillary processesProcess efficiency improvementElectrolytic agentIron salts

The invention relates to the technical field of gold smelting, and specifically provides a method for enriching and extracting gold by using molten salt electrolysis. In the salt electrolytic cell, it is dried and dehydrated first, then the oxygen-free gas is introduced, the electrode is inserted, and the temperature is raised to the molten salt electrolysis temperature, and then direct current is applied to carry out the molten salt electrolysis. After the molten salt electrolysis is completed, the metal product is extracted for casting Ingot, the flue gas is quenched to obtain the product, and then the cast metal product is used as the anode, and the solution is electrolyzed in the sulfuric acid system. After electrolysis, the gold mud is obtained from the anode, the copper is obtained from the cathode, and the iron salt product is obtained from the electrolyte. The process can achieve the advantages of strong raw material adaptability, short process flow, cyanide-free gold extraction, high comprehensive resource utilization rate, less waste residue, and high gold recovery rate.

Owner:NORTHEASTERN UNIV LIAONING

A method and device for removing and recycling nitrogen and phosphorus in biogas slurry

ActiveCN105502851BAchieving RecoveryAchieve recyclingTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentPollutant emissionsSlurry

The invention discloses a method and device for removing and recycling nitrogen and phosphorus in biogas slurry. The combined technology of struvite crystallizing, ammonia stripping, SBBR treating and BAF treating is adopted to treat and use the biogas slurry in a resource mode, nitrogen and phosphorus in the biogas slurry are converted into struvite and ammonium sulfate capable of being used as fertilizer, while it is ensured that the treated biogas slurry reaches the emission standard of livestock and poultry industry pollutants, nitrogen and phosphorus recycling is achieved, operation cost of traditional biogas slurry treatment is effectively reduced, and the method has the advantages of being stable in treatment effect and the like. The device is designed based on the method, all parts of the device are optimized and improved, and the device can continuously and stably operate and is convenient to use and popularize.

Owner:SOUTHWEST UNIV

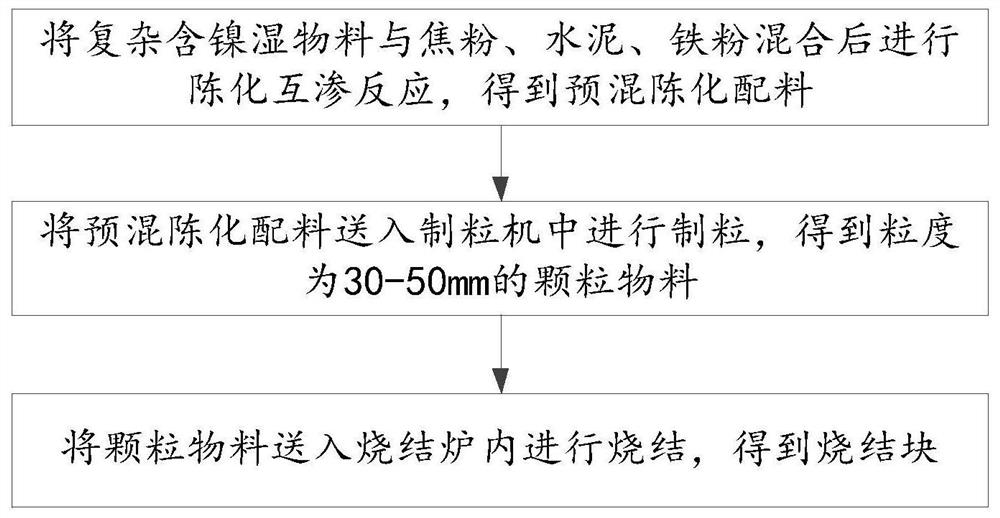

A method for producing agglomerates from complex nickel-containing wet materials

ActiveCN111763823BAchieve smelting recycling production capacityReduce consumption costProcess efficiency improvementIron powderCoke

Owner:甘肃高能中色环保科技有限公司

Method for enriching silver ions in protein-containing biological matrix, quantitative kit and detection method

ActiveCN111830115AStable quantitative method parameter resultsVerify Quantitative SensitivityPreparing sample for investigationMaterial analysis by electric/magnetic meansProtein solutionBiochemistry

The invention discloses a method for enriching silver ions in a protein-containing biological matrix, a quantitative kit and a detection method. The method for enriching the silver ions comprises thefollowing steps: S1, adding a nitric acid solution I into a biological matrix sample to enable the pH value of the system to be 4.0-6.5; S2, adding a nitric acid solution II to enable the pH value ofthe system to be 1.0-3.0, wherein the concentrations of the nitric acid solution I and the nitric acid solution II are respectively 0.5%-2.0%; the volume of the biological matrix sample is greater than that of the nitric acid solution I; and the volume of the biological matrix sample is smaller than that of the nitric acid solution II. The silver ion quantitative kit comprises the nitric acid solution I, the nitric acid solution II, a protein solution, a silver standard substance, a silver quality control substance and an indium internal standard substance, wherein the concentrations of the nitric acid solution I and the nitric acid solution II are respectively 0.5%-2.0%.

Owner:CHANGSHA DUXACT BIOTECH CO LTD

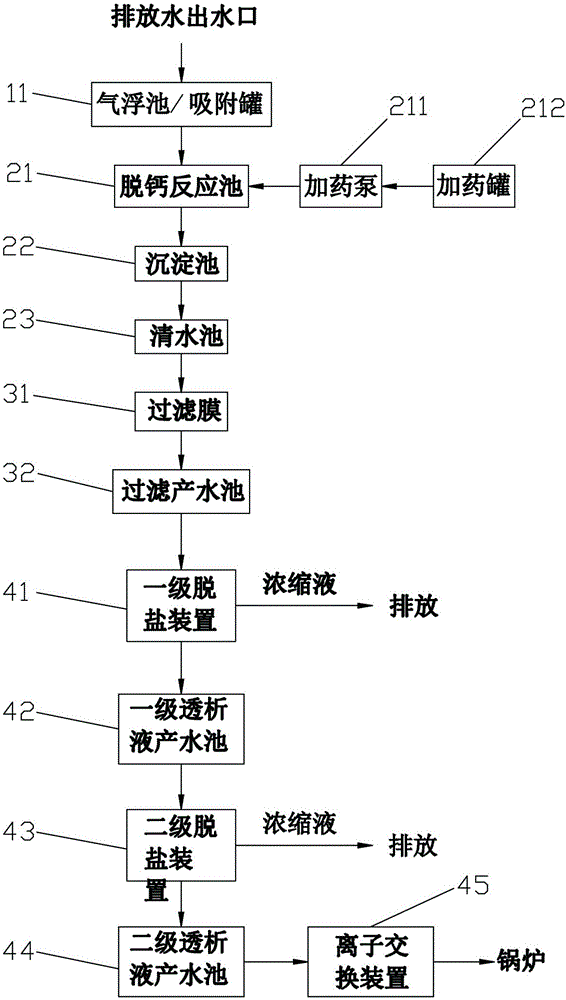

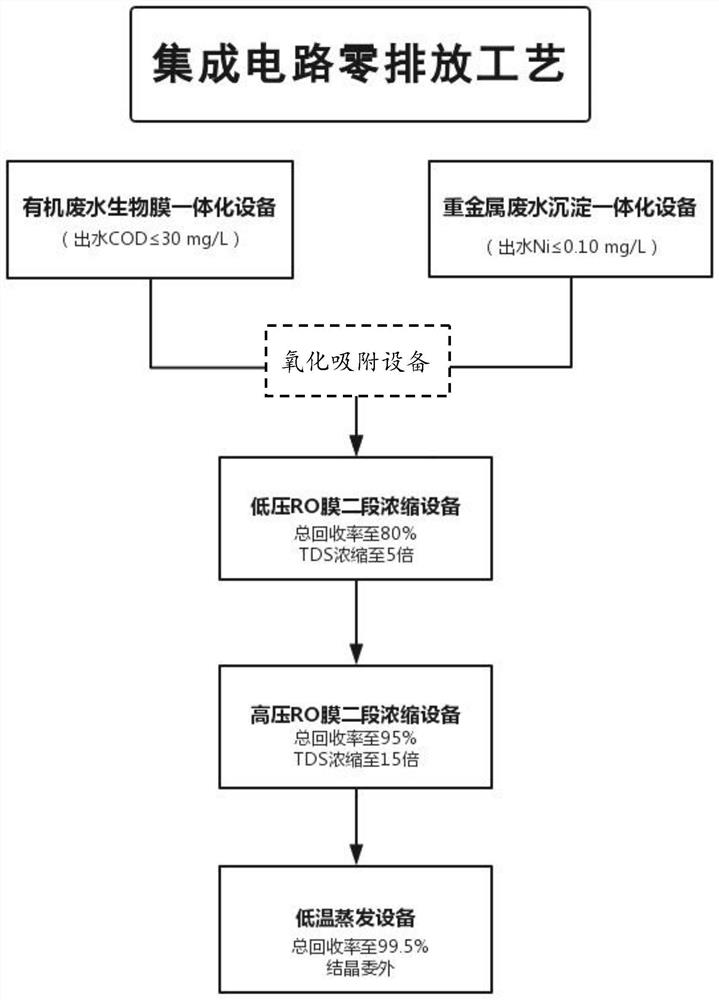

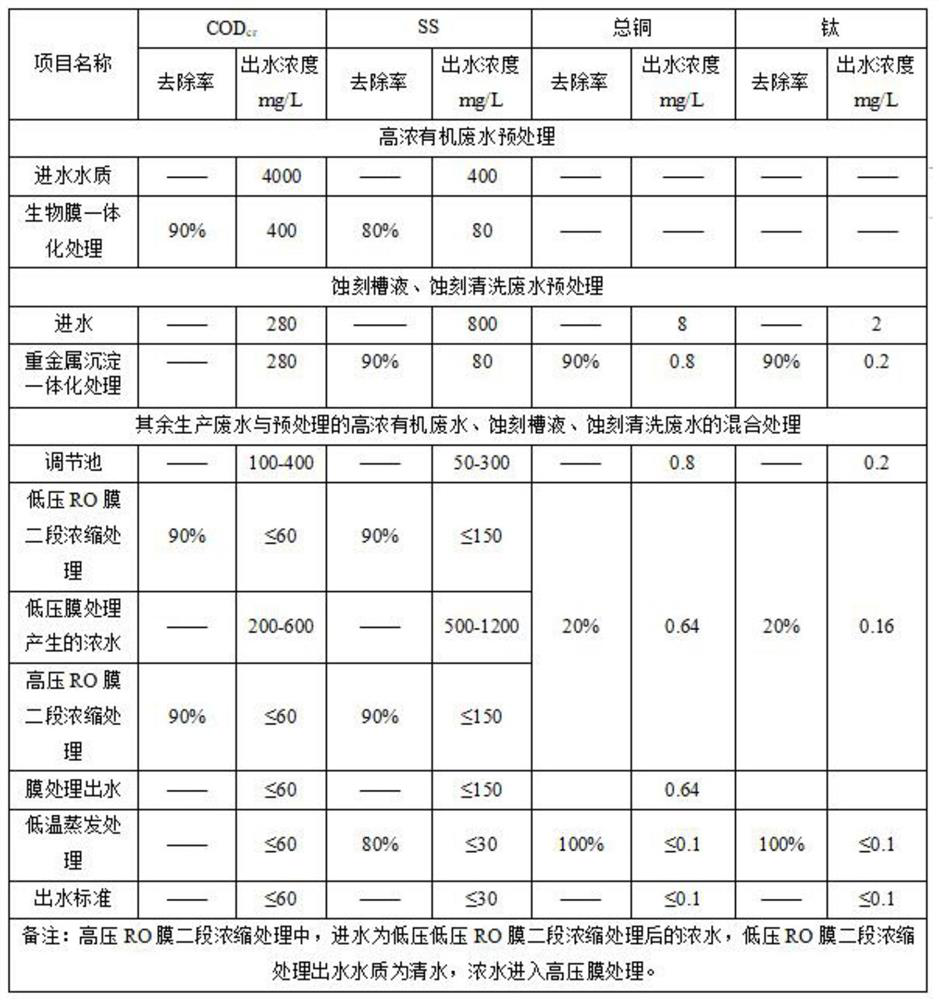

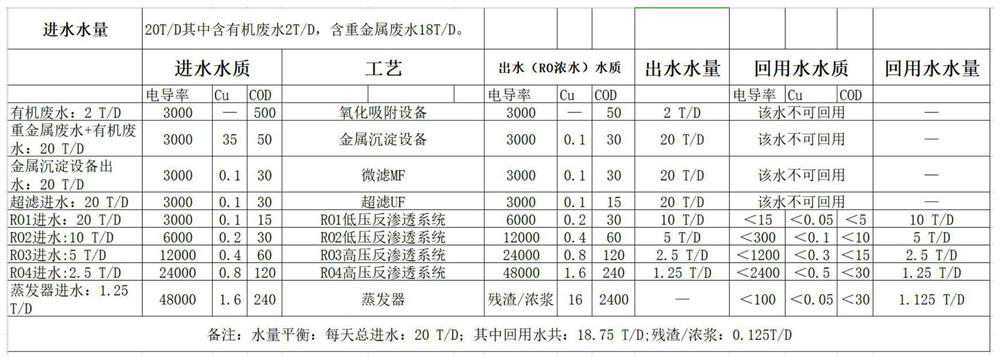

Zero-discharge process and system for wastewater reuse in integrated circuit industry

PendingCN112592004AAchieving RecoveryWater contaminantsMultistage water/sewage treatmentProcess engineeringIntegrated circuit

The invention provides a zero-discharge process and system for wastewater reuse in the integrated circuit industry. The zero-discharge process is characterized in that wastewater is sequentially subjected to oxidation adsorption, secondary physicochemical precipitation, ultrafiltration, four-section membrane concentration, secondary purification treatment and concentrated liquor evaporation treatment. According to the invention, the effect that the recovery rate can be not lower than 96% is achieved in a multi-section concentration and high-low combination mode. Considering the need for equipment maintenance, the recovery rate of not lower than 90% can still be achieved under the condition that part of equipment is adopted for bypass maintenance, namely, a one-stop-three-use condition.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

A method for the determination of bittering agents naringin and denatonium benzoate in children's finger painting ink pads by ultra-high performance liquid chromatography

The invention discloses a method for determining the bittering agent naringin and denatonium benzoate in children's finger painting ink pads by ultra-high performance liquid chromatography. 2 PO 4 (30:70, v / v) was used as solvent, and two kinds of bittering agents in children's finger painting ink pad samples were extracted by ultrasonic extraction, quantified by external standard method, and analyzed by UPLC. The linear range of naringin and denatonium benzoate is 0.1~5mg / L (R 2 ≥0.99), the detection limits (S / N>3) were 0.75 and 1.15mg / kg, respectively. The spiked recoveries of naringin and denatonium benzoate in children's finger painting ink pads at three concentration levels ranged from 86.7% to 108.4%; the relative standard deviation (RSD, n=6) was less than 5.0%.

Owner:上海海关机电产品检测技术中心

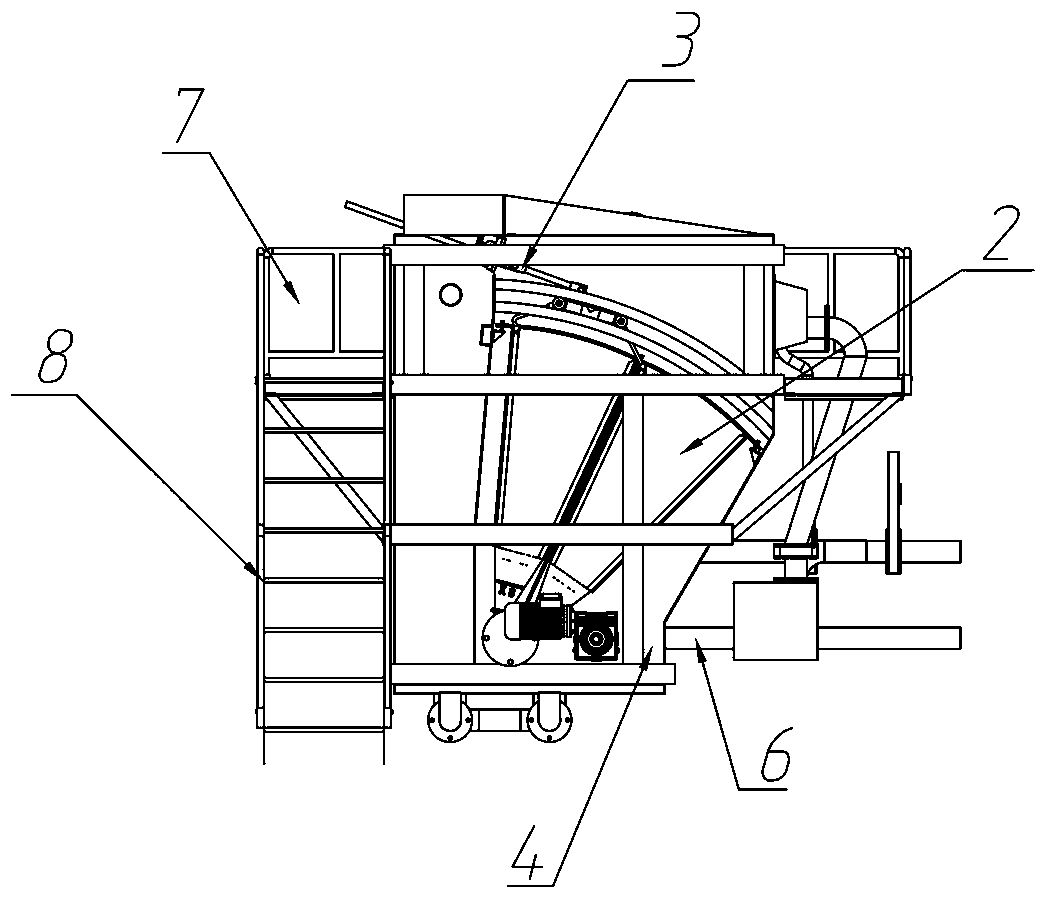

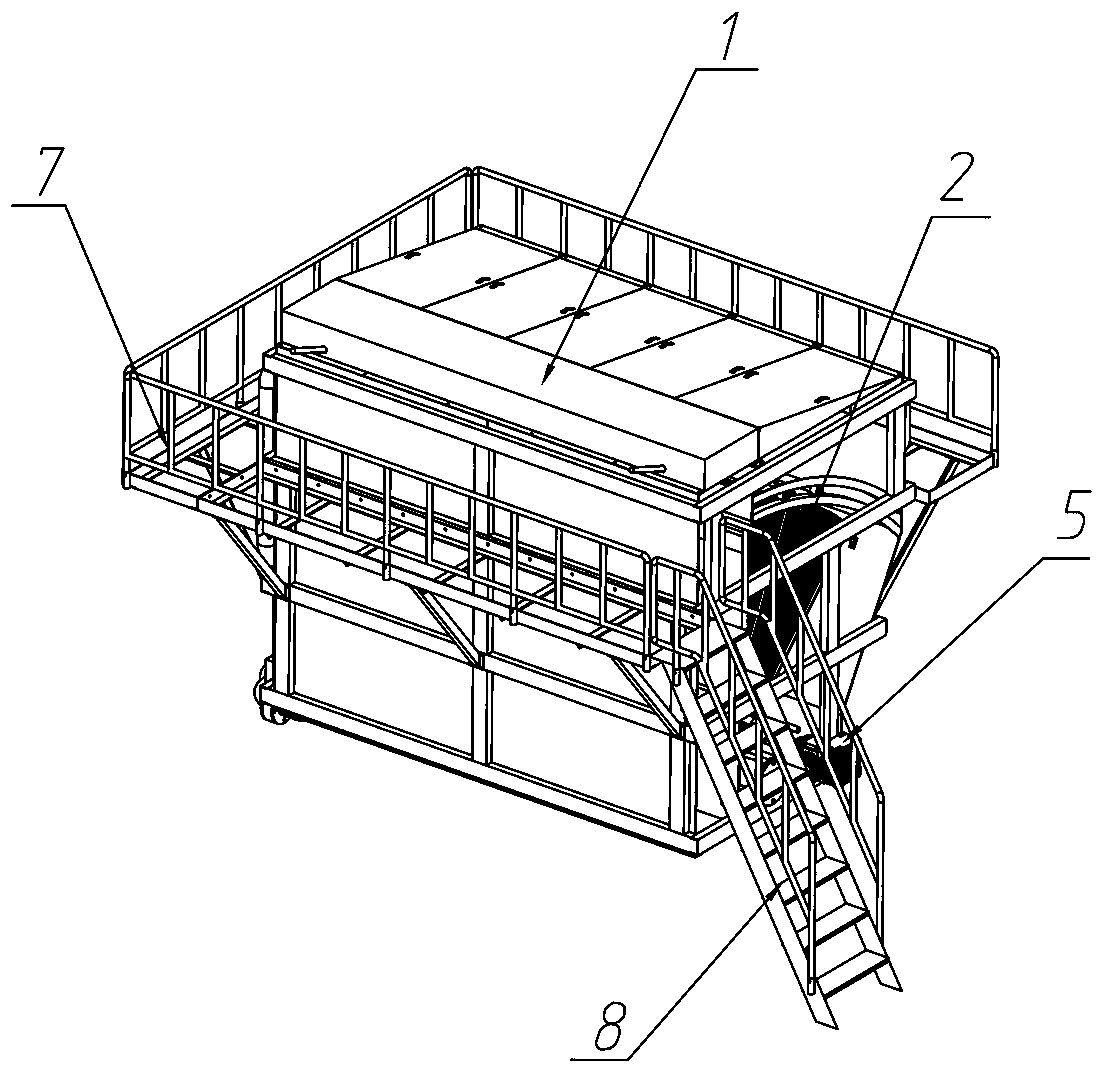

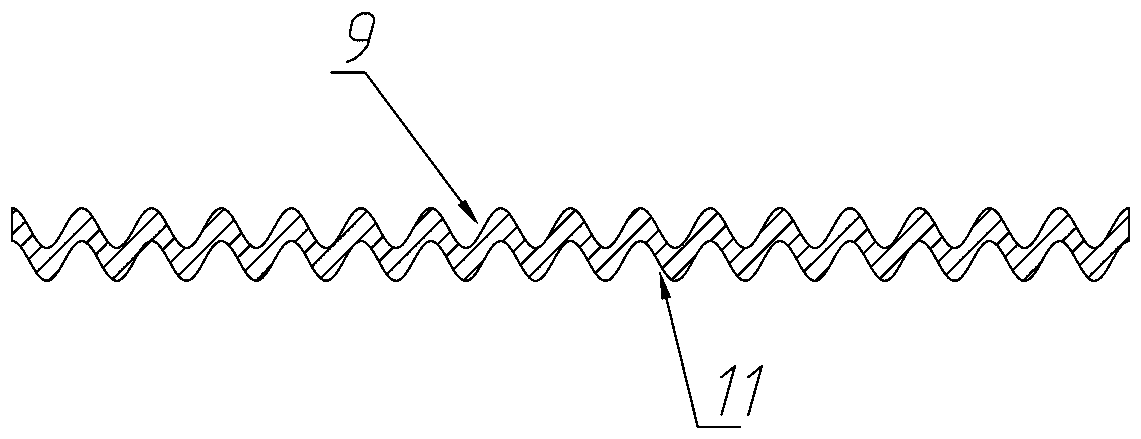

Multi-disc direct cleaning filter and use method thereof

PendingCN108342919AEnhanced hydrogen bondingEasy to operatePulp liquor regenerationSuction forceCLARITY

The invention relates to a multi-disc direct cleaning filter and a use method of the multi-disc direct cleaning filter, relates to the field of filtering of industrial sewage and papermaking white water, and particularly relates to the multi-disc direct cleaning filter and the use method of the multi-disc direct cleaning filter. The multi-disc direct cleaning filter comprises a housing and a support frame arranged in the housing, wherein a white water inlet pipe is arranged at the upper part of one side surface of the housing, a drain pipe is arranged at the lower part of the other side surface, corresponding to the one side surface, of the housing, and a plurality of mutually parallel support frames are arranged between the white water inlet pipe and the drain pipe. Aiming at the papermaking one-machine platform, the multi-disc direct cleaning filter is a piece of novel equipment developed to recycle the white water and the fiber, the equipment achieves the fiber recovery rate of morethan 99.5% by using a metal fiber filter disc, almost no fiber is lost, the clarity of a super clear filtrate is up to more than 99%, and the content of suspended solids in the super clear filtrate is less than 20 mg / L. The multi-disc direct cleaning filter avoids the problem that the vacuum water leg is formed badly because of insufficient filtrate water caused by the number of discs and the blockage of meshes of a filter screen of the traditional multi-disc, and also solves the problems that a filter cake is thin, is poor in dryness and is difficult to peel because of the small vacuum suction force.

Owner:西安兴晟生态环境有限公司

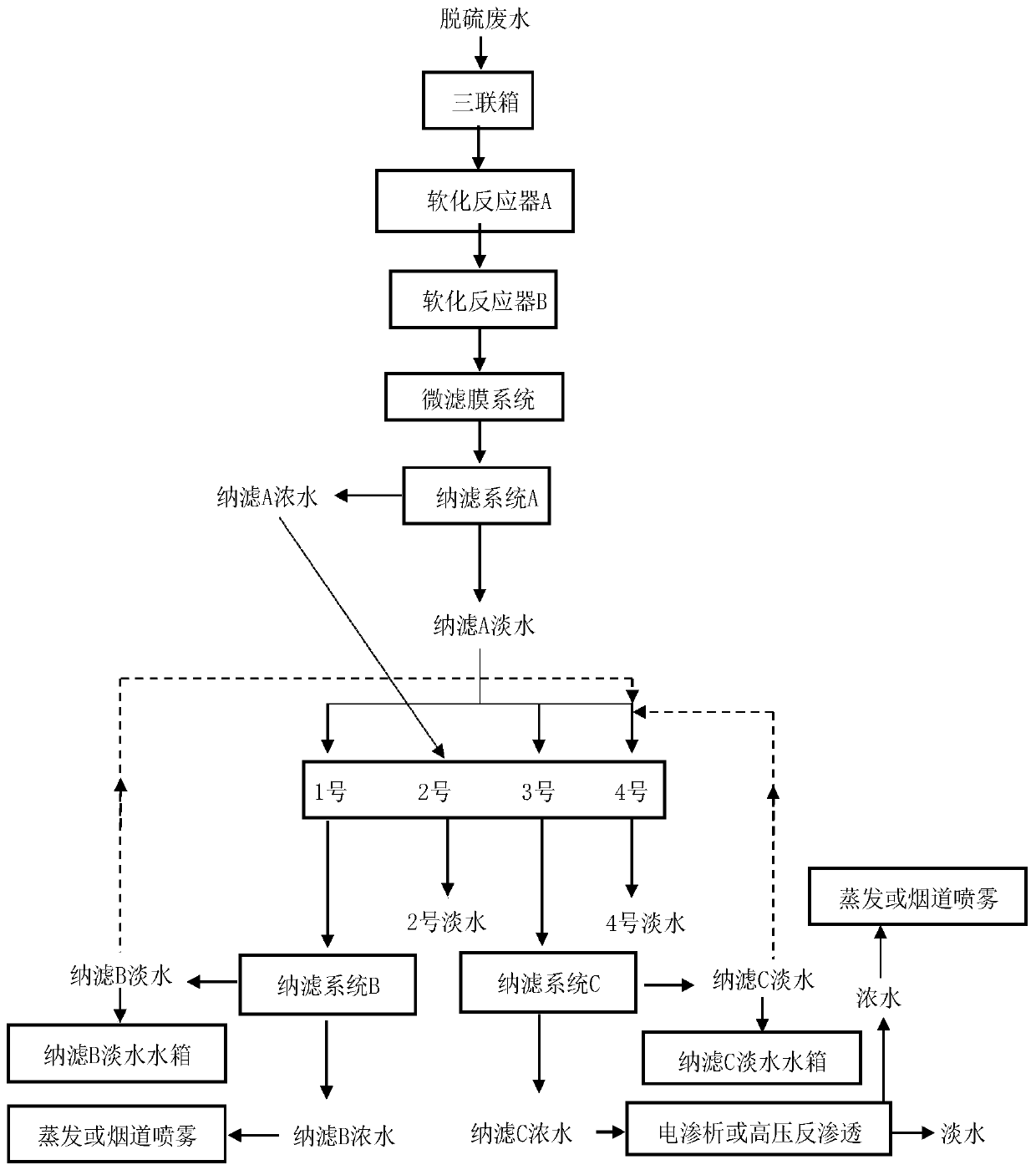

Treatment method of desulfurization wastewater

ActiveCN107089752BAchieving RecoverySolve the fouling problemGeneral water supply conservationWater contaminantsSolubilityTotal dissolved solids

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

Comprehensive recovery method of zinc oxide fume dust

The invention relates to a comprehensive recovery method of zinc oxide fume dust. The method comprises the following steps: 1. performing alkali-washing on zinc oxide fume dust with Na2CO3 and NaOH in different stages: in the first stage of alkali wash, evenly mixing the zinc oxide fume dust and solid Na2CO3, adding water, stirring at high speed to dissolve the solid into solution with slag, and filtering to obtain first-stage alkali wash liquid and alkali wash slag; in the second stage of alkali wash, adding solid Na2CO3 and NaOH into the first-stage alkali wash slag, adding water, stirring to dissolve the solid, regulating the pH value, and filtering to obtain second-stage alkali wash liquid and alkali wash slag; and carrying out neutral leaching on the second-stage alkali wash slag, purifying and electrodepositing to obtain electric zinc; 2. leaching, displacing and the like to process the low temperature purified slag to obtain sponge cadmium; and 3. processing acid leached slag to obtain coarse indium, using high-temperature high-acidity leached slag as the raw material for recovering lead, and using alkali wash liquid for recovering thallium. In the invention, metals in ZnCl2, ZnF2 and PbCl2 form carbonate solid slag, chlorine and fluorine are dissolved in solution in the form of sodium salts, the slag and the liquids are respectively processed subsequently, and the products in every stage are refined processed to comprehensively recover zinc, cadmium, lead, thallium and indium.

Owner:ZHUZHOU SMELTER GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com