Recovery method of slurry

A recycling method and slurry technology, applied in the field of solar cells, can solve the problems of limited recyclable capacity and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the invention is to provide a slurry recovery method to improve the recovery rate.

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

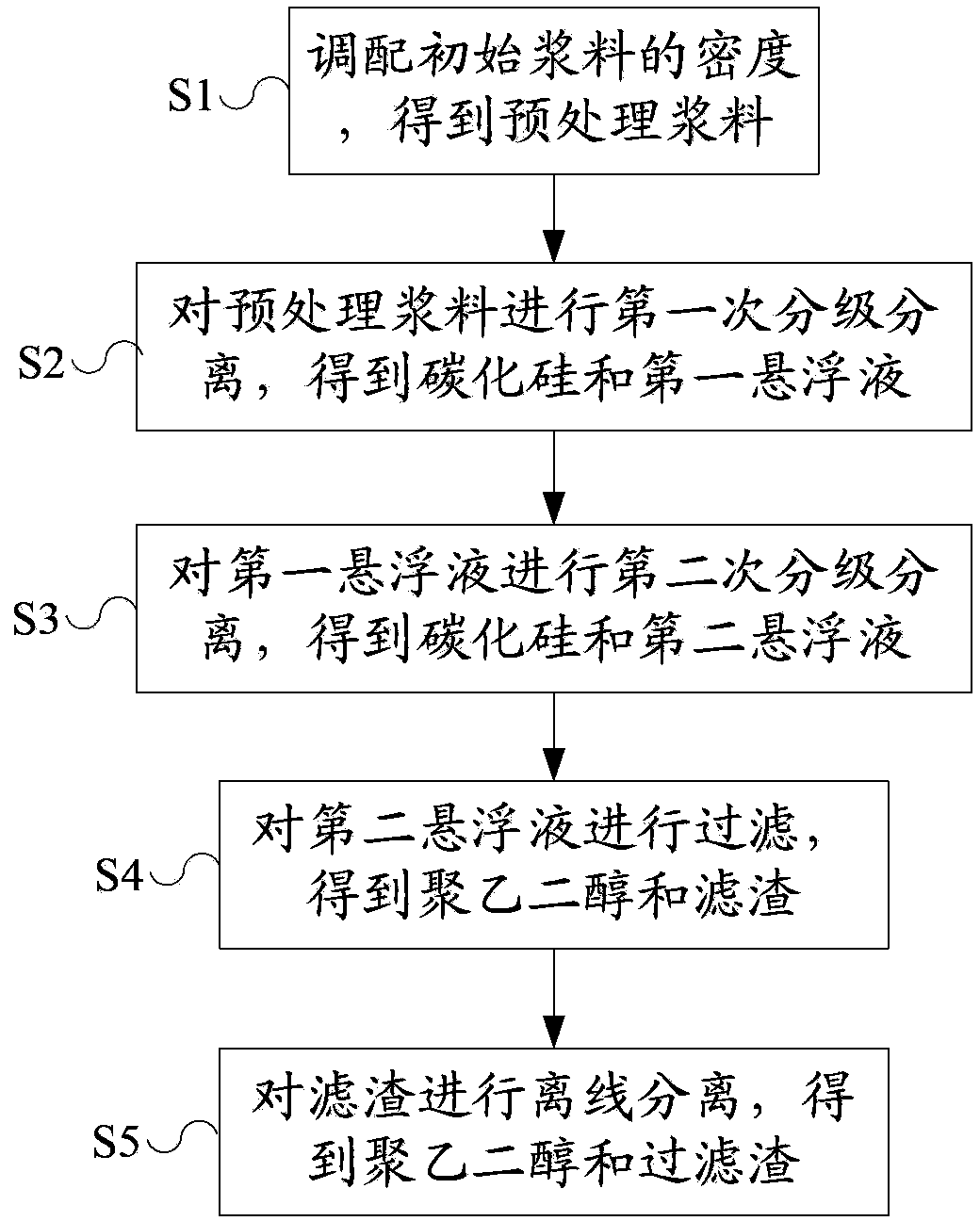

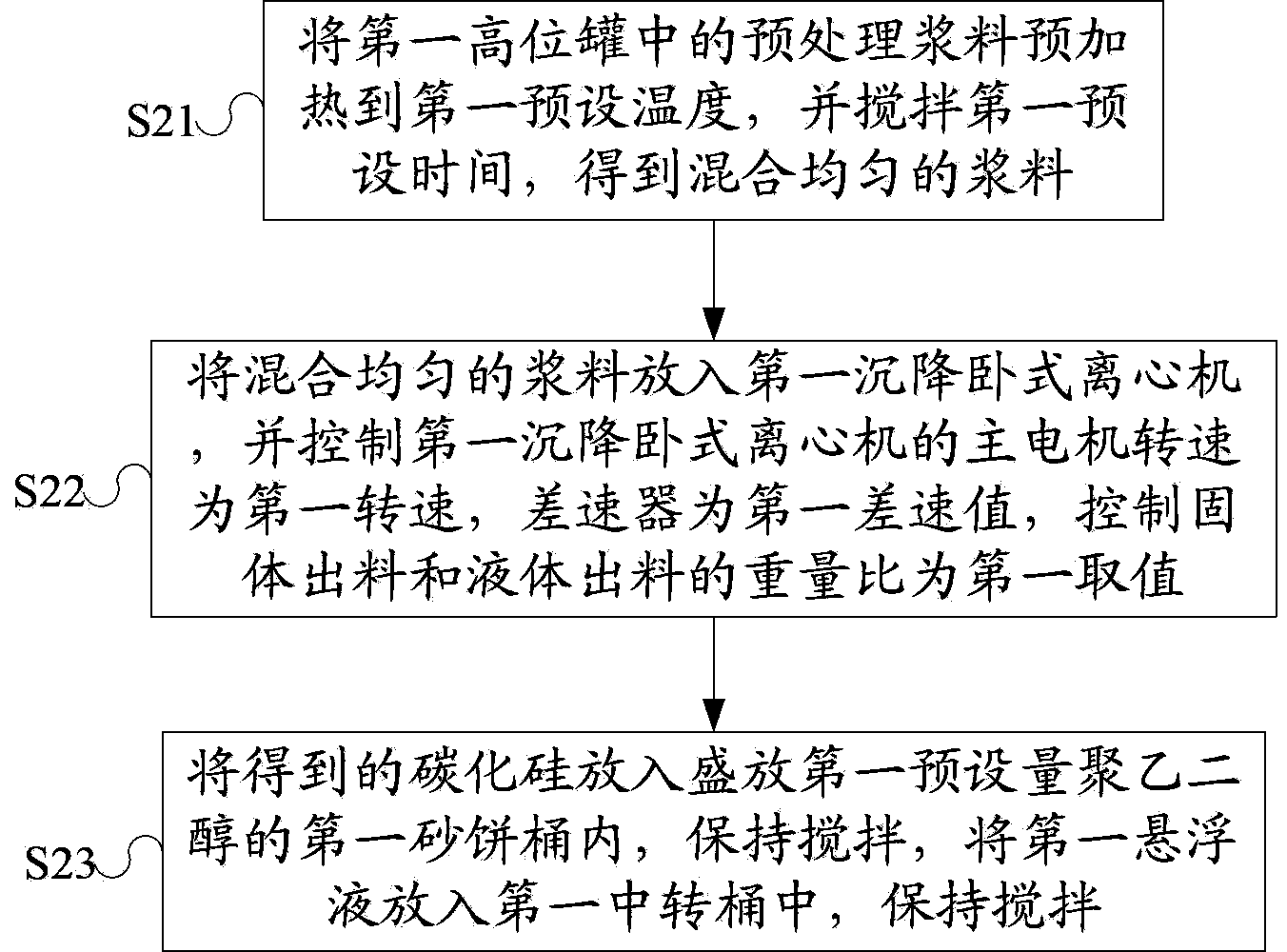

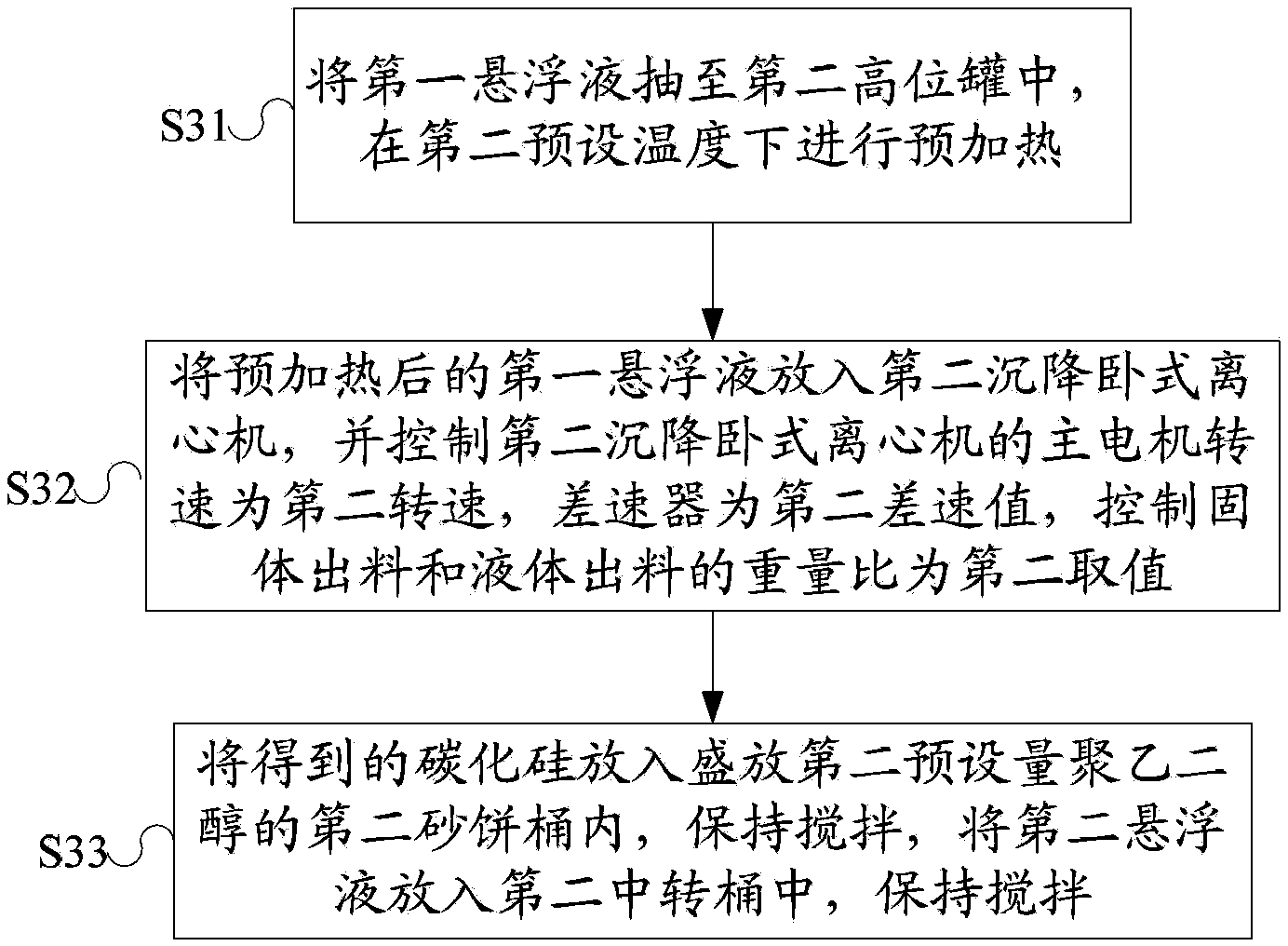

[0036] Please refer to figure 1 , the invention discloses a slurry recovery method for recovering polyethylene glycol and silicon carbide powder in the slurry, which comprises the following steps:

[0037] Step S 1: adjust the density of the initial slurry to obtain the pretreated slurry;

[0038] Since the density of the initial slurry discharged from the high-efficiency tank 1 is generally ρ=1.60-1.70g / ml, and the moisture content is ≤4%, it cannot meet the separation density requirements, so polyethylene glycol is added to the initial slurry , make the density of the initial slurry reach the first density value to obtain the pretreate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com