Green synthesis method of tetramethyl biphenyl isomer compounds

A technology for tetramethylbiphenyl and compound, which is applied in the field of green synthesis of tetramethylbiisomer, can solve the problems of large amount of reducing agent and catalyst, easy to cause a large amount of industrial waste residue, difficulty in recycling and utilization, etc., and achieves reduction of consumption Cost, wide selection, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

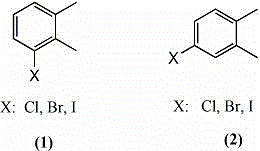

Method used

Image

Examples

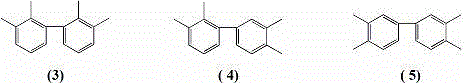

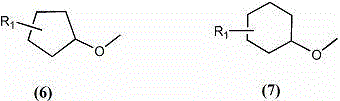

Embodiment 1

[0038] 4-Bromo-o-xylene (36.8 g, 0.2 moL), magnesium ribbon (1.2 g, 0.05 moL), anhydrous cyclopentyl methyl ether (60 g, 0.6 moL), iodine (5 mg, 0.02 mmoL), Anhydrous NiCl 2 (0.064 g, 0.5 mmoL), mixed in an argon atmosphere, heated to reflux (~115 o C) After reacting for 8 hours, cool down, filter out the precipitated magnesium bromide, recover 57 g of cyclopentyl methyl ether from the filtrate by distillation, recover 18.5 g of excess brominated o-xylene, and collect 145-155 g of brominated o-xylene by distillation under reduced pressure. o Fraction C (pressure 1-4 mmHg) yielded 19.2 g of 3, 3’, 4, 4’-tetramethylbiphenyl with a yield of 91% (calculated as magnesium) and a melting point of 74-75 o c.

Embodiment 2

[0040] 3-Chloro-o-xylene (28 g, 0.2 moL), magnesium ribbon (1.2 g, 0.05 moL), anhydrous cyclopentyl methyl ether (50 g, 0.5 moL), iodine (5 mg, 0.02 mmoL), Anhydrous NiCl 2 (0.064 g, 0.5 mmoL), bipyridine (0.078 g, 0.5 mmoL) were mixed in a nitrogen atmosphere, heated to reflux (~115 o C) After reacting for 8 hours, cool down, add 5mL of water, separate layers, collect the upper organic phase, recover 48 g of solvent cyclopentyl methyl ether from the organic phase by distillation, recover 13.5 g of excess chlorinated o-xylene, and collect under reduced pressure 130~145 o Fraction C (pressure 1~3 mmHg), obtained 17.9 g of 2, 2’, 3, 3’-tetramethylbiphenyl with a yield of 85% and a melting point of 115~116 o c.

Embodiment 3

[0042] 4-Chloro-o-xylene (14 g, 0.1 moL), magnesium ribbon (2.4 g, 0.1 moL), anhydrous cyclopentyl methyl ether (50 g, 0.5 moL), tert-butylmagnesium chloride (11 mg, 0.1 mmoL), reflux under nitrogen atmosphere (~110 o C) React until the metal magnesium is completely dissolved, that is, the Grignard reagent is completely generated, and then add the catalyst anhydrous NiCl 2 (0.13 g, 1 mmol) and triphenylphosphine (0.26 g, 1 mmol), then added 3-chloro-o-xylene (14 g, 0.1 moL), ~110 o C carried out the coupling reaction for 7 hours, then cooled and filtered off the inorganic salt precipitate, and the filtrate was distilled to recover 46 g of cyclopentyl methyl ether, and 140 to 145 g of cyclopentyl methyl ether was collected by vacuum distillation. o Fraction C (pressure 1~5 mmHg), 18.5 g of 2,3’,3,4’-tetramethylbiphenyl was obtained with a yield of 88% and a melting point of 45~46 o c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com