Multi-disc direct cleaning filter and use method thereof

A filter and filter disc technology, applied in textiles and papermaking, fiber raw material processing, papermaking, etc., can solve the problems of expensive mechanical maintenance, failure to form a pulp layer, blockage of high-pressure nozzles, etc., and achieve significant economic and social benefits. The effect of reducing sewage discharge per ton of paper and convenient maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

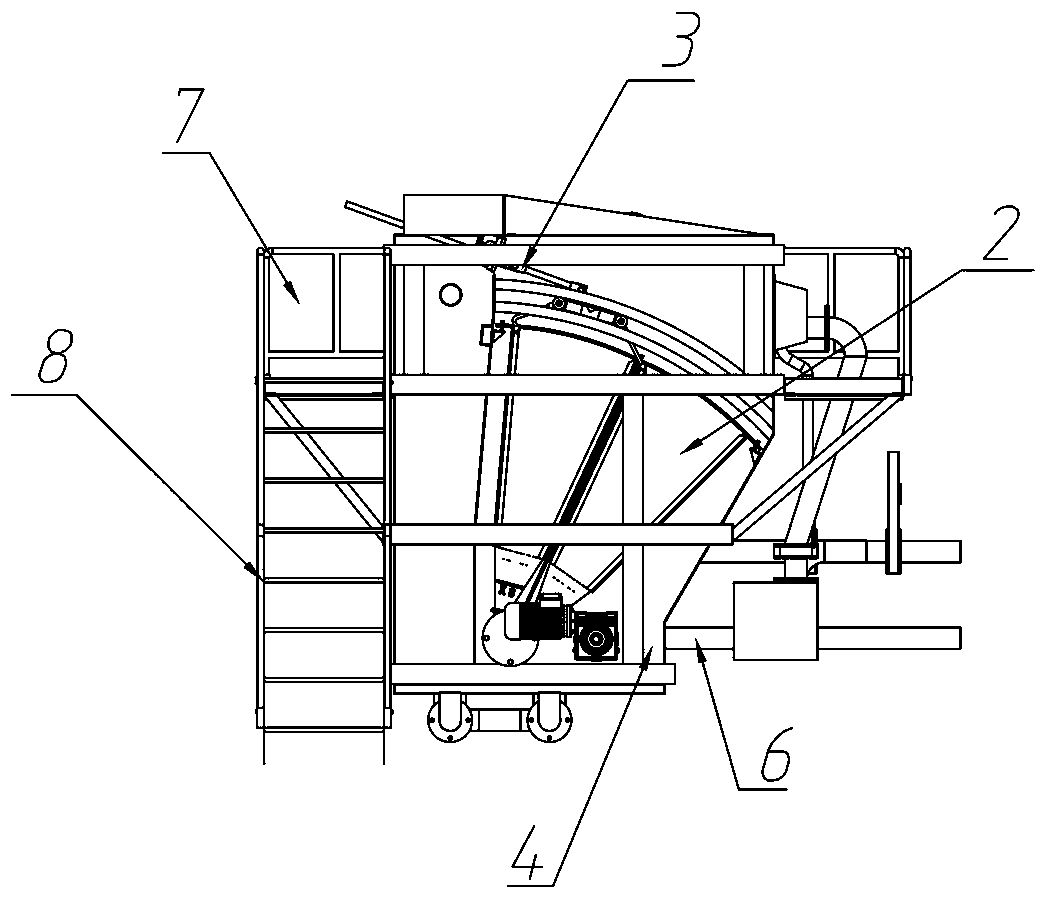

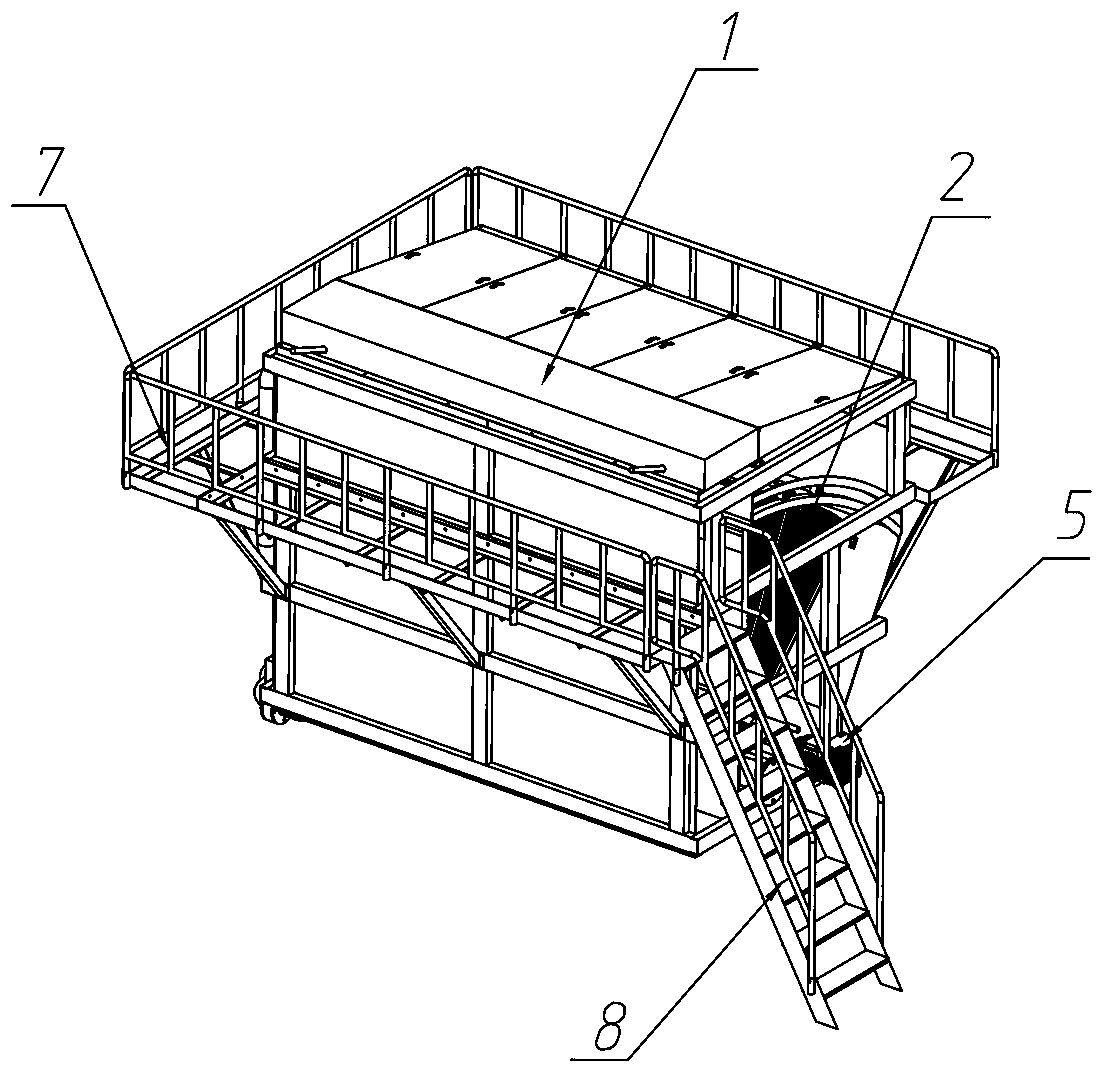

[0041] The multi-disc direct cleaning filter of the present invention includes a housing 1 and a support frame arranged in the housing 1. A white water inlet pipe is arranged on the upper part of one side of the housing 1, and the other side of the housing 1 corresponds to The lower part is provided with a drainage pipe, and several support frames parallel to each other are provided between the white water inlet pipe and the discharge pipe, and several metal fiber filter discs 2 are arranged on the support frames, and the metal fiber filter discs 2 are all parallel to each other set up;

[0042] The top of the housing 1 is fixedly provided with filter cake stripping devices whose number and position correspond to the number and position of the metal fiber filter discs 2;

[0043] The bottom of the housing 1 is provided with a pulp receiving hopper 4, the pulp receiving hopper 4 and the housing 1 are connected to each other, and a stirring device 5 is arranged in the pulp recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com