A biological treatment method for improving paper strength

A biological treatment and paper strength technology, applied in fiber raw material treatment, textiles and papermaking, etc., can solve problems such as increasing production costs and affecting the effect of paper-making reinforcing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

detailed description

[0024] The present invention will be further described below in conjunction with the embodiments, but the protection scope of the present invention is not limited thereto.

[0025] The laccase described in the examples was purchased from Novozymes (China) Investment Co., Ltd. with the product number NS51003. Syringaldehyde is analytically pure, and both alkali lignin and lignosulfonate are commercially available products with purity For industrial grade.

Example Embodiment

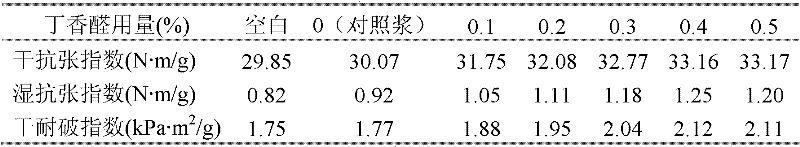

[0026] Example 1

[0027] A biological treatment method for improving the strength of paper, the steps are as follows:

[0028] (1) Pulping the OCC waste paper with a disintegration concentration of 10%, screening and washing, and beating to a beating degree of 45°SR to prepare a slurry with a material-to-liquid ratio of 5:100 (g / ml);

[0029] (2) Use 0.2M H 2 SO 4 Adjust the pH of the slurry prepared in step (1) to 4.5, add laccase at the addition amount of 10U / g absolute dry slurry, and then divide it into 6 groups, of which 5 groups are added with 0.1% and 0.2 of the weight of the absolute dry slurry. %, 0.3%, 0.4%, 0.5% syringaldehyde, the control pulp group did not add syringaldehyde, stirring for 1 hour at 45°C and the oxygen content of the slurry ≥5mg / L to obtain the biologically treated pulp;

[0030] (3) The biologically treated pulp prepared in step (2) is washed with water until it is colorless, and then the paper is made into paper, dried at 95°C, and then tested.

[0031] ...

Example Embodiment

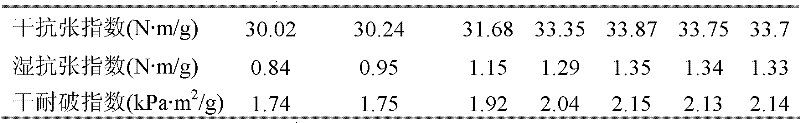

[0041] Example 2

[0042] The biological treatment method for improving the strength of paper as described in Example 1, the difference is that while adding different amounts of syringaldehyde, 0.2% of industrial alkali lignin (relatively dry pulp) is added and reacted for 1 hour.

[0043] Blank: The preparation method is as above, except that laccase, syringaldehyde and alkali lignin are not added.

[0044] Control pulp: the preparation method is as above, the difference is that syringaldehyde and alkali lignin are not added.

[0045] The detection method is the same as in Example 1.

[0046] The results are shown in Table 2.

[0047] Table 2

[0048]

[0049]

[0050] Analysis: When 0.2% alkali lignin is added, adding different amounts of syringaldehyde can improve the strength performance of paper to varying degrees. According to Table 1, when the same amount of syringaldehyde is added, and the additional 0.2% of industrial lignin is added, higher paper strength, especially wet tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com