Zero-discharge process and system for wastewater reuse in integrated circuit industry

A technology for industrial wastewater and integrated circuits, applied in the field of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

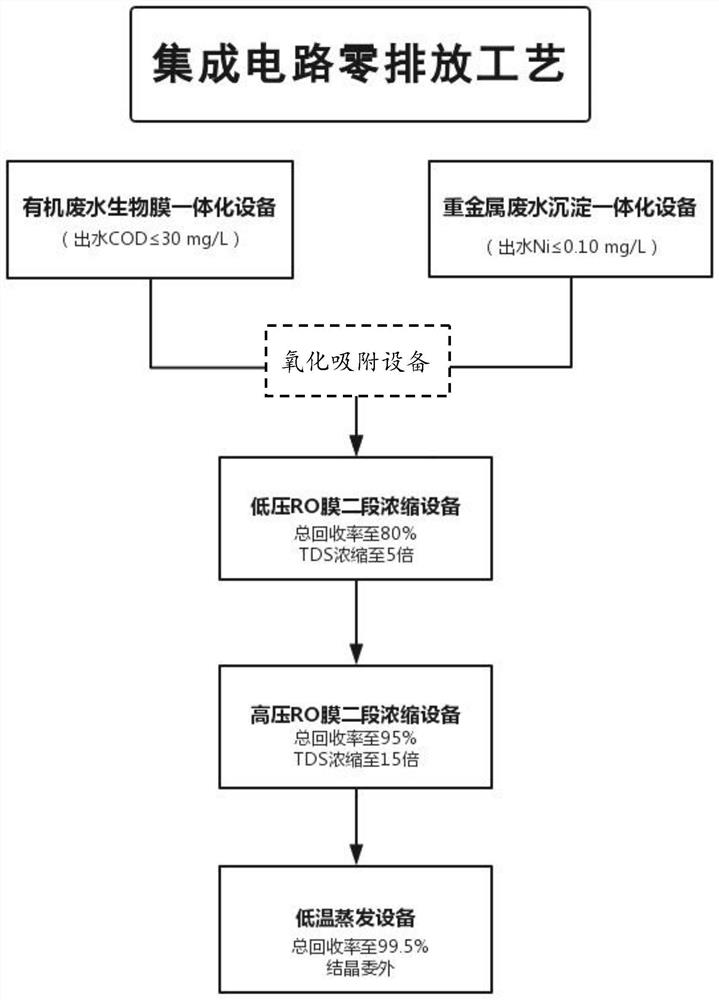

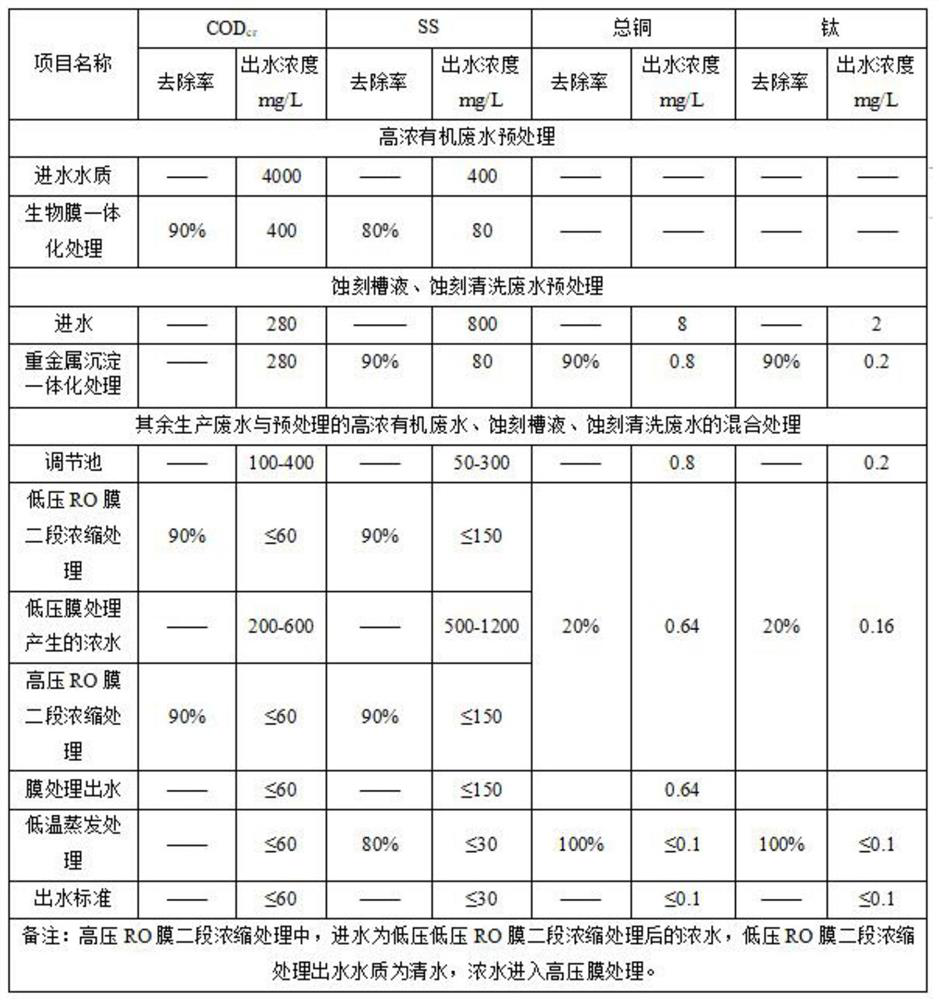

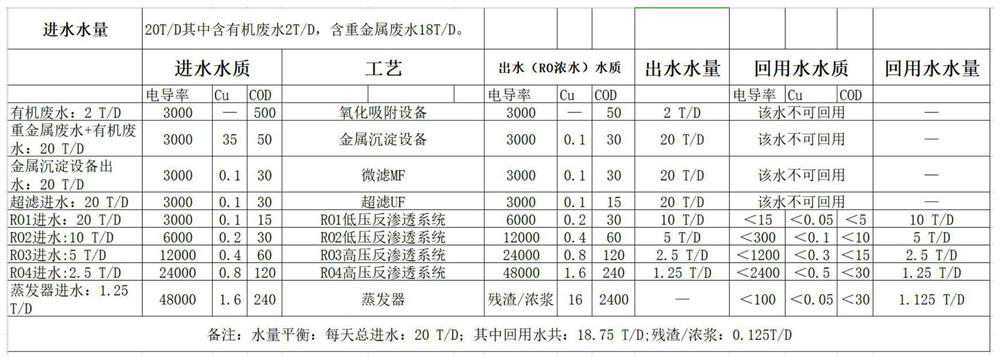

[0037] This embodiment provides a zero-discharge technology for wastewater reuse in the integrated circuit industry, such as figure 1 As shown in the figure, the specific process is as follows: the wastewater is sequentially treated by organic biomembrane integrated treatment / oxidative adsorption equipment / secondary physicochemical precipitation equipment, ultrafiltration, four-stage membrane concentration equipment and evaporator to achieve the effect of zero discharge.

[0038] Among them, the purified water treated by the four-stage membrane concentration equipment is also purified by the second purification equipment.

[0039] Here, the use of organic biofilm integrated treatment / oxidative adsorption equipment / secondary physicochemical precipitation equipment is as follows:

[0040] In general, different pretreatment methods are used for different wastewaters.

[0041] For example: for high-concentration organic wastewater (ie, the COD index is greater than 3000mg / L, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com