Treatment method of desulfurization wastewater

A treatment method and technology for desulfurization wastewater, applied in the field of environmental engineering, can solve the problems of large sludge output, difficult regulation and serious equipment scaling phenomenon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

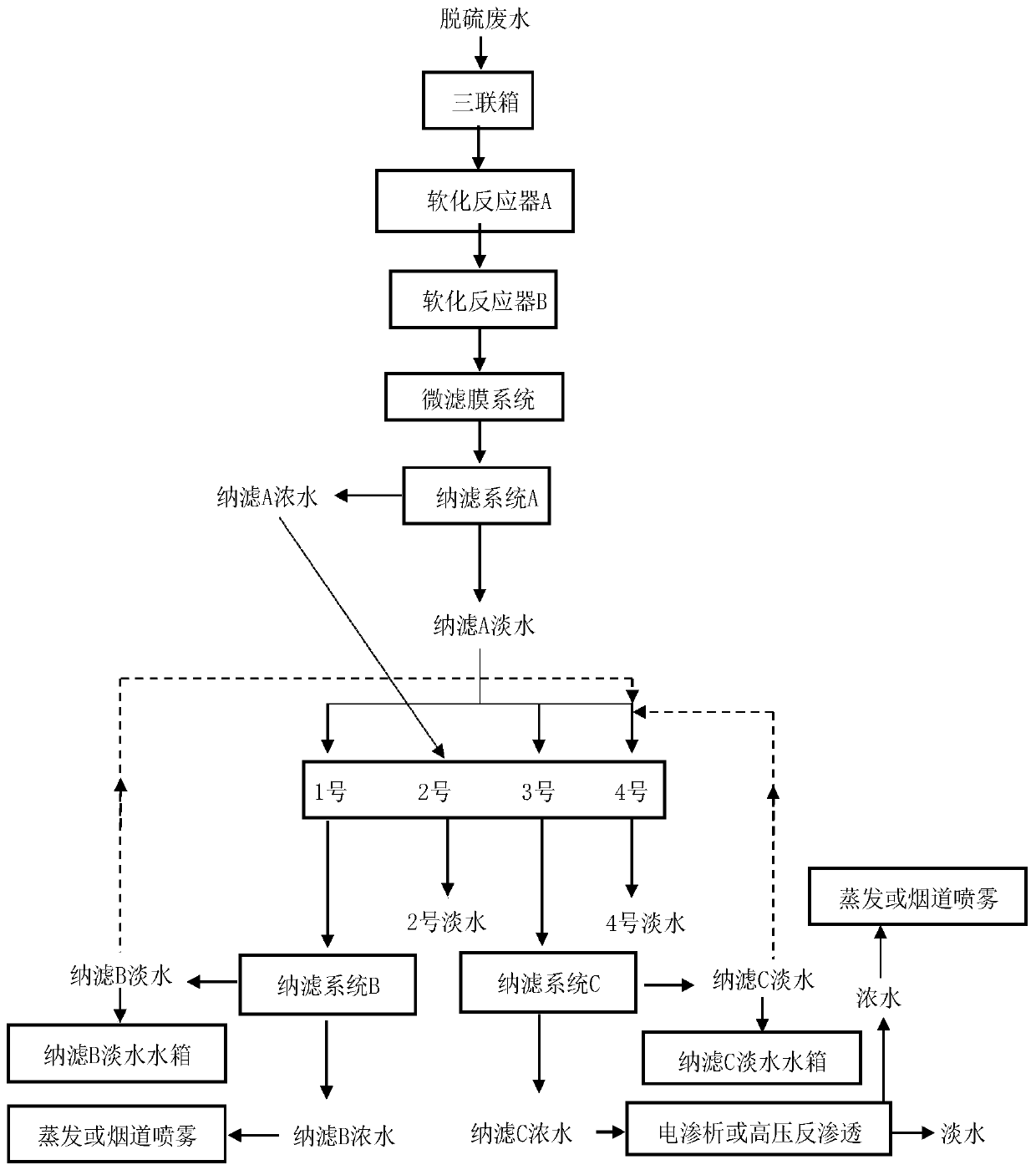

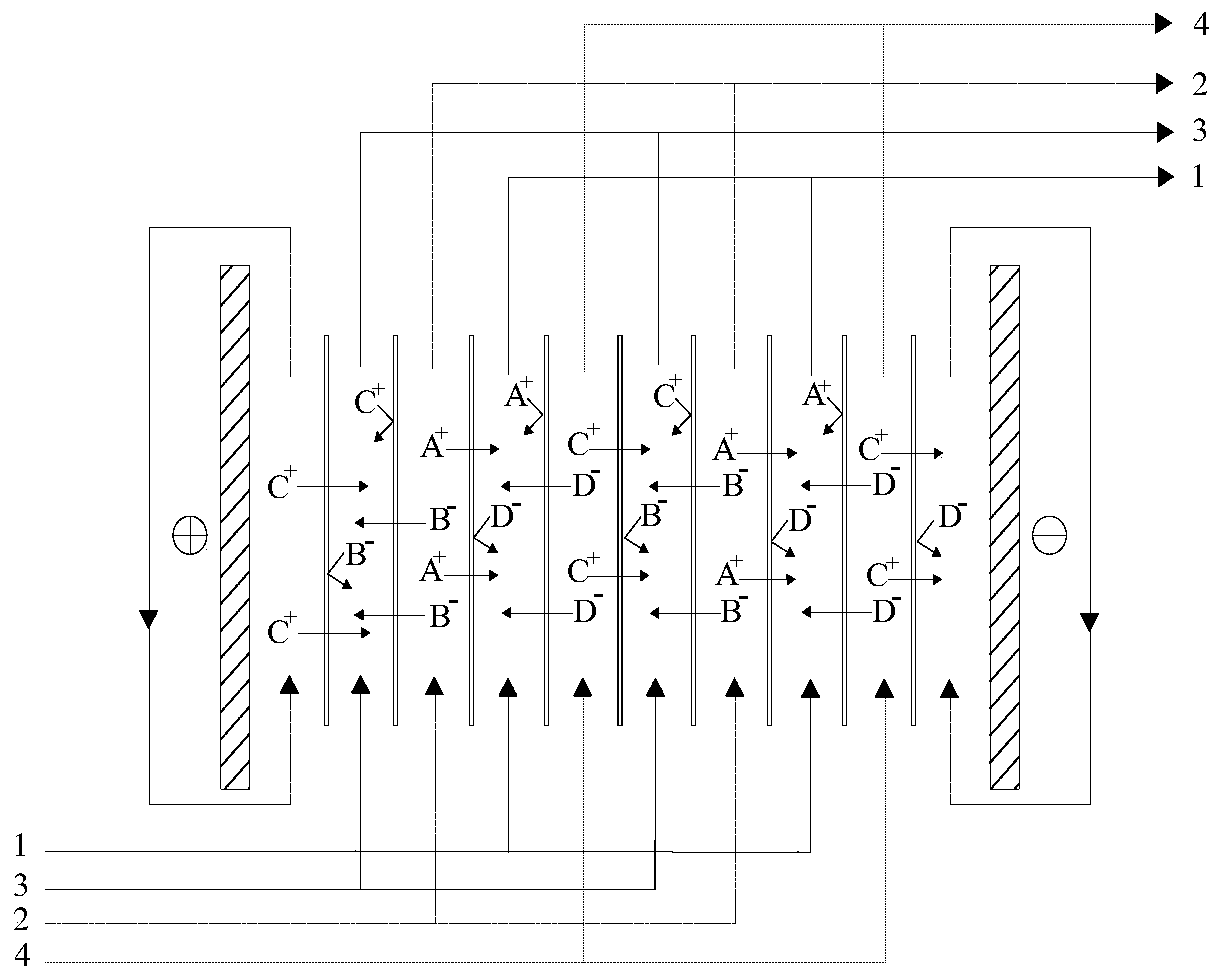

[0030] The invention provides a treatment method for desulfurization wastewater, by recombining magnesium sulfate, magnesium sulfate, magnesium carbonate, and magnesium carbonate that are easy to scale in wastewater to form calcium chloride and magnesium chloride that are difficult to scale, thereby solving the problem of subsequent electrodialysis Fouling problems in equipment or high pressure reverse osmosis systems. Next, the method for treating desulfurization wastewater of the present invention will be described in detail.

[0031] The present invention is a kind of processing method of desulfurization waste water, as follows figure 1 As shown, the treatment steps include: firstly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com