A method for enriching and extracting gold by using molten salt electrolysis

A molten salt electrolysis and enrichment technology, applied in the improvement of process efficiency, instruments, optics, etc., can solve the problems of poor adaptability of raw materials, difficult processing, and high equipment requirements, and achieve rapid and efficient removal, separation and enrichment. The effect of high ratio and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

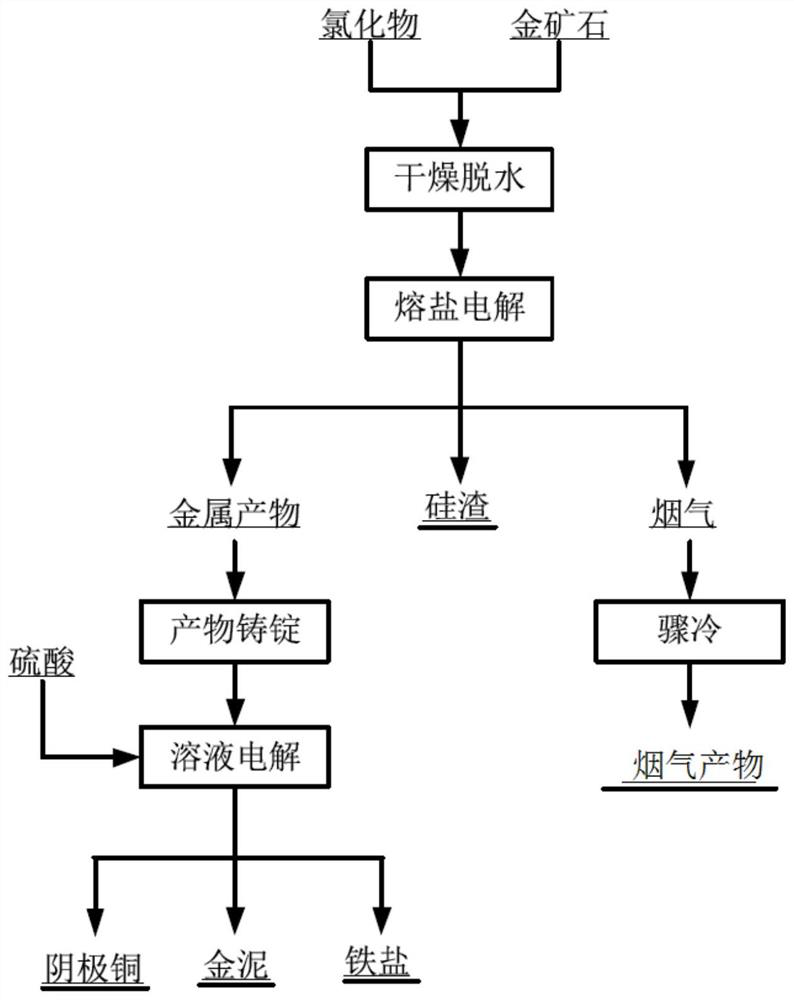

Method used

Image

Examples

Embodiment 1

[0053]In this example, a refractory gold mine in Liaoning is selected. Most of the gold is wrapped in sulfide, and its composition is 55.6g / t of gold, 14.8% of iron, 22.3% of sulfur, 5.2% of copper, and 5.9% of arsenic. Based on the above raw materials The method for extracting gold by enrichment by molten salt electrolysis comprises the steps of:

[0054] 1. Gold ore and chloride are dropped into the molten salt electrolyzer with flue gas collection hood according to the mass ratio=1:50, and the chloride is a mixture of sodium chloride and calcium chloride with a mass ratio of 2:1, In a natural air atmosphere, first raise the temperature to 150°C for drying and dehydration for 5 hours, then pass in nitrogen and raise the temperature to 680°C, use graphite as the cathode and anode, insert the electrodes and pass in direct current, and conduct molten salt electrolysis at 680°C and electrolysis voltage 4.0V 8h;

[0055] 2. The flue gas produced in the molten salt electrolysis p...

Embodiment 2

[0059] In this example, a difficult-to-treat gold mine in Gansu is selected. The gold is in the state of fine particle dissemination, and its composition is 15.6g / t of gold, 21.5% of iron, 30.1% of sulfur, and 5.3% of copper. Based on the above-mentioned raw materials, it is enriched by molten salt electrolysis A method for extracting gold, comprising the steps of:

[0060] 1. Put the gold ore and potassium chloride into the molten salt electrolytic cell with the flue gas collection hood according to the mass ratio = 1:2, first raise the temperature to 300°C for 0.5h in the natural air atmosphere, and then pass the volume ratio The mixture of 1:1 argon and helium is heated to 1350°C, with graphite as the cathode and noble metal iridium oxide as the anode, the electrodes are inserted and direct current is applied, and molten salt electrolysis is carried out at 1350°C and electrolysis voltage 2.0V 0.5h;

[0061] 2. The flue gas produced in the molten salt electrolysis process i...

Embodiment 3

[0065] In this embodiment, a gold mine in Inner Mongolia is selected. The gold mine contains both oxides and sulfides. Its composition is 63.8g / t of gold, 20.5% of iron, 10.1% of copper, and 5.2% of carbon. Based on the above raw materials, molten salt is used A method for electrolytic enrichment and extraction of gold, comprising the steps of:

[0066] 1. Gold ore and chloride are dropped into the molten salt electrolyzer with the flue gas collection hood according to the mass ratio=1:20, and the chloride is a mixture of magnesium chloride and potassium chloride with a mass ratio of 1:1. In a natural air atmosphere, first raise the temperature to 200°C for drying and dehydration for 3.5 hours, and then pass in argon gas to raise the temperature to 1000°C. With graphite as the cathode and titanium oxide as the anode, insert the electrodes and pass in direct current. At 1000°C, the electrolysis voltage is 3.0V Carry out molten salt electrolysis for 5 hours;

[0067] 2. The flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com