Method for recovering ammonia from ammonia-containing gas based on ionic liquid

A technology of ammonia-containing gas and ionic liquid, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high cost, low recovery rate of ammonia absorbed by water, pollution by water absorption, etc., and achieves easy promotion and installation The effect of simple structure and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

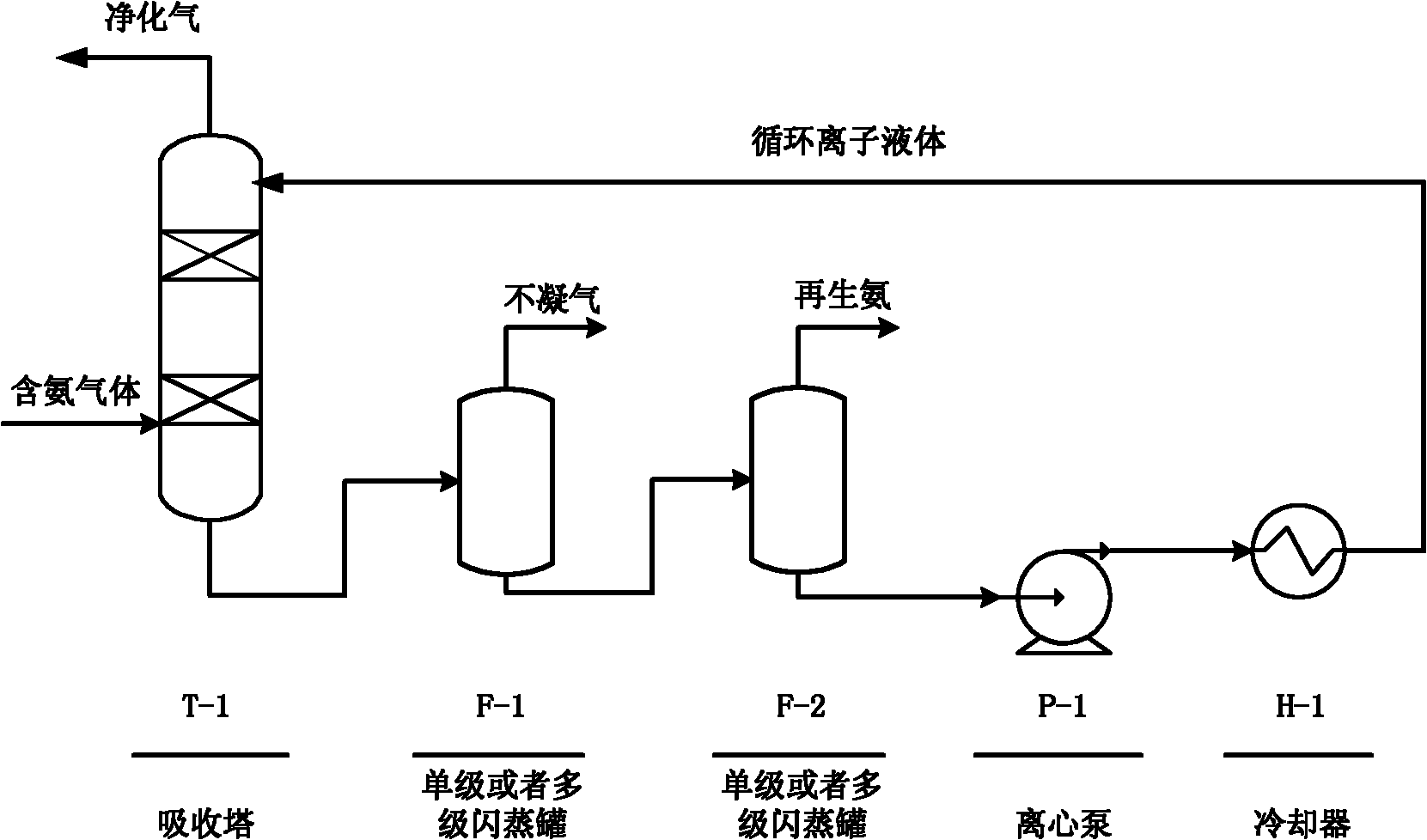

Method used

Image

Examples

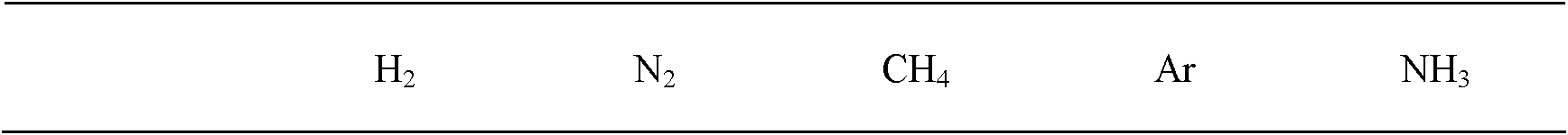

Embodiment 1

[0027] Using the above-mentioned embodiment, the flow rate of synthetic ammonia release gas is 516.35kg / h, the mass fraction of ammonia is 4.4%, the pressure is 60atm, and the temperature is -8°C; the ionic liquid [C 4 MIM][BF 4 ] The feed flow rate is 2000kg / h, the pressure is 59atm, and the temperature is 30°C; the operating pressure of the absorption tower is 59atm~60atm. The ammonia-rich liquid enters the secondary flash tank to flash non-condensable gas, and the flash temperature is 60°C; then enters the secondary flash tank to recover ammonia, and the flash temperature is 100°C; the desorbed lean liquid is compressed to 59atm, then cooled to 30°C, and then enters the absorption tower for cyclic absorption. The absorption of ammonia is 22.275kg / h, the recovery rate of ammonia is 97.1%; the recycling rate of ionic liquid is 1999.929kg / h, the recovery rate of ionic liquid is 99.99%, and the mass concentration of ammonia in the desorbed ionic liquid is 35ppm. Examples The ...

Embodiment 2

[0032] Adopt above-mentioned embodiment, the flow rate of synthetic ammonia release gas is 516.35kg / h, the mass fraction of ammonia is 4.4%, the pressure is 60atm, temperature-8 ℃; Composite solvent feed flow rate is 2100kg / h, ionic liquid [C 4 MIM][BF 4 ] mass fraction 95.2% polyethylene glycol mass fraction 4.8%, pressure 59atm, temperature 20°C. The ammonia-rich liquid enters the secondary flash tank to flash non-condensable gas, and the flash temperature is 60°C; then enters the secondary flash tank to recover ammonia, and the flash temperature is 100°C; the desorbed lean liquid is compressed to 59atm, then cooled to 20°C, and then enters the absorption tower for cyclic absorption. The absorption of ammonia is 21.733kg / h, the recovery rate of ammonia is 95.7%; the recycling rate of ionic liquid is 1999.929kg / h, the recovery rate of ionic liquid is 99.99%, and the mass concentration of ammonia in the desorbed ionic liquid is 35ppm. The results of the examples are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com