Method and device for removing and recycling nitrogen and phosphorus in biogas slurry

A biogas slurry and solution technology, applied in the field of water treatment, achieves the effects of stable treatment effect, simple and easy process, and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with specific embodiments.

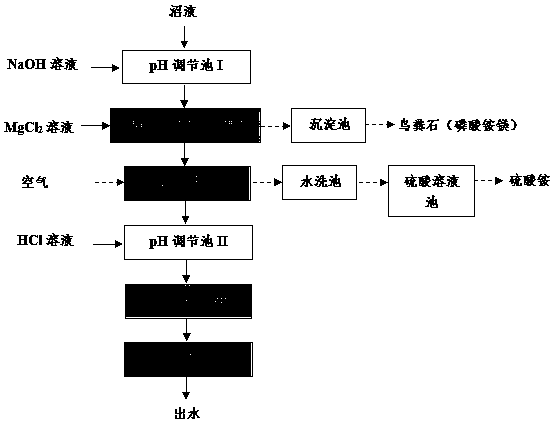

[0038] 1. A method for removing and recycling nitrogen and phosphorus in biogas slurry, the technological process is as follows figure 1 shown, including the following steps:

[0039] 1) Struvite crystallization: first adjust the pH value of the biogas slurry to 9~10 with NaOH solution, and then add MgCl to the biogas slurry 2 solution, so that n(Mg 2+ ):n (orthophosphate)=1.3~1.4:1; Stir the biogas slurry at a uniform speed to generate struvite (magnesium ammonium phosphate) crystals, and the struvite crystals finally form sludge-like precipitates to obtain struvite sewage Sludge sedimentation and dephosphorization biogas slurry.

[0040] Due to the large amount of NH in the biogas slurry 4 + Nitrogen in the form of and phosphorus in the form of phosphate, so a certain amount of Mg is added to it 2+ It can be reacted such that nitrogen, phosphorus, especial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com