Patents

Literature

52results about How to "High technical efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

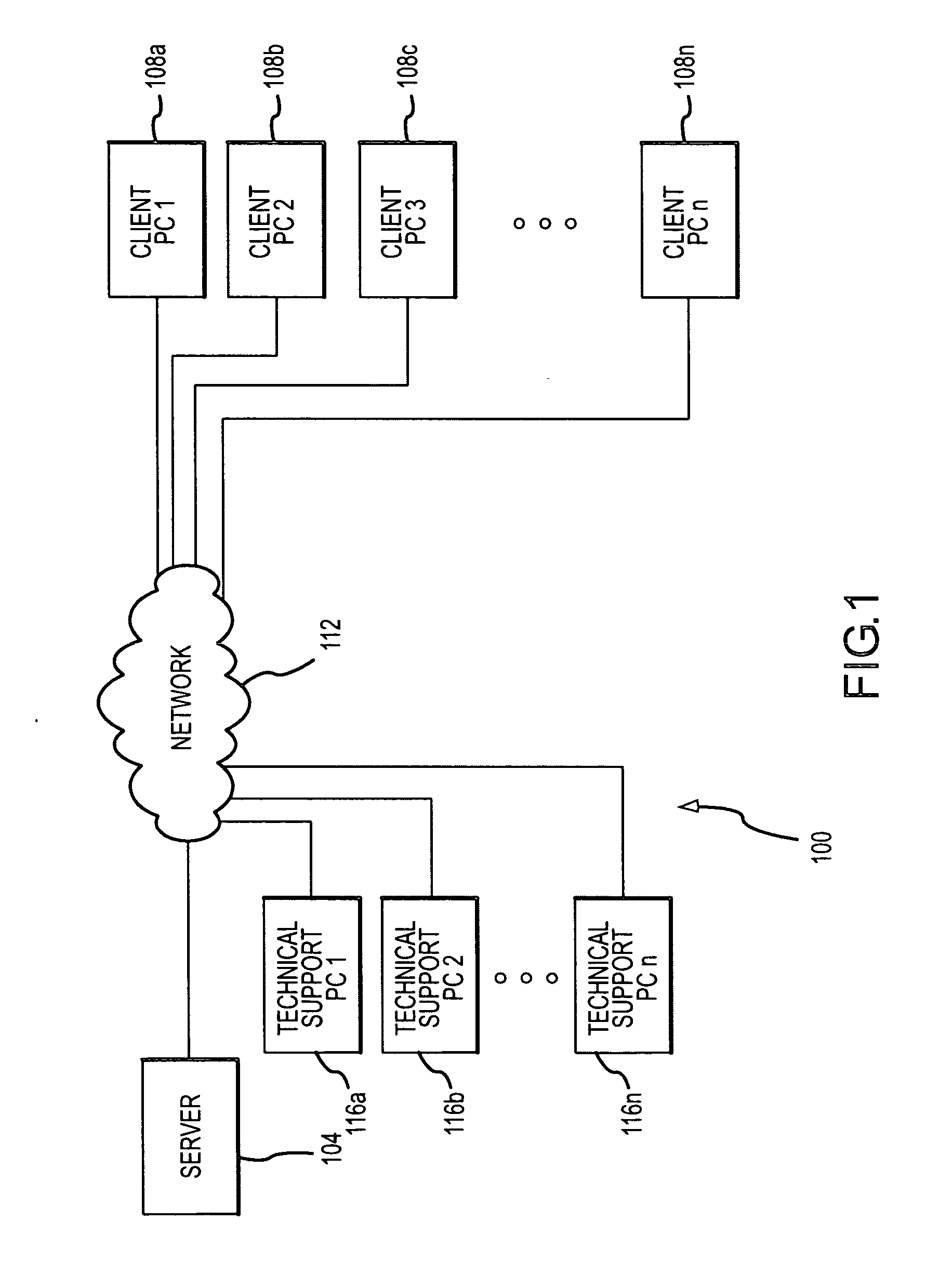

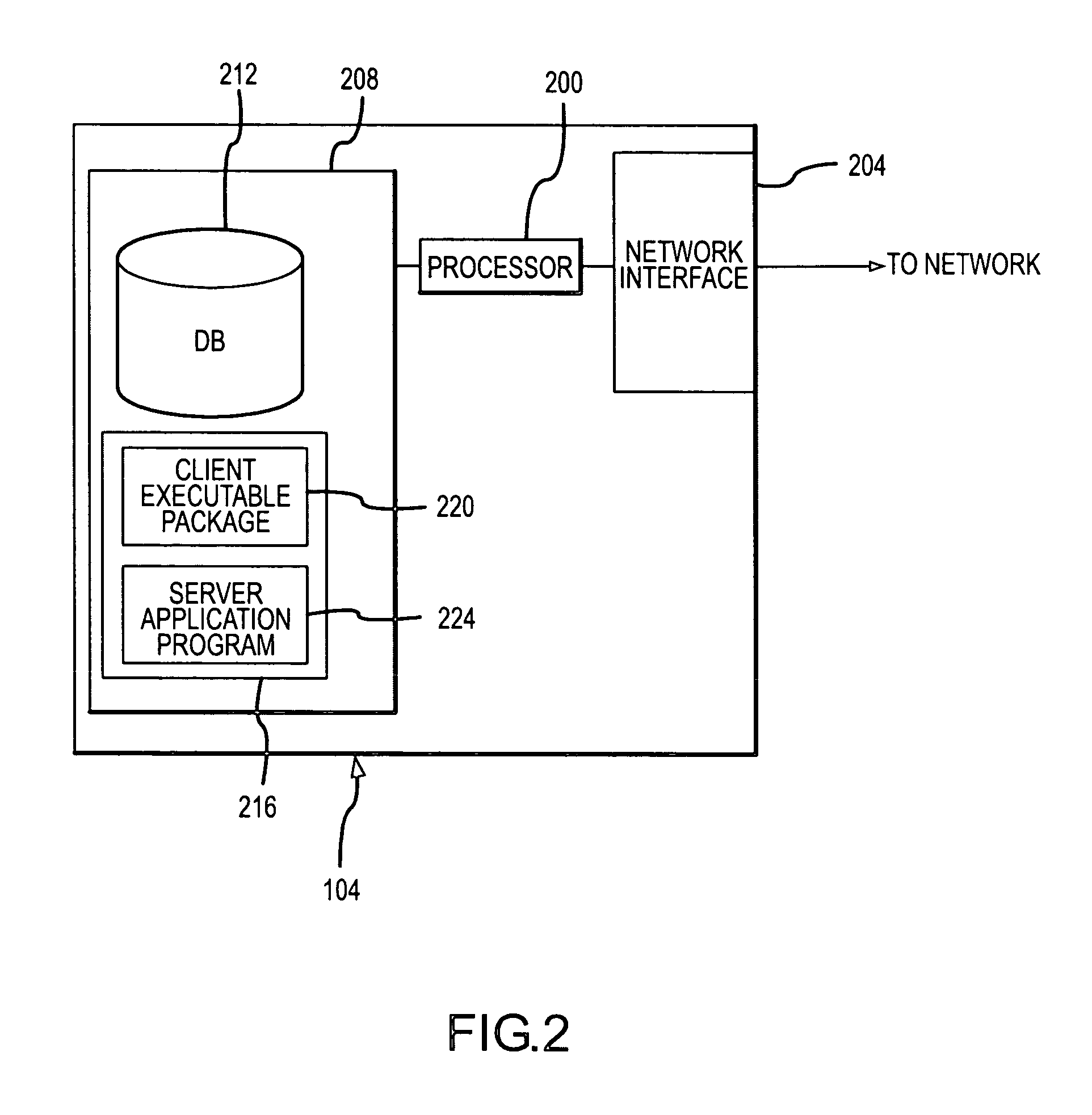

Intelligent knowledge management and content delivery system

InactiveUS20050120112A1Improve efficiencyQuick fixDigitally marking record carriersMultiple digital computer combinationsIntelligent managementKnowledge management

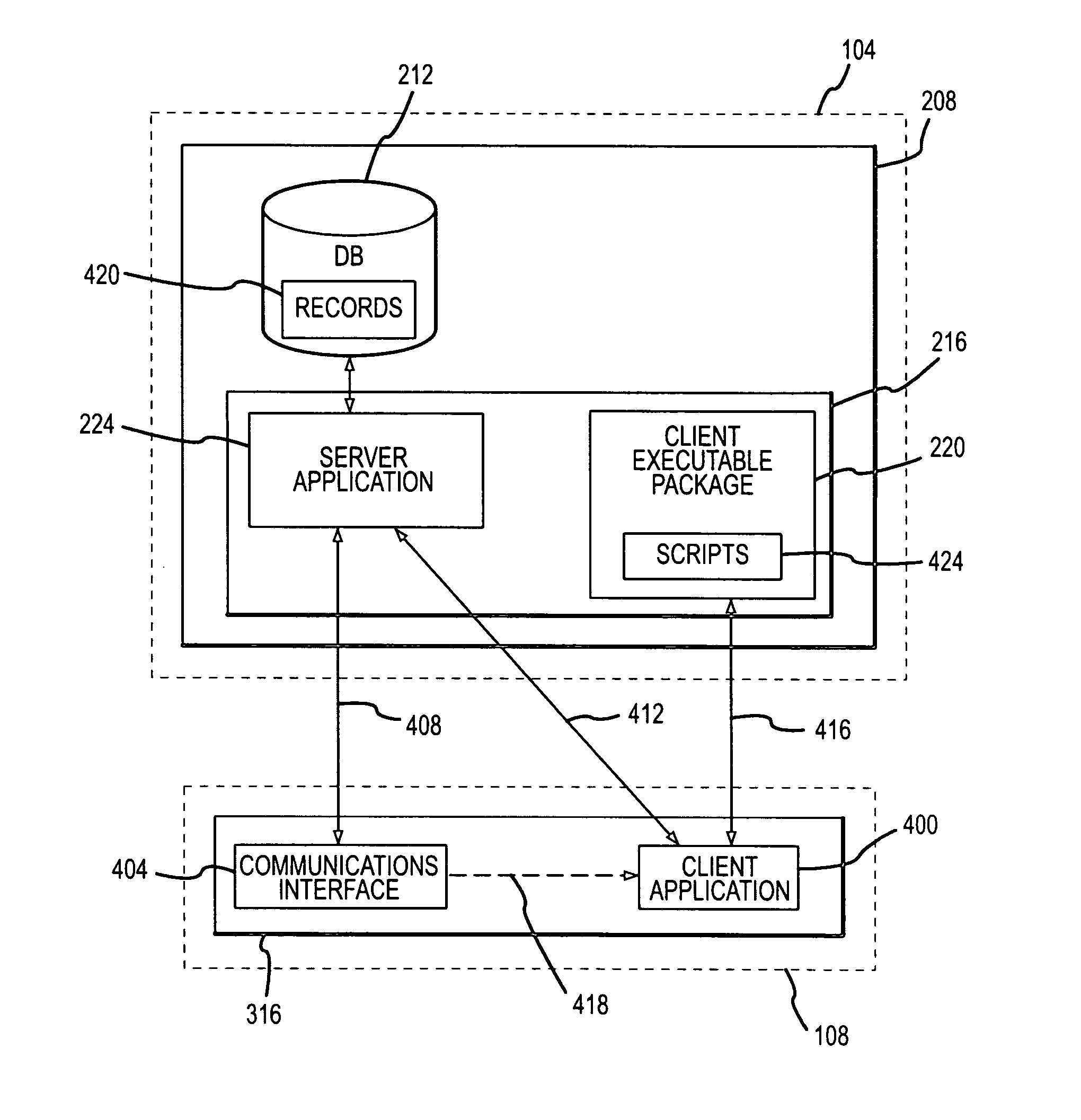

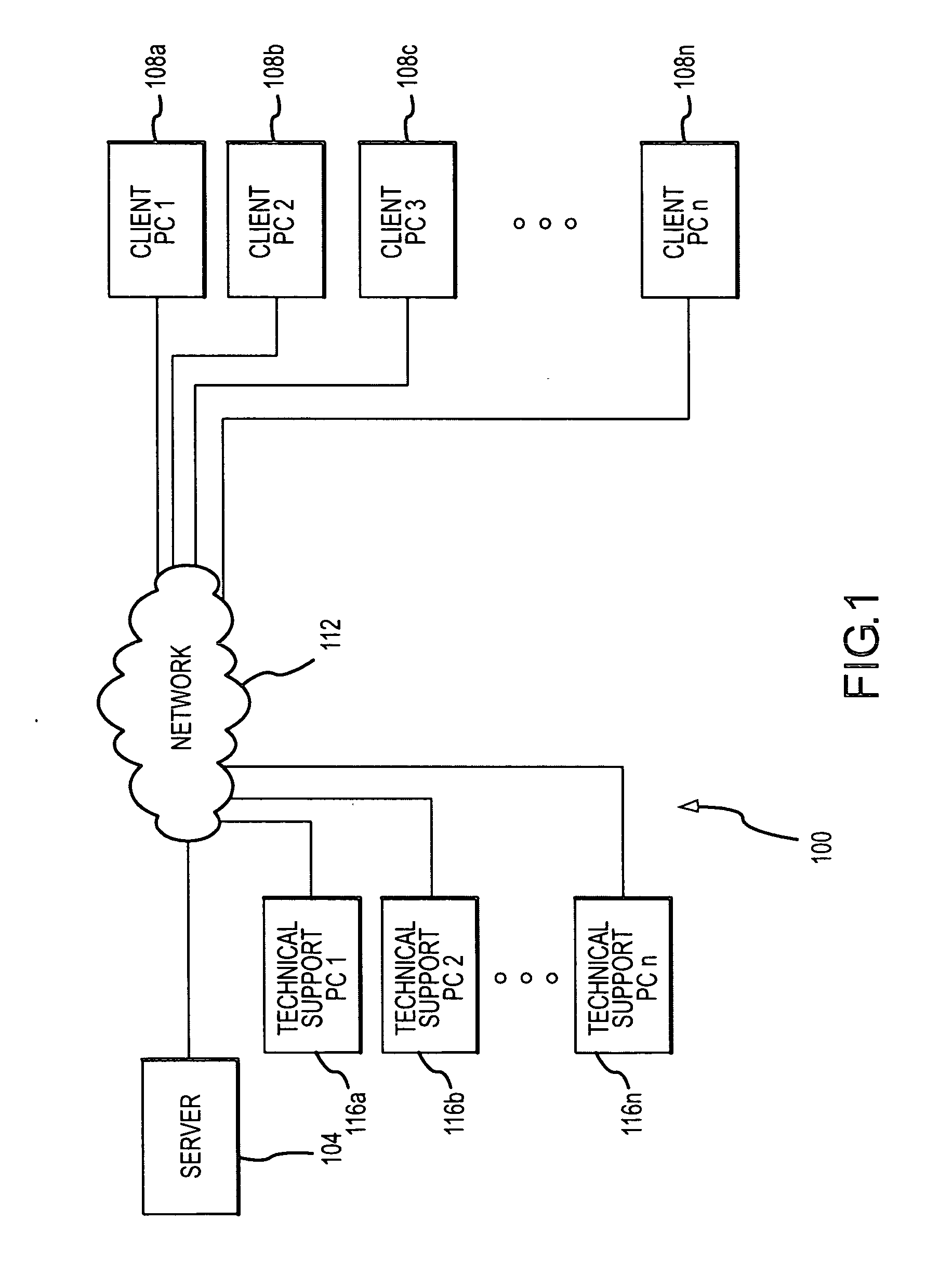

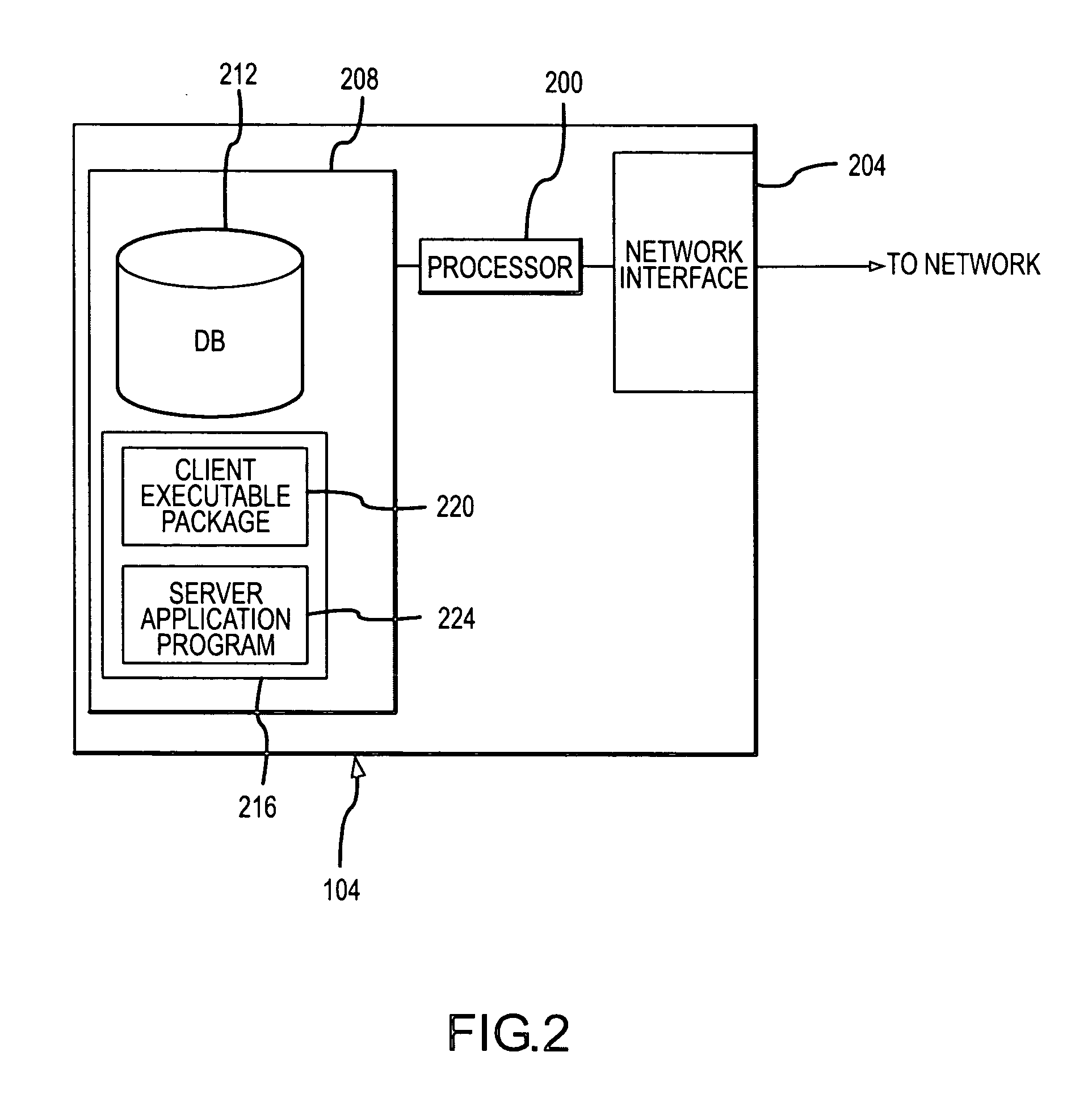

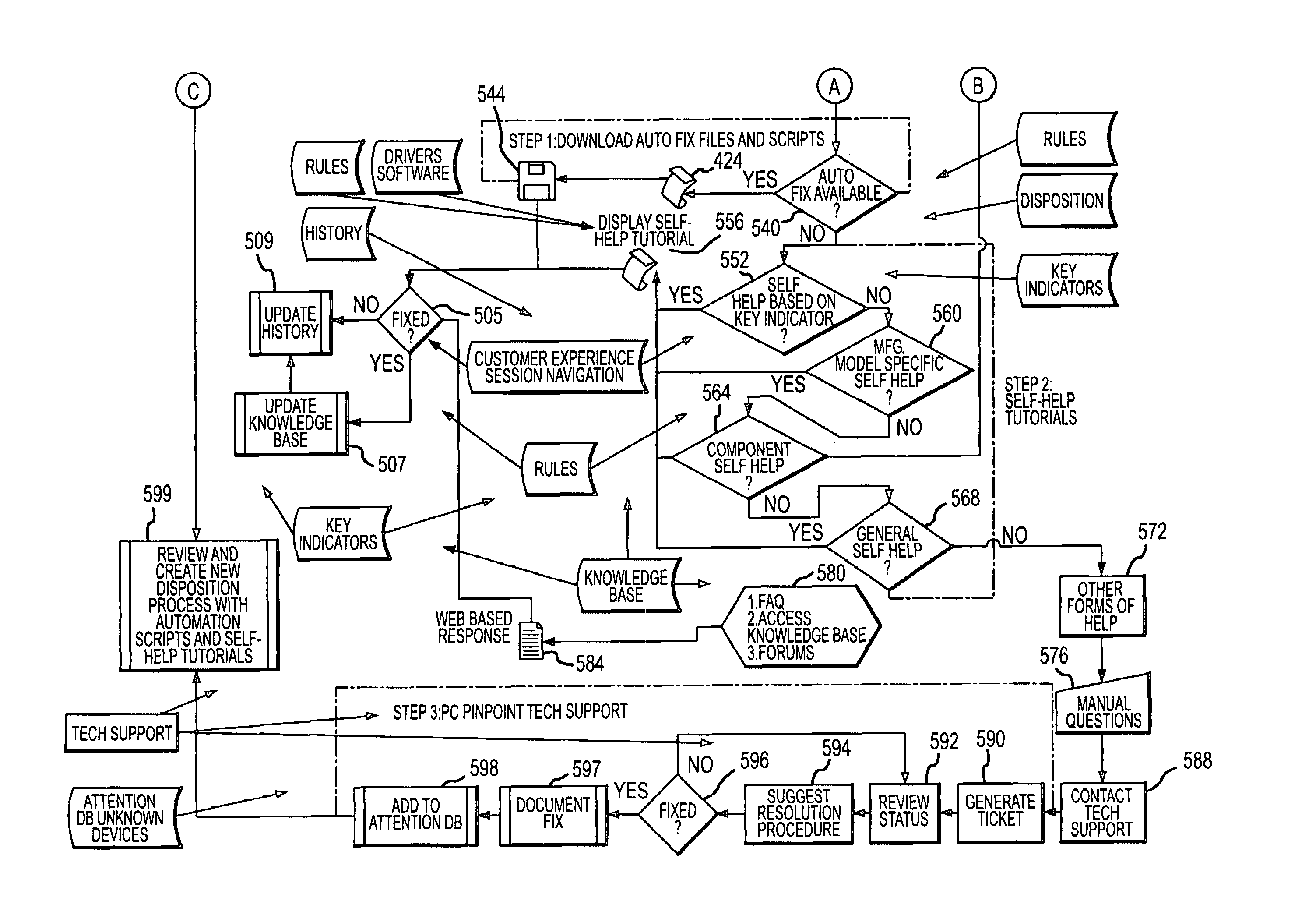

A system for the intelligent management of knowledge and delivery of content is provided. The system allows end users to access targeted fixes in connection with resolving problems with appliances, such as computers or other devices. The system further provides for the delivery of inventory information and information regarding attempts that have been made to fix problems with an appliance to technical support personnel. Technical support personnel may selectively access approved fixes or potential fixes through selections made from a tree of devices and / or problems or through the identification of key indicators. Technicians may also create fixes and made such fixes available to other technicians immediately.

Owner:DMO

Collecting appliance problem information over network and providing remote technical support to deliver appliance fix information to an end user

InactiveUS7305465B2Improve efficiencyQuick fixDigitally marking record carriersDigital data processing detailsInformation transmissionIntelligent management

Owner:DMO

Titanium alloy surface high temperature oxidation resistance and wear resistance oxide gradient coat, and preparation method thereof

ActiveCN102732832ADense tissueSolve the problem of poor high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingAntioxidant capacityCoated surface

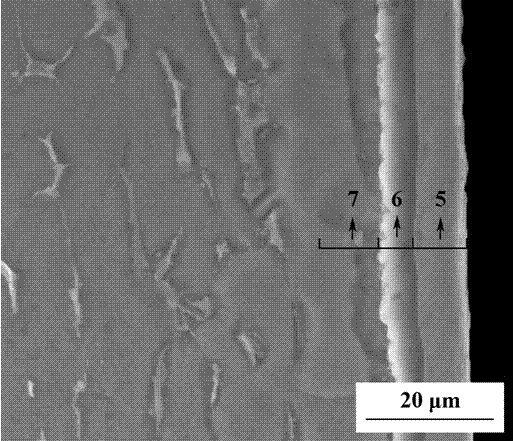

The invention relates to a titanium alloy surface high temperature oxidation resistance and wear resistance oxide gradient coat. According to the coat, the surface of the coat is an oxide film layer comprising Al2O3, Cr2O3 and NiO2, wherein the thickness is 4-6 mum; the middle of the coat is an Al-Cr-Ni alloy layer, wherein the thickness is 2-4 mum; and an Al-Cr-Ni-Ti interdiffusion layer is arranged between the coat and a substrate to achieve metallurgical collection, wherein the thickness of the Al-Cr-Ni-Ti interdiffusion layer is 4-6 mum. According to the present invention, the oxide film layer on the surface of the coat has characteristics of compactness, flatness and strong antioxidant capacity; the Al-Cr-Ni alloy layer in the middle of the coat has characteristics of compact structure and high hardness so as to greatly improve wear resistance of the titanium alloy; the metallurgical collection of the coat and the substrate is achieved through the Al-Cr-Ni-Ti interdiffusion layer, and the combination strength is high; and a double glow plasma surface metallurgy technology is adopted to prepare the Al-Cr-Ni alloy layer on the surface of the titanium alloy, and then a plasma oxygen permeation treatment is performed on the Al-Cr-Ni alloy layer to prepare the high temperature oxidation resistance and wear resistance coat, such that the efficiency is high, and the process is simple.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

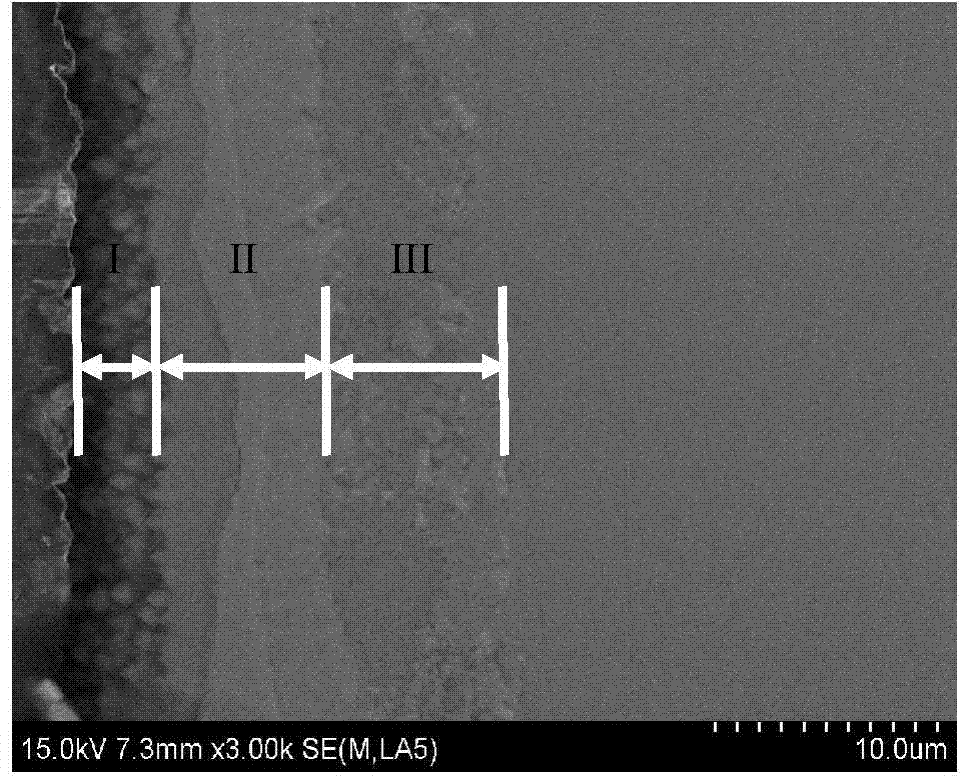

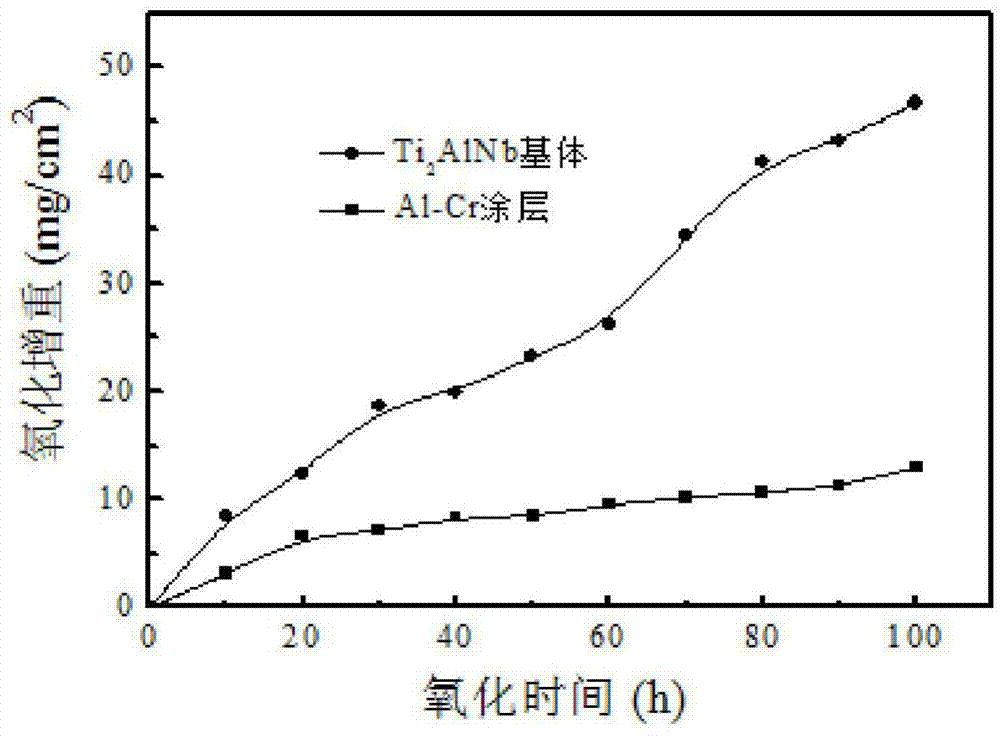

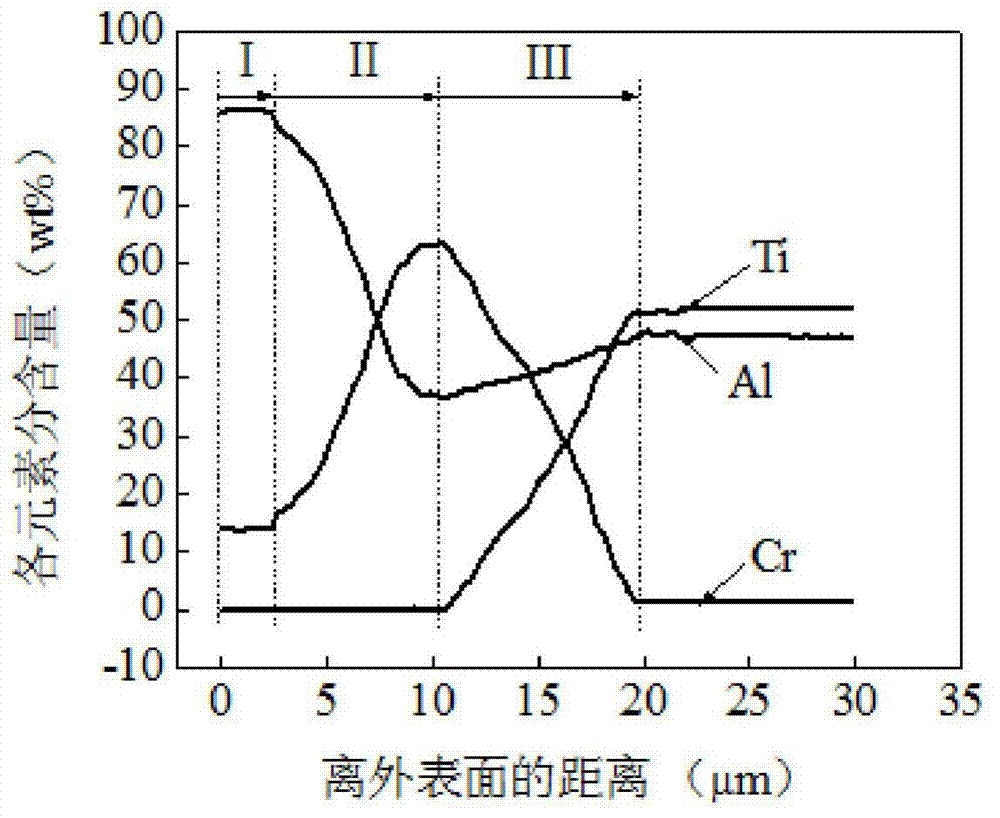

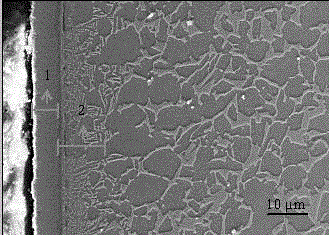

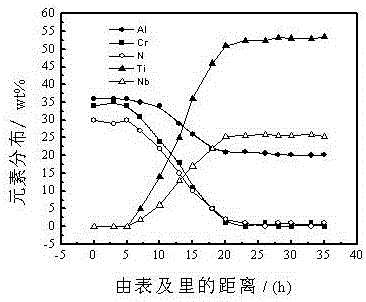

Titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating and preparation method thereof

InactiveCN104760349AImprove high temperature oxidation resistanceAccelerated corrosionVacuum evaporation coatingSputtering coatingOxidation resistantThermal shock

The present invention discloses a titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; an Al-rich deposition layer, an Al-Cr alloy layer and a Cr diffusion layer are successively arranged from surface to a titanium aluminum alloy substrate. The content of Al in the Al-rich deposition layer remains the same. The content of Al in the Al-Cr alloy layer gradually reduces outside-to-inside to 70%-100% of the content of Al in the titanium aluminum alloy substrate, and the rest in the Al-Cr alloy layer is Cr. The contents of Cr and Al in the Cr diffusion layer respectively gradually reduces outside-to-inside to same as the contents of Cr and Al in the titanium aluminum alloy substrate, and the rest in the Cr diffusion layer is other elements in the titanium aluminum alloy substrate, and the contents of other elements in the Cr diffusion layer respectively gradually rise to same as the contents of the other elements in the titanium aluminum alloy substrate from zero. The invention also discloses a preparation method of the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating can give titanium aluminum alloy excellent oxidation resistance and heat resistance corrosion performance under high temperature and long term service conditions, and due to the presence of the diffusion layer of the gradient components, the reliable binding strength and excellent thermal shock resistance can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

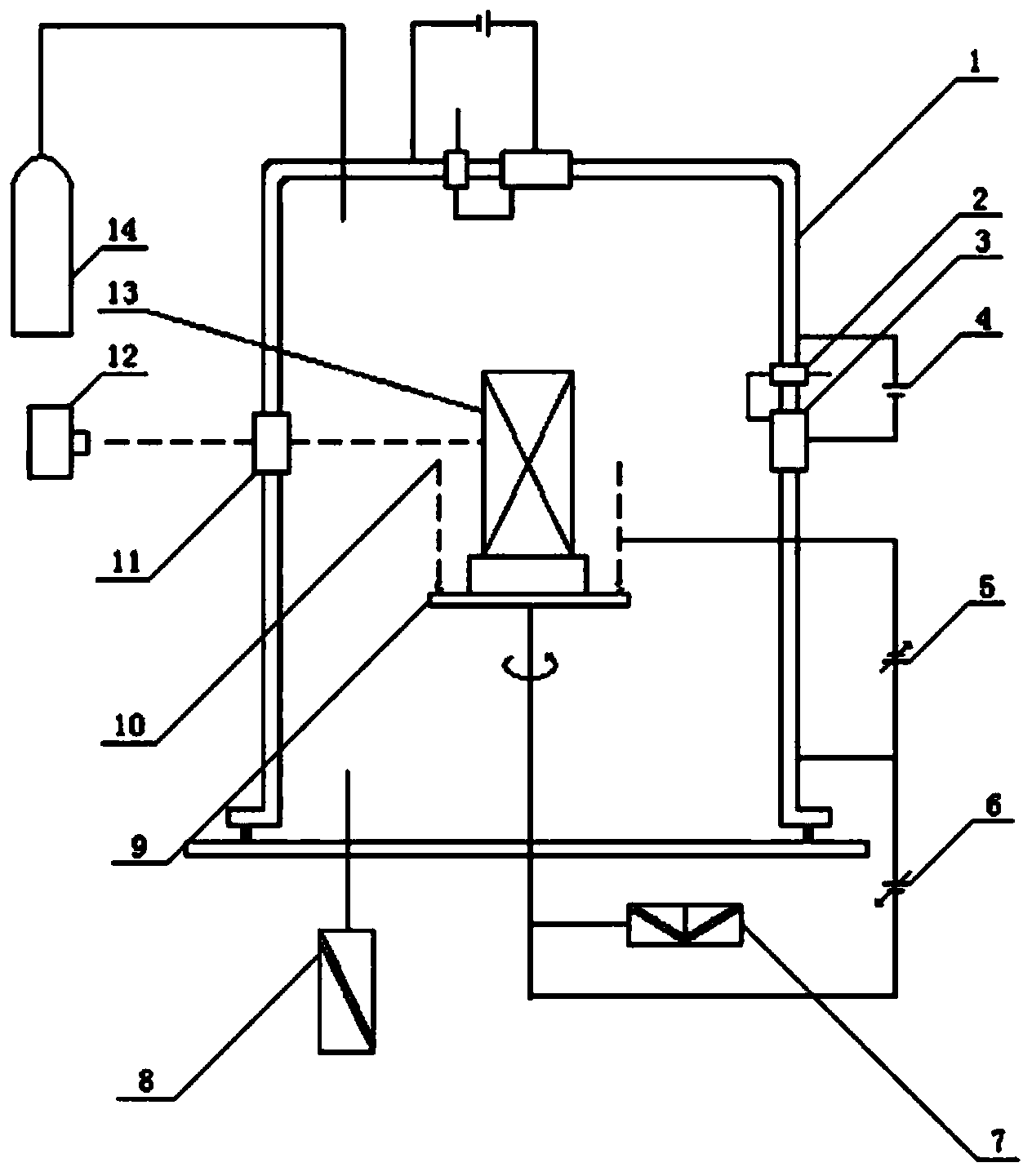

Gamma-TiAl alloy surface high temperature oxidation resistance and wear resistance coat, and preparation method thereof

ActiveCN102732833AImprove high temperature oxidation resistanceImprove wear resistanceVacuum evaporation coatingSputtering coatingCoated surfaceGlow plasma

The invention relates to a gamma-TiAl alloy surface high temperature oxidation resistance and wear resistance coat. According to the coat, the surface of the coat is an oxide film layer comprising Cr2O3 and NiO2, wherein the thickness is 2-3 mum; the middle of the coat is a Cr-Ni alloy layer, wherein the thickness is 2-4 mum; and a Cr-Ni-Ti-Al interdiffusion layer is arranged between the coat and a substrate to achieve metallurgical collection, wherein the thickness of the Cr-Ni-Ti-Al interdiffusion layer is 4-6 mum. According to the present invention, the Cr2O3 and NiO2 oxide film on the surface of the coat has characteristics of compact structure and strong antioxidant capacity; the Cr-Ni alloy layer in the middle of the coat has characteristics of uniform structure and high hardness so as to greatly improve wear resistance of the gamma-TiAl alloy; the metallurgical collection of the coat and the substrate is achieved through the Cr-Ni-Ti-Al interdiffusion layer, and the combination strength is high; and a double glow plasma surface metallurgy technology and a plasma oxygen permeation technology are firstly combined in the coat preparation process of the present invention, special plasma oxygen permeation equipment is not required, the coat can be directly prepared in 5 hours by adopting double glow plasma surface metallurgy equipment, the process is simple, and the efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

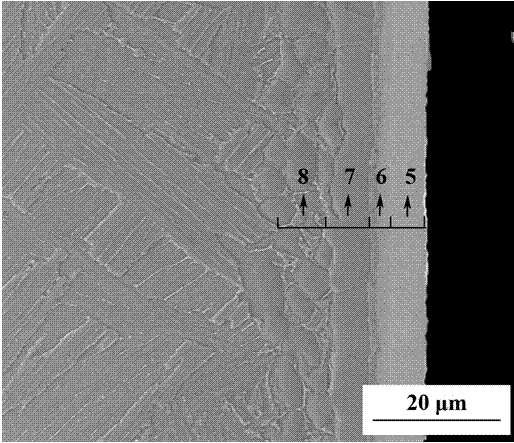

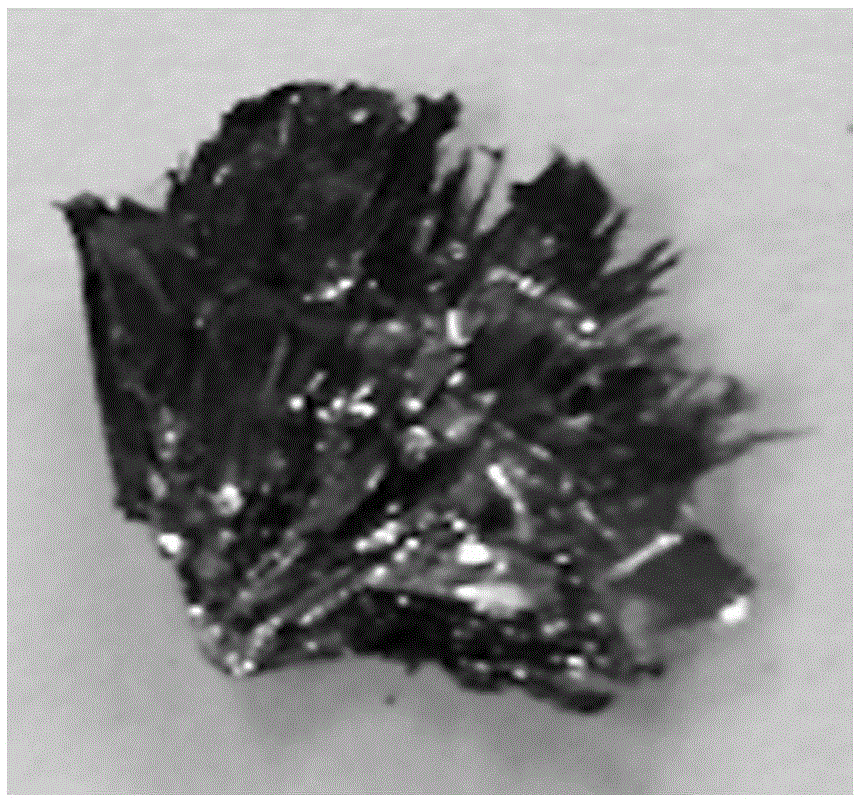

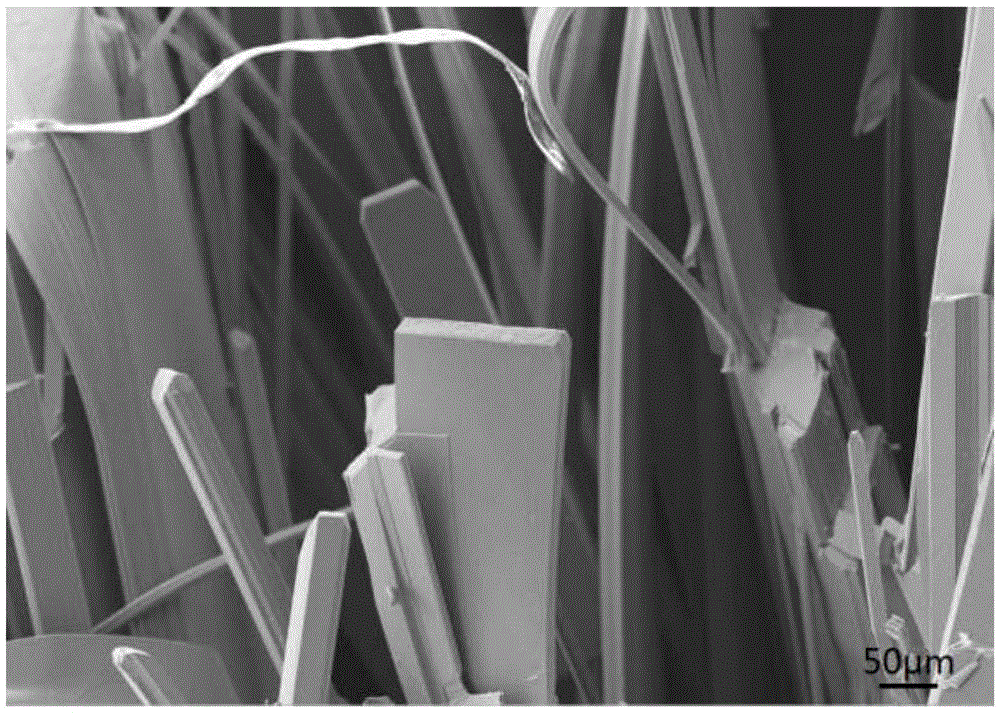

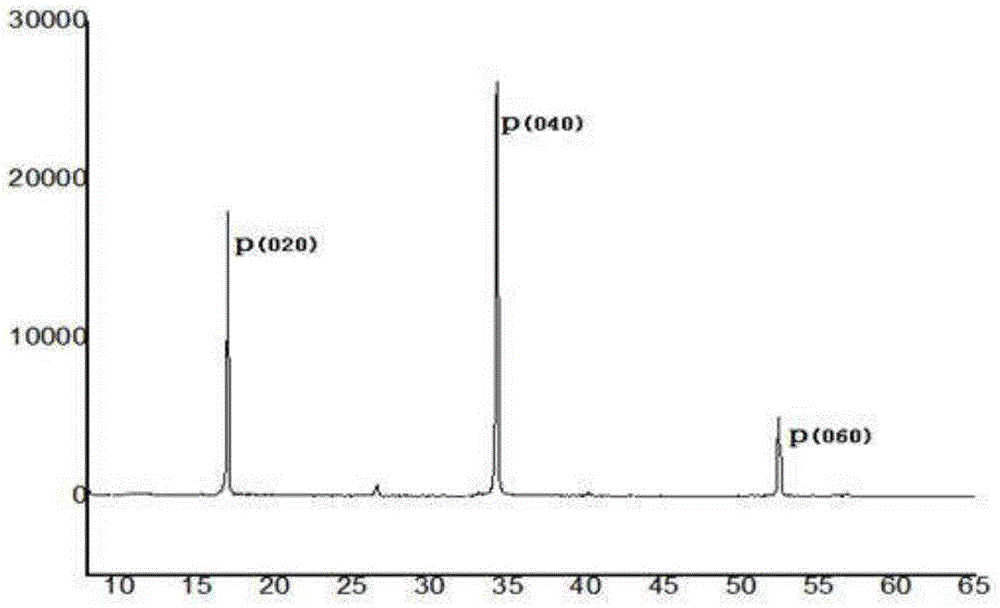

Method for growing monocrystal black phosphorus based on solid-source chemical vapor deposition method

InactiveCN105603517AFast preparationHigh technical efficiencyPolycrystalline material growthFrom chemically reactive gasesSingle crystalMaterials science

A method for growing monocrystal black phosphorus based on a solid-source chemical vapor deposition method includes the steps that red phosphorus, metallic tin and tin tetraiodide are placed in one end, serving as a high-temperature zone, of a sealed cavity under the vacuum condition, and the other end of the sealed cavity is reserved to serve as a low-temperature zone; then, the high-temperature zone and the low-temperature zone are respectively heated for a reaction, cooling is performed in a gradient mode, and monocrystal black phosphorus is obtained in the low-temperature zone. By means of the method, high-purity monocrystal black phosphorus can be rapidly prepared.

Owner:SHANGHAI JIAO TONG UNIV

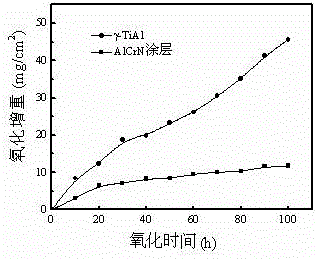

High-temperature-oxidation-resistant and abrasion-resistant AlCrN coating on surface of titanium-aluminum alloy and preparation method thereof

InactiveCN105839049AImprove wear resistanceThe surface of the coating is smooth and denseVacuum evaporation coatingSputtering coatingOxidation resistantGlow plasma

The invention discloses a high-temperature-oxidation-resistant and abrasion-resistant AlCrN coating on the surface of a titanium-aluminum alloy and a preparation method thereof. The coating is deposited on the surface of a titanium-aluminum alloy workpiece through the double glow plasma surface technology, an AlCrN deposited layer is located on the surface of the coating and is 5-10 micrometers thick, and a compact oxidized layer rich in Al2O3 and Cr oxide is formed by the AlCrN deposited layer at a high temperature; an AlCrN diffused layer is arranged in the coating and is 12-15 micrometers thick; the hardness of the obtained coating is 30-37 GPa, the room temperature friction coefficient of the coating is 0.3-0.33, and the high-temperature friction coefficient of the coating is 0.47-0.49. The preparation method includes the steps of charging, vacuumizing, workpiece surface activation, plasma permeation of the AlCrN coating, cooling and discharging. The obtained AlCrN coating solves the problem that the titanium-aluminum alloy is poor in high-temperature-oxidation resistance; meanwhile, the gradient structure of the diffused layer achieves metallurgical bonding of the coating and a substrate, and good high-temperature-oxidation resistance and good abrasion resistance are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High temperature oxidation resistant composite gradient coating on Ti2AlNb alloy surface and preparation method thereof

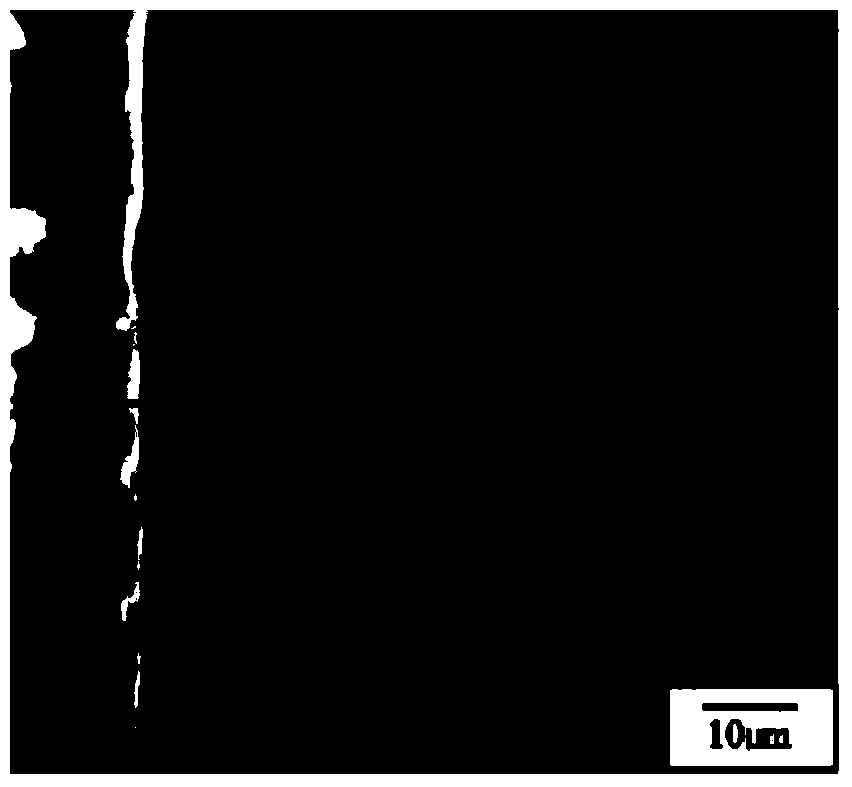

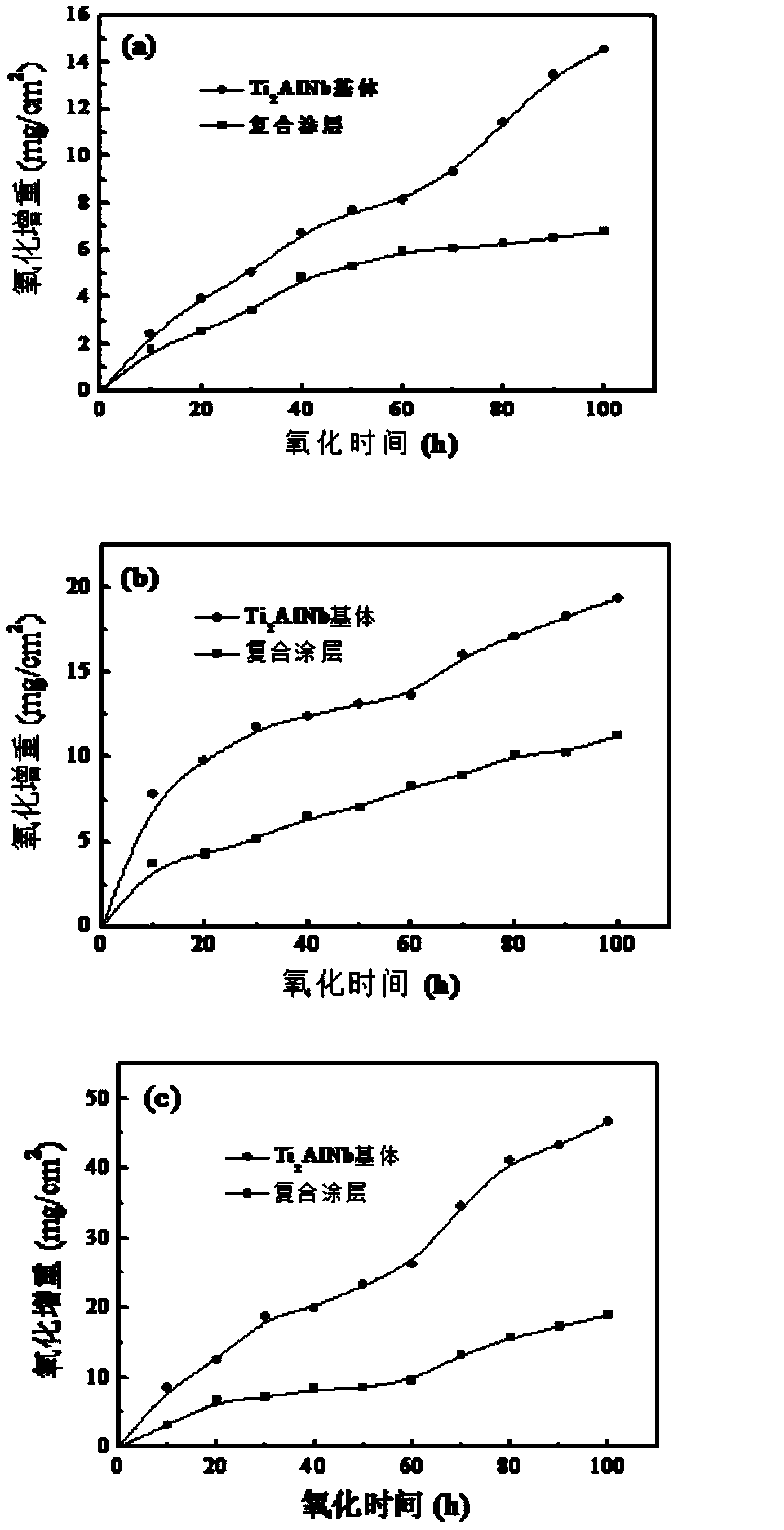

ActiveCN104357804AImprove high temperature oxidation resistanceNo crackVacuum evaporation coatingSputtering coatingOxidation resistantGlow plasma

The invention relates to a high temperature oxidation resistant composite gradient coating on a Ti2AlNb alloy surface and a preparation method thereof. The composite gradient coating sequentially comprises a pure Al layer, an Al-Ti alloy layer and an Al-Ti-Nb mutual diffusion layer from the surface to a substrate; the Al content of the Al-Ti alloy layer is decreased in a slow gradient manner from the surface of an Al-Ti seeping layer from outside to inside, the Ti content is slowly increased, and component mutation is avoided; and Al content of the Al-Ti-Nb mutual diffusion layer is decreased in a gradient manner from the surface of a diffusion layer from outside to inside, and the Ti content and the Nb content are increased from outside to inside in a gradient manner from the surface of the diffusion layer. The preparation method comprises the steps as follows: Ti2AlNb base alloy is taken as a workpiece electrode, an Al-Ti alloy target material is taken as a source electrode, the Al-Ti alloy layer is prepared by adopting an arc-glow plasma surface metallurgy technology, and then a pure Al target material is taken as the source electrode to prepare the pure Al layer on the Al-Ti alloy layer. The technology efficiency is high, the preparation technology is simple, and the obtained coating has high oxidation resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

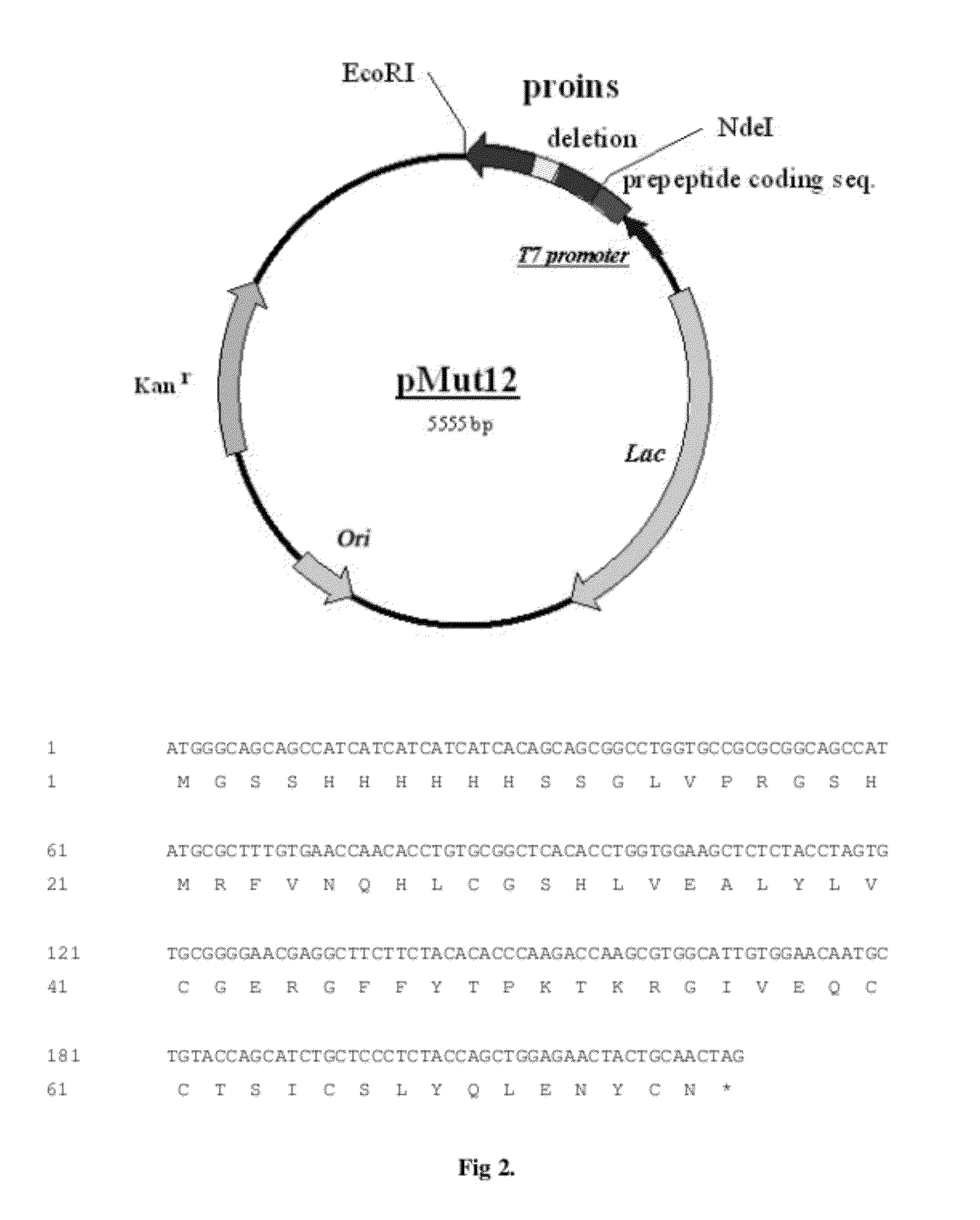

Method for producing human recombinant insulin

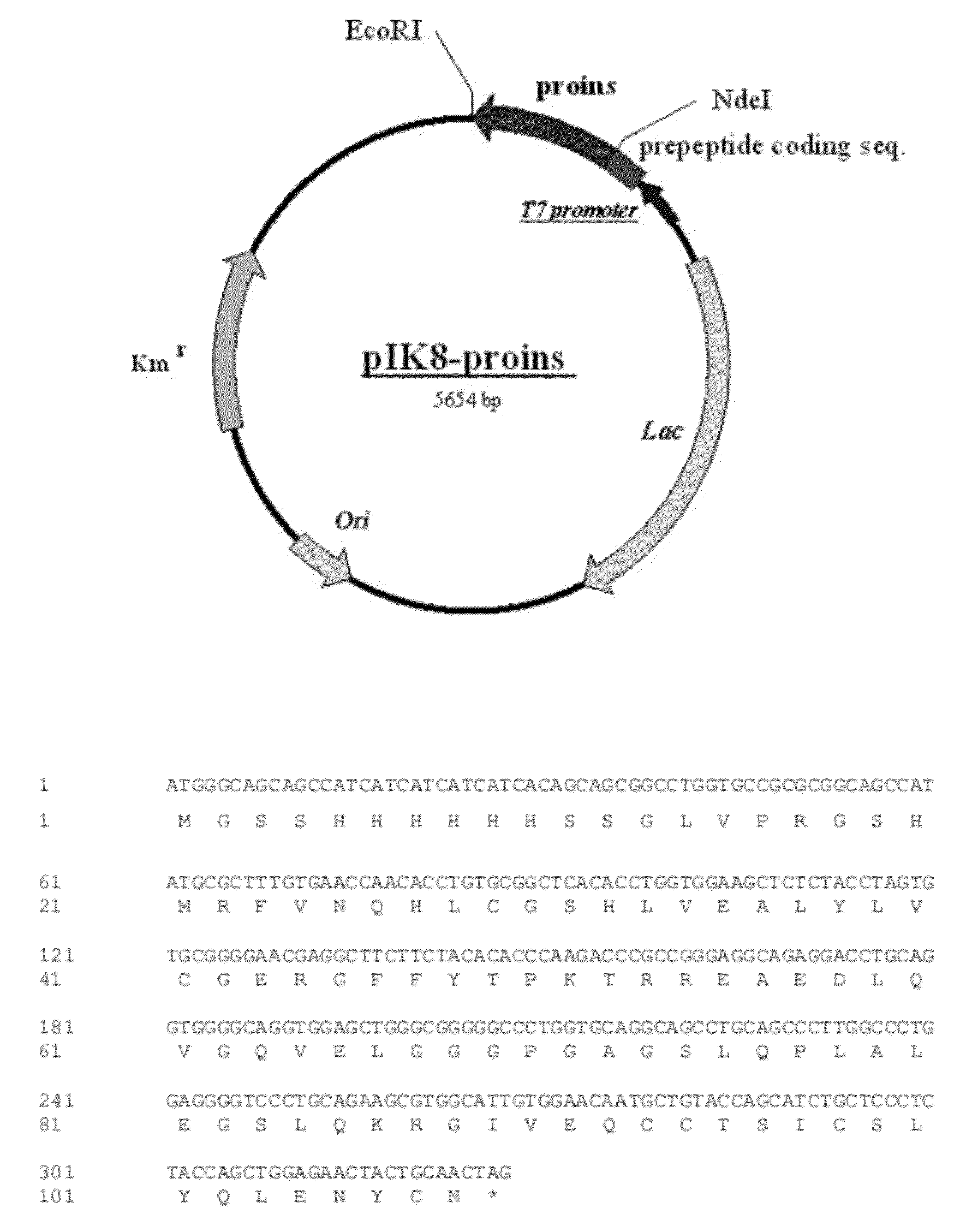

InactiveUS20120058513A1Increase productionQuality improvementPeptide/protein ingredientsRecombinant DNA-technologyInclusion bodiesInsulin Precursor

The invention relates to biotechnology and can be used for producing human recombinant insulin for preparing medicinal agents for the treatment of pancreatic diabetes. A variety of recombinant plasmid DNAs which contain an artificial gene and encode the human insulin precursor is proposed. The biosynthesis of a hybrid polypeptide is induced using isopropyl-thiogalactopyranoside so that the post-induction level of the hybrid polypeptide is equal to or greater than 25% of the total cellular protein. According to the claimed procedure, human insulin is produced by cultivating a producer strain containing one of the recombinant plasmids, isolating inclusion bodies, solubilizing and renaturing the fusion protein, and enzymatically degrading and chromatographically purifying said protein. The invention simplifies the process for producing human recombinant insulin and increases the yield thereof.

Owner:LIABILITY MAKO

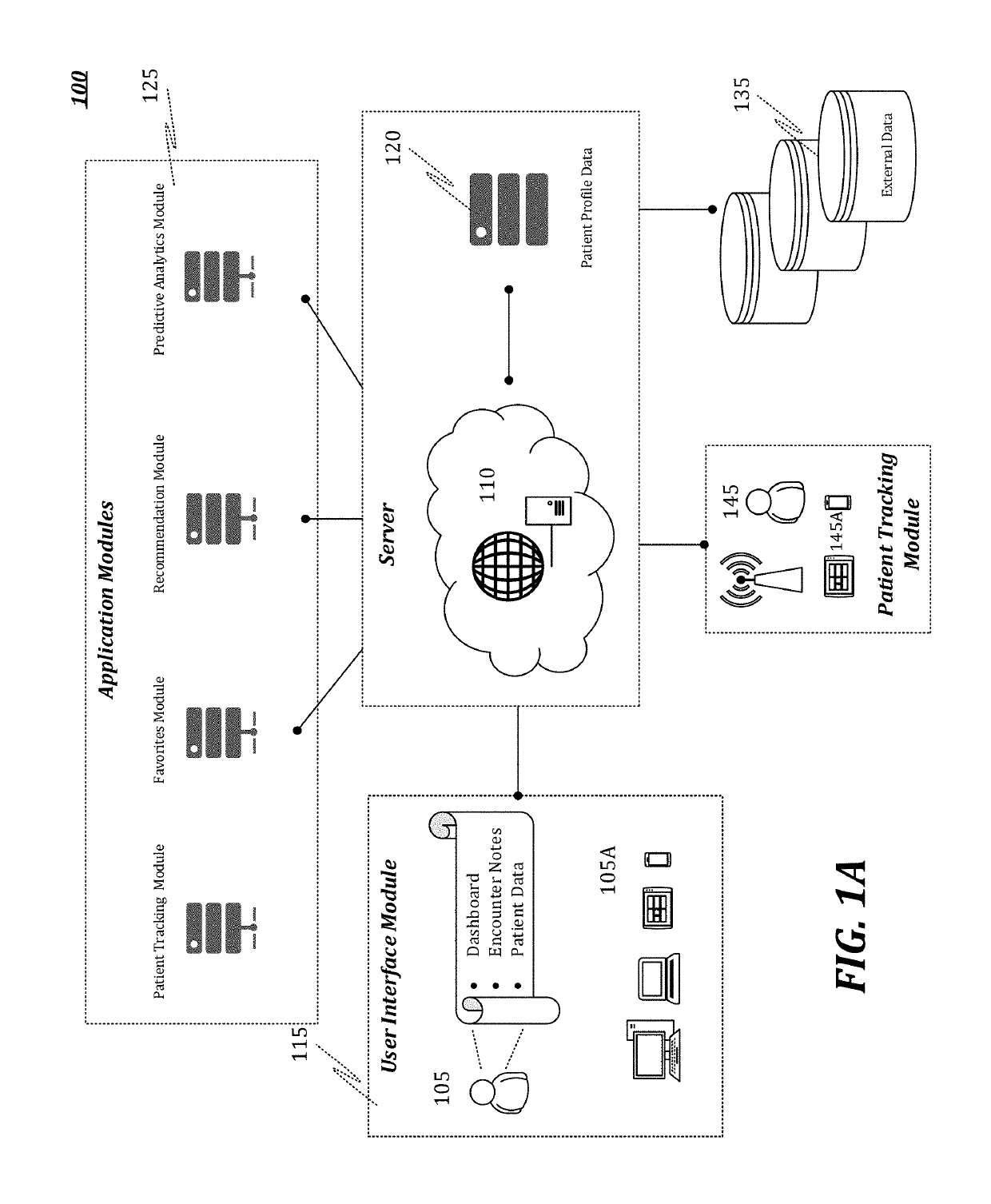

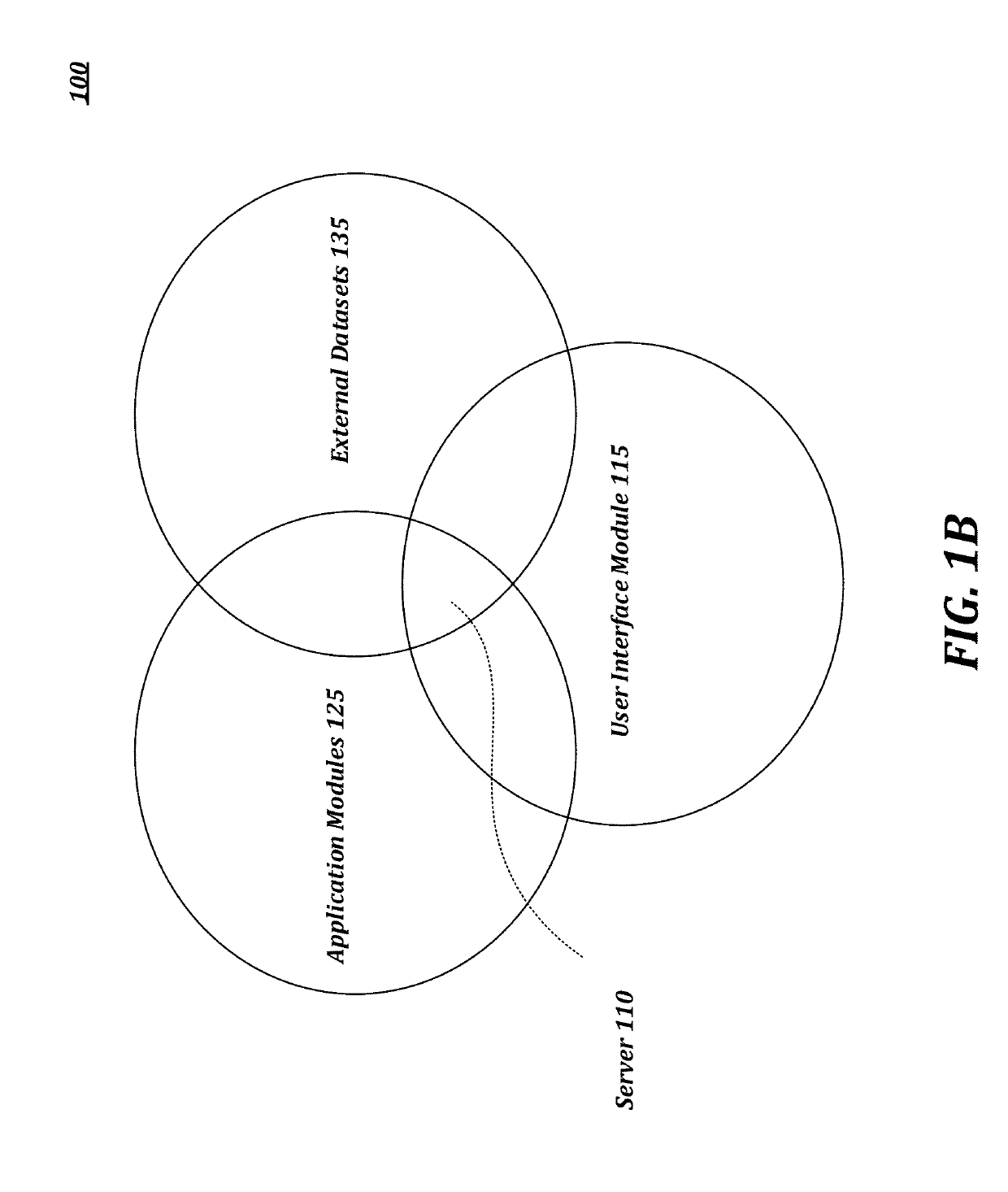

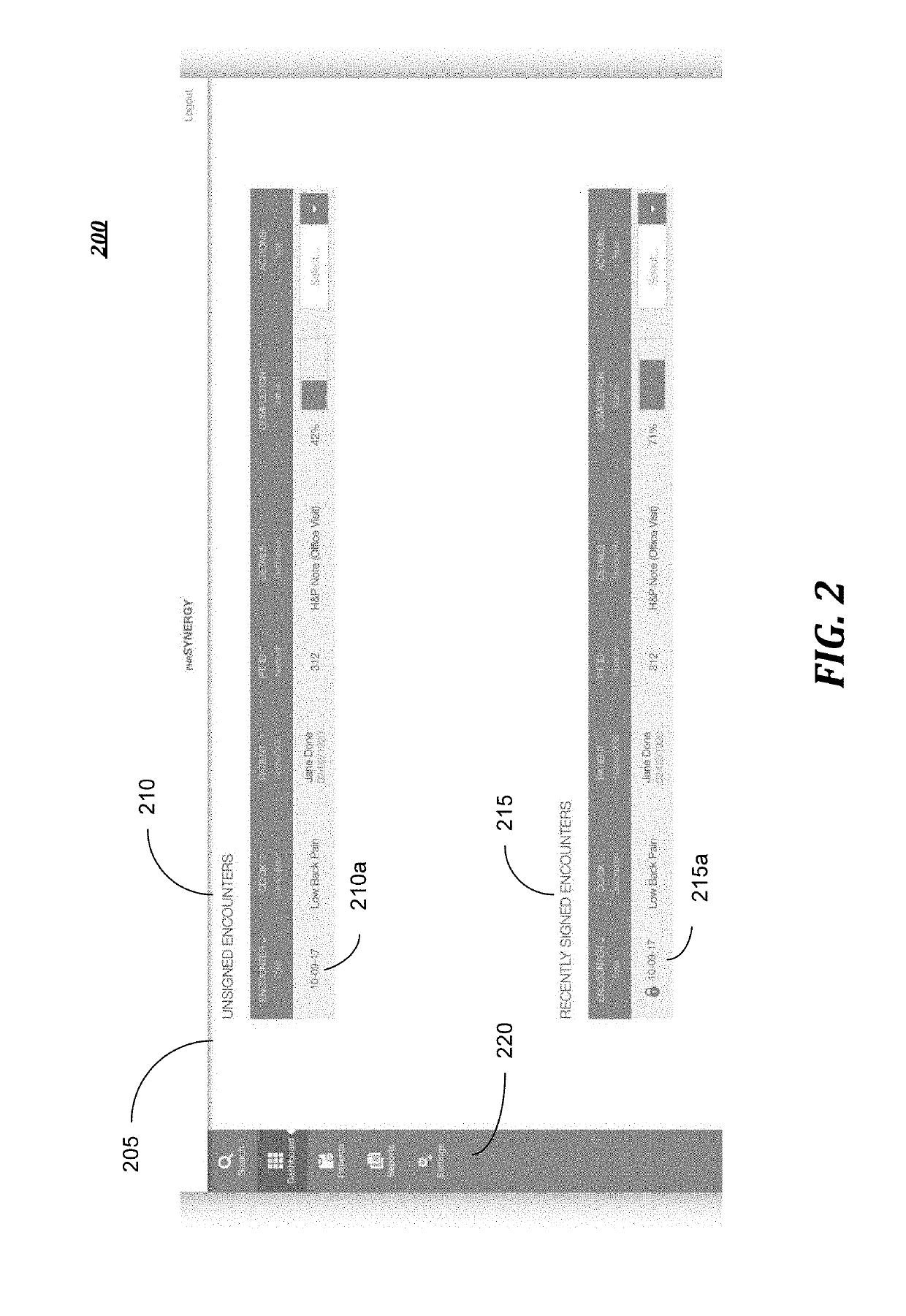

Method and system for recommending treatment plans, preventive actions, and preparedness actions

PendingUS20190221308A1Improve abilitiesReducing redundant data entryMedical data miningMedical automated diagnosisMedical recordRelevant information

A method, system and computer readable medium for recommending treatment plans, preventive actions, and preparedness actions is provided in this disclosure. The present disclosure relates to a platform for assisting practitioners during patient encounters to receive, and input patient information. The present disclosure relates to a platform configured to manage, analyze, determine, correlate, sort, categorize, and organize patient information, external data, and other related data. The present disclosure relates to a platform configured to analyze the data from the metrics and data sources to recommend diagnoses, make predictions, make recommendations, make suggestions, and provide further data relating to electronic medical records and related information.

Owner:EHRSYNERGY LLC

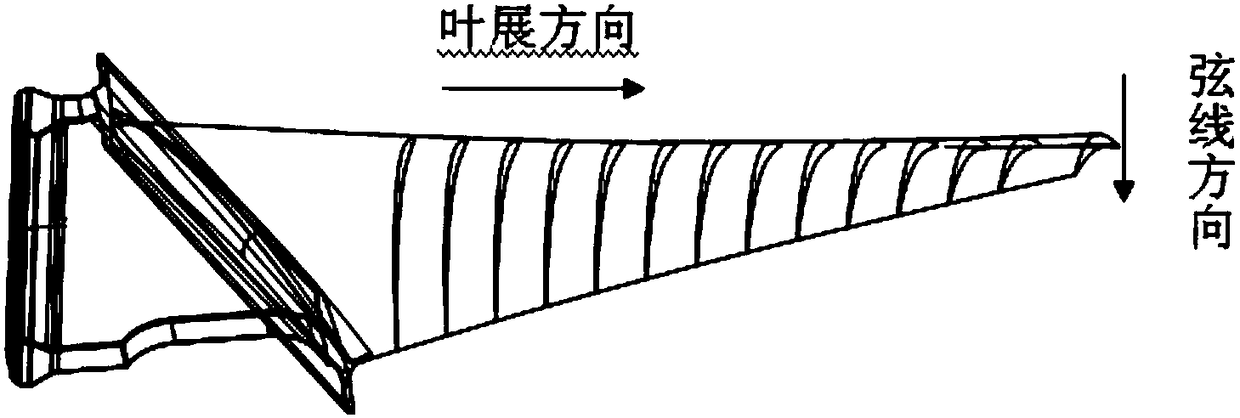

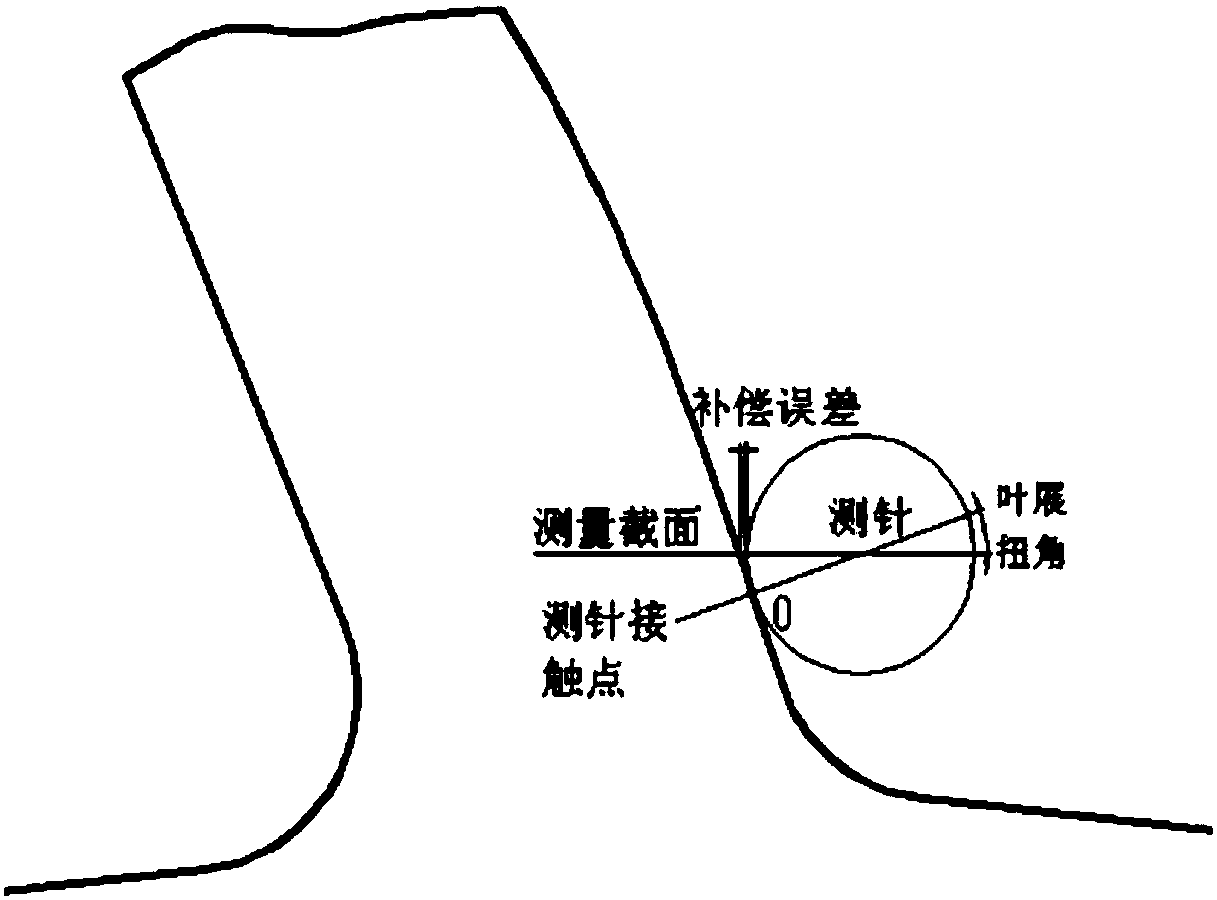

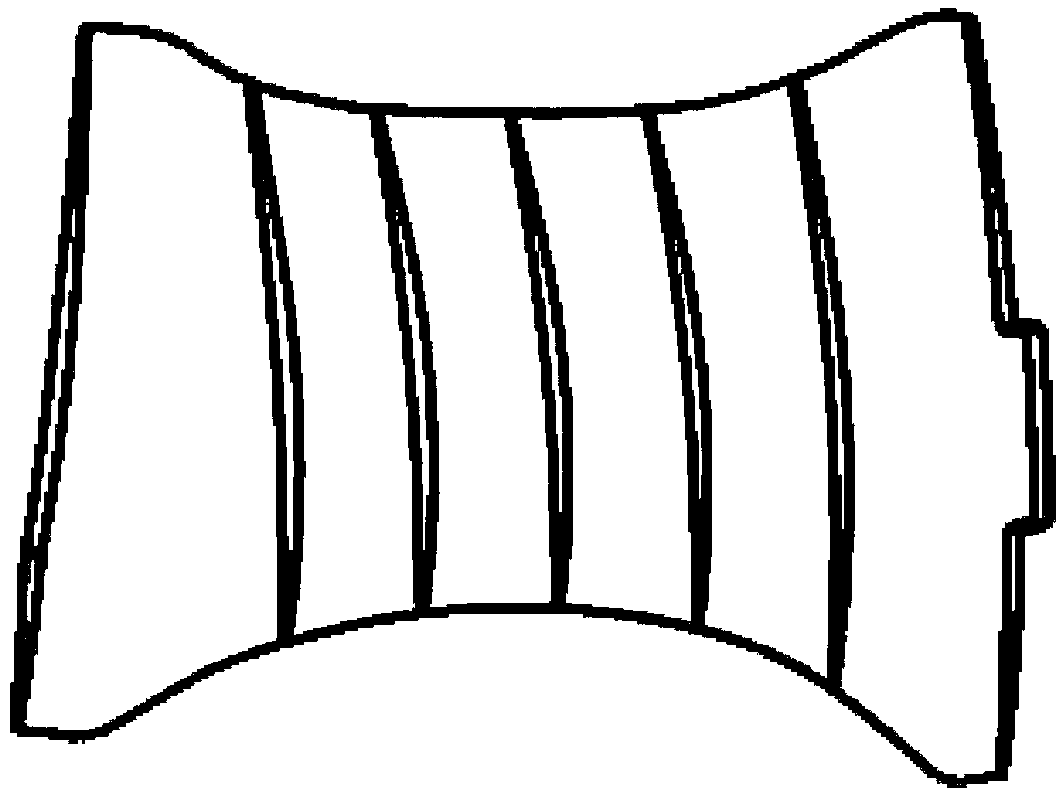

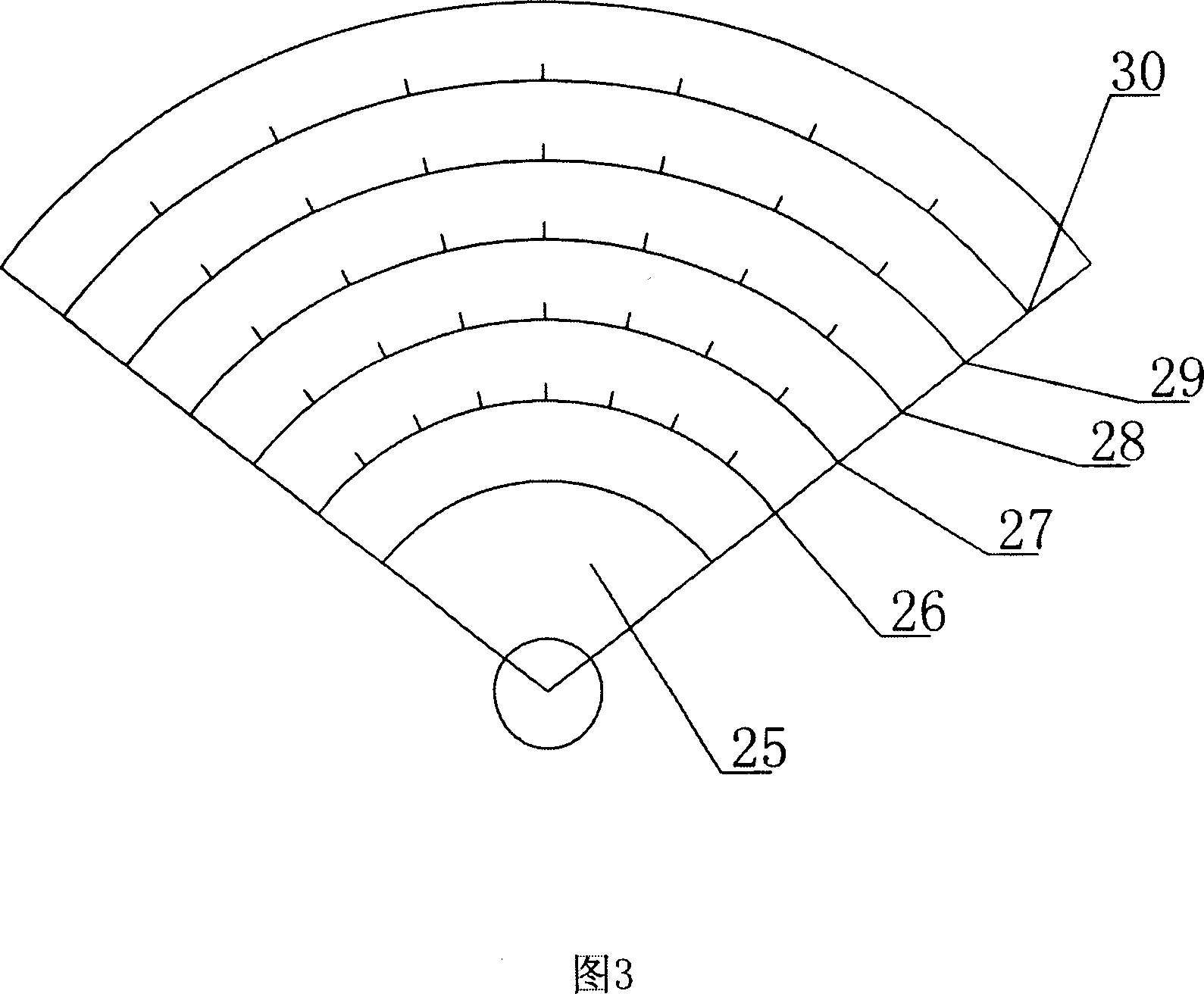

Three dimensional measurement method of irregular curved surface

InactiveCN108106522AHigh technical efficiencyImprove detection efficiencyMechanical counters/curvatures measurementsMeasurement pointThree dimensional measurement

The present invention relates to a three dimensional measurement method of an irregular curved surface. The measurement method comprises the steps of firstly planning a measurement track of a measurement needle sphere center according to an appointed cross-section position required by a drawing on a parts MBD model, generating a measurement path, then compensating the measurement data according tothe model vectors, enabling the compensated data points at an appointed cross-section height, and finally connecting the cross-section points into a curve to evaluate the blade parameters; measuringaccording to the track of the measurement needle sphere center, and then compensating the radius of a measuring head according to the model vectors, and calculating the radius compensation according to the model vectors, wherein the vectors of each measurement point on a three dimensional curved surface are different, so that the compensation directions are different; connecting the compensated cross-section actual measurement points into a blade type curve to evaluate the blade parameters. The advantages of the present invention are that a three dimensional model measurement technology of theirregular curved surface is realized, at the same time, by adopting a model-based measurement mode, the digital design, manufacturing and detection integrated flow of an engine is promoted, and a keydetection technology and the detection efficiency are also improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

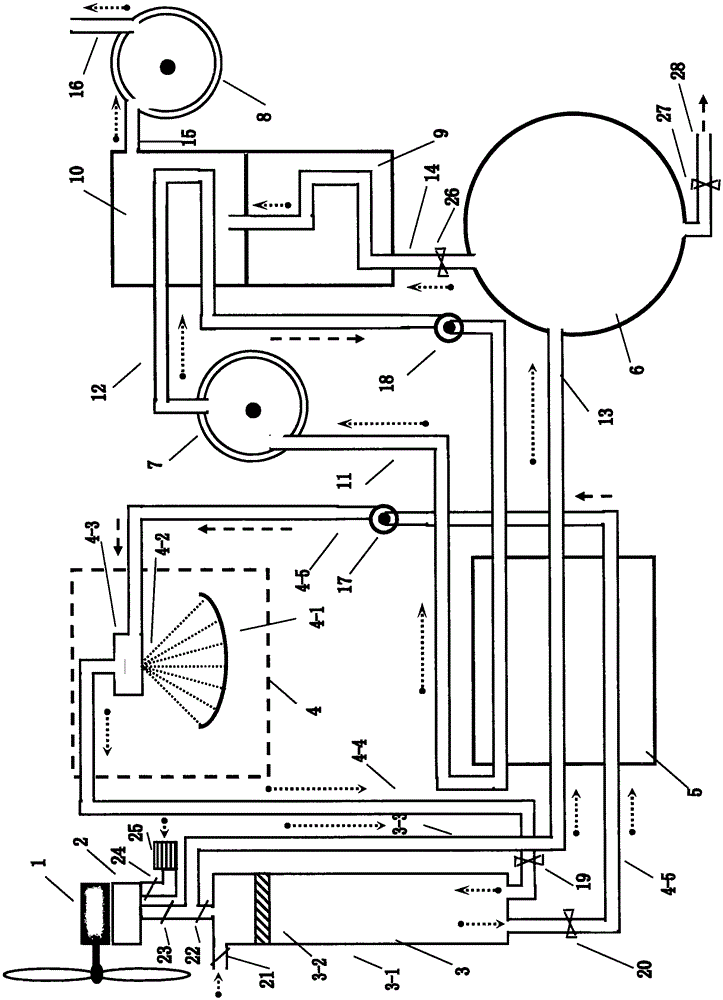

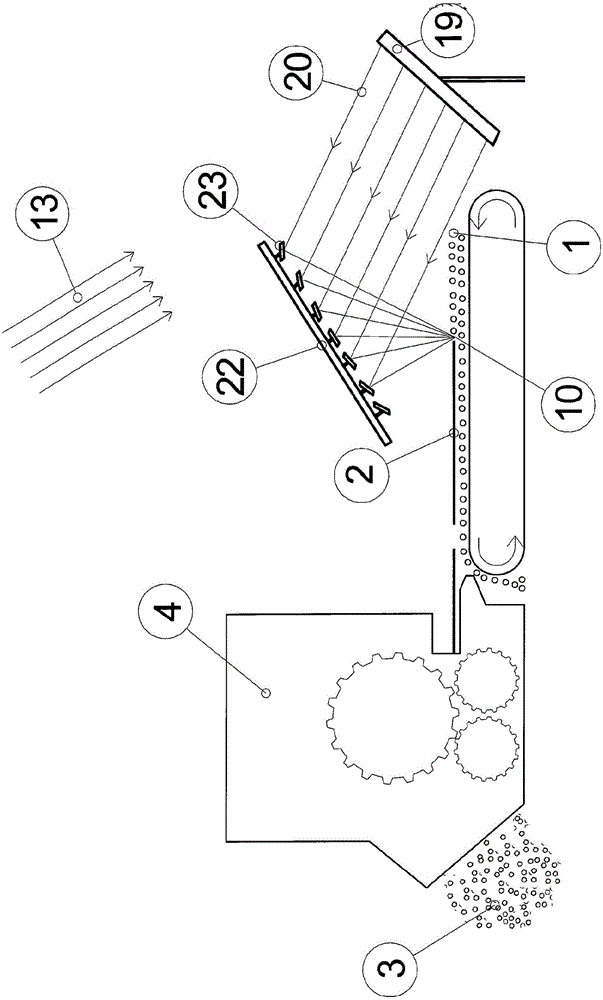

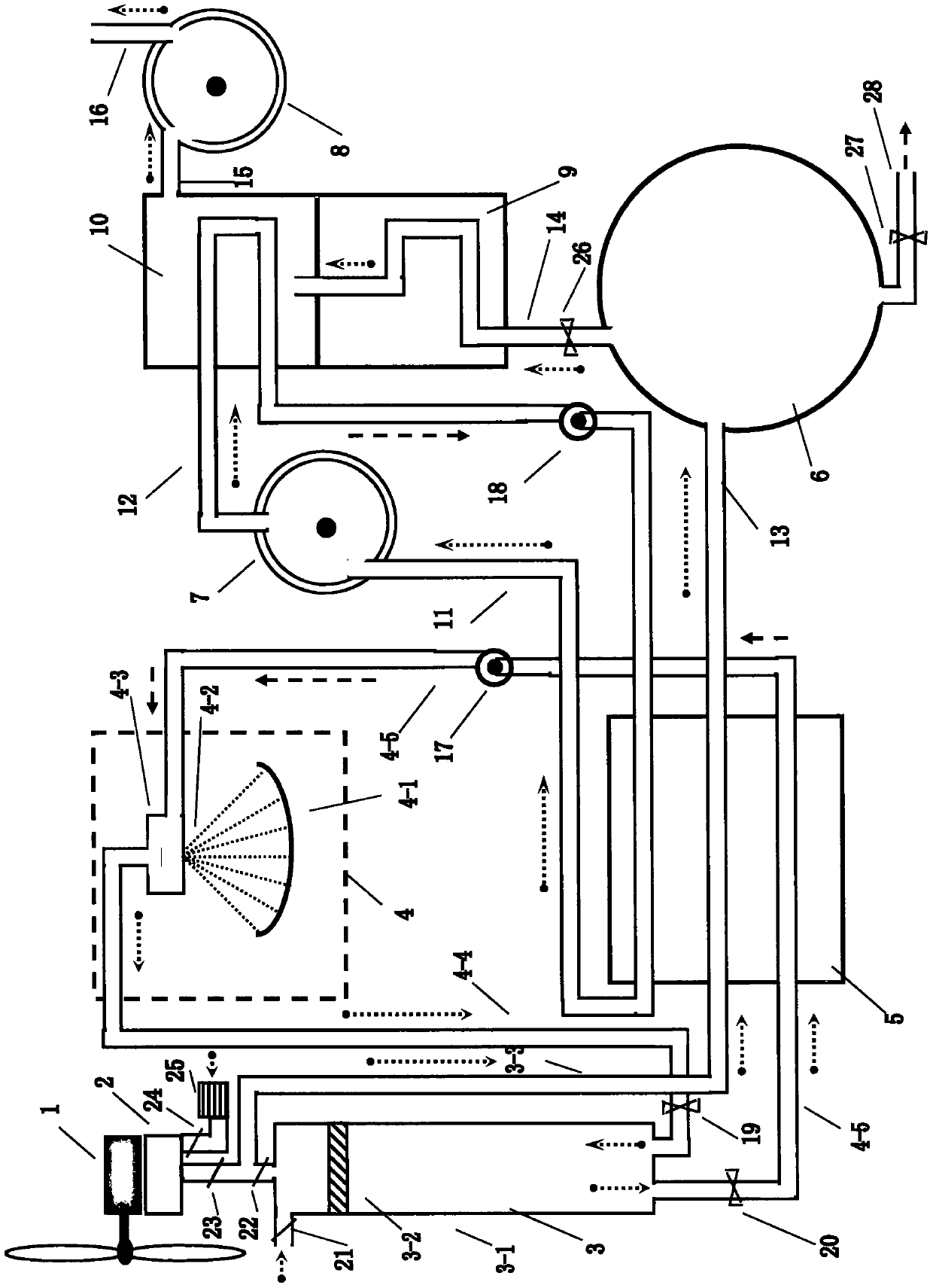

Wind-solar complementary cold and hot pneumoelectric new energy system of compressed air energy storage

ActiveCN105257354ANot easy to storeEasy to storeSteam engine plantsHeating and refrigeration combinationsThermal energy storageNew energy

The invention discloses a wind-solar complementary cold and hot pneumoelectric new energy system of compressed air energy storage and relates to the field of new energy utilization system engineering. The wind-solar complementary cold and hot pneumoelectric new energy system can be divided into the two subsystems of a compressed air expansion pneumatic wheel electricity generation subsystem and a low boiling point working medium vaporization expansion pneumatic wheel electricity generation subsystem. The purposes of wind-solar complementary cold and hot pneumoelectric new energy system are that 1, a novel technical route is found out, and an energy conversion chain is shortened as far as possible; and 2, a novel complementary energy storage mode is adopted to improve the overall efficiency of new energy utilization. The wind-solar complementary cold and hot pneumoelectric new energy system has four characteristics.

Owner:贡茅

BIOX long-lasting biological oxidation promoting agent

InactiveCN104099103AImprove utilization efficiencyPromote degradationOrganic fertilisersBiological water/sewage treatmentMicroorganismBiological oxidizer

The invention relates to a BIOX long-lasting biological oxidation promoting agent, which is characterized by comprising the following components by mass 40%-80% of an oxidizing agent precursor, 10%-40% of a stabilizer and 1%-20% of a biological carrier. The BIOX long-lasting biological oxidation promoting agent has the characteristics of long effect time, high oxidant utilization efficiency and capability of promoting biodegradation, and compared with a traditional soil and groundwater oxidation remediation reagent, the BIOX long-lasting biological oxidation promoting agent can promote pollutant micro-biological degradation while chemical oxidation, and can improve technical and economical efficiency by synergistic effect of the chemical oxidation and micro-biological degradation.

Owner:南京清科中晟环境技术有限公司 +1

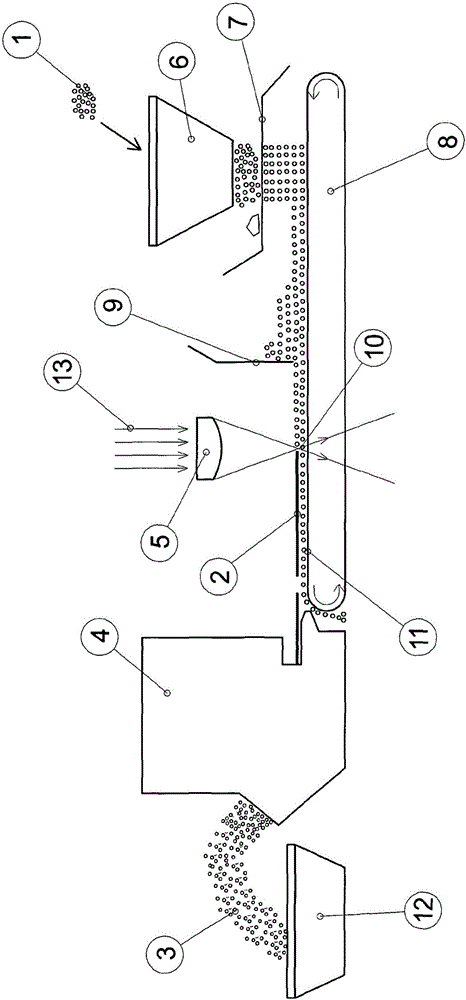

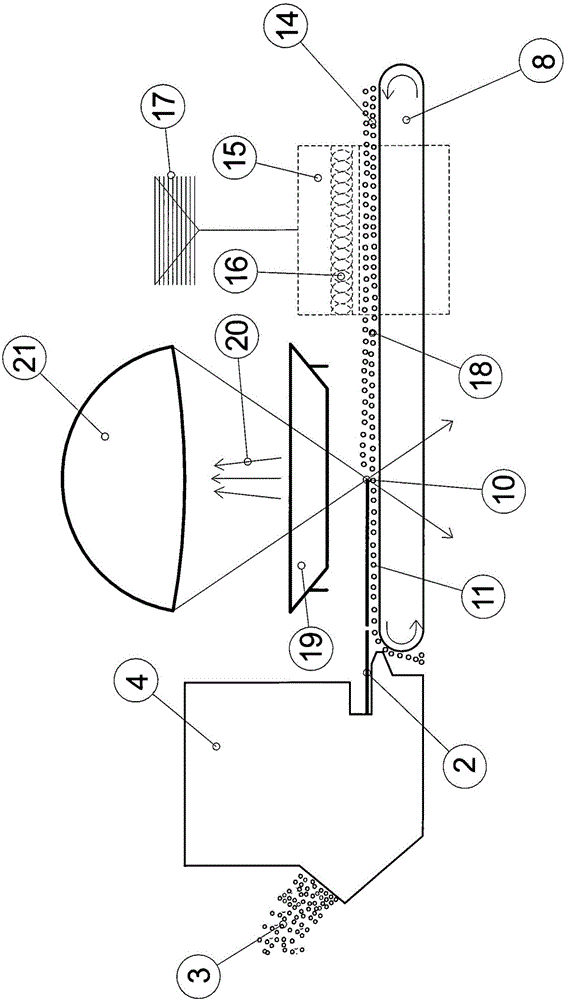

Method and device for producing artificial crushed sand by means of a thermal treatment using sand in the form of fine sand (fS/FSa) and/or round sand as the starting material

ActiveCN106414360AHigh technical efficiencyNatural Disaster Risk ReductionSolar heating energyPretreatment controlConstruction industrySupply energy

The invention relates to a method for producing artificial crushed sand by means of a thermal treatment using sand in the form of fine sand (FS / FSa) and / or round sand as the starting material (1). The starting material (1) in variant A is heated to a melting temperature by bundling sun rays (13), and / or the starting material in variant B is heated to a melting temperature by using a conventional melting device which achieves its energy supply using converted or stored solar power, whereby each of a plurality of sand grains are melted together into a three-dimensional intermediate product (2). The intermediate product (2) produced in this manner is cooled and finally comminuted to a particle size of less than 2 mm in a comminuting process. An end product (3) is produced which differs from the starting material (1) with respect to the shape and surface roughness. The method offers a long-term solution for meeting the demand for crushed sand and provides sand for the construction industry.

Owner:BLACK RAMEL LTD

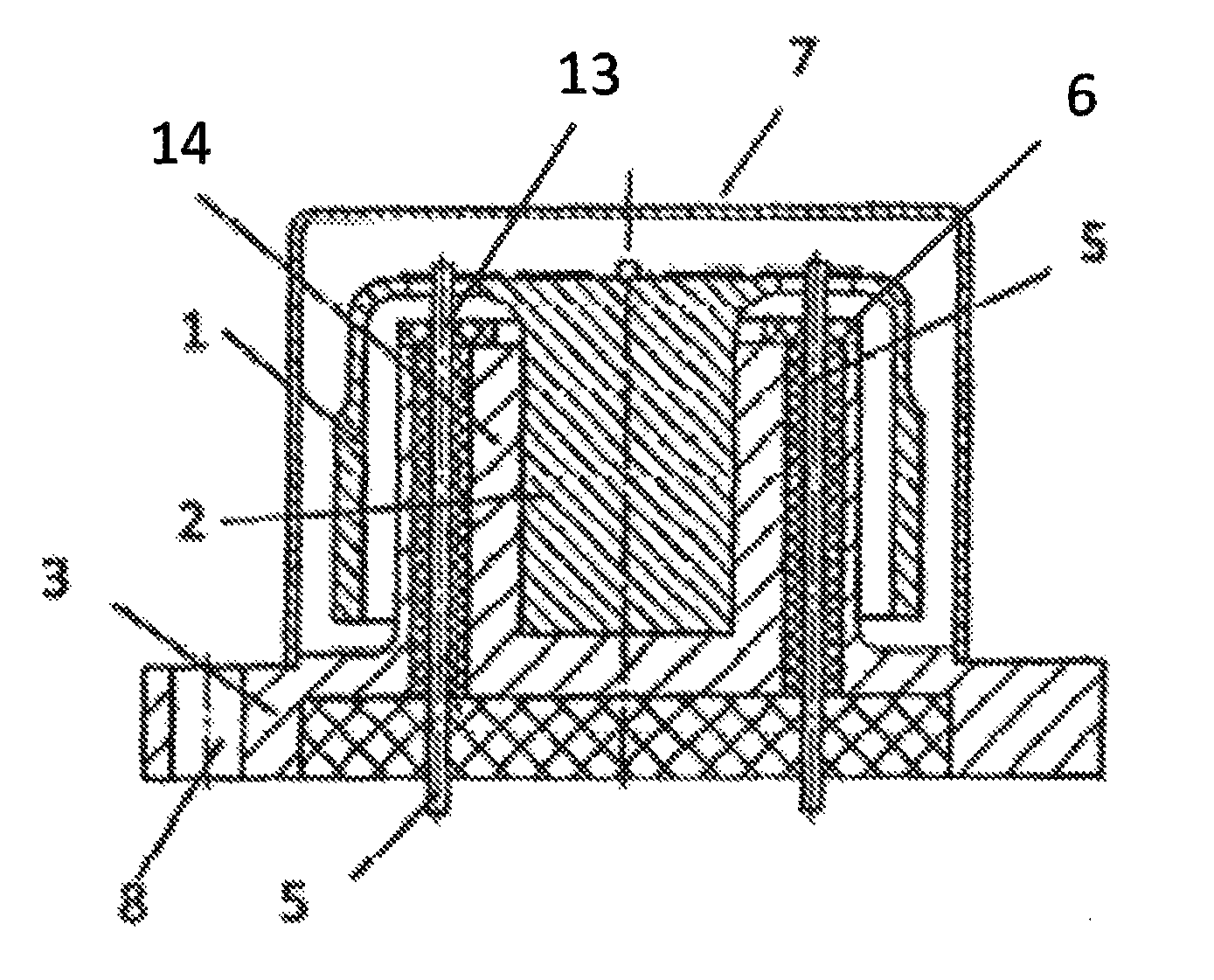

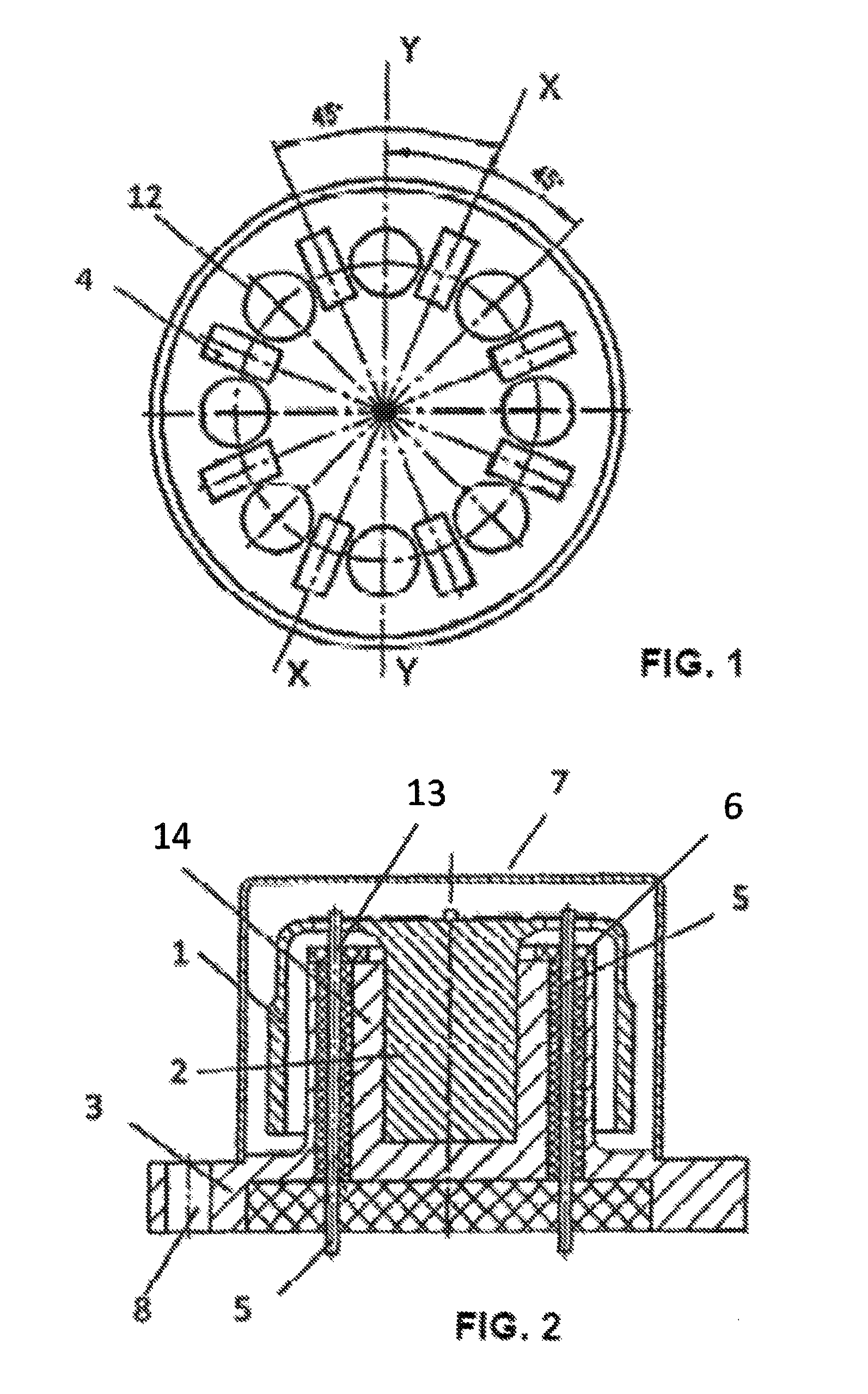

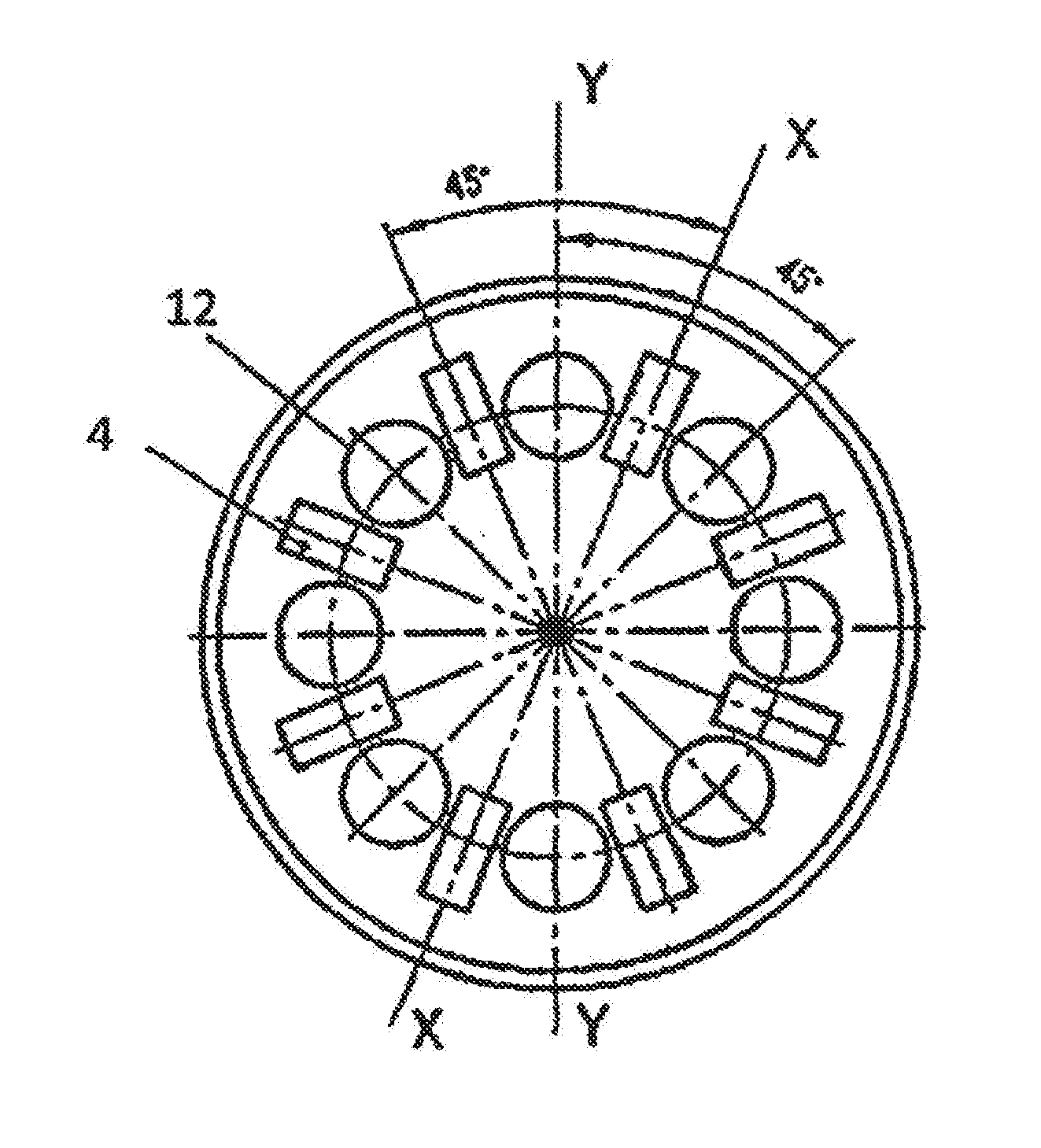

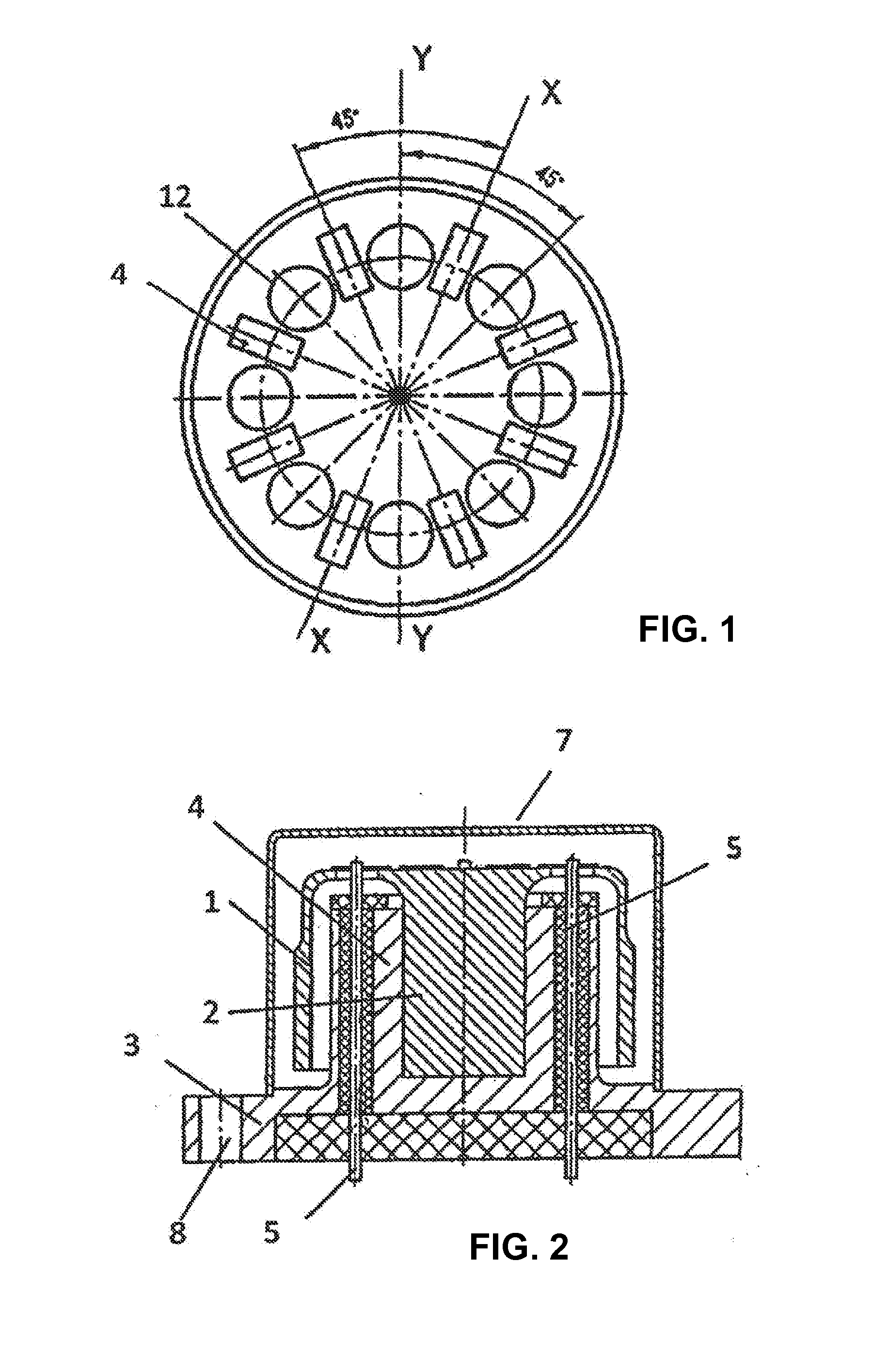

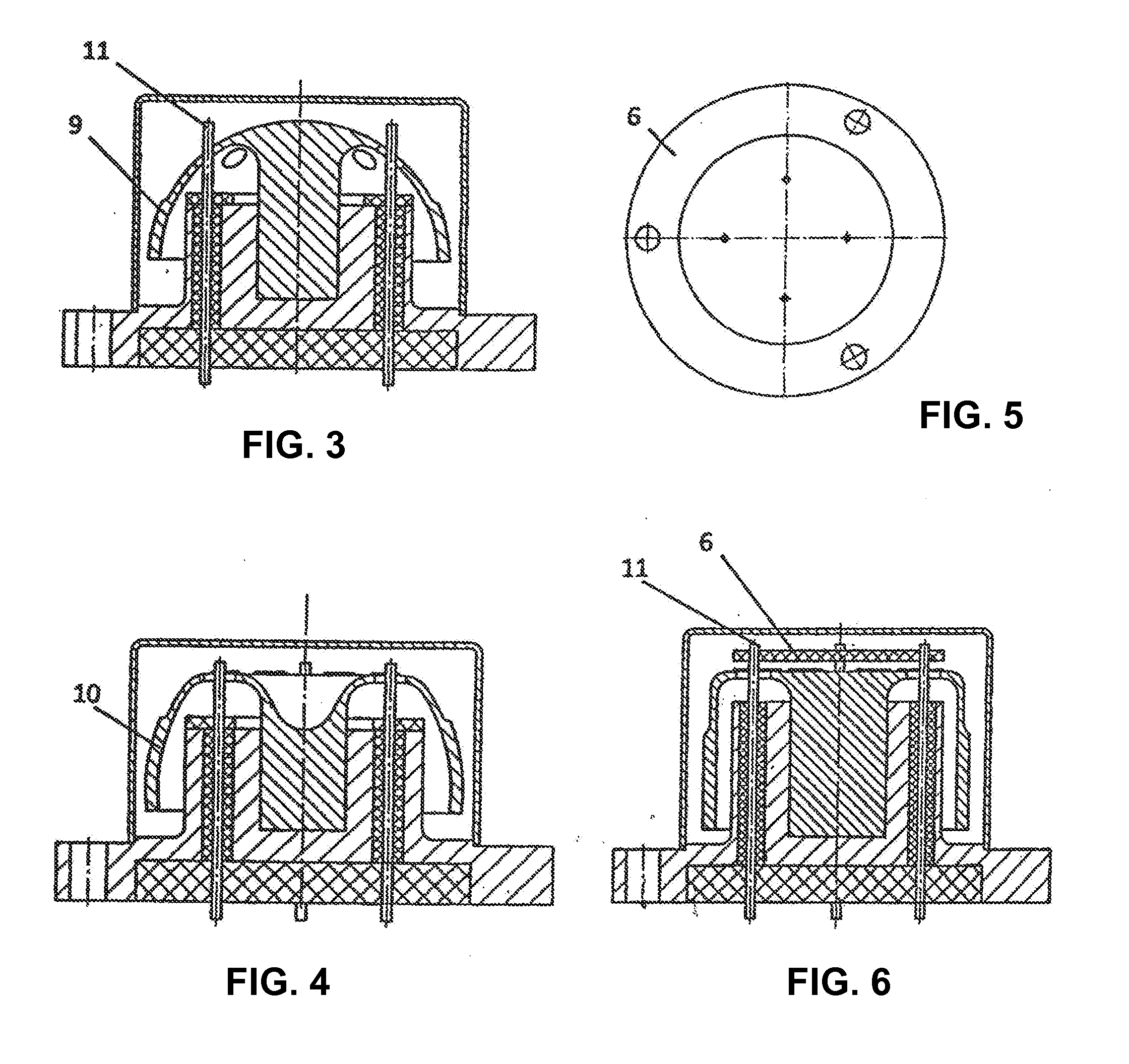

Axially symmetrical coriolis force gyroscope (variants)

ActiveUS9322655B2High technical efficiencyImprove reliabilitySpeed measurement using gyroscopic effectsTurn-sensitive devicesGyroscopeClassical mechanics

An axially symmetrical Coriolis vibratory gyroscope includes a thin-walled resonator with a hemispherical or cylindrical or toroidal form, the resonator being fixed at the center to a support and being formed with openings in that wall of the resonator which is located around the support, the number of openings being determined on the basis of the formula 4nk, where k is an integer, n is the order of oscillation modes, wherein the support has a symmetrical form along the longitudinal axis and is fixed to a base, electrodes are positioned on the wall of the resonator or next to the resonator for exciting and measuring two oscillation modes, a constant amplitude of one of the modes is maintained and a secondary oscillation mode which is sensitive to Coriolis forces is monitored, and the base is provided with a seat for the support of the resonator and with electrically insulated hermetically sealed leads which pass outwards via the base and through the openings in of the resonator.

Owner:INNALABS

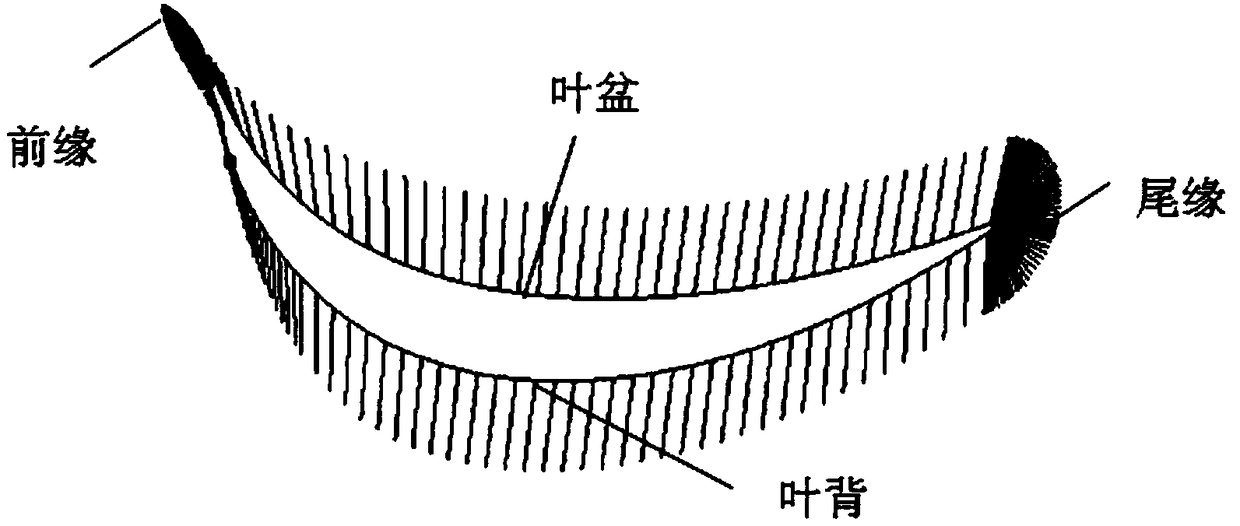

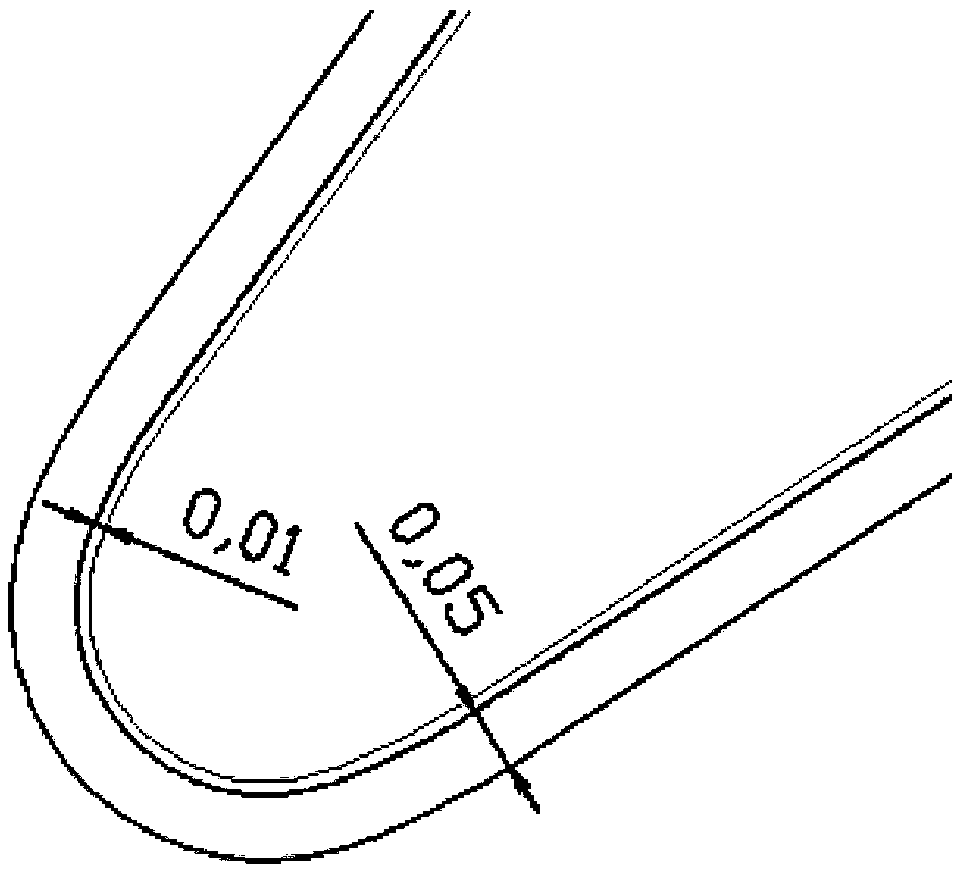

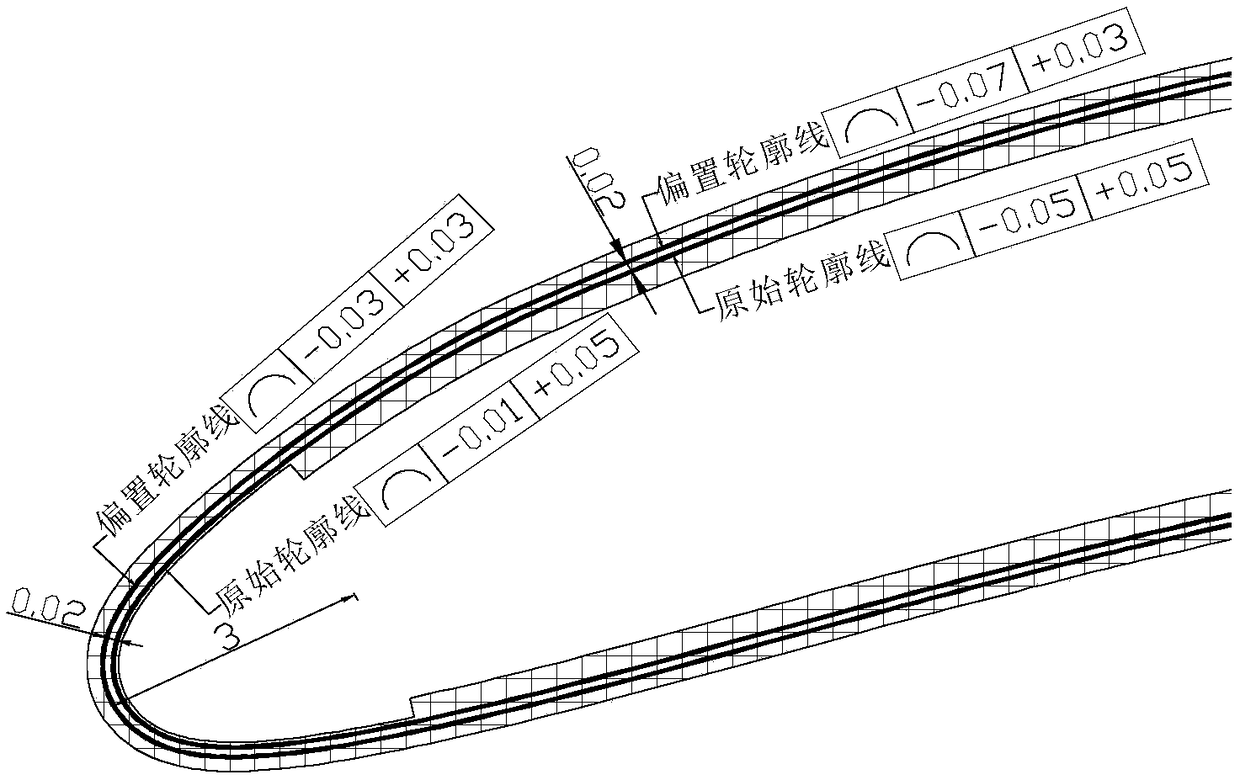

Aviation-engine-blade-surface data evaluation method based on model

ActiveCN109470196AGood measurement reproducibilityImprove detection technology and detection efficiencyMeasurement devicesEngineeringAviation

The invention discloses an aviation-engine-blade-surface data evaluation method based on a model. The method includes the steps that the profile degree of an evaluated blade surface is a linear profile degree, and the linear profile degree and a theory molded line fit before evaluation; an existing blade-surface design model is thickened, a new blade surface is generated through a curve set of a blade to serve as a theory model of profile degree evaluation; under the condition that it is guaranteed that the position of a blade-surface tolerance band is invariable, an upper limiting value and alower limiting value of the tolerance band are changed, original tolerance is changed to be +0.05 mm to -0.01 mm, new tolerance is changed to be +0.03 mm to -0.03 mm, and the profile tolerance band is a symmetry tolerance band; theory data of the thickened theory model is used as a theory molded line that the profile degree evaluates the blade-surface profile degree. According to the aviation-engine-blade-surface data evaluation method based on the model, reality of a part is reflected, the measuring reproducibility is good, integrated development from the engine detection technology capacityto digitization designing, manufacturing and detecting is promoted, and the key detection technology and detection efficiency are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

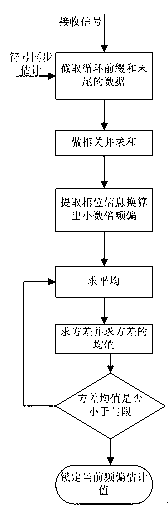

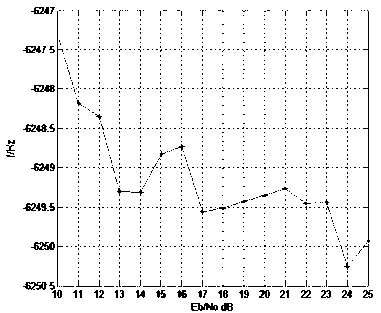

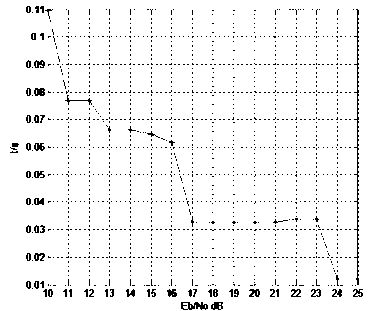

Decimal carrier synchronization algorithm based on cyclic prefix

InactiveCN103001914AReduce error rateOvercome deficienciesMulti-frequency code systemsAlgorithmCarrier frequency offset

The invention discloses a decimal carrier synchronization algorithm based on cyclic prefix. The decimal carrier synchronization algorithm solves the problem in the prior art that the carrier synchronization technical precision is not high enough to meet modulation order development requirements. The decimal carrier synchronization algorithm based on the cyclic prefix includes the following steps: dividing received signals into a carrier frequency offset portion and a remaining portion, dividing the carrier frequency offset portion into decimal frequency offset and integral multiple frequency offset, calculating to obtain a single estimation value of the decimal frequency offset, and obtaining the ith estimation value according to the single estimation value of the decimal frequency offset; repeating the step (b), calculating variance of the obtained decimal frequency offset, and calculating a variance average value; arranging a threshold V, if Vf>V, executing the step (a), if Vf<V, locking a current decimal frequency offset estimation value, and conducting frequency offset compensation according to the estimation value. By means of the scheme, purposes of reducing decimal frequency estimation residual, improving system stability, and enabling a system to work in a smaller residual environment are achieved, and the algorithm has high practical value and popularization value.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Axially symmetrical Coriolis force gyroscope (variants)

ActiveUS20140102193A1Reduced dimensionReduce size of resonatorAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsElectricityGyroscope

The invention relates to gyroscope equipment. The axially symmetrical Coriolis vibratory gyroscope comprises a thin-walled resonator with a hemispherical or cylindrical or toroidal form, said resonator being fixed at the center to a support and being formed with openings in that wall of the resonator which is located around said support, the number of openings being determined on the basis of the formula 4nk, where k is an integer, n is the order of oscillation modes, and the angle between two neighboring openings is equal (I), wherein said support has a symmetrical form along the longitudinal axis thereof and is fixed to a base, solenoids and electrodes are positioned on the wall of the resonator or next to the resonator for exciting and measuring two oscillation modes, the constant amplitude of one of the modes thereof being intended for monitoring a secondary oscillation mode which is sensitive to Coriolis forces, and the base is provided with a seat for the support of the resonator and with electrically insulated hermetically sealed leads which pass outwards via the base and are passed through the openings in the wall of the resonator for connection to elements of an electronics board.

Owner:INNALABS

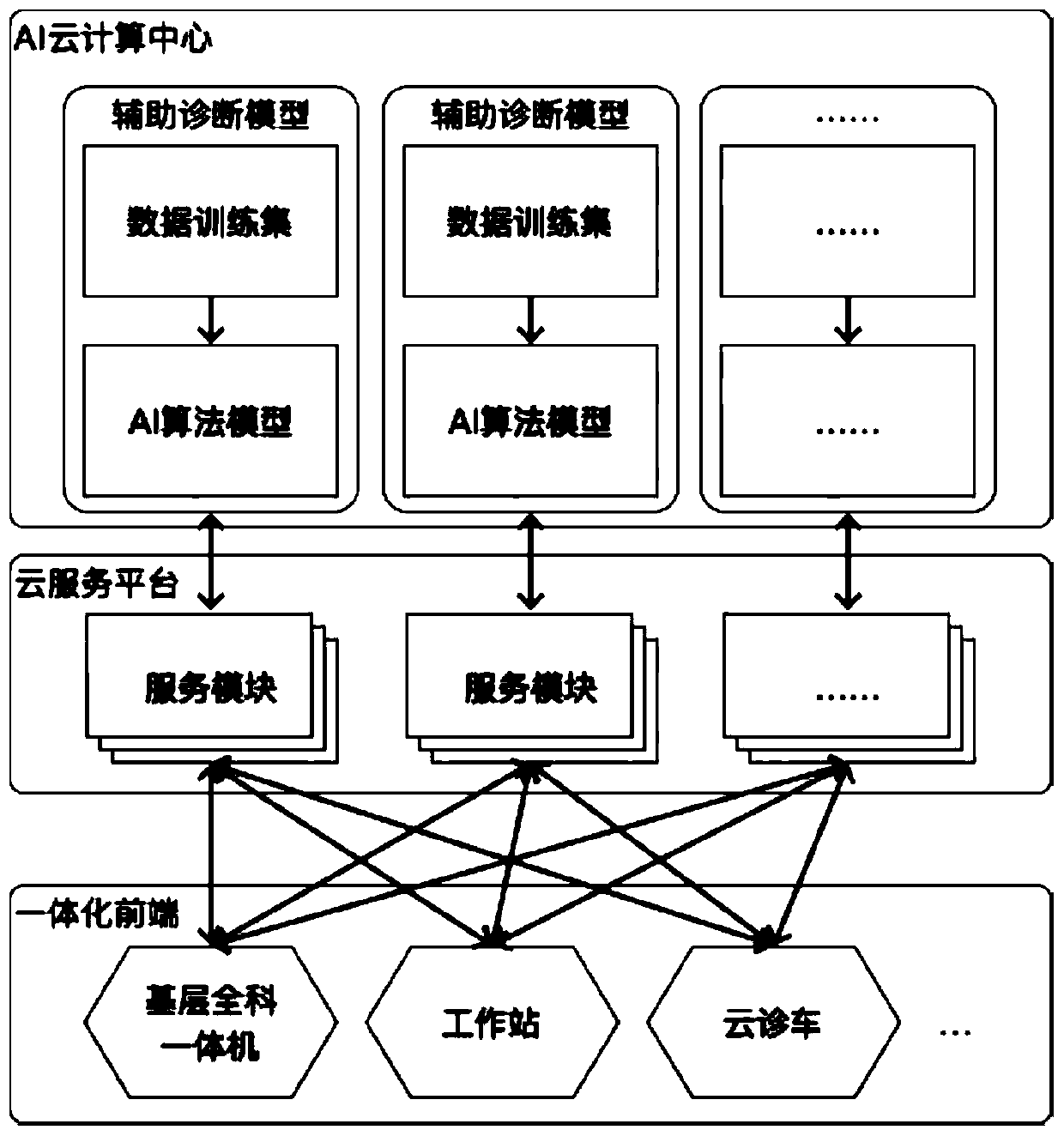

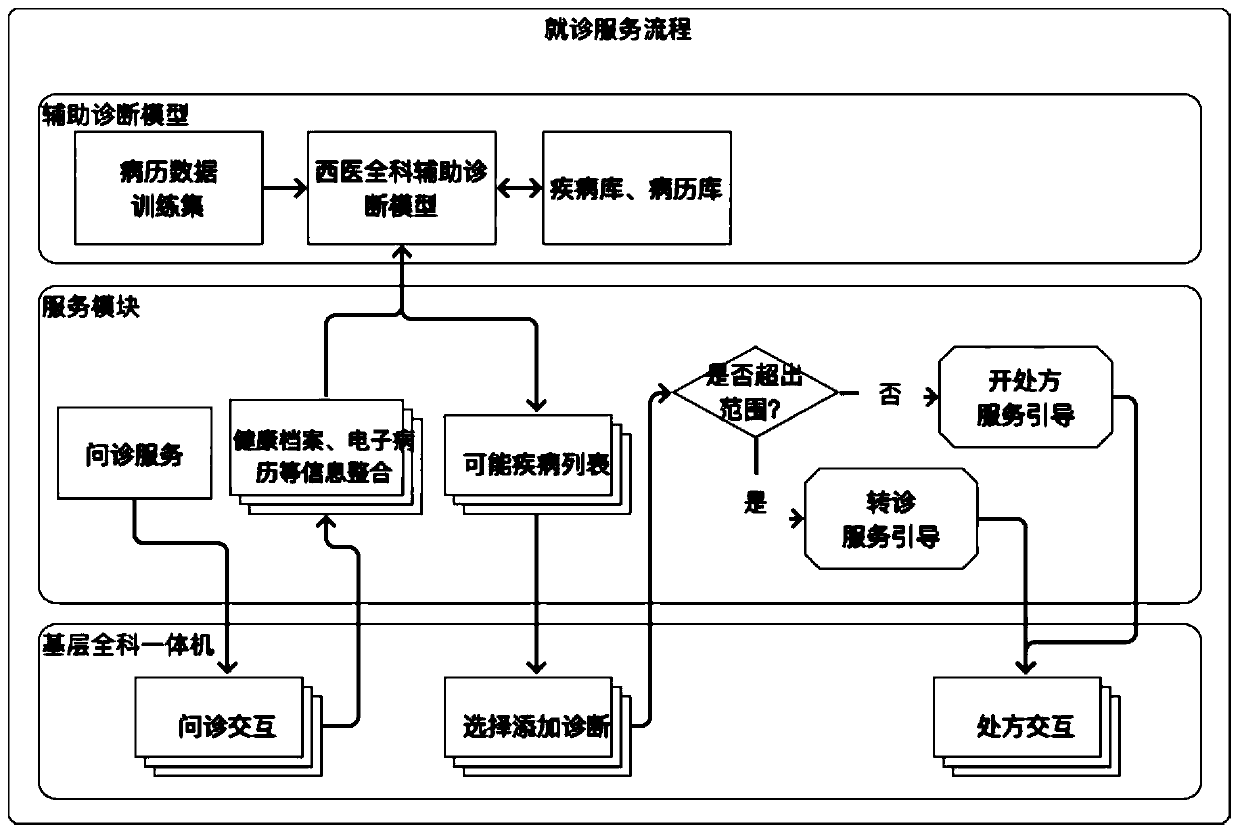

Primary care doctor intelligent practice cloud platform supporting health service communities

InactiveCN111276263AGuaranteed flexibilityHigh technical efficiencyMedical communicationHealth-index calculationHealth servicesComputing center

The invention discloses a primary care doctor intelligent practice cloud platform supporting health service communities. The platform comprises at least one AI cloud computing center which comprises aplurality of auxiliary diagnosis models; at least one cloud service platform which carries a plurality of different service modules, wherein the cloud service platform interacts with the auxiliary diagnosis models in the AI cloud computing center through a network to complete uploading of medical data and fusion judgment and processing of diagnosis results and corresponding services; and an integrated front end which comprises detection equipment used for acquiring physical sign data of a patient, wherein the integrated front end and the cloud service platform carry out data, service and pageinteraction, the service module is displayed on the integrated front end, and the physical sign detection data is transmitted to the service module through the integrated front end. The system has the advantages of wide coverage range of practice content, high intelligent auxiliary degree, support of a city-county-village integrated hierarchical diagnosis and treatment mode in a medical team or health service community mode, and the like.

Owner:挂号网(杭州)科技有限公司

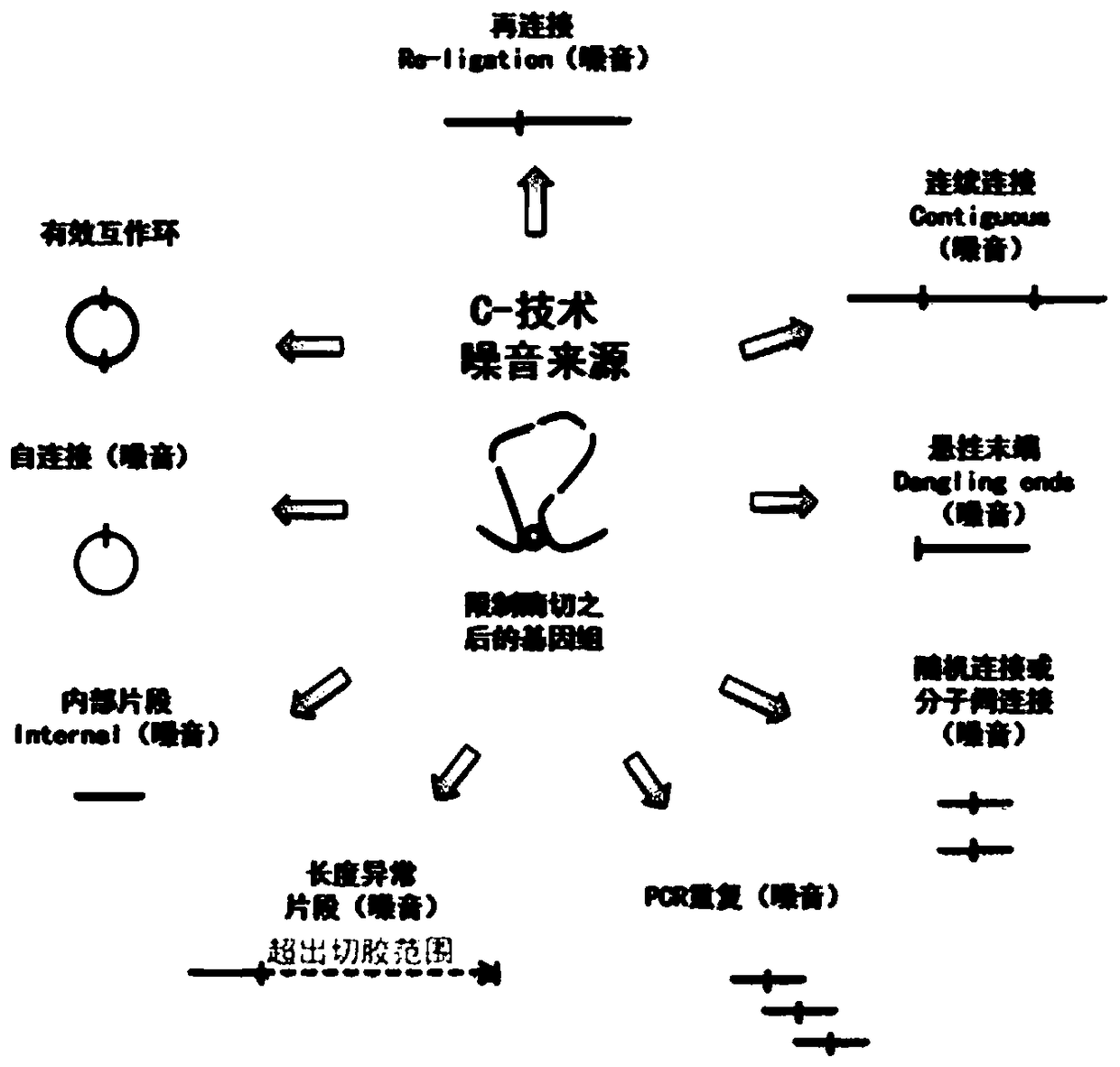

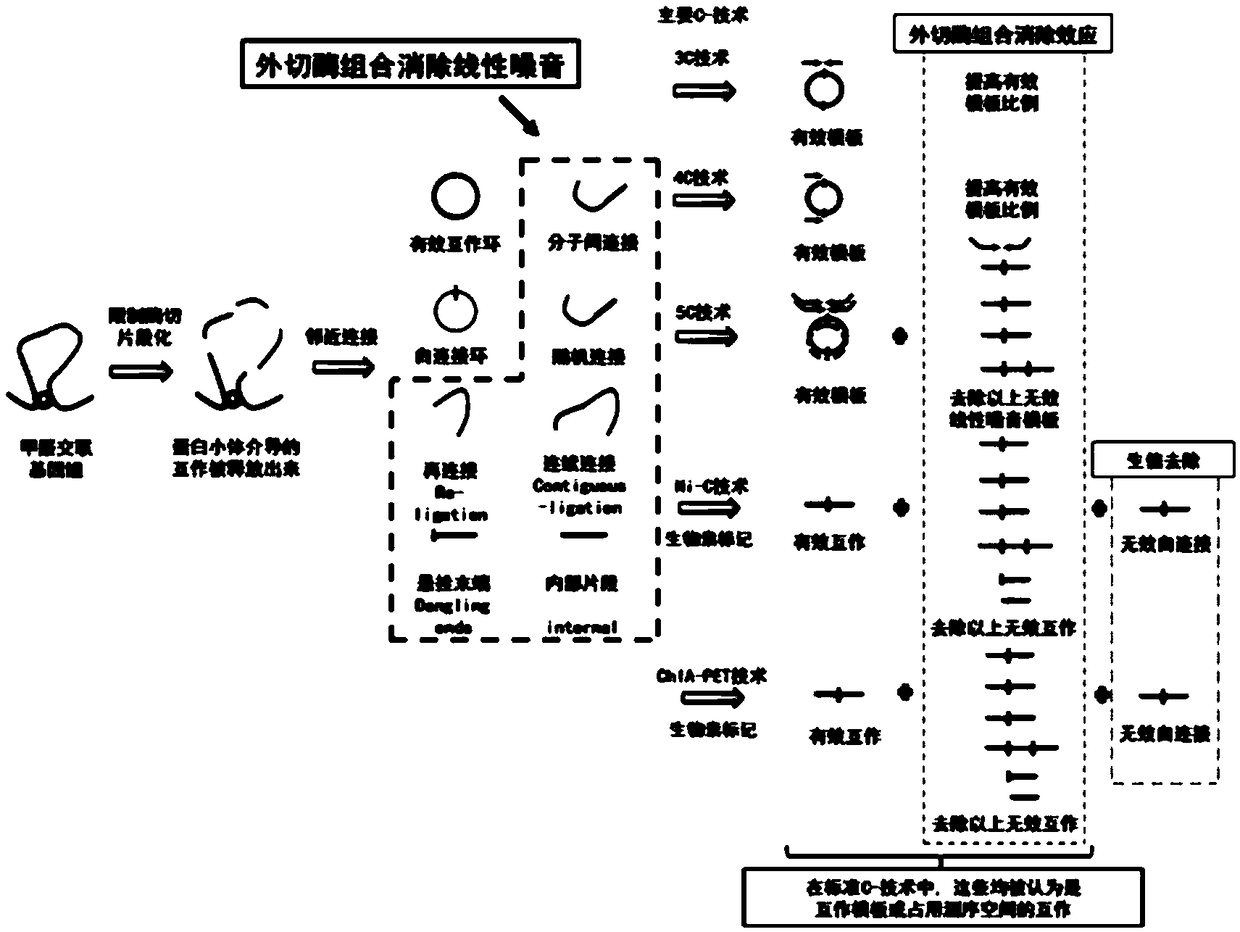

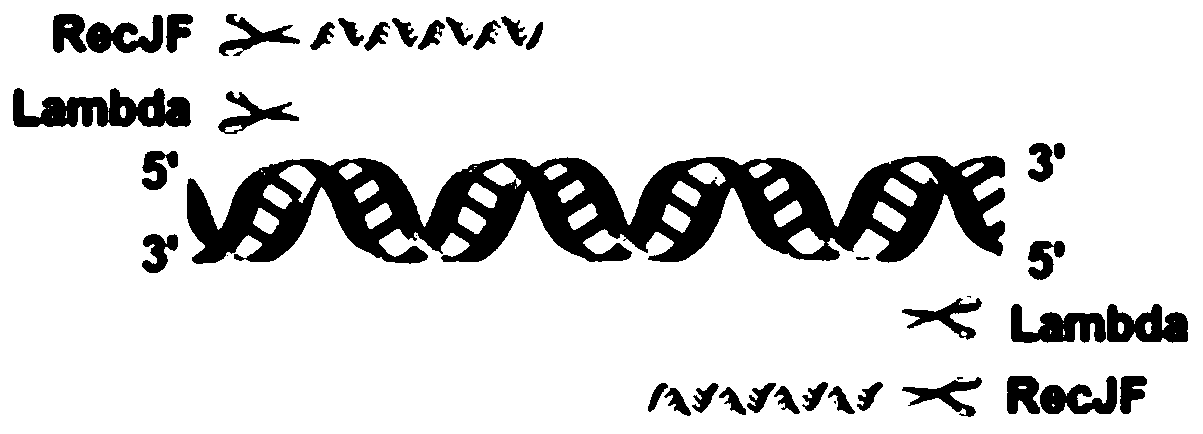

Method for eliminating three-dimensional genomics technology noise by utilizing exonuclease combination

PendingCN108804872AIncrease the proportionIncrease output ratioSpecial data processing applicationsEnzyme digestionExonuclease I

The invention discloses a method for eliminating three-dimensional genomics technology noise by utilizing exonuclease combination. The method comprises the step of adding exonuclease combination to eliminate adjacently connected linear DNA when performing the adjacent connection at the key step of the three-dimensional genomics technology, thereby improving the cyclic effective interaction proportion. The excellent performance of the exonuclease combination for eliminating the linear DNA provides an effective measure for eliminating the noise through the enzyme digestion of the exonuclease combination after the C-technology connection; the method for eliminating the three-dimensional genomics technology noise by utilizing exonuclease combination has the advantages of being convenient, fastand efficient, the possibility of producing the false-positive product or signal can be reduced, the effective interaction cyclic DNA proportion is enhanced, the terminal effective interaction data output ratio is greatly improved, the sequencing space is saved, the sequencing cost is reduced, and the operation for eliminating the resource consumed by ineffective information in the big data by using the complex biological information at later is simplified.

Owner:AGRI GENOMICS INST CHINESE ACADEMY OF AGRI SCI

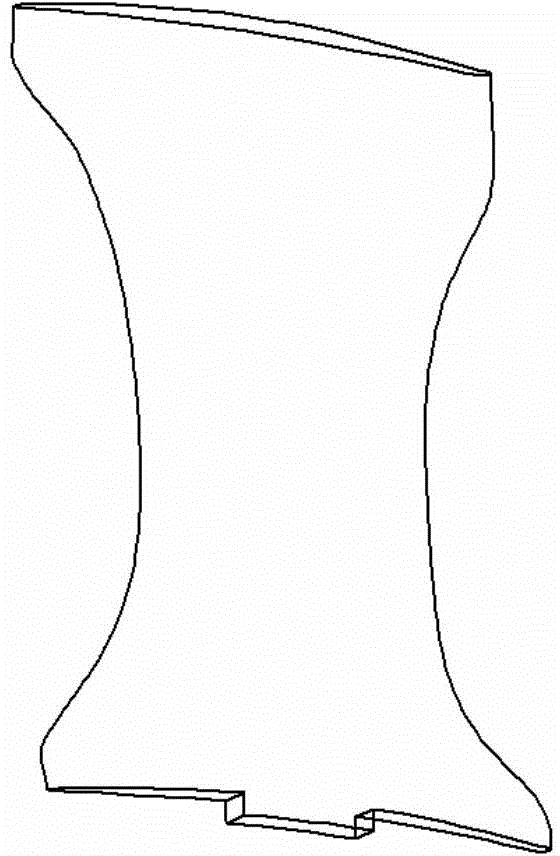

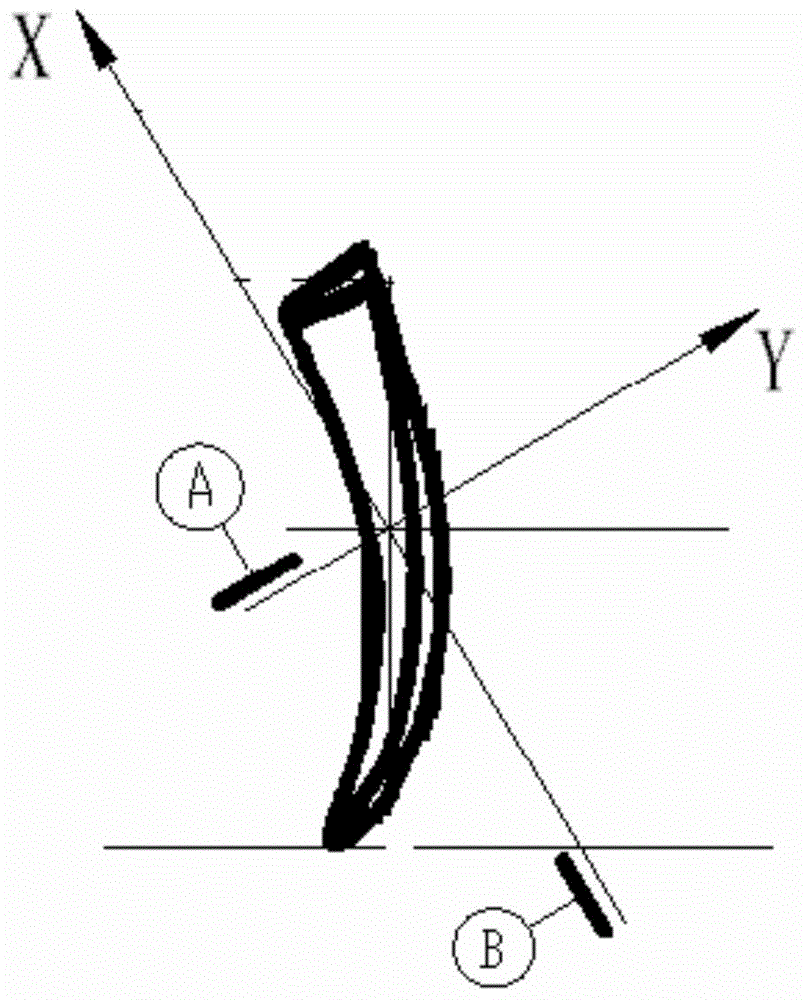

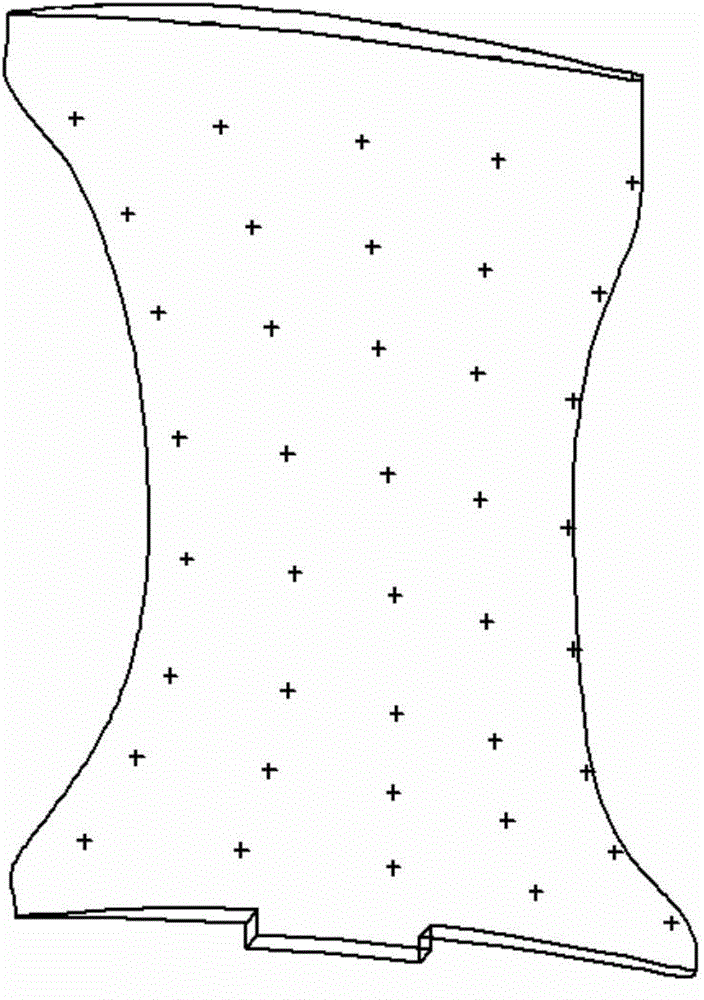

Coordinate system measurement method for blade parts without positioning datum plane

ActiveCN105651216ARealize measurementHigh technical efficiencyMeasurement devicesSpecial data processing applicationsMeasurement pointIndustrial engineering

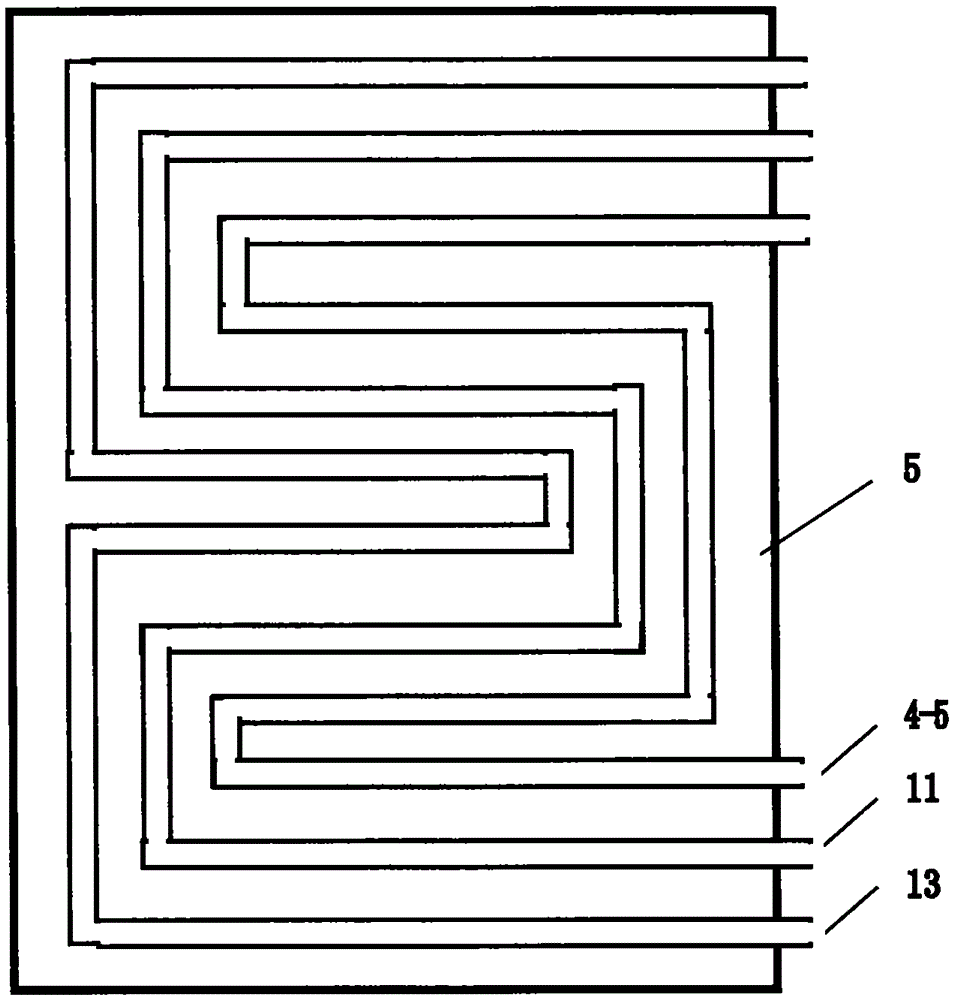

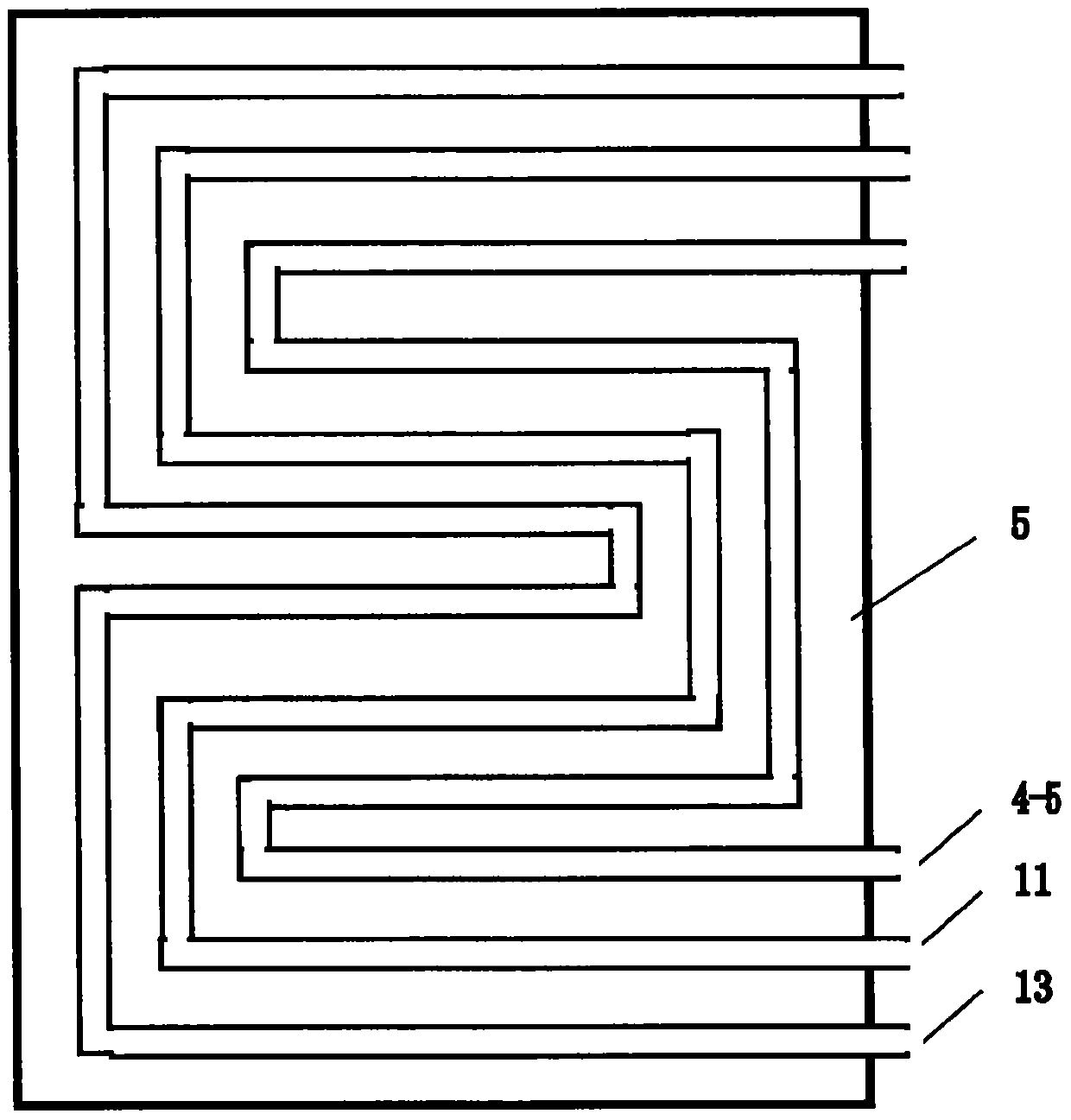

Disclosed is a coordinate system measurement method for blade parts without a positioning datum plane. A measurement method for blades without direct positioning datum comprises the following steps: (1) generating an MBD model of a part based on spline surface characteristics according to blade profile coordinate data; (2) importing the MBD model into offline measurement software, and adjusting the coordinate system direction of the model to make the coordinate system direction of the model consistent with that of a measuring machine to avoid interference between a virtual probe and the model; and (3) designing measurement point distribution (please see attached figure 3) to ensure that the measurement points cover a measured surface or the part length. The method not only satisfies the requirements of parts, but also conforms to the principle of economical measurement. Through the measurement method for blades without direct positioning datum, measurement of special-form characteristics is realized. The method plays an important role in keeping the quality of engine running stable, improves the product quality and the detection efficiency, and is of great economic and social values.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

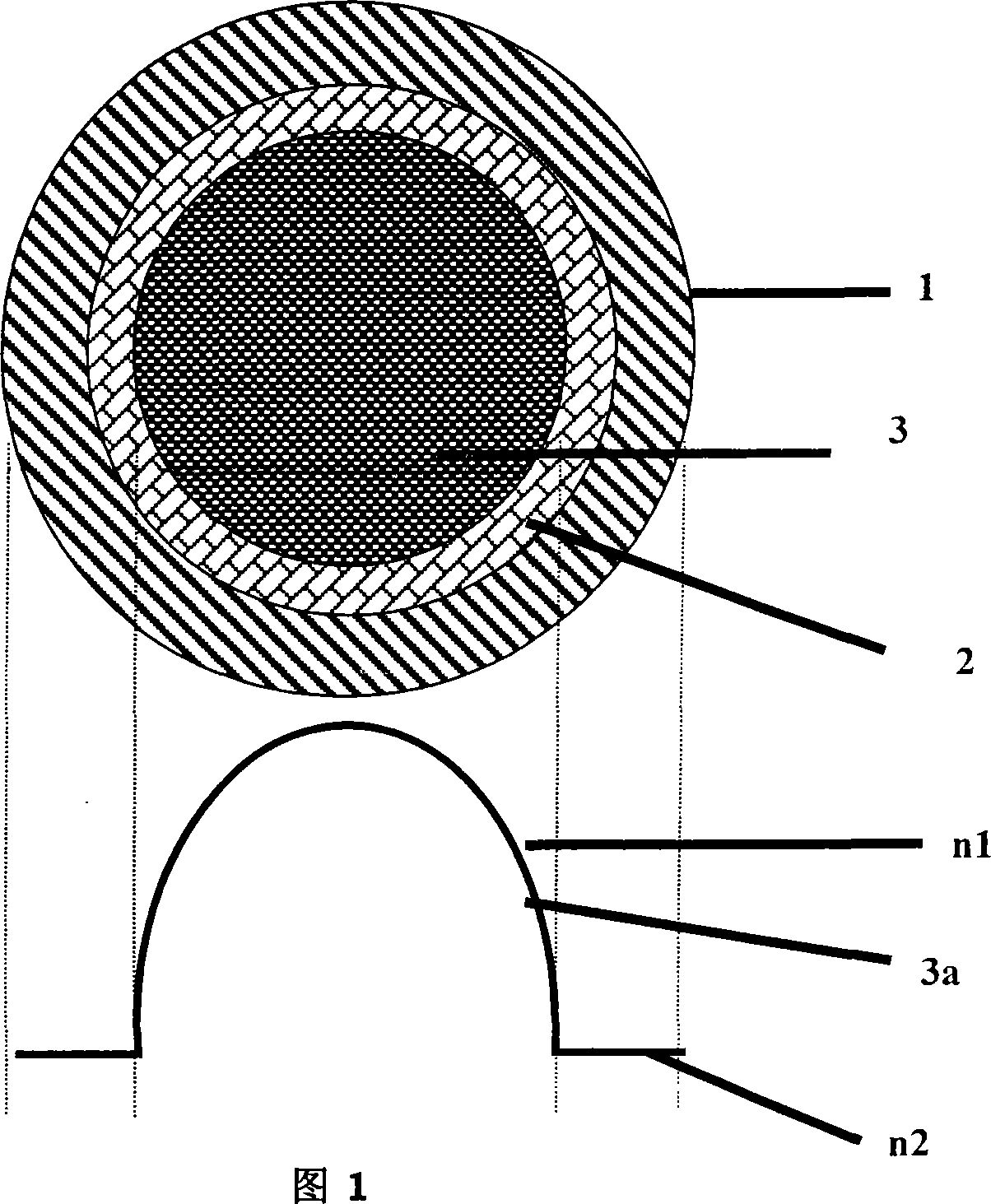

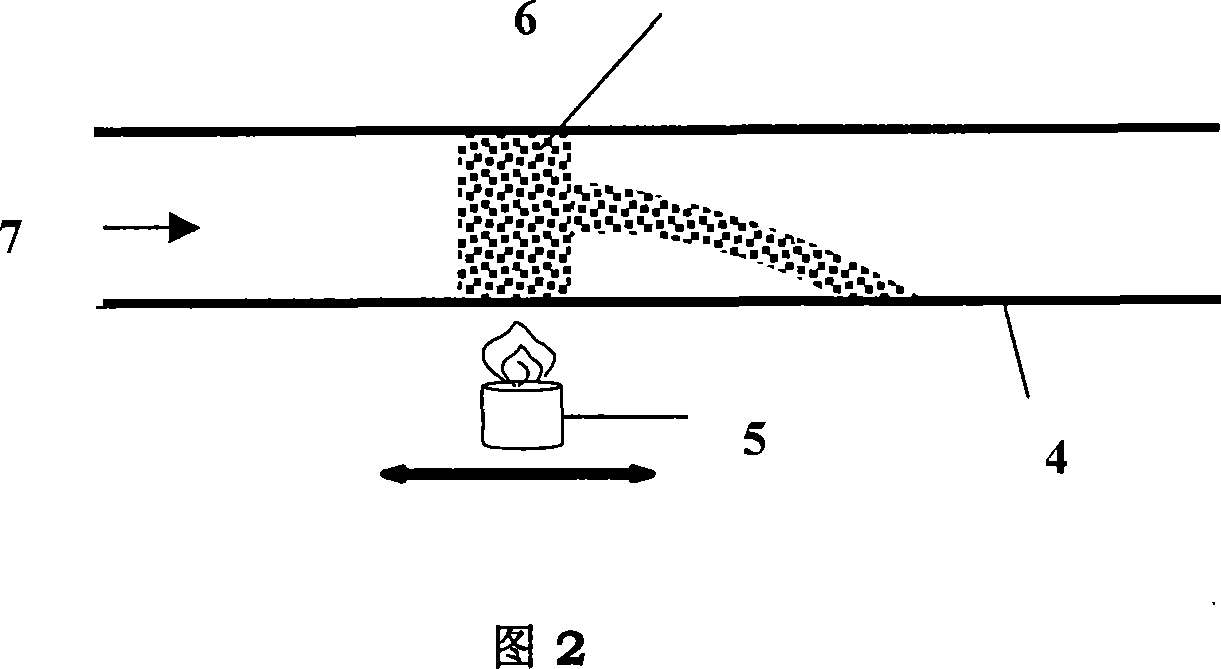

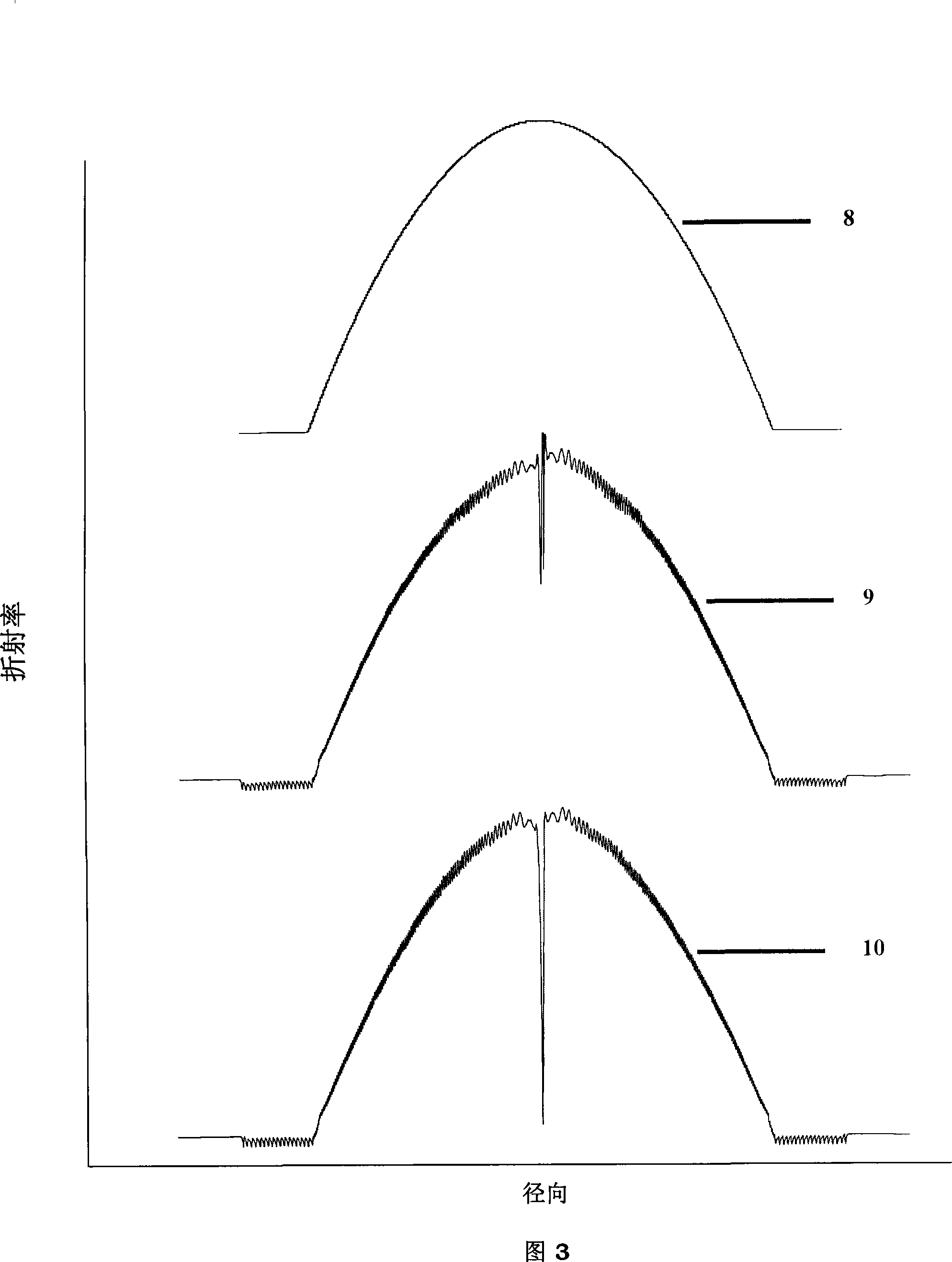

Fibre-optical with high wide-band and manufacturing method thereof

InactiveCN101052596AMaximize bandwidthHigh technical efficiencyGlass making apparatusOptical light guidesRefractive index profileNucleic acid sequencing

This invention relates to a novel protein, termed INSP152, herein identified as a secreted protein, in particular, as a MAM domain containing protein and to the use of this protein and nucleic acid sequence from the encoding gene in the diagnosis, prevention and treatment.

Owner:STERLITE OPTICAL TECH

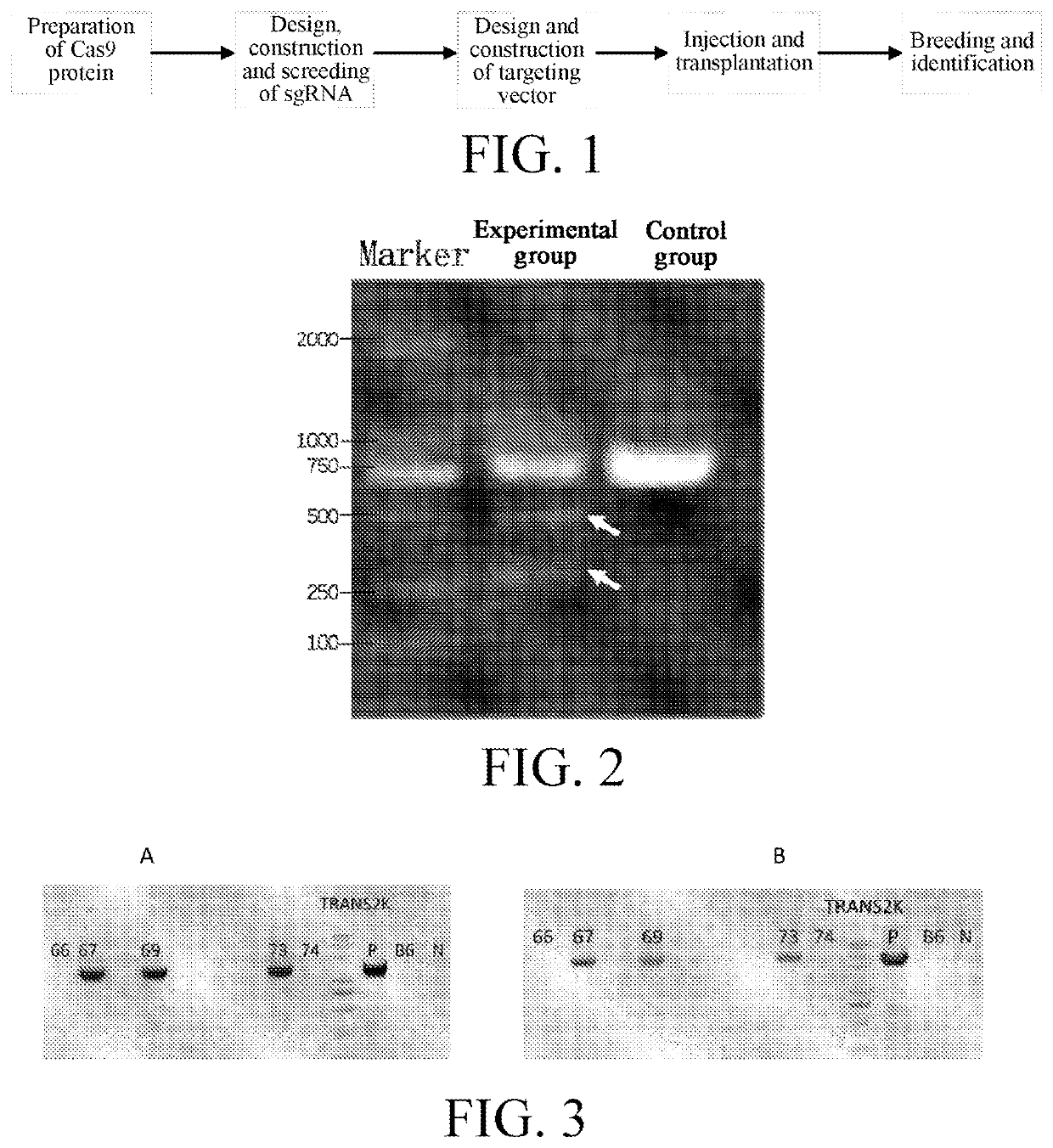

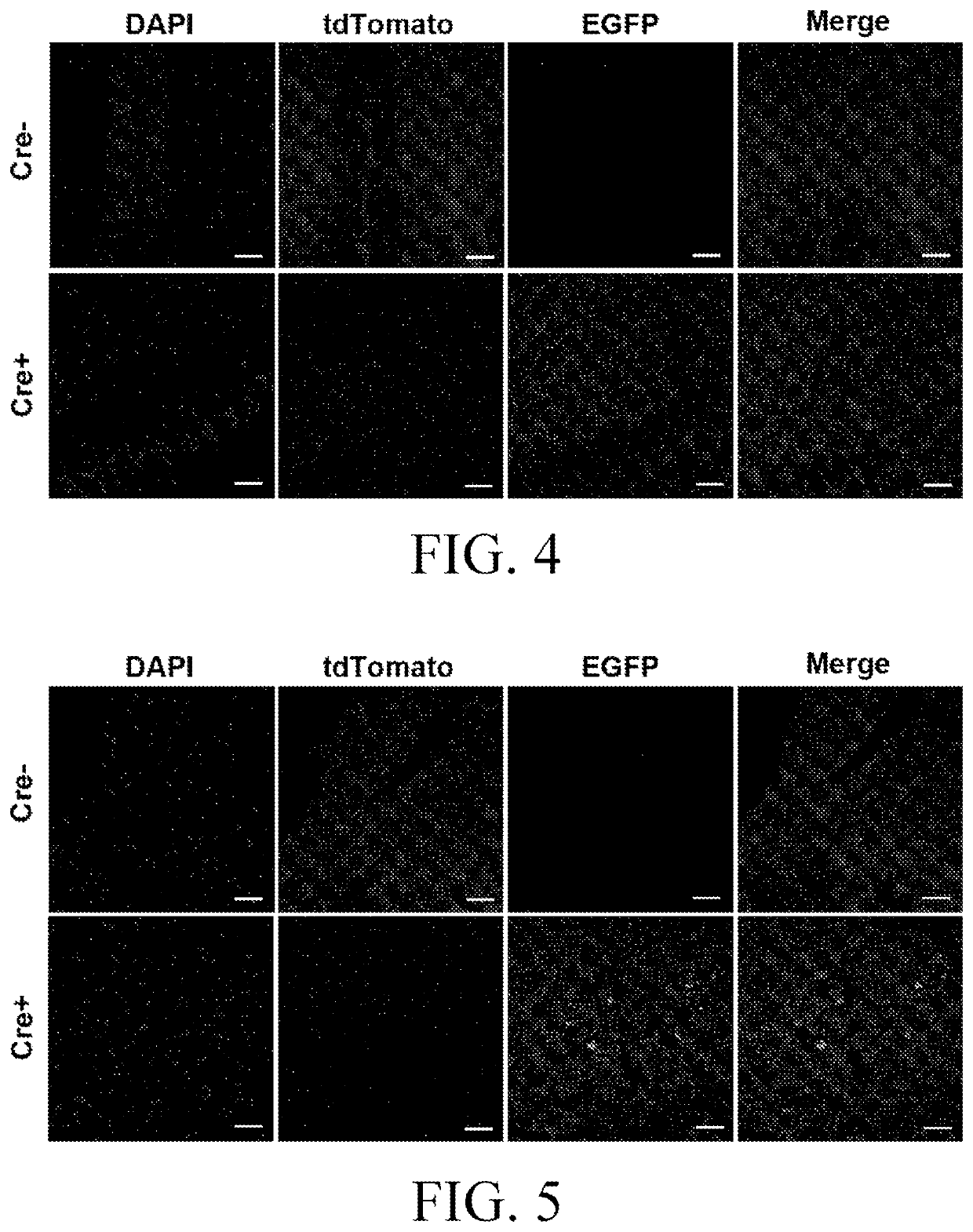

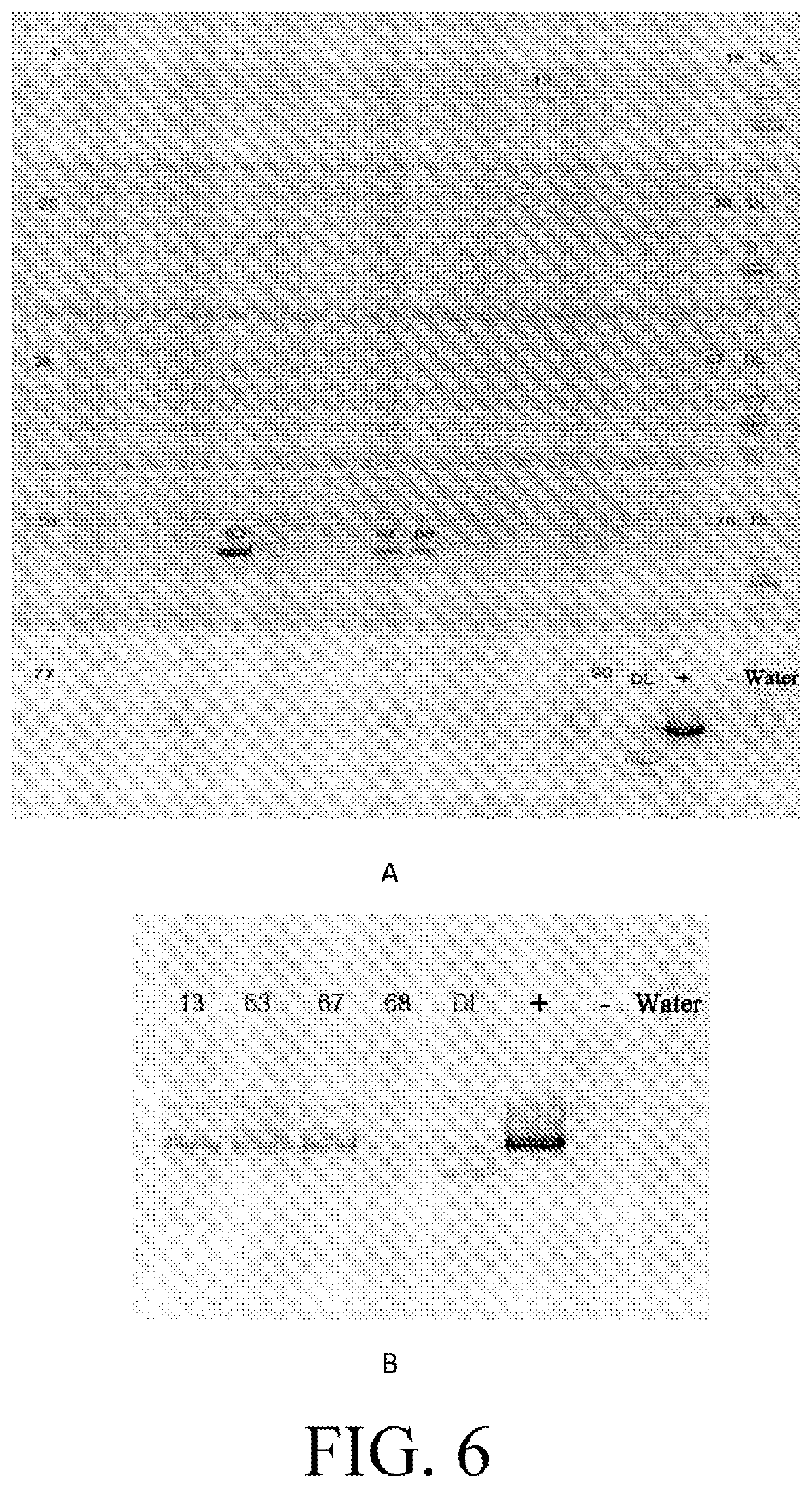

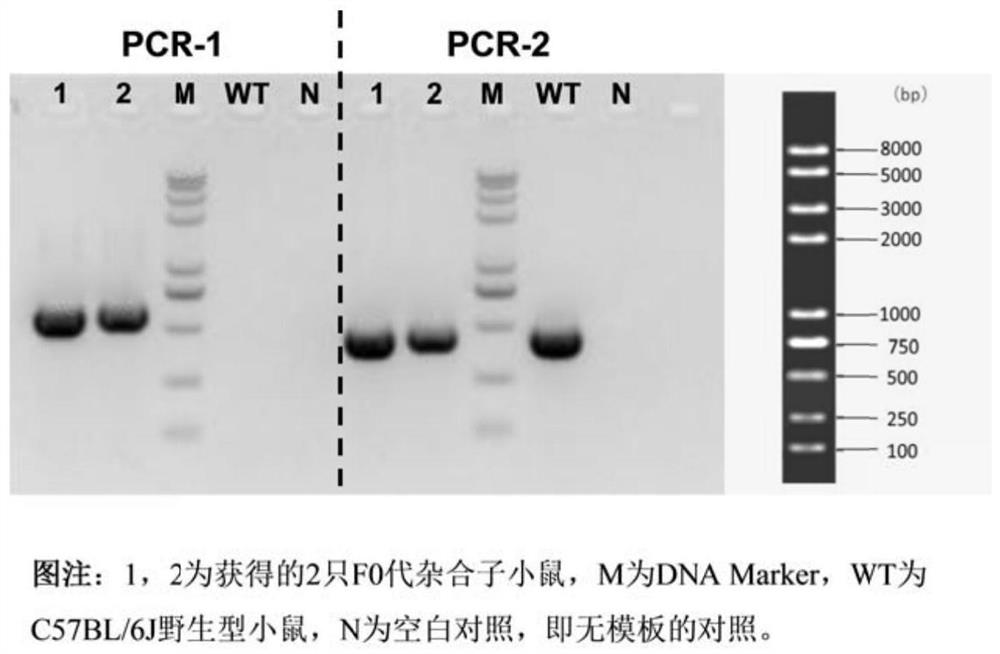

Method for preparing cko/ki animal model by using cas9 technology

ActiveUS20210307303A1Reduce rateEnsure success rateHydrolasesStable introduction of DNAAnimal scienceSingle strand

A method for preparing a CKO / KI animal model by using Cas9 technology includes a Cas9 protein expressed and purified in vitro, high-efficiency sgRNA(s) screened by sgRNA cleavage efficiency test on embryos in advance, and single-stranded DNA as targeting vector(s) are mixed with Cas9 protein and sgRNA(s) and then subjected to embryo injection and transplantation; mice born after transplantation are marked as F0 and the genotype identification of F0 is carried out; sexually mature F0 with the correct genotype are bred, and the offspring mice thereof are marked as F1; and the F1 mice are analyzed and verified, and the F1 mice with the correct genotype are the prepared CKO / KI animal model.

Owner:GEMPHARMATECH CO LTD

Refined grinding process and grinding medium supplementing device

The invention relates to a mineral grinding method, wherein it uses grinding medium feeder to continuously feed grinding medium, combined with controllable continuous mine feeder, it can adjust the medium and mine amount based on the rigidity and property of mine. And it adjusts the water flux to adjust the mine density. Said medium feeder is formed by storage tank, discharge roller, power transmitter, speed reducer, and speed-variable motor, support, speed recorder, speed-variable controller, and meter.

Owner:ANSTEEL GRP MINING CO LTD

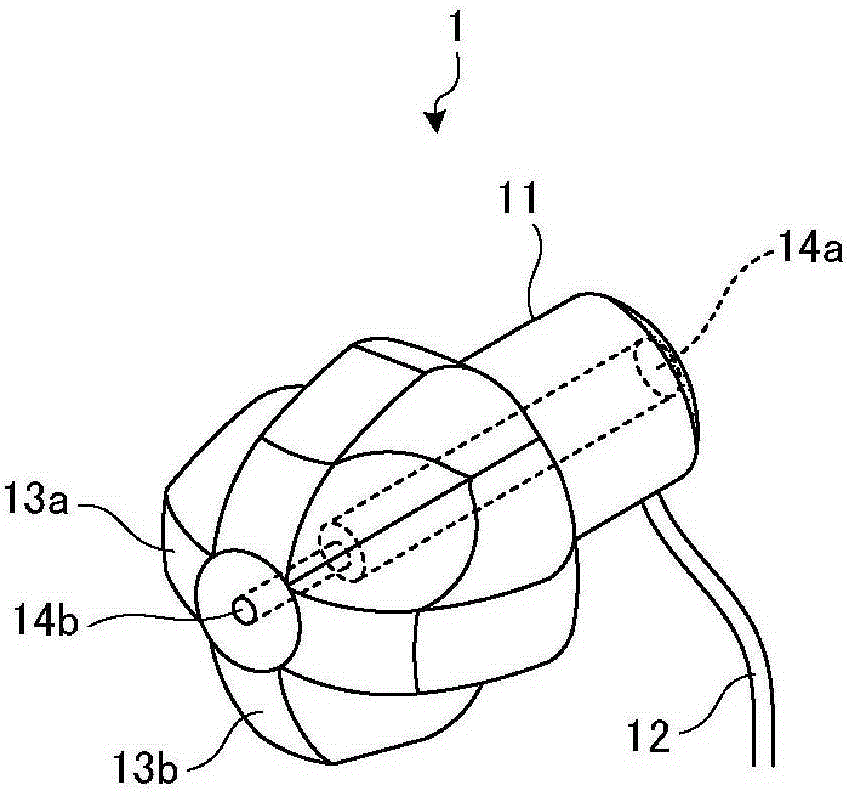

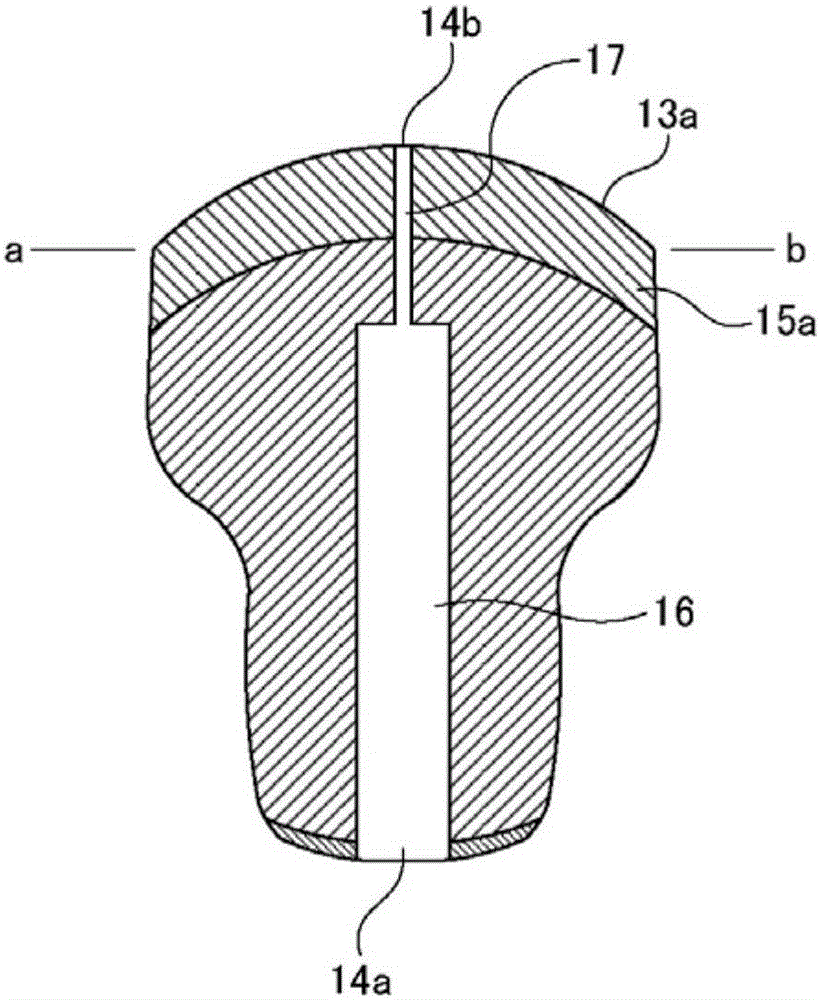

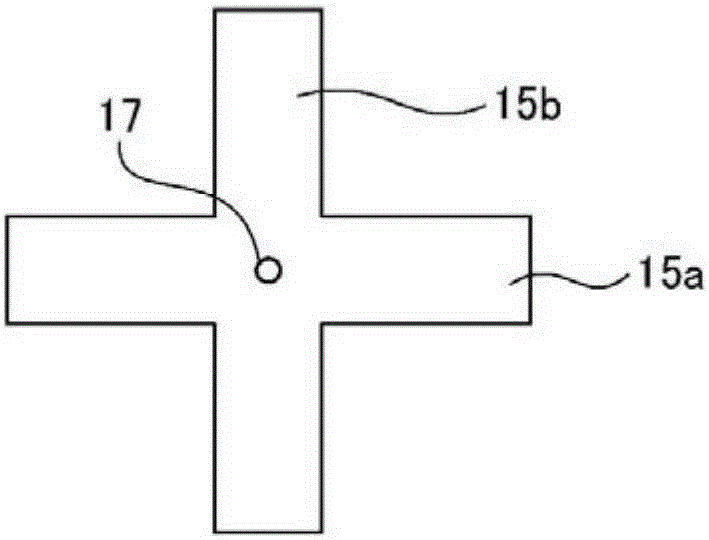

Ultrasonic probe and ultrasonic diagnostic device

InactiveCN103702615BEasy diagnosisGood treatment effectDiagnostic probe attachmentPiezoelectric/electrostrictive transducersUltrasoundUltrasonic transducer array

In the ultrasonic probe according to the embodiment, the first ultrasonic transducer array scans the first scanning surface. The second ultrasonic transducer array engages with the first ultrasonic transducer array, is arranged to cross the first ultrasonic transducer array, and scans a second scanning surface different from the first scanning surface. A first ultrasonic transducer array and a second ultrasonic transducer array are arranged on the probe main body, an opening is provided at a position where the ultrasonic transducer arrays intersect, and the probe main body has a through hole leading to the opening. The engaging portion engaging the first and second ultrasonic transducer arrays is provided so that an angle at which the first ultrasonic transducer array and the second ultrasonic transducer array intersect can be changed.

Owner:TOSHIBA MEDICAL SYST CORP

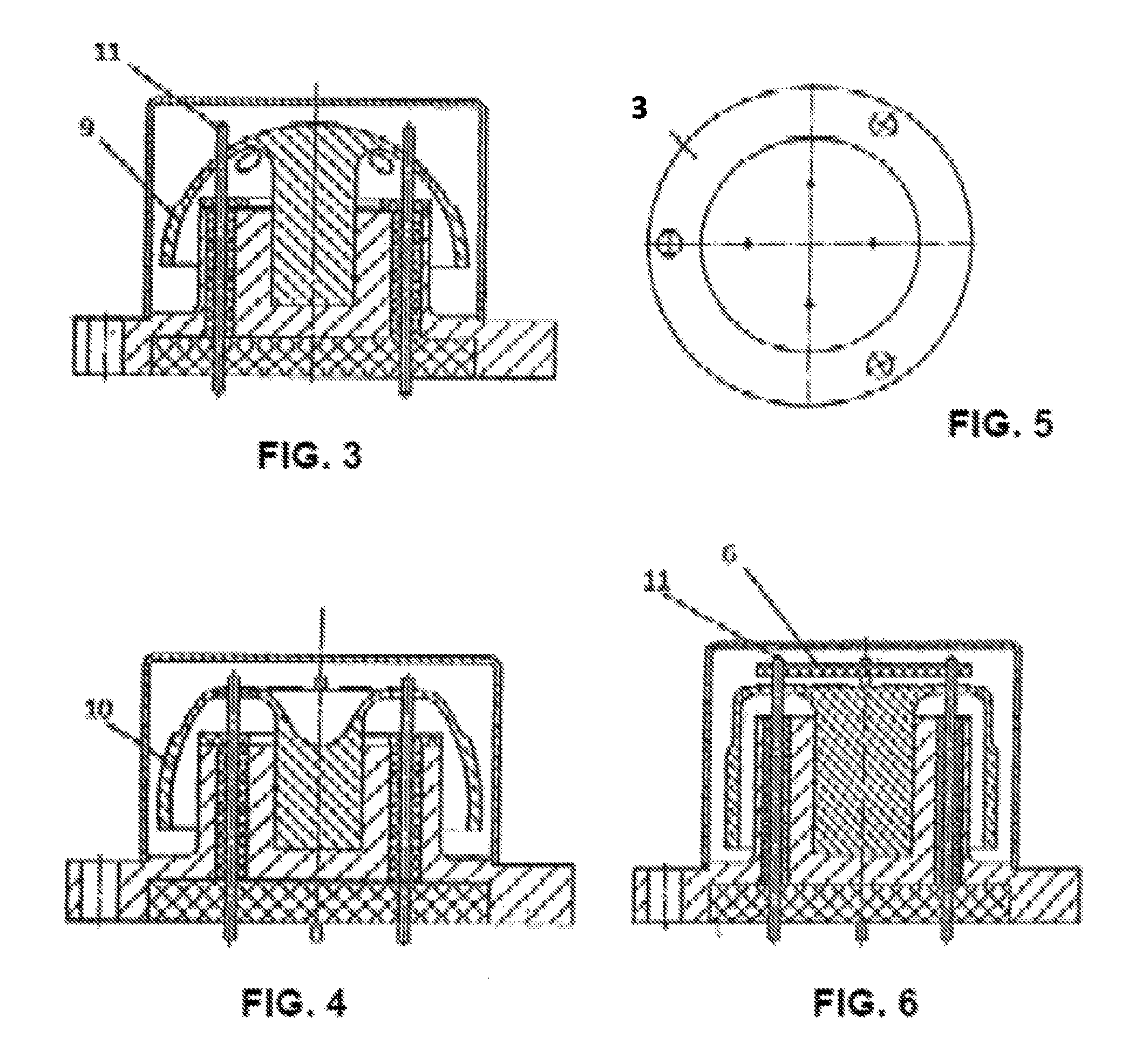

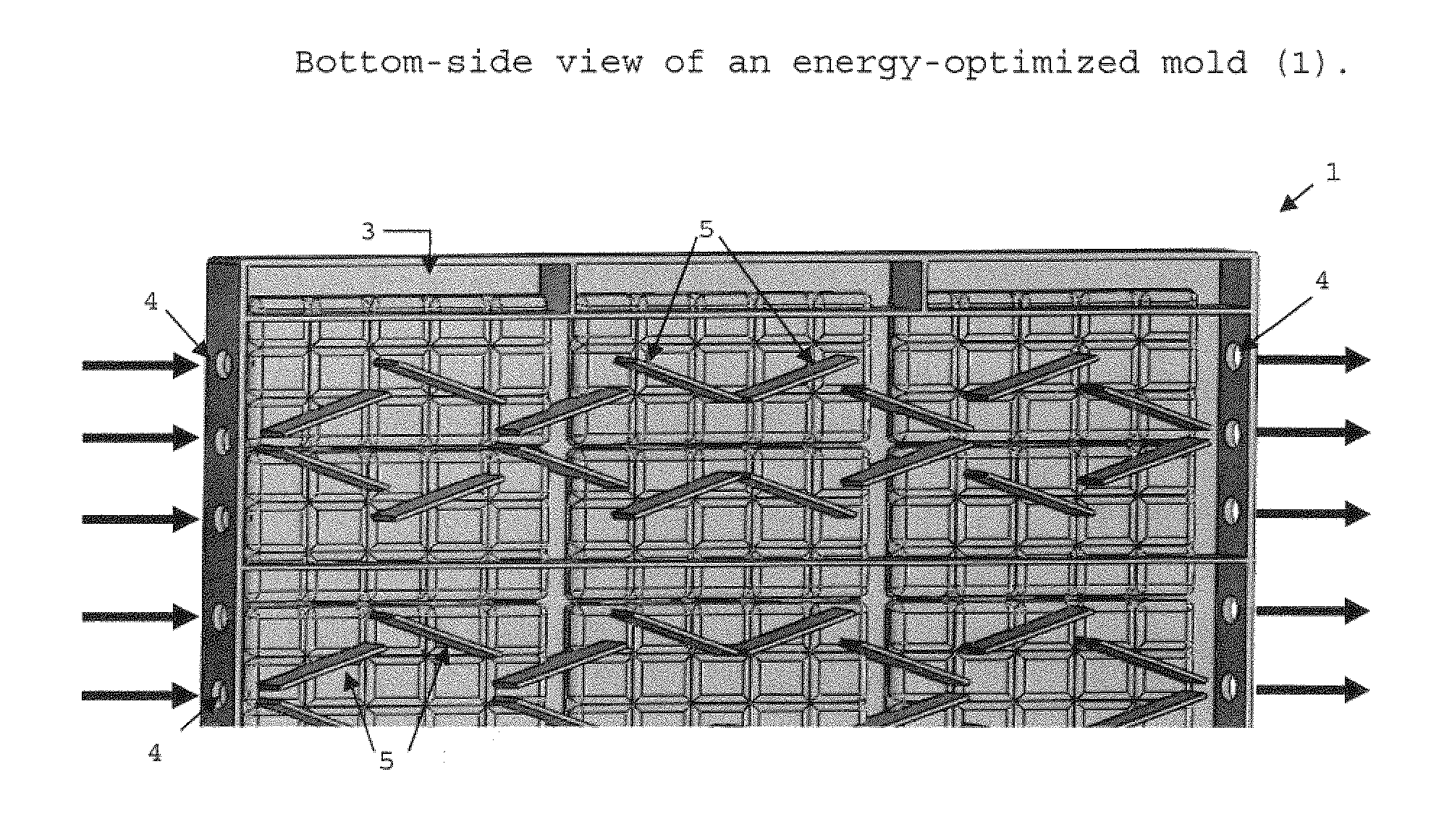

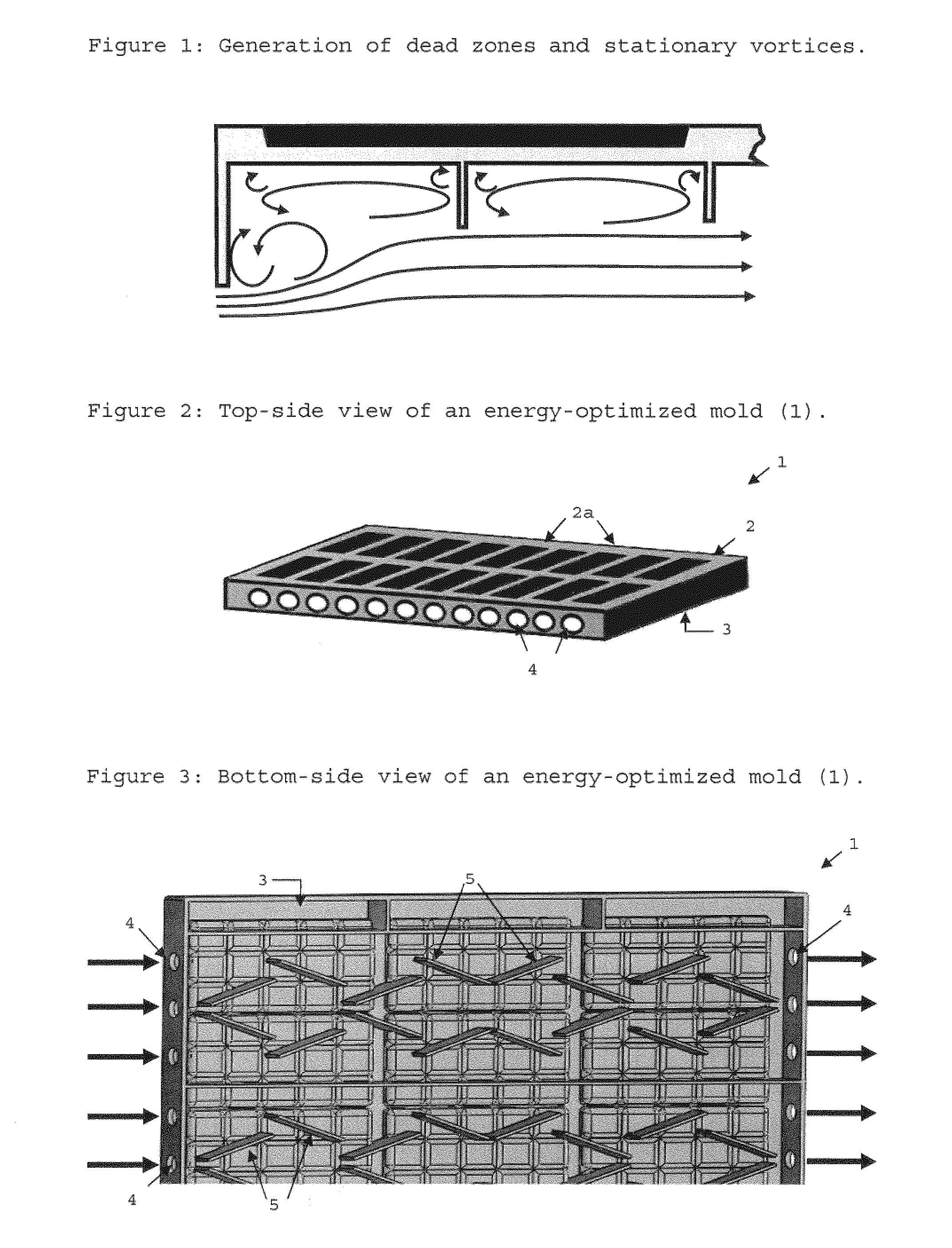

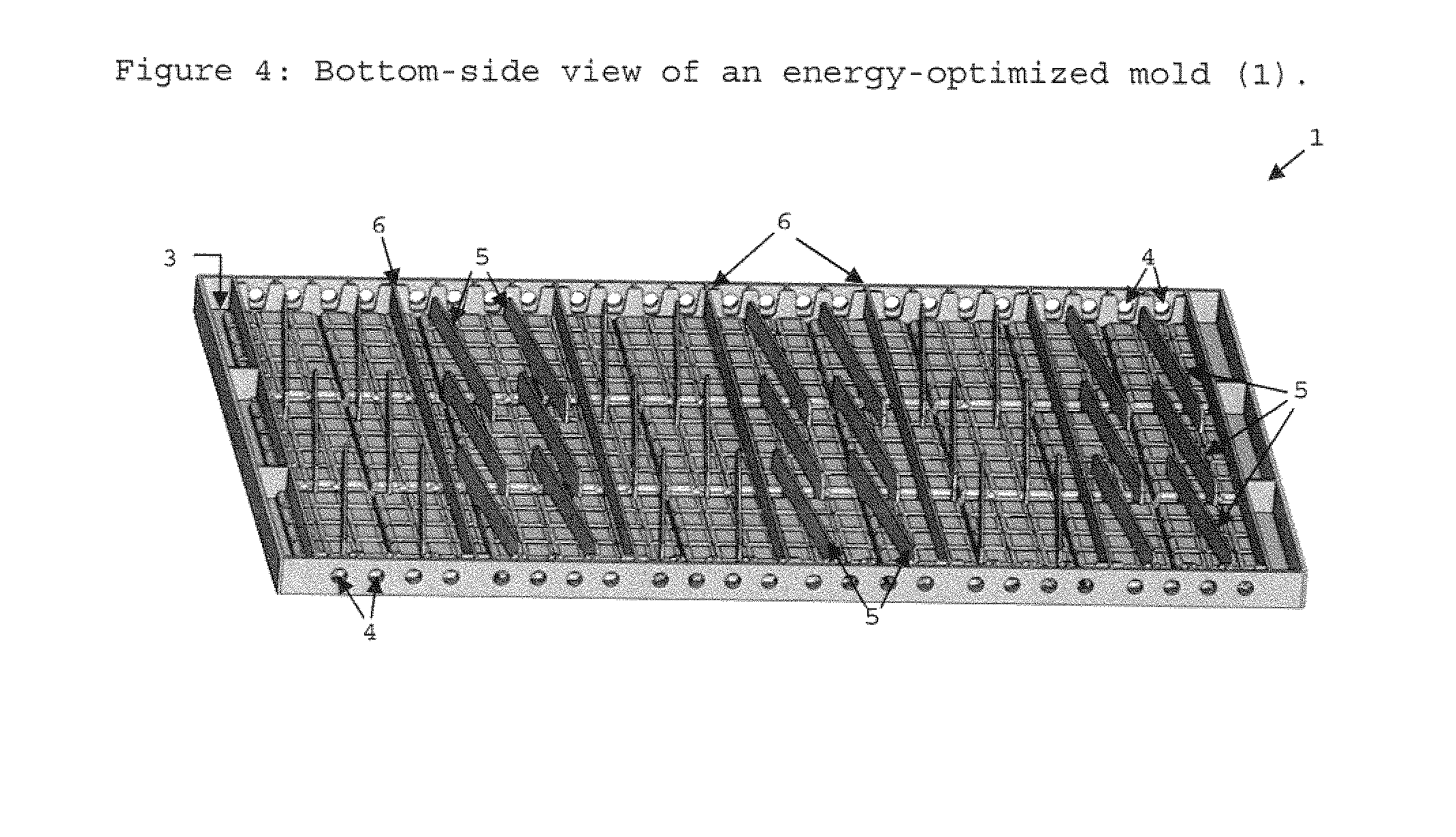

Mold with optimized heat transfer properties

InactiveUS20150132461A1High technical efficiencyPositive financial impactFrozen sweetsConfectioneryProcess engineeringHeat transfer

A mold (1) for the production of confectionery products, comprising a top surface (2) having cavities (2a) and an opposite bottom surface (3), comprising at least one protruding element (5) at the bottom surface (3) of the mold (1) for increasing the heat transfer rate between the mold (1) and a fluid flowing along the bottom surface (3).

Owner:KRAFT FOODS SCHWEIZ HLDG AG

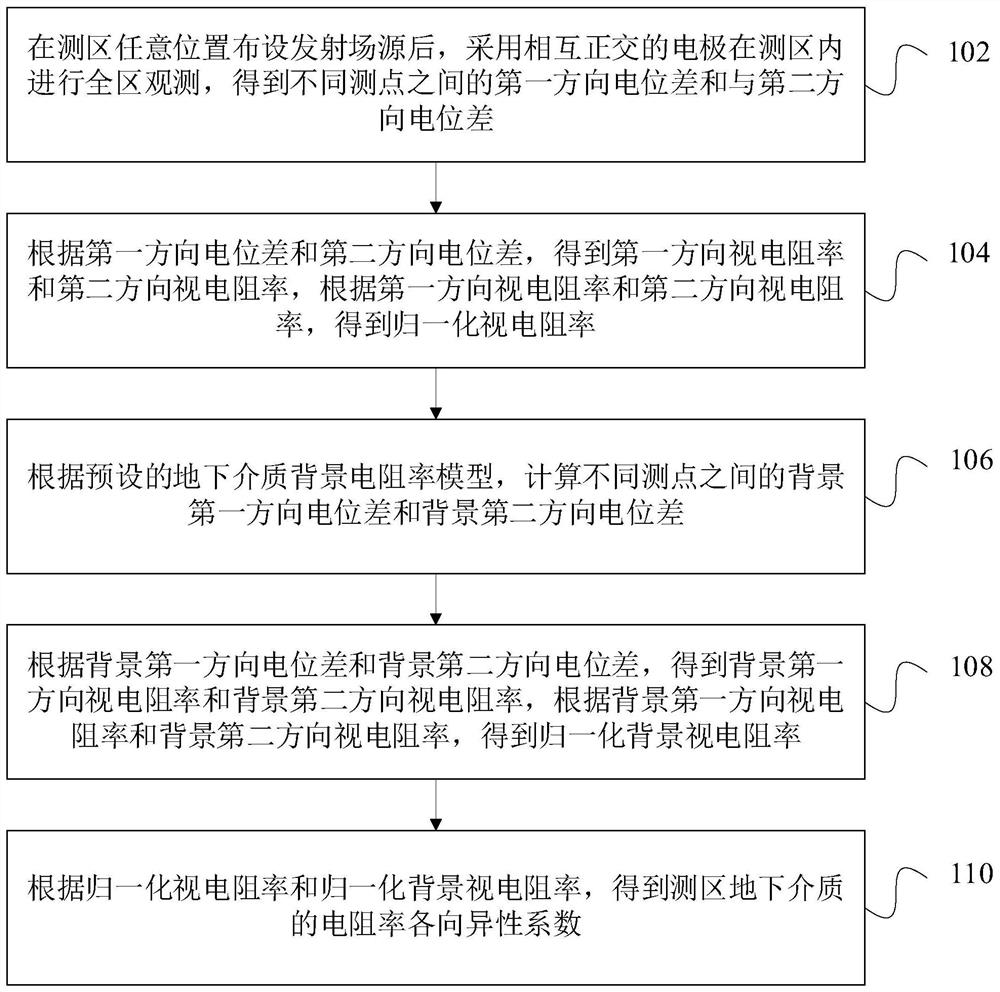

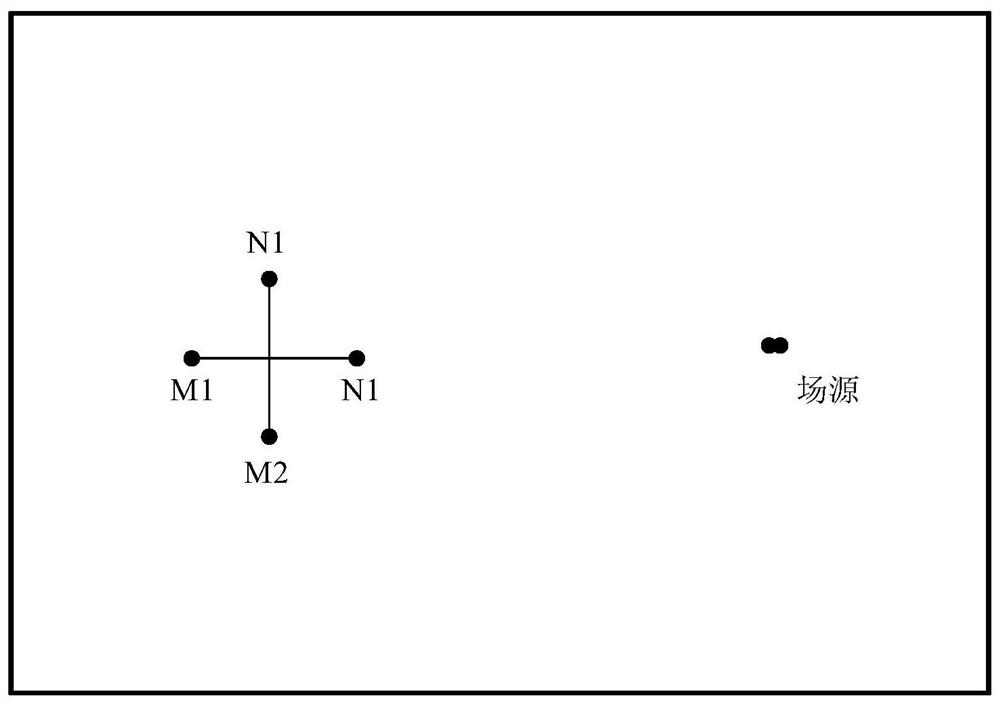

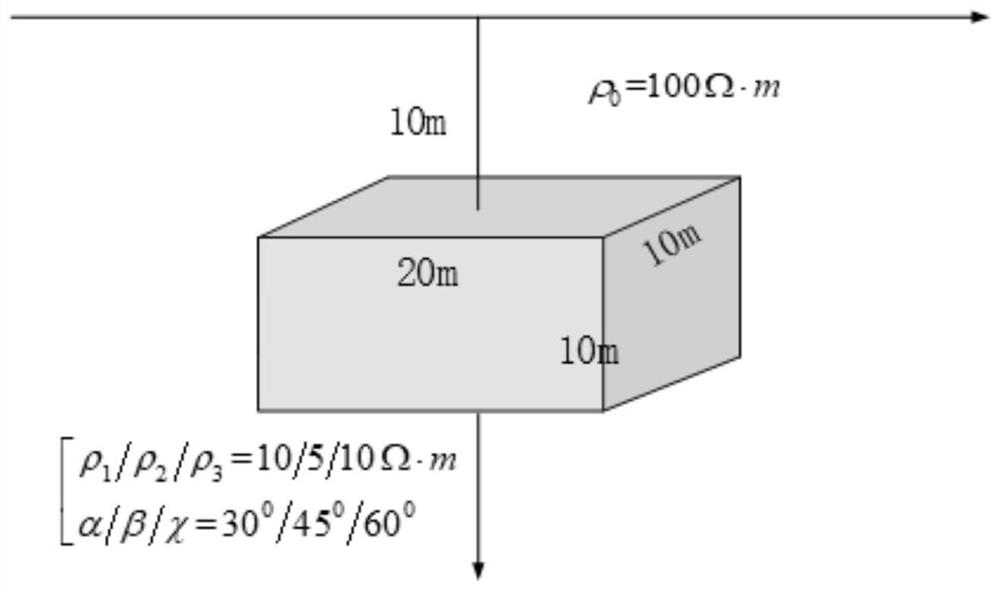

Method and device for acquiring electric anisotropy of underground media based on direct current method

PendingCN113917541AOffset errorAvoid cumbersome calculationsMaterial resistanceElectric/magnetic detectionPotential differenceElectric resistivity

The invention relates to a method and device for acquiring electrical anisotropy of underground media based on a direct current method. The method comprises the following steps: after arranging an emission field source at any position of a measurement area, carrying out whole-area observation in the measurement area by adopting mutually orthogonal electrodes to obtain mutually orthogonal potential differences in two directions between different measurement points, calculating apparent resistivity according to the potential differences, calculating normalized apparent resistivity, calculating background apparent resistivity according to a selected background resistivity model, calculating normalized background apparent resistivity, and calculating the resistivity anisotropy coefficient according to actual normalized resistivity and the normalized background apparent resistivity. According to the invention, field source arrangement is flexible and simple; by adopting the resistivity anisotropy coefficient, the influence of an apparent resistivity null line can be effectively suppressed, the projection and the shape of an underground anisotropic structure on the ground can be well reflected, tensor resistivity can be prevented from being solved, and high efficiency is obtained; and the normalized apparent resistivity is adopted, so the error of the apparent resistivity near the field source can be effectively counteracted, and precision is improved.

Owner:HUNAN UNIV OF SCI & TECH

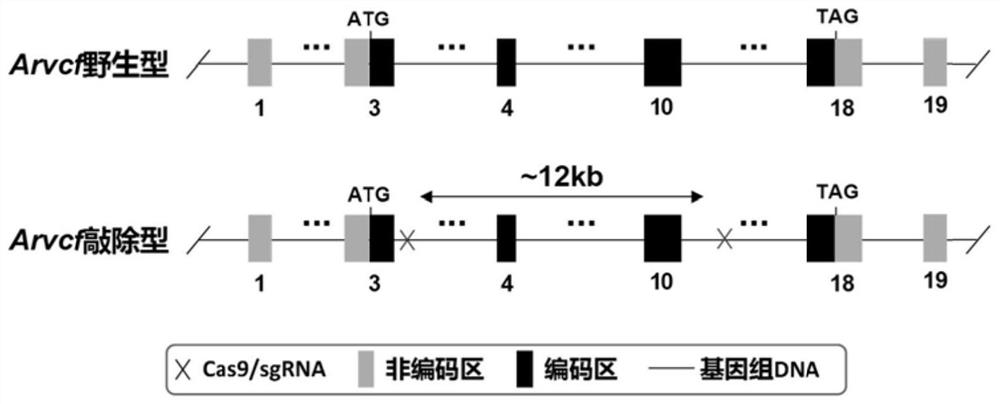

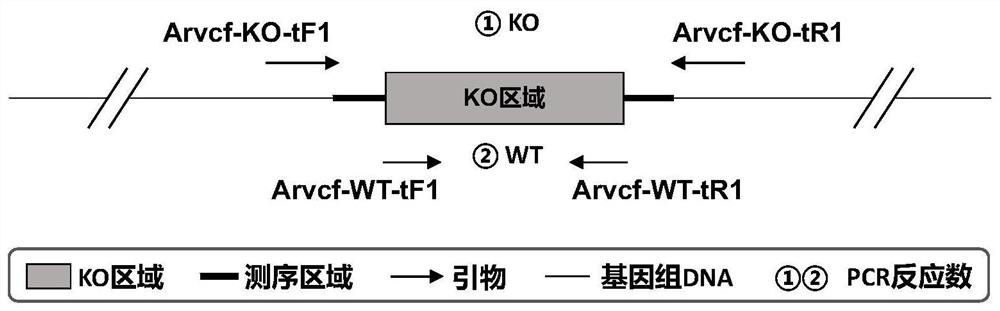

Construction method and application of Arvcf gene knockout animal model

ActiveCN112980881AHigh technical efficiencyLow costFermentationAnimals/human peptidesBiotechnologyKnockout animal

The invention relates to a method for constructing an Arvcf gene knockout mouse model and application. The mouse model is a mouse of which seven exons in an Arvcf gene are knocked out, and meanwhile, the invention discloses the method for constructing the Arvcf gene knockout mouse model. The method comprises the following steps of firstly, determining a knockout region of the gene Arvcf to be knocked out, then designing and synthesizing specific sgRNA and a corresponding primer, linearizing and purifying a constructed sgRNA / Cas9 vector, then carrying out in vitro transcription, finally injecting the sgRNA / Cas9 vector into fertilized eggs of the mouse through micro-injection, and transplanting the sgRNA / Cas9 vector into the uterus of a pseudopregnant female mouse to establish the Arvcf gene knockout mouse model. Tails of the obtained filial generation mouse are collected and subject to DNA extraction, and PCR reaction and sequencing are conducted twice by using two pairs of primers to confirm that the obtained mouse is a wild-type mouse or homozygous or heterozygous mouse of which Arvcf gene target regions are knocked out. The gene knockout mouse model can be used for researching the effect of the ARVCF in mental diseases in which the ARVCF is involved.

Owner:ZHEJIANG UNIV

Titanium alloy surface high temperature oxidation resistance and wear resistance oxide gradient coat, and preparation method thereof

ActiveCN102732832BDense tissueSolve the problem of poor high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingGlow plasmaOxidation resistant

The invention relates to a titanium alloy surface high temperature oxidation resistance and wear resistance oxide gradient coat. According to the coat, the surface of the coat is an oxide film layer comprising Al2O3, Cr2O3 and NiO2, wherein the thickness is 4-6 mum; the middle of the coat is an Al-Cr-Ni alloy layer, wherein the thickness is 2-4 mum; and an Al-Cr-Ni-Ti interdiffusion layer is arranged between the coat and a substrate to achieve metallurgical collection, wherein the thickness of the Al-Cr-Ni-Ti interdiffusion layer is 4-6 mum. According to the present invention, the oxide film layer on the surface of the coat has characteristics of compactness, flatness and strong antioxidant capacity; the Al-Cr-Ni alloy layer in the middle of the coat has characteristics of compact structure and high hardness so as to greatly improve wear resistance of the titanium alloy; the metallurgical collection of the coat and the substrate is achieved through the Al-Cr-Ni-Ti interdiffusion layer, and the combination strength is high; and a double glow plasma surface metallurgy technology is adopted to prepare the Al-Cr-Ni alloy layer on the surface of the titanium alloy, and then a plasma oxygen permeation treatment is performed on the Al-Cr-Ni alloy layer to prepare the high temperature oxidation resistance and wear resistance coat, such that the efficiency is high, and the process is simple.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com