Fibre-optical with high wide-band and manufacturing method thereof

A manufacturing method and high-bandwidth technology, applied in manufacturing tools, glass manufacturing equipment, optics, etc., can solve the problems of increasing processing time and increasing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

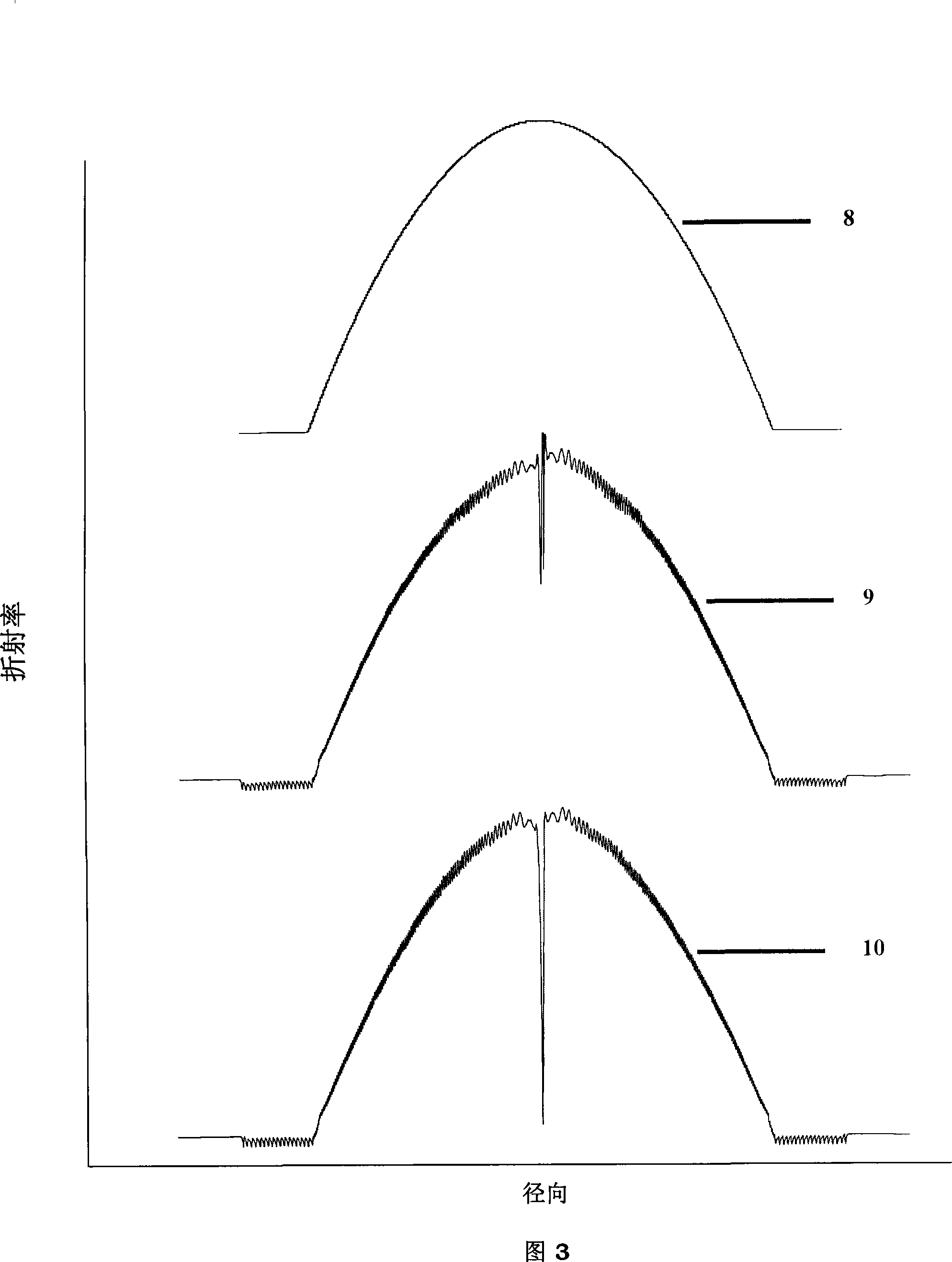

[0123] The preform is deposited according to conventional methods to achieve the target alpha value between 1.9 and 2 as described in the prior art, and the corresponding refractive index profile is measured by a profiler. The alpha value of this core layer was 1.96, which was close to the target value, but the core layer drawn from the mandrel had a very low bandwidth of 123 and 225 MHz·Km at wavelengths of 850 and 1300 nm, respectively.

example 2

[0125] The method according to the invention analyzes the above profile to determine the cause of the low bandwidth at target α. The dotted line of the layered delay diagram 16 of the mandrel above has great fluctuations with the ideal delay diagram 15, as shown in FIG. 6 . Based on this deviation from the ideal delay, correction factors for each layer are calculated using empirical equations. This correction factor is used to vary the dopant flux per layer to deposit a second core rod. The refractive index of this mandrel was measured to give an alpha value of 1.955. The profile was analyzed hierarchically according to the method of the present invention previously used to check for local variations. In Fig. 18, the time delay along the radial dotted line has been nearly reduced, as shown in Fig. 7. Comparing the time delay diagram 18 of the second mandrel with the time delay diagram 16 of Example 1, it is obvious that the difference between the ideal delay diagram and the...

example 3

[0127] Based on the correction factor obtained for the second mandrel, the layered dopant flux was further corrected to make another mandrel. The mandrel has an alpha value of 1.96, and a layered delay map is obtained from this example. This delay graph is very close to the ideal graph, except because of the center and edges of the central depression. After the core rod is stretched, its bandwidth is 750MHz·Km and 880MHz·Km at wavelengths of 850nm and 1300nm respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com