Three dimensional measurement method of irregular curved surface

A technology of three-dimensional measurement and curved surface, which is applied in the field of three-dimensional measurement of irregular curved surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

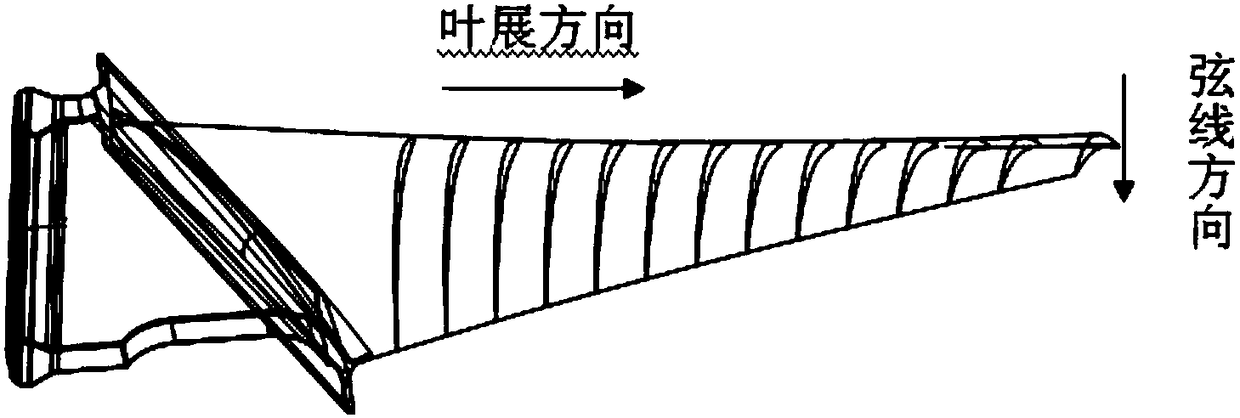

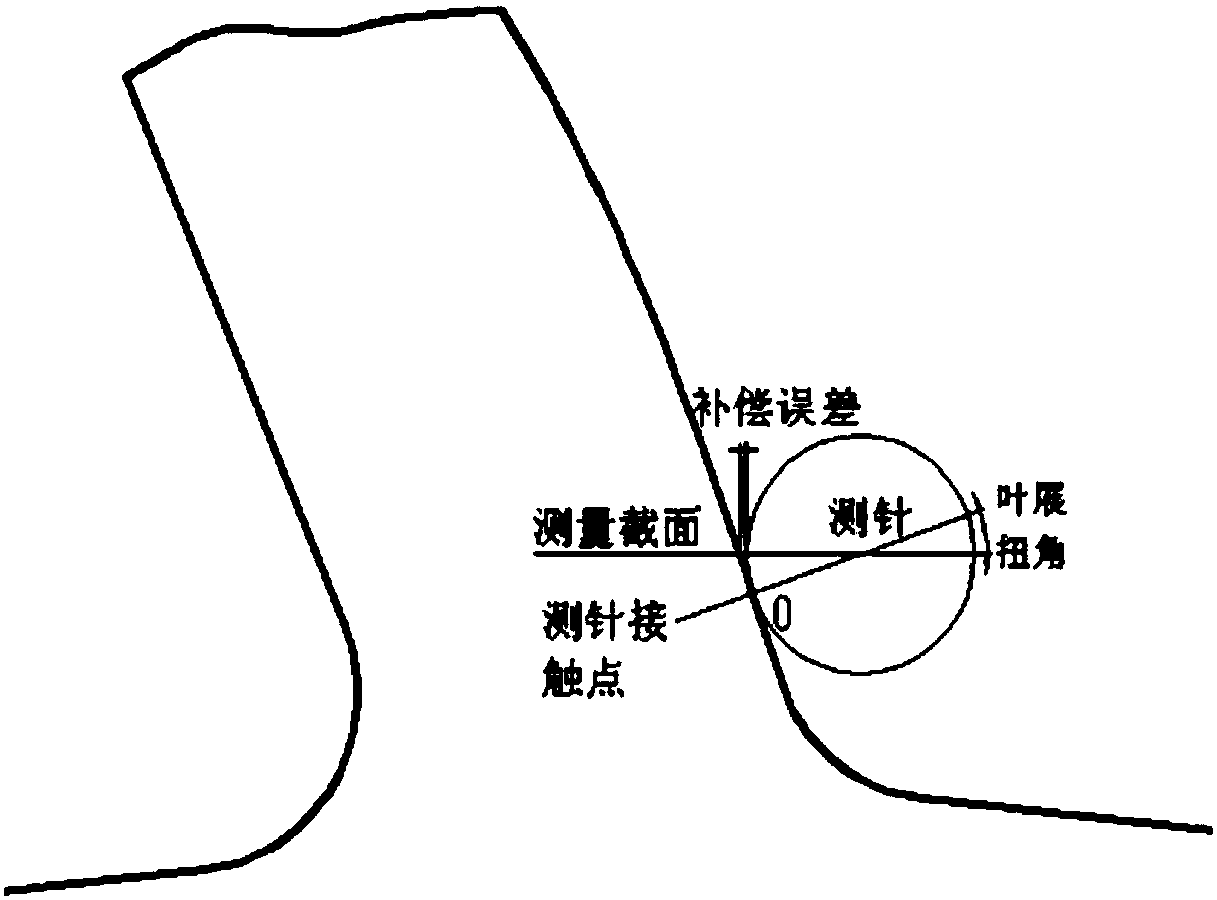

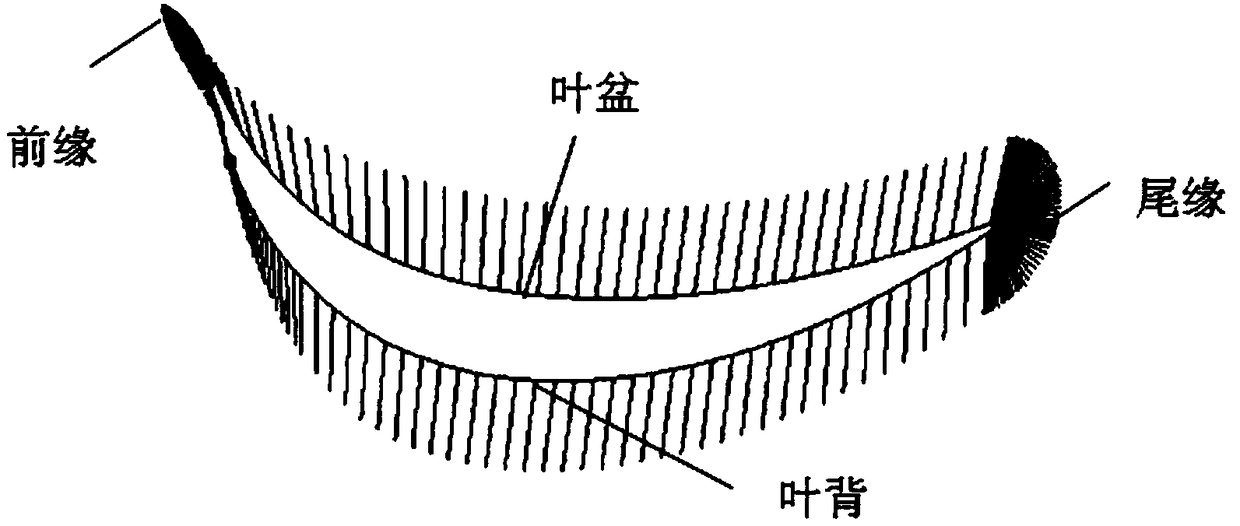

[0024] The invention provides a three-dimensional measurement method for irregular curved surfaces, which is characterized in that: the measurement method first plans the measurement track of the center of the stylus according to the specified position on the MBD model of the part according to the specified section position required by the drawing, and generates a measurement route, and then compensate the measured data according to the model vector, the compensated data points are at the specified section height, and finally connect the section points into a curve to evaluate the blade parameters; technical plan points:

[0025] The MBD model is a part expression method with full three-dimensional features, which provides the only theoretical detection data for the measured feature points, lines and surfaces. Define the required measurement position according to the shape of the blade of the part and the specified section of the design, so that it meets the requirements of the...

Embodiment 2

[0035] The invention provides a three-dimensional measurement method for irregular curved surfaces, which is characterized in that: the measurement method first plans the measurement track of the center of the stylus according to the specified position on the MBD model of the part according to the specified section position required by the drawing, and generates a measurement route, and then compensate the measured data according to the model vector, the compensated data points are at the specified section height, and finally connect the section points into a curve to evaluate the blade parameters; technical plan points:

[0036] The MBD model is a part expression method with full three-dimensional features, which provides the only theoretical detection data for the measured feature points, lines and surfaces. Define the required measurement position according to the shape of the blade of the part and the specified section of the design, so that it meets the requirements of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com