Patents

Literature

248results about How to "Not easy to store" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

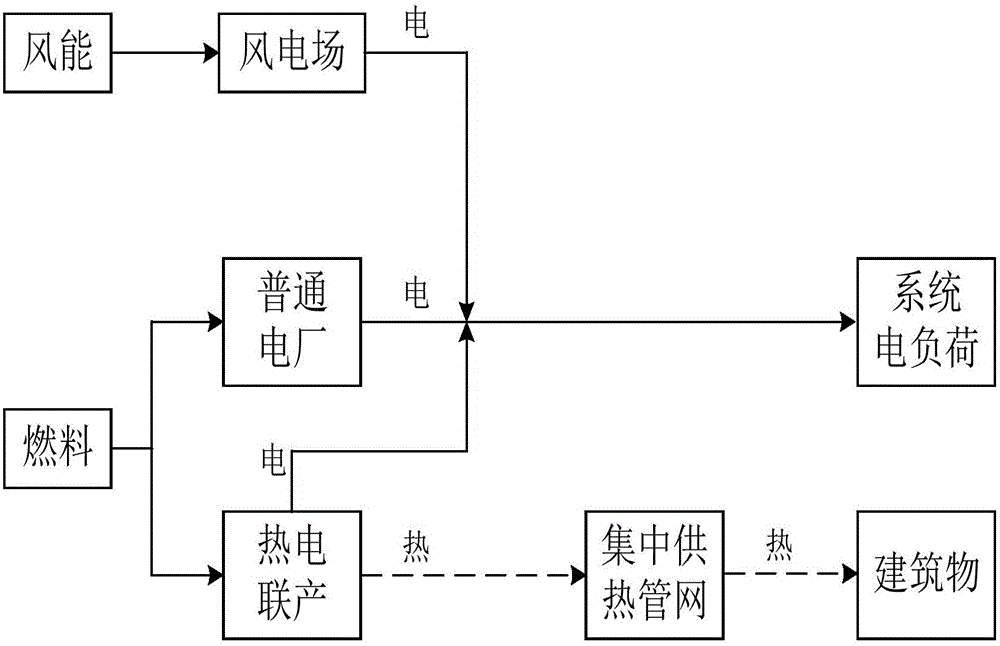

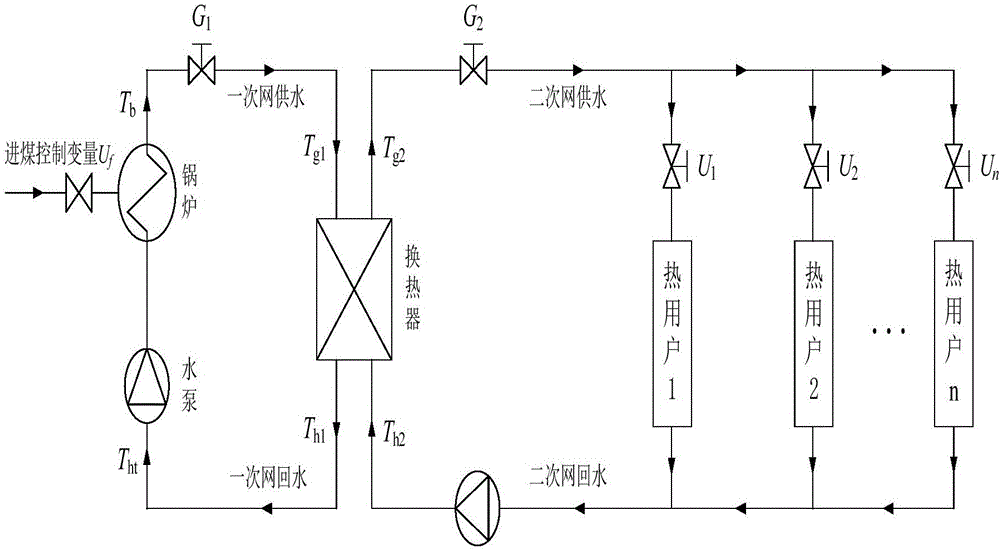

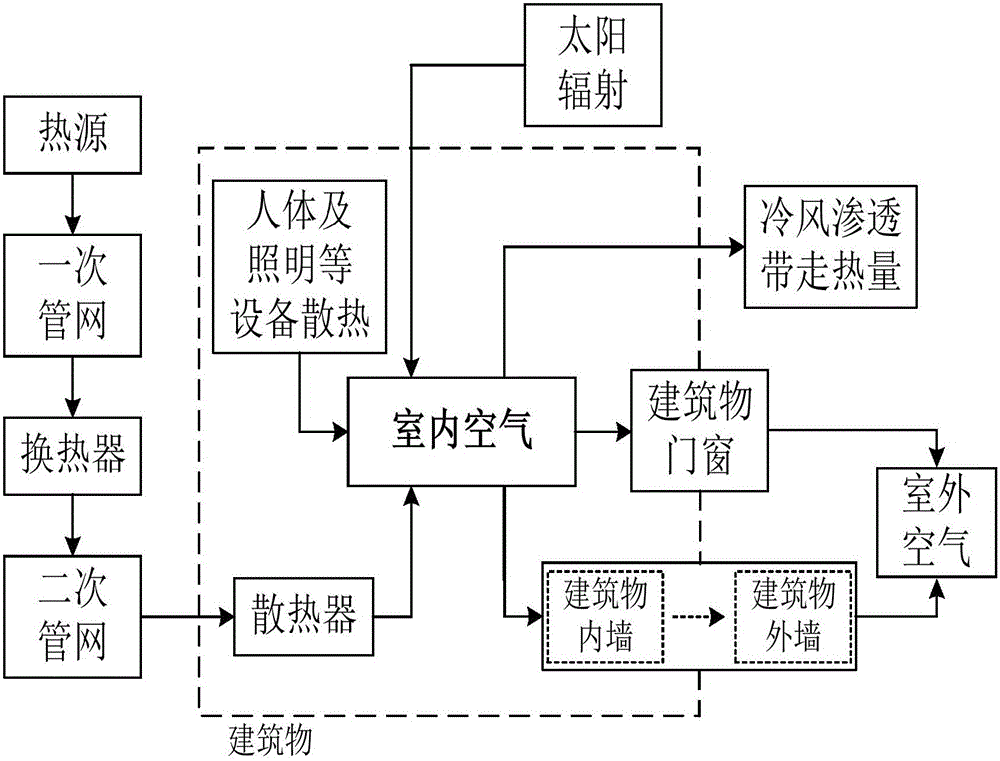

Thermoelectric combined system scheduling method for achieving wind power absorption based on energy storage of centralized heat supply pipe network and buildings

InactiveCN105807633AImprove peak shaving flexibilityAchieve interactionSimulator controlThermal energyElectric power system

The invention discloses a thermoelectric combined system scheduling method for achieving wind power absorption based on energy storage of a centralized heat supply pipe network and buildings.The thermoelectric combined system scheduling method includes the following steps that S1, a wind power absorption thinking based on energy storage characteristics of the centralized heat supply pipe network of a thermoelectric combined system and the buildings is proposed; S2, thermal dynamic characteristics of the centralized heat supply pipe network and the buildings are analyzed; S3, a thermoelectric combined system optimization scheduling model is established based on the energy storage characteristics of the centralized heat supply pipe network and the buildings; S4, coordinative optimization is conducted on hour-by-hour power supply of energy supply bodies of a power system and a thermodynamic system in the thermoelectric combined system according to the solution to obtain an optimal control strategy for achieving in-regional wind power absorption and cross-regional wind power coordinative absorption.The method can change an original local wind power absorption mode, integrates the characteristics that electric energy is easy to transmit and is not easy to store and heat energy is easy to store but is not easy to transmit and achieves the purposes of wide-area interaction between wind power and thermal power and wide-area wind power absorption.

Owner:DALIAN UNIV OF TECH

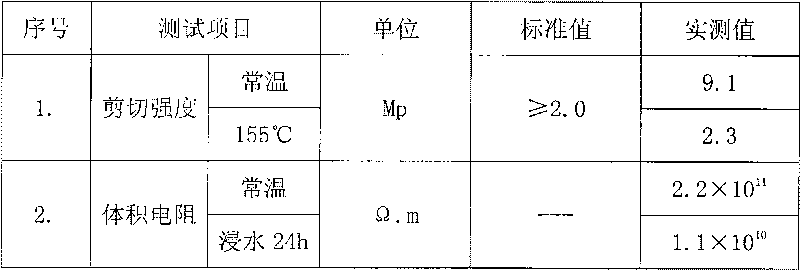

Adhesive, preparation method thereof, and epoxy glass fabric prepared from adhesive

ActiveCN101696349AFair priceNot easy to storePlastic/resin/waxes insulatorsFibre treatmentImidePolymer science

The invention discloses an adhesive, a preparation method thereof, and an epoxy glass fabric prepared from the adhesive. The adhesive comprises the following components in percentage by mass: 10 to 11 percent of tung oil, 2 to 3 percent of maleic anhydride, 38 to 40 percent of methylbenzene, 5 to 6 percent of bismaleimide resin, 17 to 19 percent of 601 epoxy, 11 to 12 percent of novolac epoxy and 15 to 16 percent of filler. The improvement on the formula design of the adhesive and the preparation method is carried out by adopting a plurality of technical means, and alkyd resin is mainly modified to improve the heat resistance; and a toughening agent, a cosolvent and a latent curing agent are selected, and all the selected component materials have moderate cost and are easy to purchase. The epoxy glass fabric product produced by the method is difficult to adhere and is easy to store in the storing process, does not fall off rubber powder or pollute environment, and has no influence on the health of operators.

Owner:CHINA XIDIAN GRP CO LTD

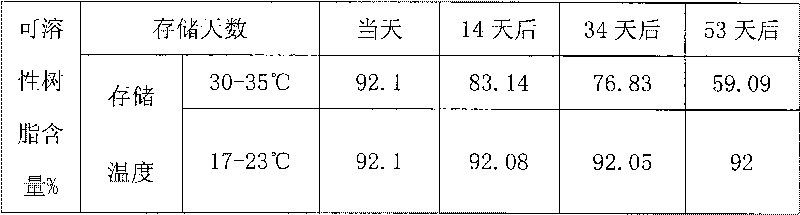

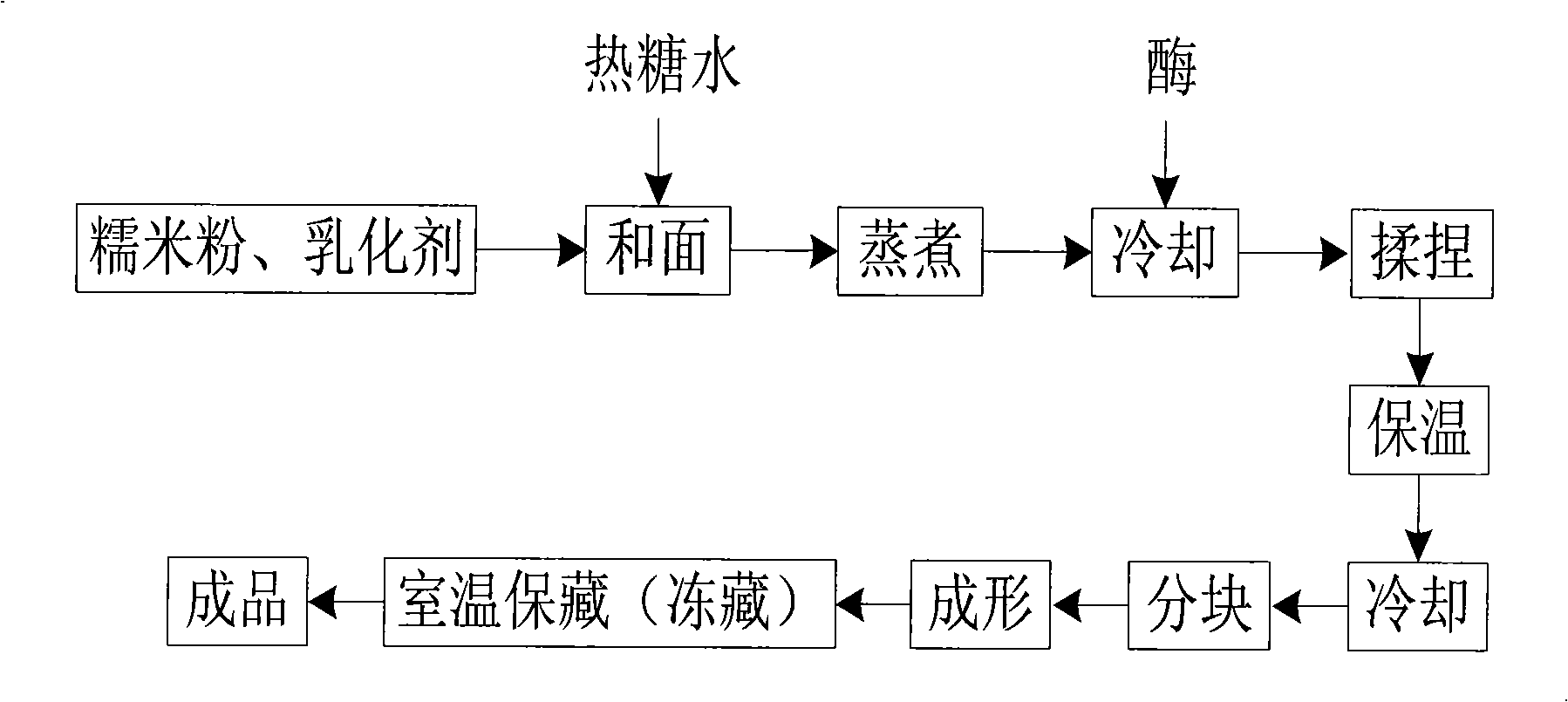

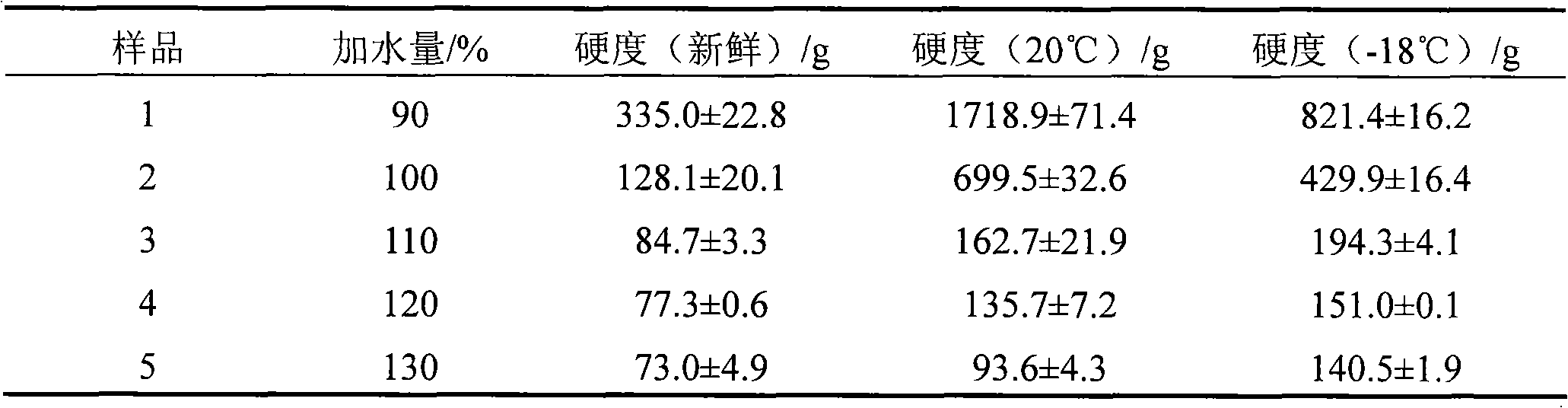

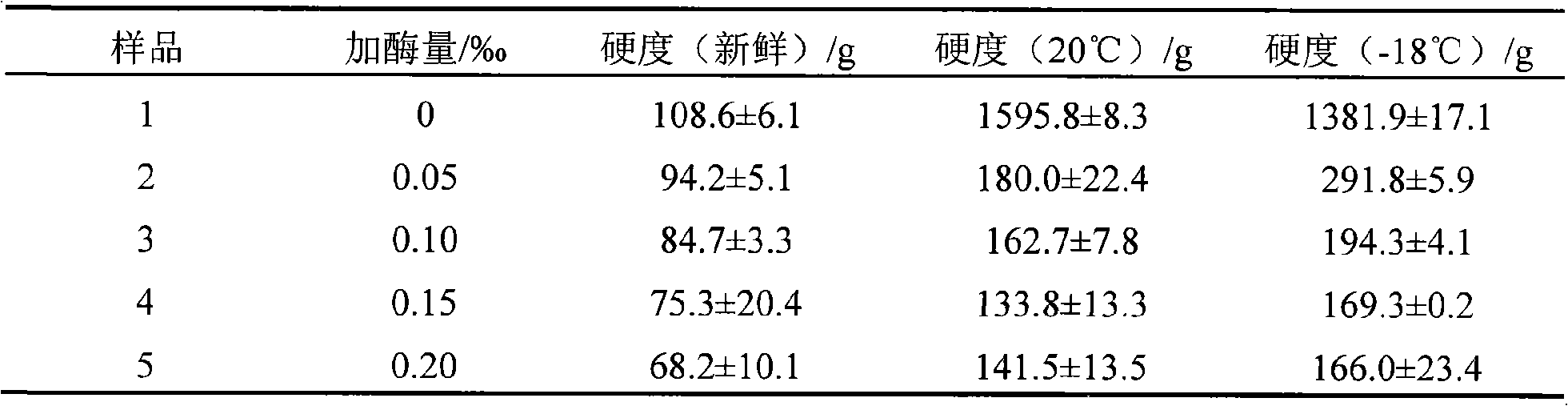

Antiaging method for rice product-mashu

InactiveCN101406311AExtended shelf lifeEasy to storeFood preservationBakery product preservationBiotechnologyFood additive

The invention provides an anti-aging method for deep-fried glutinous rice cake stuffed with bean paste, which belongs to the technical field of agro-product processing and food additive. The invention mainly relates to preparation of an anti-aging compound emulsifying agent and anti-aging application of the compound emulsifying agent and an enzyme agent to the deep-fried glutinous rice cake stuffed with bean paste. In the invention, glutinous rice flour is taken as a main raw material, certain amount of the compound emulsifying agent, the enzyme agent, sugar and water are added, and the product, namely deep-fried glutinous rice cake stuffed with bean paste is produced by stewing and forming processes. The compound emulsifying agent is mainly produced by an extrusion method. A plurality of powder emulsifying agents with good anti-aging effect is evenly distributed on the surface of starch particles. The compound emulsifying agent with good anti-aging effect is obtained by controlling extrusion parameters. The optimal adding amount of the compound emulsifying agent is between 0.2 and 3 percent. The enzyme agent mainly adopts maltose amylase with the adding amount of between 0.02 and 0.15g / kg. The adding amount of the water and the sugar is respectively 110 to 120 percent and 20 to 50 percent of the weight of the glutinous rice flour. Through adding the compound emulsifying agent and the enzyme agent, the deep-fried glutinous rice cake stuffed with bean paste has good anti-aging function, and ensures that the guarantee period is more than 60 months.

Owner:JIANGNAN UNIV

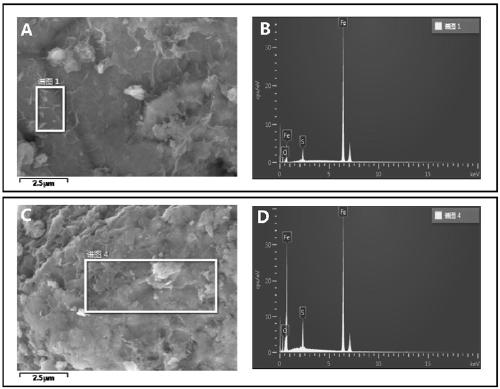

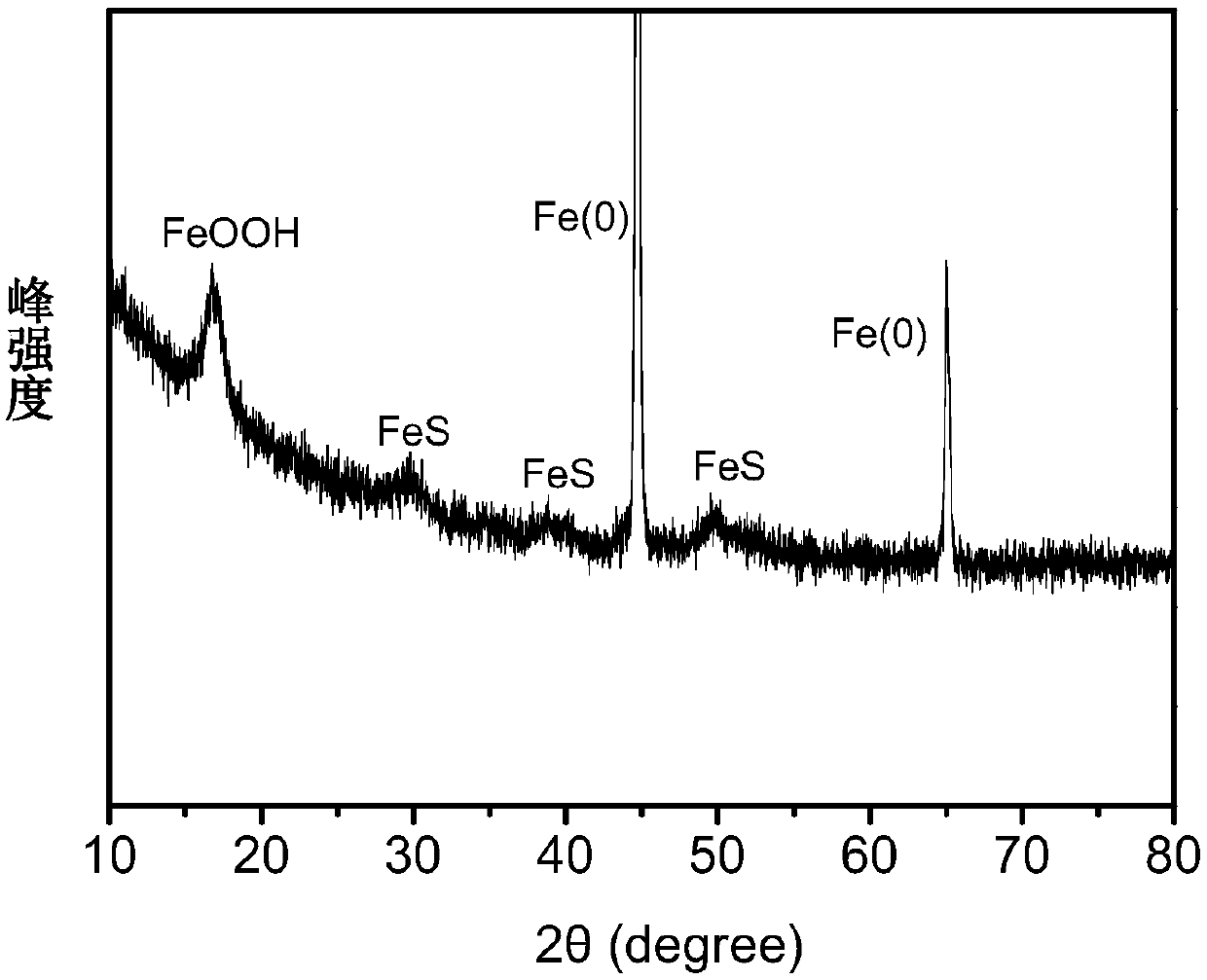

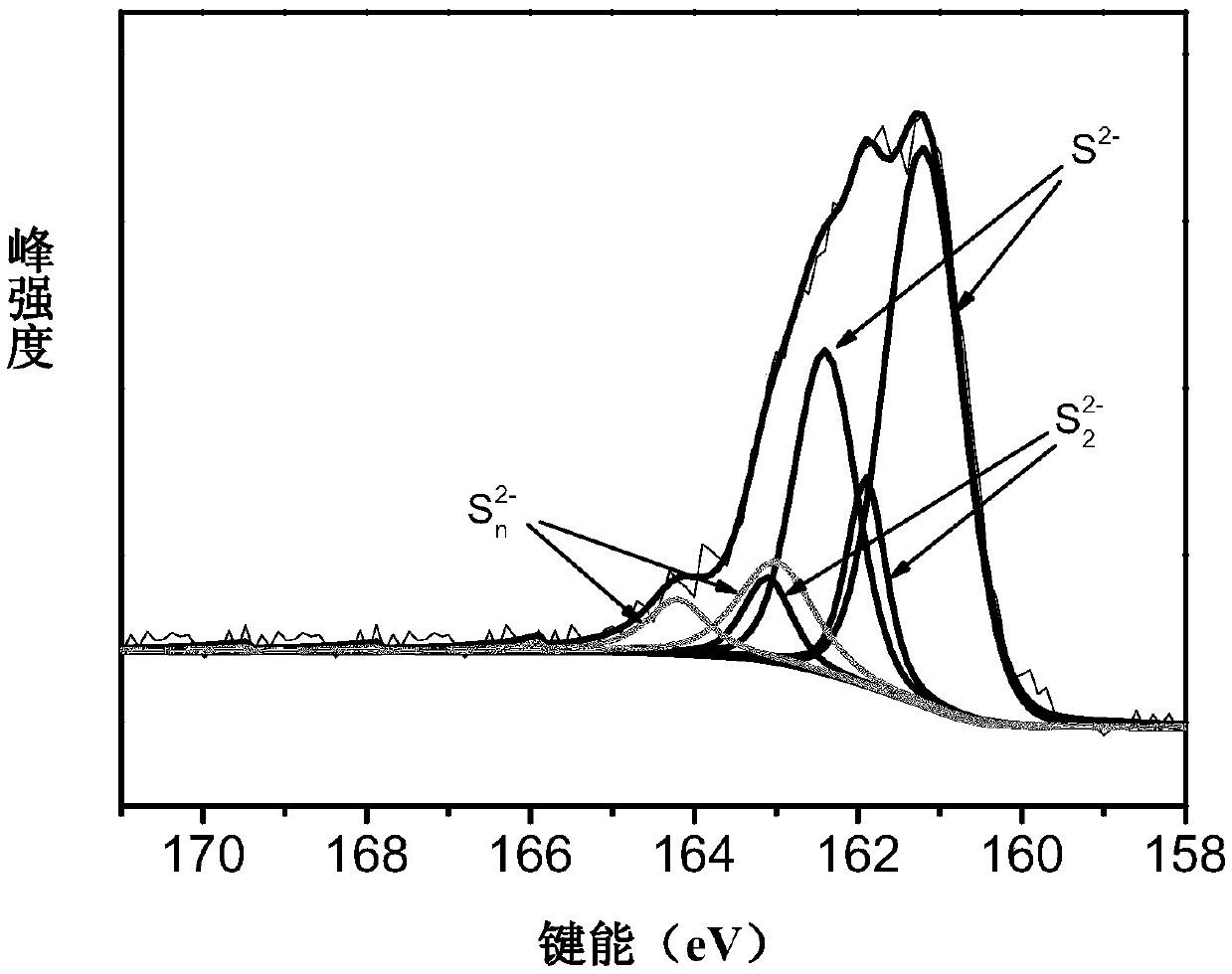

Preparation method of zero-valent iron sulfide and application thereof

ActiveCN109607635ALess energy consumptionSimple and efficient operationWater contaminantsWater/sewage treatmentHeavy metalsAqueous solution

The invention discloses a preparation method of zero-valent iron sulfide and application thereof. The preparation method comprises the steps that under the ambient temperature condition, zero-valent iron and simple-substance powdered sulfur are mixed to be subjected to a reaction in a water solution to obtain zero-valent iron sulfide. According to the method, zero-valent iron and simple-substancepowdered sulfur are mixed to be subjected to the reaction in the water solution, little energy is consumed, operation is easy and convenient, the preparation time is relatively short, the preparationcost is low, and the obtained zero-valent iron sulfide has the high removal efficiency for heavy metal and organic contaminants.

Owner:ZHEJIANG UNIV OF TECH

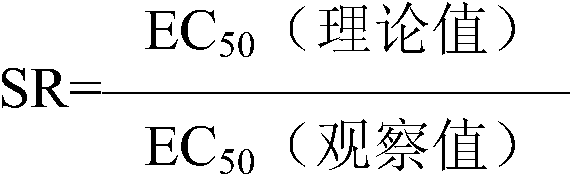

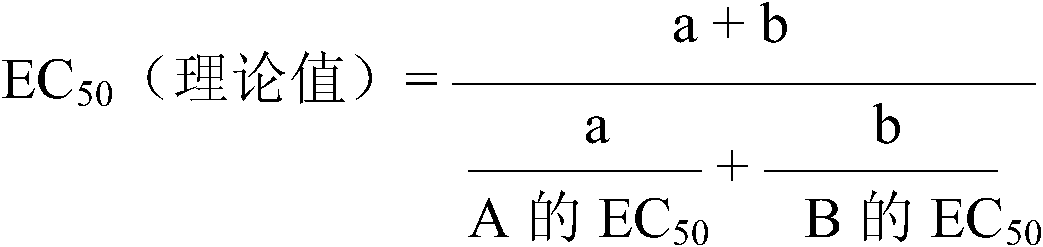

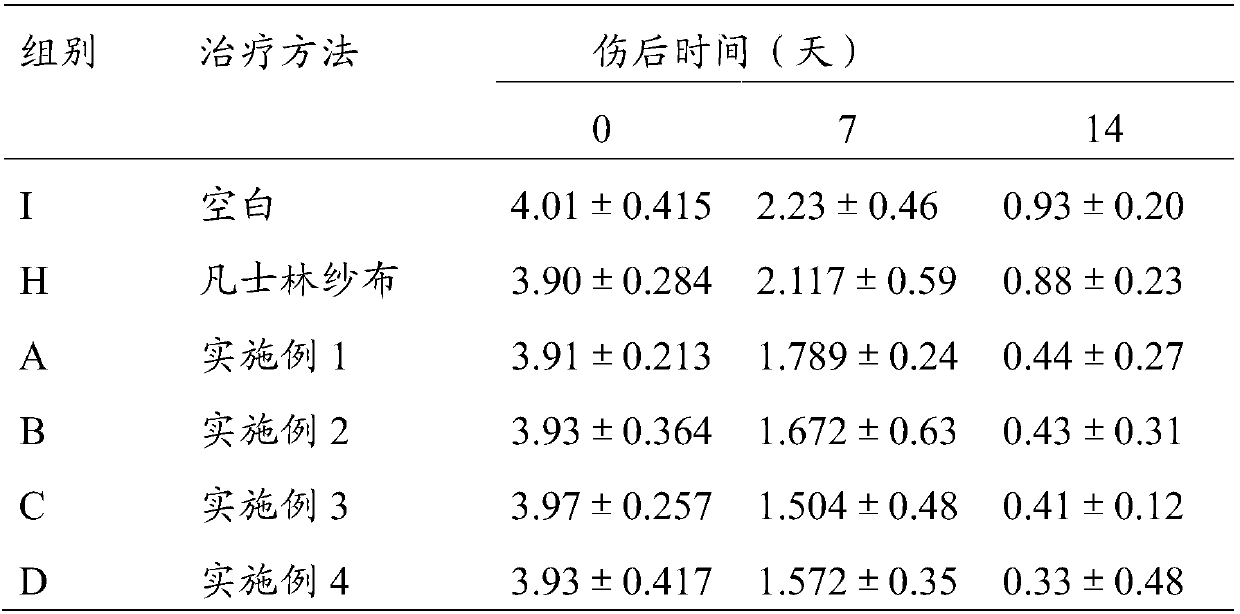

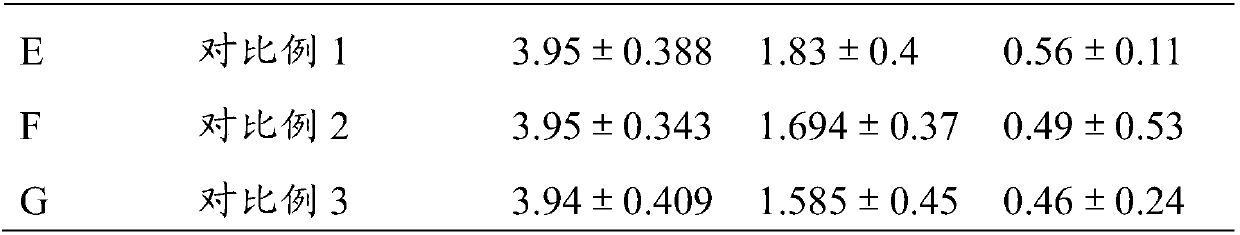

Fungicide combination containing polyoxin

The invention discloses a fungicide combination containing polyoxin, which is a fungicide combination containing active component A and active component B, the polyoxin is selected as the active component A, the active component B is selected from any of the following fungicides: ethirimol, 2-cyan-3-amino-3-ethyl aminoacrylate, bromothalonil, zineb, chlorothalonil and dithianon, and moreover, the ratio of the active component A to the active component B in part by weight is 32:1 to 1:64. The fungicide combination can prevent and control a variety of crop diseases, has a remarkable synergistic effect, broadens the antifungal spectrum, and has high activity on downy mildew, epidemic diseases, anthracnose, powdery mildew, leaf spot, fusarium head blight, rice blast and other diseases; and moreover, the dosage of pesticide is reduced, the residue of pesticide on crops is decreased, and thereby the environmental pollution is reduced.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

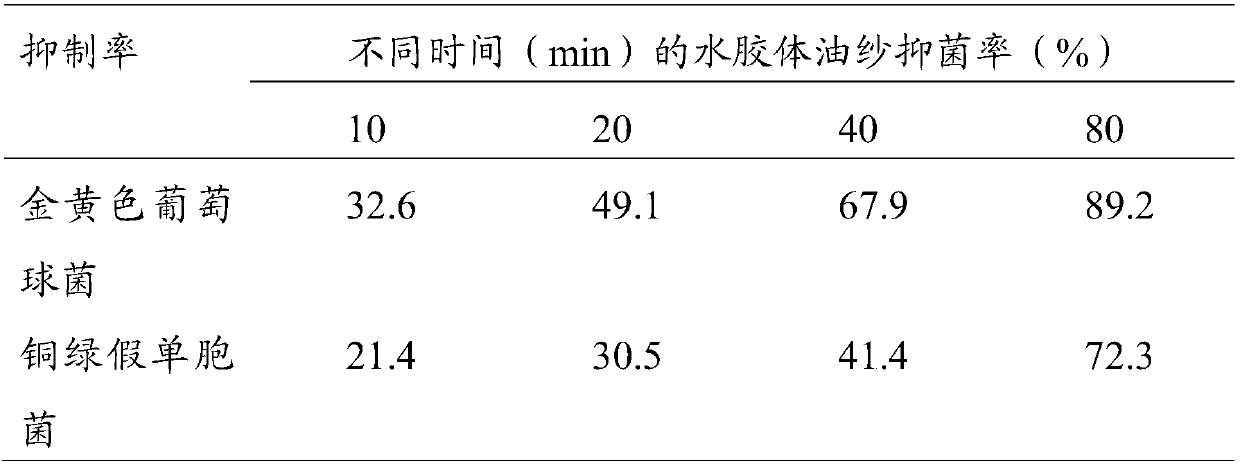

Hydrocolloid oil yarn and preparation method thereof

ActiveCN108126232AGood air permeabilityGood compatibilityAbsorbent padsBandagesParaffin waxSodium carboxymethylcellulose

The invention relates to a hydrocolloid oil yarn. The hydrocolloid oil yarn comprises a base material and a hydrocolloid ingredient, wherein the base material is netty polyester fiber; the hydrocolloid ingredient comprises the following raw materials in parts by weight: 8 to 10 parts of thermoplastic elastomers, 16 to 30 parts of sodium carboxymethylcellulose, 1 to 5 parts of growth factor microspheres, 1 to 5 parts of chitosan, 100 to 200 parts of liquid paraffin, 30 to 40 parts of Vaseline and 5 to 10 parts of wool fat. The content of grown factors inside the grown factor microspheres is 0.01wt% to 0.03wt%.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

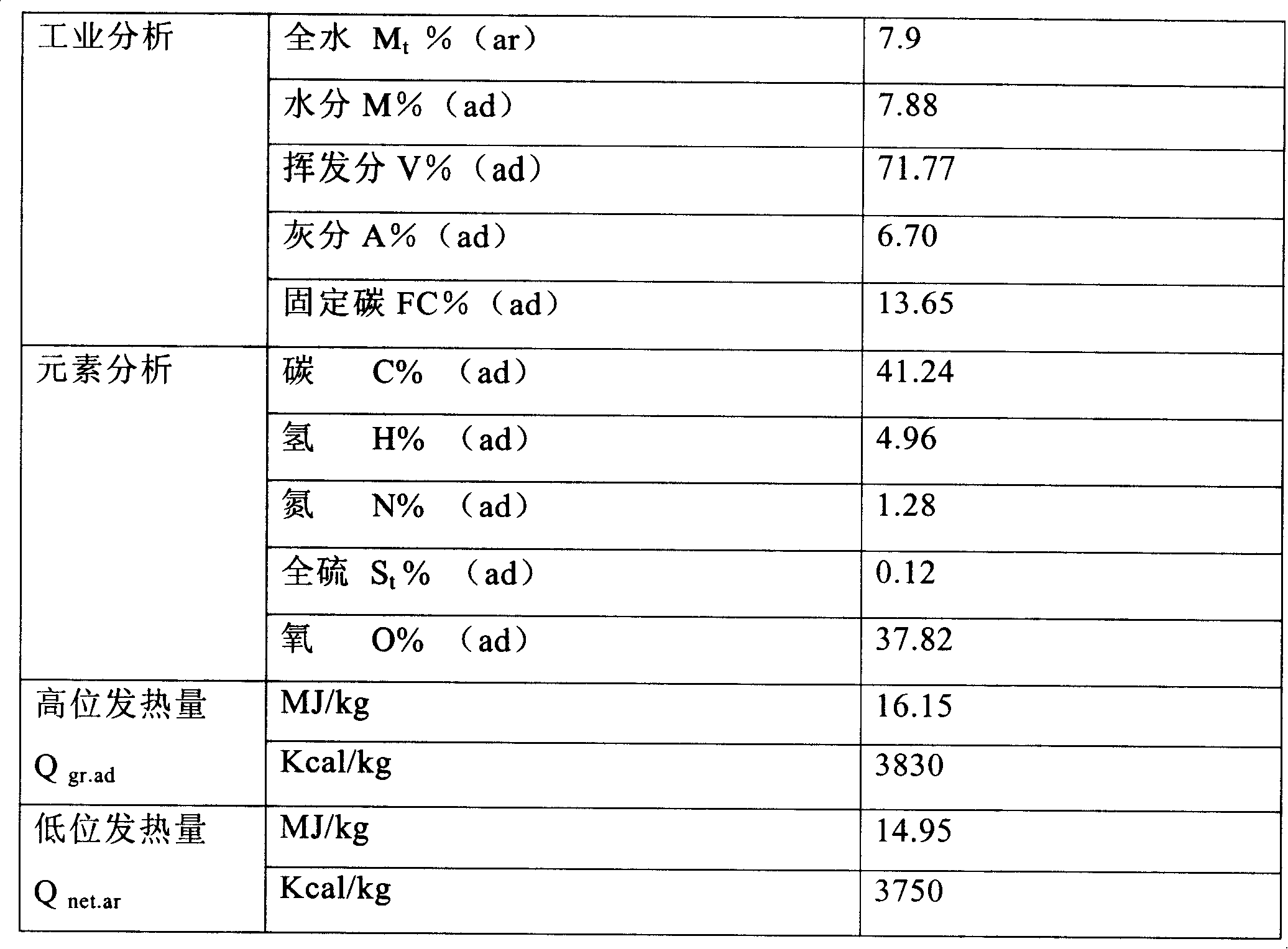

Organic matter fuel and its preparation method and application

InactiveCN101191090ASolve processingSolve the reuse problemBiofuelsSolid fuelsOil and greaseOrganic matter

The invention discloses an organic matter fuel, in particular a biomass fuel and the preparation method and the application thereof. The organic matter fuel provided by the invention is mainly made of raw materials comprising binding agent and organic matter waste materials or mineral fuel, wherein, the binding agent is produced by removing the non-edible waste of the waste food, then the waste food being steamed and boiled under high temperature to be disinfected, then the grease, bones, fish bones and so on being removed, and the remaining waste food residue materials being pulped. The invention solves not only the problems of the treatment and the recycle of the waste food, but also the treatment problem of the organic matter waste materials, converts the waste food and the organic matter waste materials which are harmful to the environment into the usable products which have no any pollution to the environment, and truly turns the wastes into the value.

Owner:汤广武

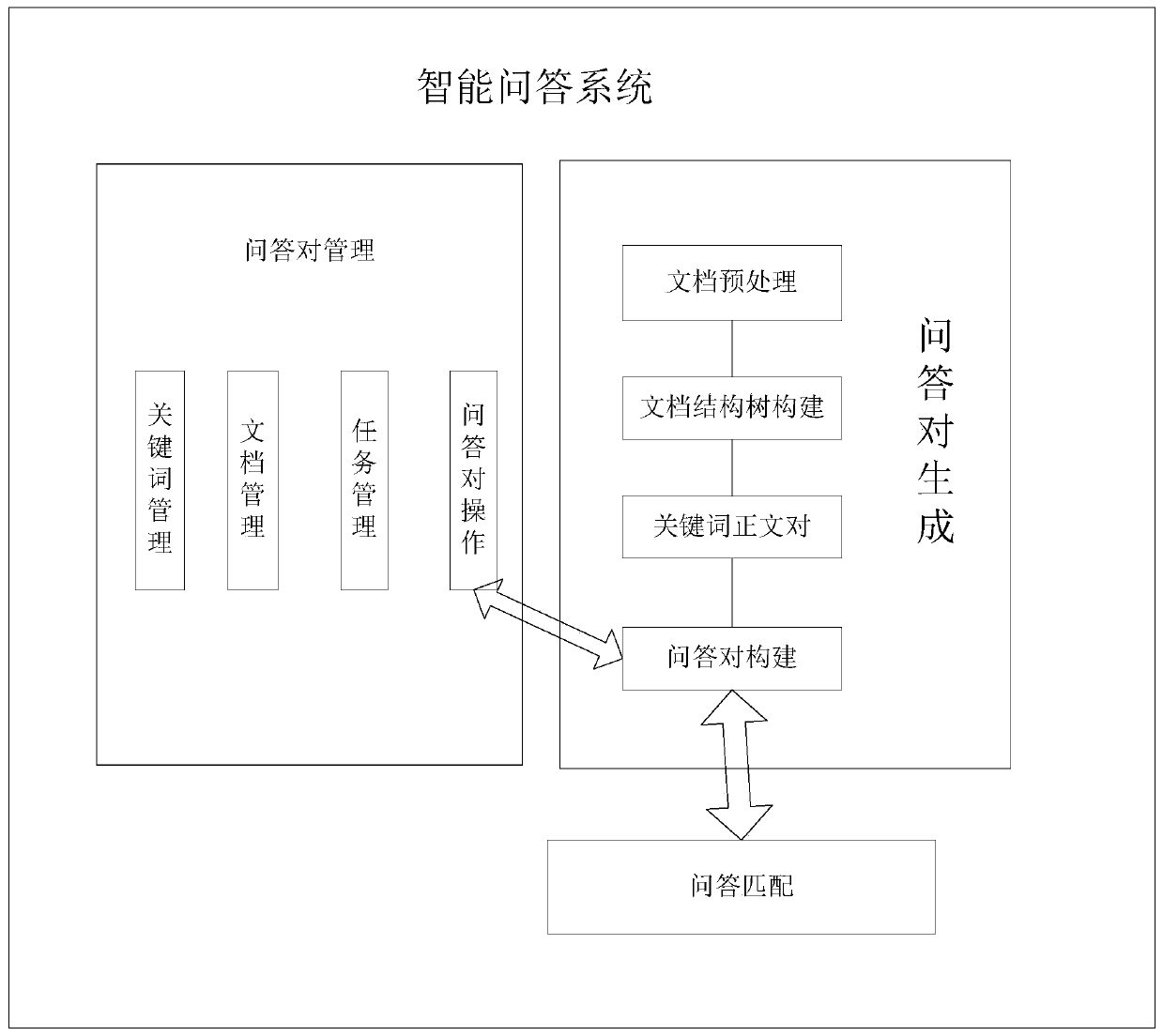

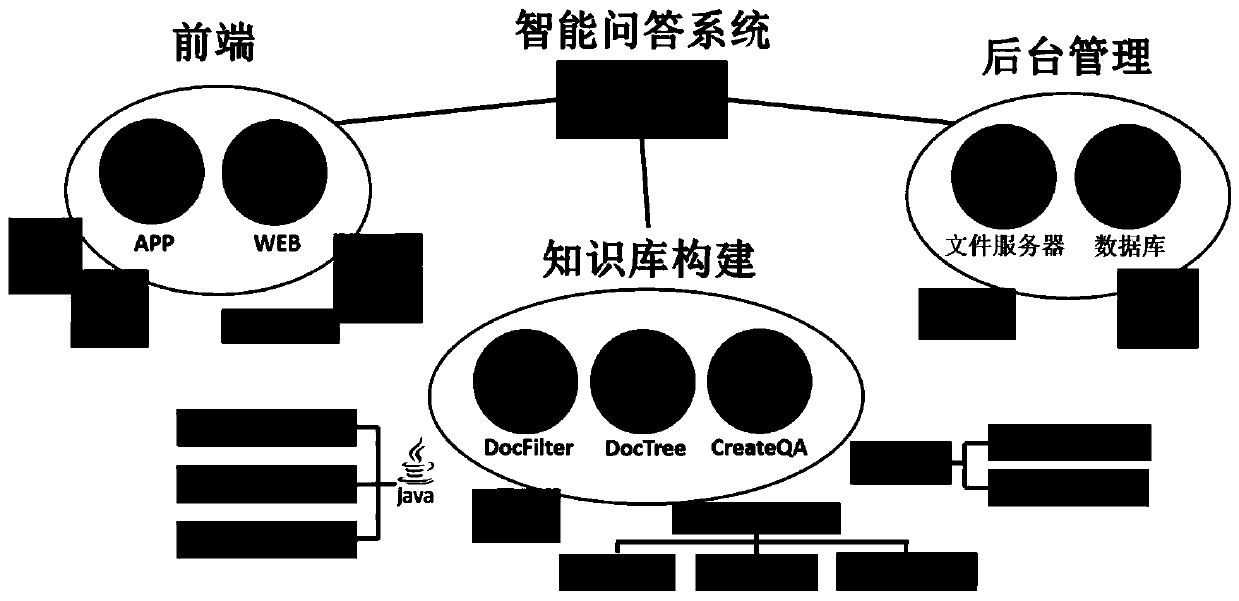

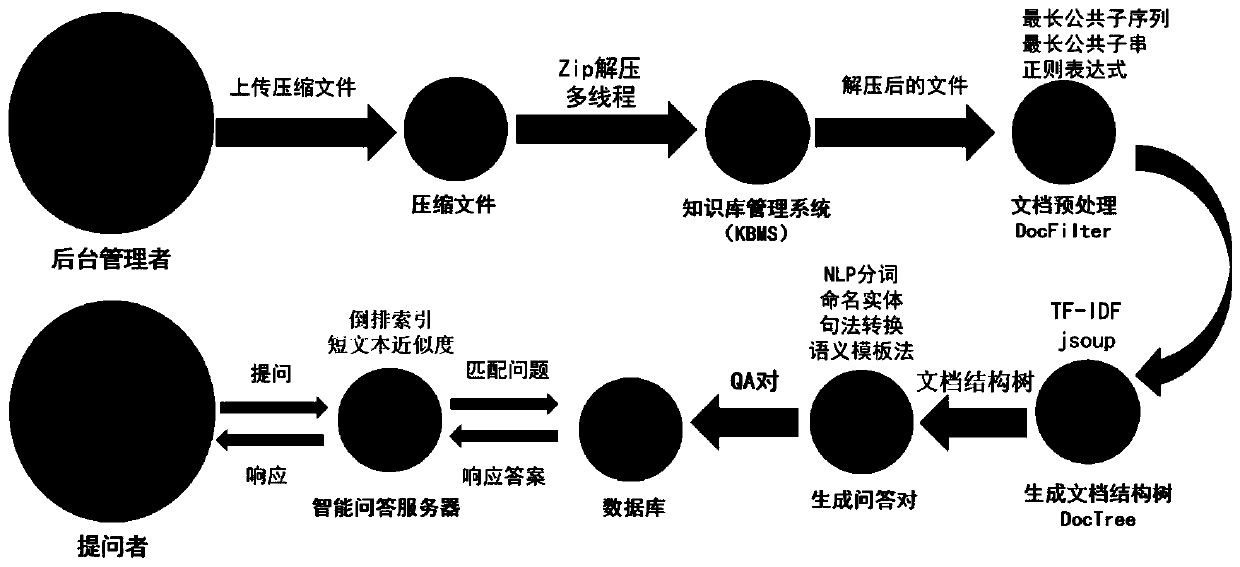

An intelligent question and answer system based on natural language processing

ActiveCN109947921AFlexible storageNot easy to expandText database indexingSpecial data processing applicationsQuestions and answersDocumentation

The invention discloses an intelligent question and answer system based on natural language processing. The system comprises a knowledge base construction module, a question and answer pair managementmodule and a question and answer matching module. The knowledge base construction module comprises a document preprocessing module, a document structure tree construction module and a question and answer pair construction module; the question and answer pair management module comprises a task management module, a document management module, a keyword management module and a question and answer pair operation module; the question and answer matching module is used for matching questions extracted by a user with the question and answer pairs created by the knowledge base generation module. As many as possible high-quality question and answer pairs are extracted from documents, the retrieval efficiency and accuracy of the knowledge base are improved.

Owner:HOHAI UNIV CHANGZHOU

Catalytic cracking process of refining biological oil

InactiveCN1432626ANot perishableNot easy to storeLiquid hydrocarbon mixture productionBio-feedstockMolecular sieveReaction temperature

The present invention relates to a catalytic cracking process of refining biological oil. In a cracking reactor, the biological oil produced through cracking various biomass as material oil is catalytically cracked to eliminate excessive oxygen to obtain high quality refined biological oil in the presence of marketed HZSM-5 zeolite molecular sieve as catalyst and at normal pressure and 200-550 deg.c temperature. The yield may reach 50%. The refined biological oil is not easy to deteriorate at normal temperature, easy to store and transport, and good in burning performance. The present invention is favorable to solve the problem of lacking energy source for human to be faced with.

Owner:EAST CHINA UNIV OF SCI & TECH

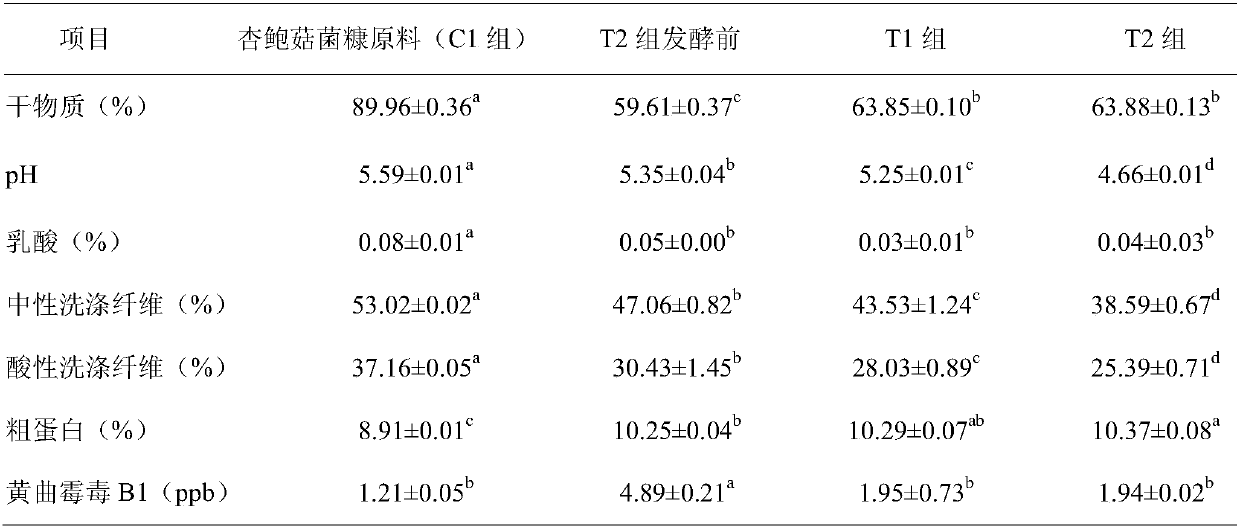

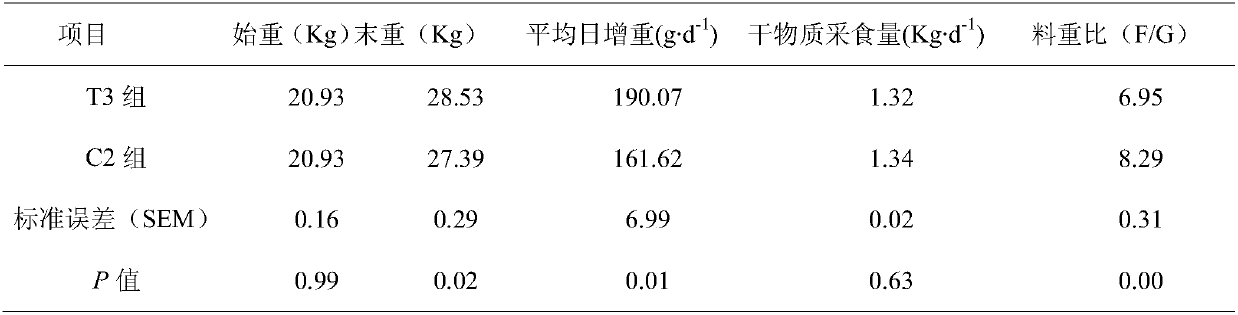

Preparation method and application of pleurotus eryngii bran fermented feed

PendingCN107897506ALow costRealize resource utilizationFood processingAnimal feeding stuffFlavorResource utilization

The invention provides a preparation method and application of pleurotus eryngii bran fermented feed. The feed is prepared from pleurotus eryngii brans, bacterial complex, brans, brown sugar and edible salt. According to the preparation method, the fermenting base material containing the bacterial complex, brans, brown sugar, edible salt and pleurotus eryngii brans is adopted, and is subjected toanaerobic fermentation to obtain bran fermenting feed. Compared with pleurotus eryngii brans, the fermented feed has the advantages that the nutritional structure and flavor are remarkably improved; since the pleurotus eryngii brans do not need drying pretreatment, the fermented feed cannot be easily mildewed or go bad, and can be stored for a long time. The method can be used for reducing the cost for transforming pleurotus eryngii brans into fermented feed along with high transformation efficiency, is favorable to realizing large-scale and resource utilization of bacterial brans, and can beapplied to mutton sheep fattening. The raw materials for preparing the pleurotus eryngii bran fermented feed is not affected by seasons, can be supplied all year; and the preparation procedure is simple, can be easily popularized and applied, and has remarkable economic benefit.

Owner:NORTHWEST A & F UNIV

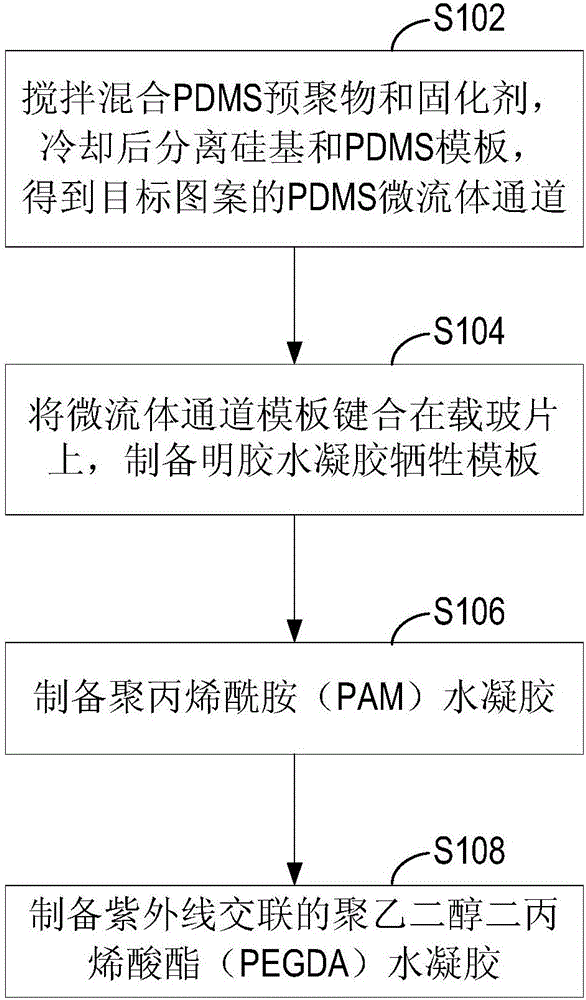

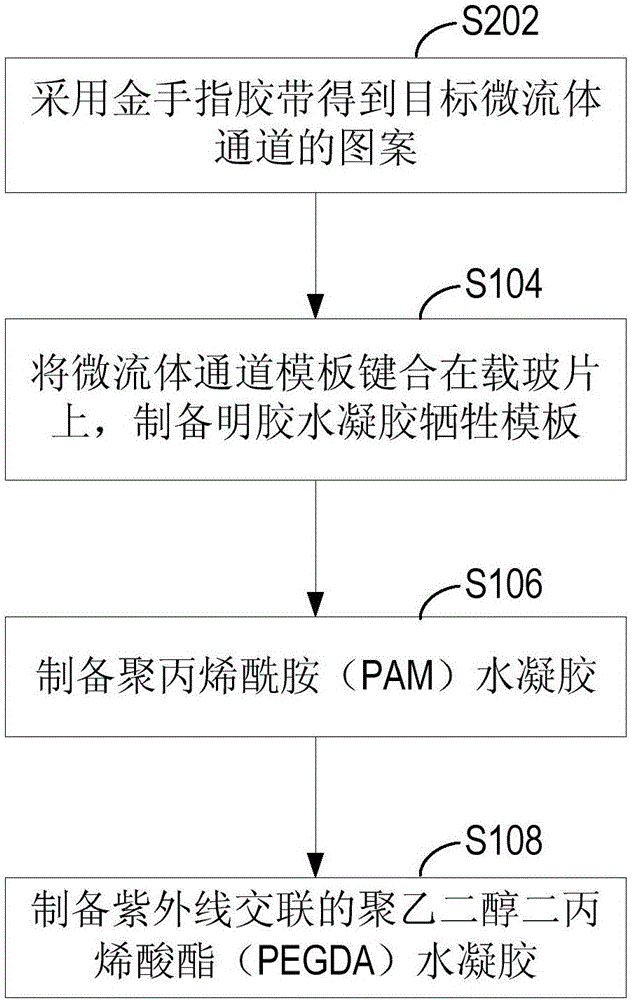

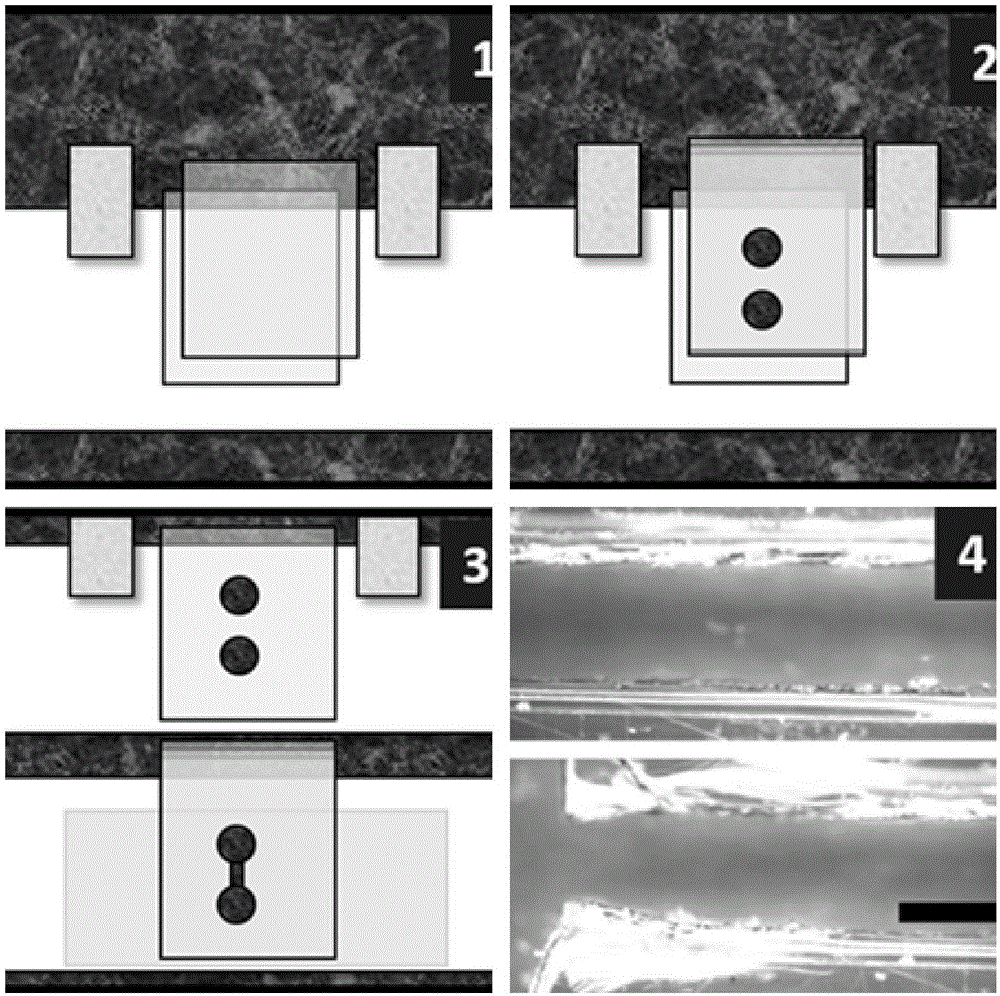

Preparation method of hydrogel with microfluid channel

The invention discloses a preparation method of hydrogel with a microfluid channel. The preparation method of the hydrogel with the microfluid channel is characterized by comprising the following steps: (1) placing a silica-based microstructure film with a targeted pattern on a substrate, uniformly mixing polydimethylsiloxane (PDMS) prepolymer and a curing agent according to the mass ratio of 10:1, pouring a solution on the substrate, curing for 1 hours at the temperature of 100 DEG C, taking out and then cooling at room temperature, and after cooling, separating a silica base from a PDMS template to obtain a PDMS microfluid channel template of the targeted pattern; (2) bonding the PDMS microfluid channel template in the step (1) on a glass slide, and preparing a gelatin and hydrogel sacrificial template; and (3) preparing polyacrylamide (PAM) hydrogel to obtain PAM hydrogel of the microfluid channel with the targeted pattern. By the preparation method of the hydrogen with the microfluid channel, the hydrogen of the microfluid channel with the targeted pattern can be prepared quickly, and the industrial manufacturing cost is low.

Owner:SHENZHEN MICRO & NANO INTEGRATED CIRCUITS & SYST RES INST

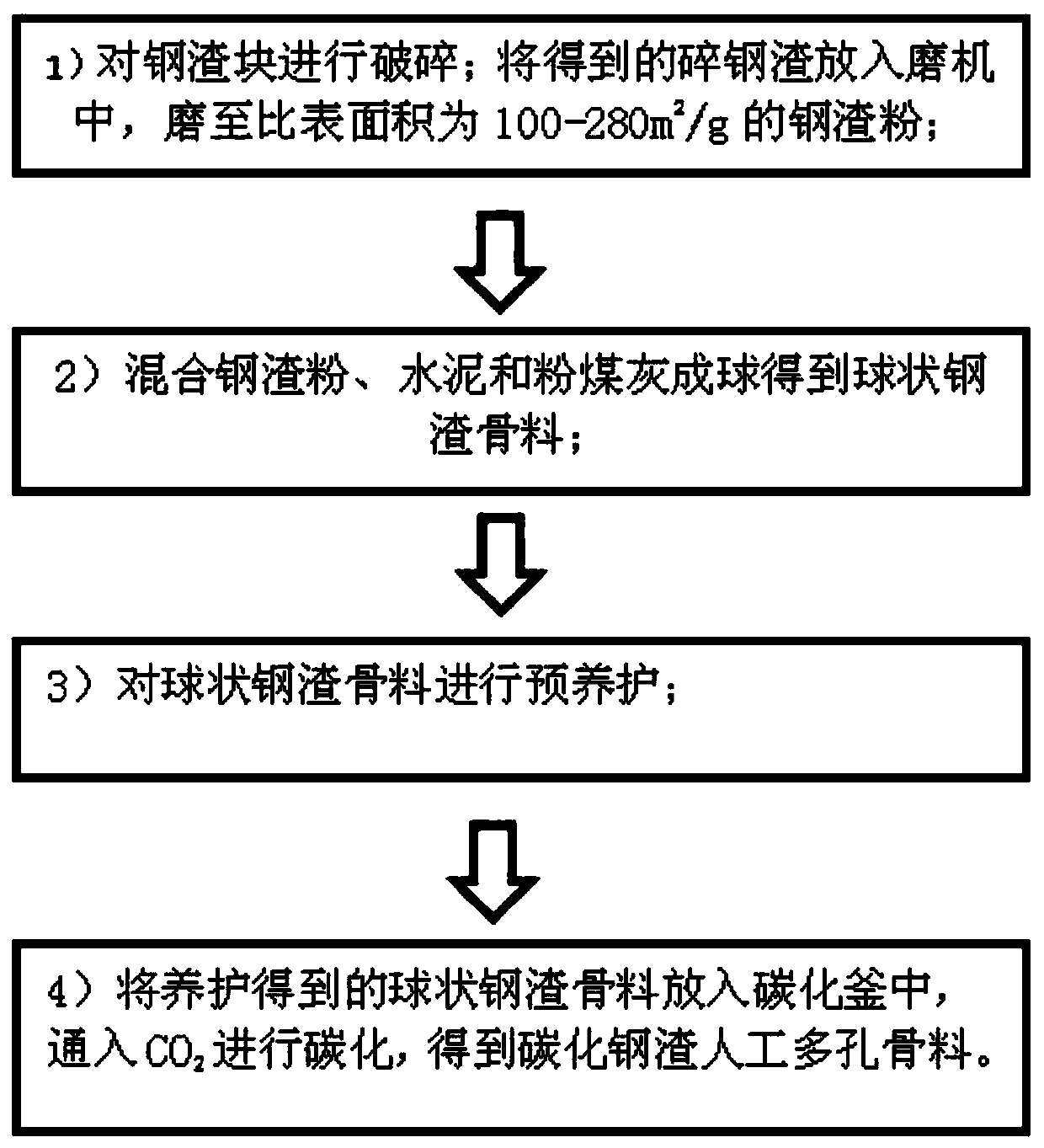

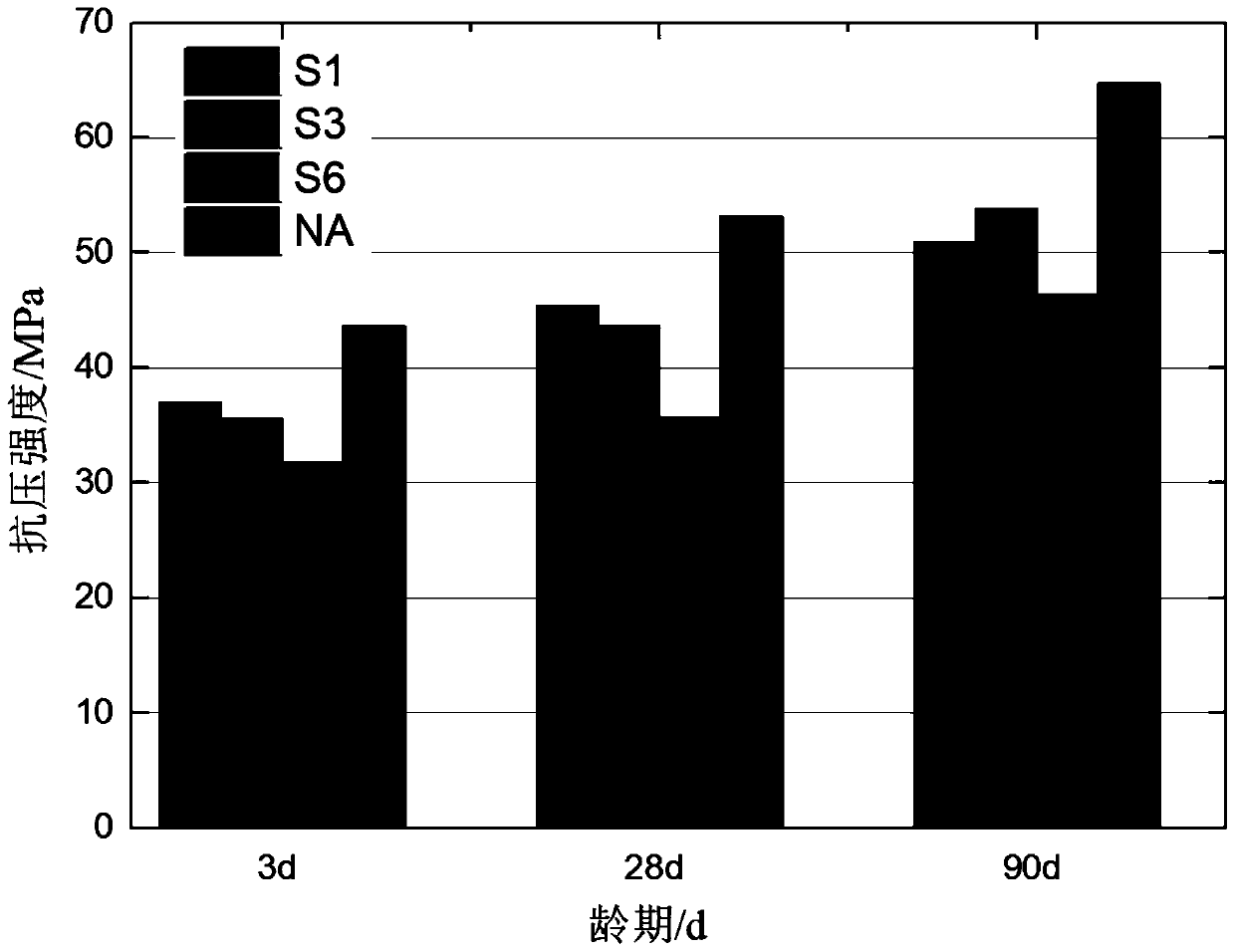

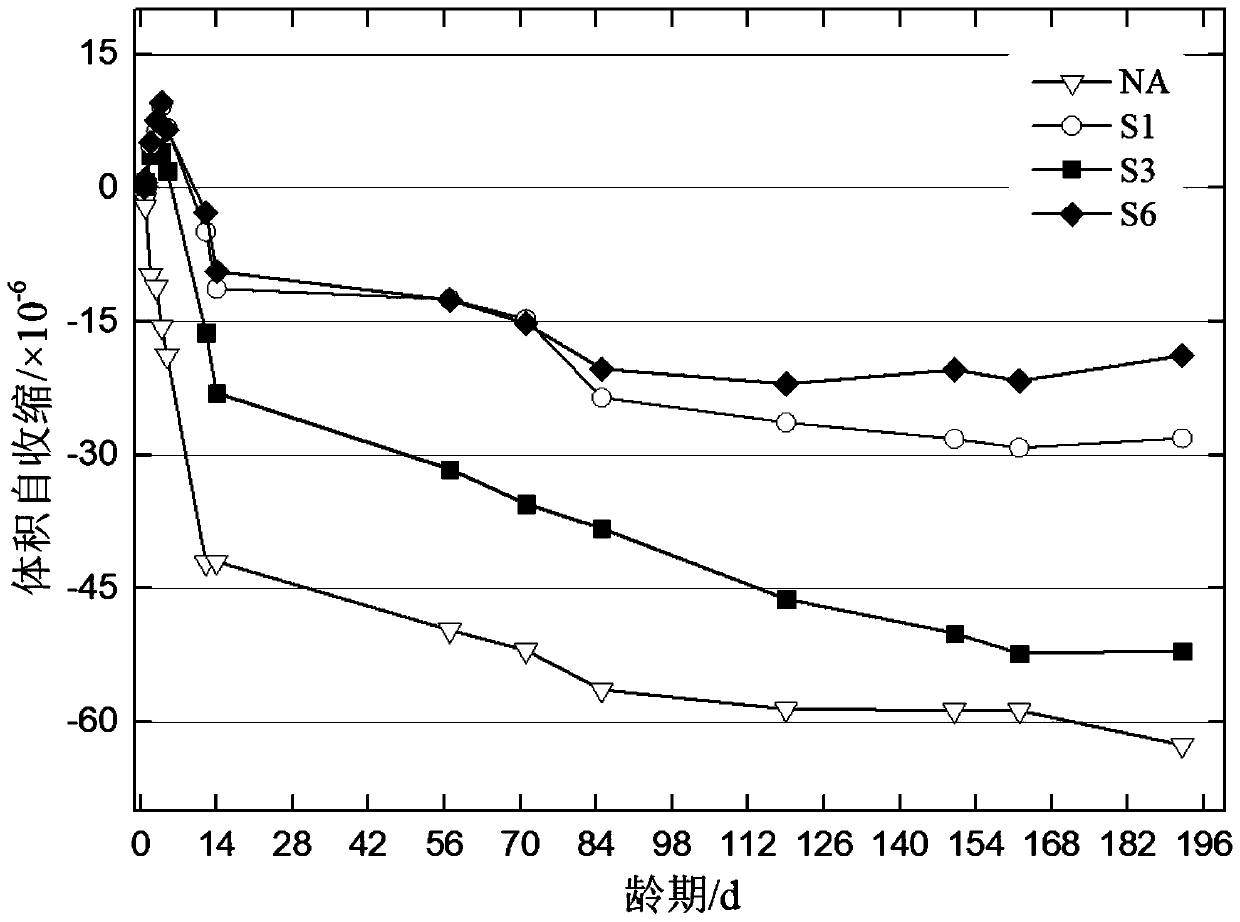

Carbonized steel slag artificial porous aggregate and preparation method thereof

The invention discloses a carbonized steel slag artificial porous aggregate and a preparation method thereof, and belongs to the technical field of industrial waste slag utilization. The preparation method comprises the following steps of preparation of steel slag powder, wherein steel slag blocks are crushed, and the obtained crushed steel slag is put into a grinding machine to be ground into the steel slag powder; preparation of a pelletized steel slag aggregate, wherein at least one of the steel slag powder, Portland cement, brick powder and pulverized fuel ash is weighed and mixed, and water is added for pelletizing to obtain the pelletized steel slag aggregate; pretreatment of the aggregate, wherein the pelletized steel slag aggregate is pre-maintained; carbonization of the steel slag aggregate, wherein the pre-maintained pelletized steel slag aggregate is put into a carbonization vessel for carbonization to obtain the carbonized steel slag artificial porous aggregate. The prepared carbonized steel slag artificial porous aggregate has the advantages of high strength, safety, stability, simple preparation processes and equipment, easy operation, low production cost, high efficiency, low carbon, environmental protection and the like. The inner maintenance can be provided for concrete while the demand of the concrete for the strength of the aggregate is met, the self-shrinkage of the concrete is reduced, and the frost resistance is improved.

Owner:苏州博纽强新材料科技有限公司

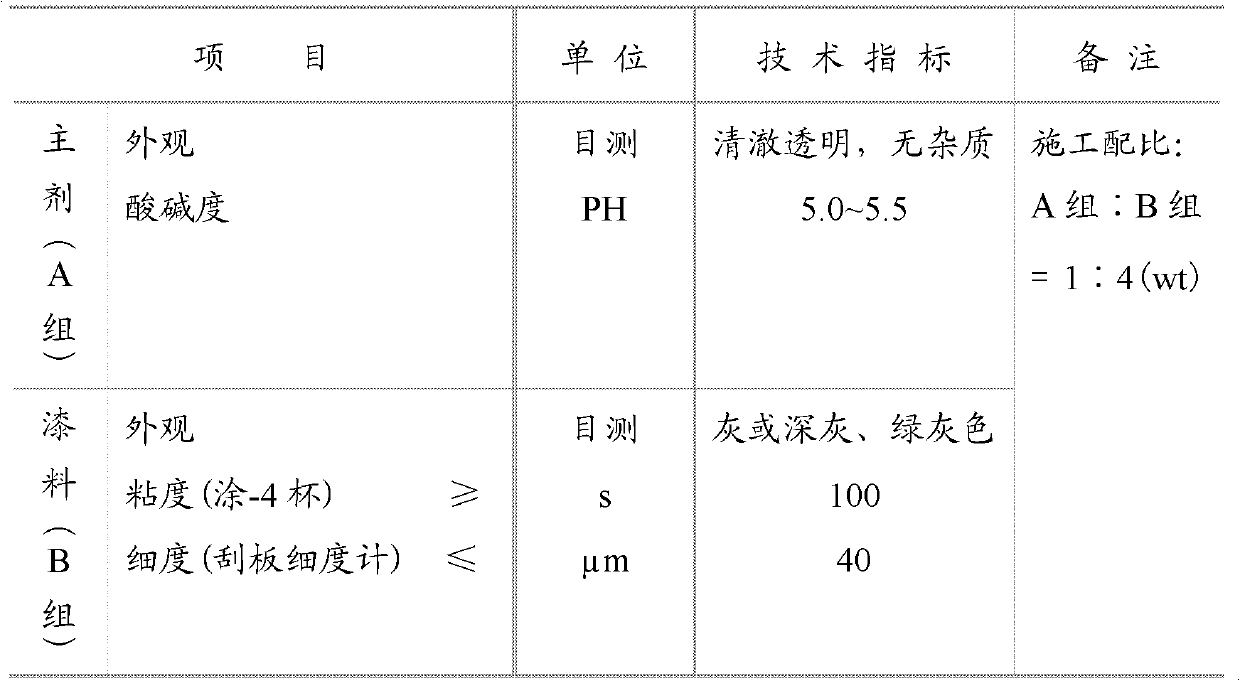

Delayed-combustion-retarding high-temperature-resisting workshop primer and preparation method thereof

ActiveCN102558922AGuaranteed Membrane PerformanceSmall burning areaCoatingsCombustionHeat resistance

The invention discloses a delayed-combustion-retarding high-temperature-resisting workshop primer. The key technology is that high-temperature film-forming materials are used. Two high-temperature film-forming materials are compounded in the formula, the melting points of the high-temperature film-forming materials are respectively in a range of 480-490 DEG C and a range of 680-700 DEG C, accordingly a primary film material can be followed to form a secondary continuous film and a ternary continuous film before the high-temperature heat weightlessness is not yet invalid completely, and coatings are ensured to be not crack. Simultaneously, the heat resistance of the coatings reaches to more than 800 DEG C, the area of the burning loss is very small, and smoke is hardly produced in the cutting or welding operation process.

Owner:GUANGZHOU GEMBOND CHEM

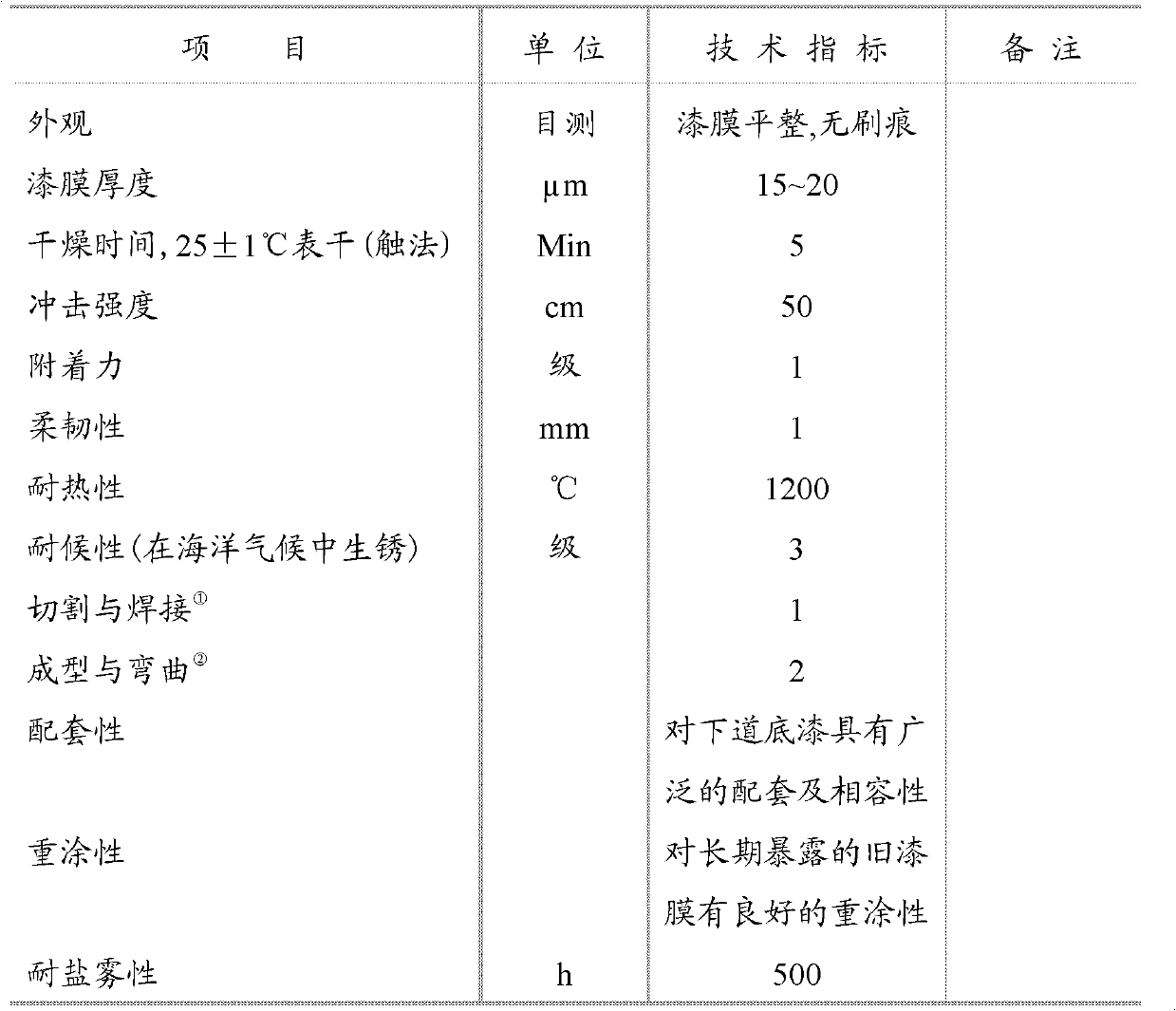

Processing method for improving quality of canned edible mushrooms

ActiveCN102919824AOvercoming Barriers to BrowningImprove qualityFood preparationSpinsEdible mushroom

The invention provides a processing method for improving the quality of canned edible mushrooms. The processing method comprises the following process flows of preparing for raw materials (dried edible mushrooms), re-watering, fixing colors, spin-drying, tumbling and seasoning in vacuum, packaging in vacuum, sterilizing at high temperature under high pressure and storing. According to the processing method for improving the quality of the canned edible mushrooms, the greatest obstacle of brown stain of dried products is overcome, and the canned edible mushrooms have the advantages of high production efficiency, long storage time, instant eating after opening bags, nutrition and delicious taste, can be subjected to mass industrial production and has the characteristics of the edible mushrooms and the function of health care. According to the processing method, a compound color fixative and carboxymethylcellulose with a certain concentration are adopted to treat, by combining a vacuum tumbling process, a proper process is adopted by aiming at different small pack snack canned edible mushrooms, and snack soft cans having good quality and a long shelf period can be finally obtained; and various defects caused by severe brown stain or irrigation treatment of a product sterilization process are overcome.

Owner:ZHEJIANG UNIV OF TECH

Beverage for replenishing athlete energy

InactiveCN105520024AEasy to oxidizeNot easy to storeFood ingredient functionsBeta-CaroteneMagnesium salt

The invention provides a beverage for replenishing athlete energy. The beverage is prepared from the following components in percentage by weight: 3 to 5 percent of medium chain triglyceride (MCT Oil), 4 percent of taurine, 0.02 percent of L-carnitine, 0.0023 percent of vitaminB6, 0.48 percent of kali salt, 0.64 percent of magnesium salt, 0.0373 percent of sodium chloride, 1 to 1.5 percent of sodium carboxymethylcellulose, 14 percent of glucose, 14 percent of fructose, 14 percent of maltodextrin, 0.25 to 0.4 percent of citric acid, 0.05 percent of sorbic acid, 0.2 percent of coloring agent beta-carotene, 5 to 8 percent of flavouring agent and the balance of water. The beverage provided by the invention is designed for athletes with high intensity training, three kinds of carbohydrates and the medium chain triglyceride are added into the beverage, so that the energy needed by the athletes are met, the fatigue can be effectively resisted, muscular endurance is strengthened, and the physique of the athletes is strengthened.

Owner:JIANGSU ALAND NOURISHMENT

Technique for processing delicious fresh dried salted fish

InactiveCN101513264AEasy to storeExtended shelf lifeMeat/fish preservation by heatingMeat/fish preservation using acidsDried fishCarp

The invention relates to a technique for processing dried salted fish, in particular to a technique for processing delicious fresh dried salted fish. The technique for processing the delicious fresh dried salted fish comprises the steps of slaughtering fresh carps, and performing rinsing, curing, flushing for desalinization, air-drying and the like. The delicious fresh dried salted fish has fresh and delicious taste, can be eaten directly after opening a bag, is convenient to carry, and is easy to preserve.

Owner:袁跃成

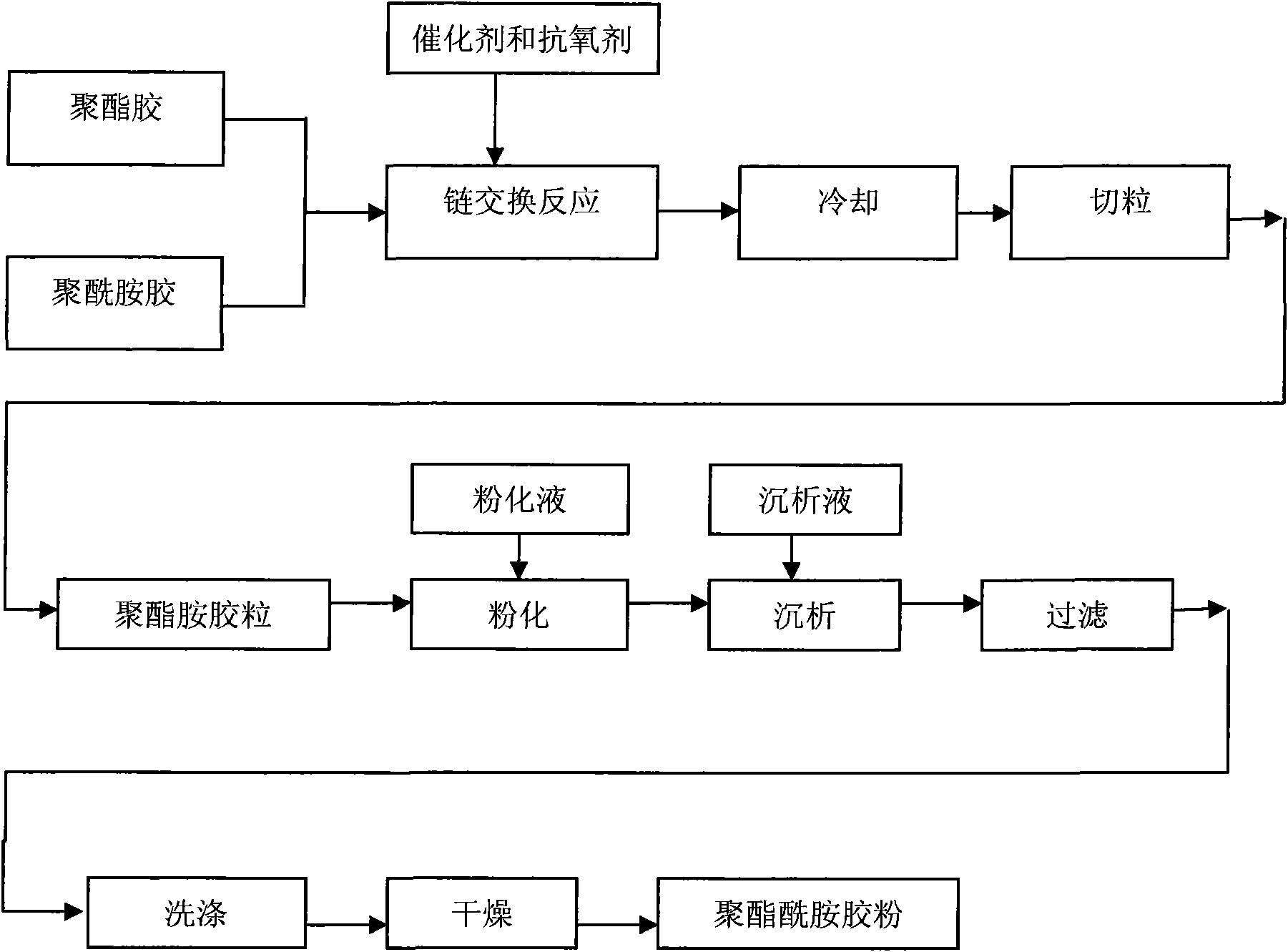

Method of producing polyester amide hot melt adhesive

InactiveCN101586015AEfficient control of ester bondsEffective control of amide bond contentAdhesivesPolyesterPolymer science

The invention discloses a method of producing polyester amide hot melt adhesive, comprising the steps as follows: adding the polyester adhesive with melting range being 130 to 140 DEG. C and polyamide adhesive being 140 to 150 DEG. C into a reaction kettle according to 1:1 weight ratio, then adding catalyst and antioxidant into the reaction kettle, slowly heating until the colloid melting under the protection of nitrogen, stirring, heating to carry out chain exchange reaction, then slowly decompressing until the melt viscosity being 72.3 to 78.3 Pa.s, filling the nitrogen to the normal pressure, then changing to 1.03 to 1.09 high atmospheric pressure to obtain melt material, pressing the melt material into sink by strip shape, cooling, cutting to obtain colloid. The invention has the advantages of effectively controlling the contents and sequence distribution of ester linkage and amido link of the colloid, solving the shortcomings that the daiamid has large dependence to the temperature, and the adhesive is easy to percolate from liner, and the absorption ratio is high and is difficult to store, and is easy to discolor under illumination.

Owner:陈国新

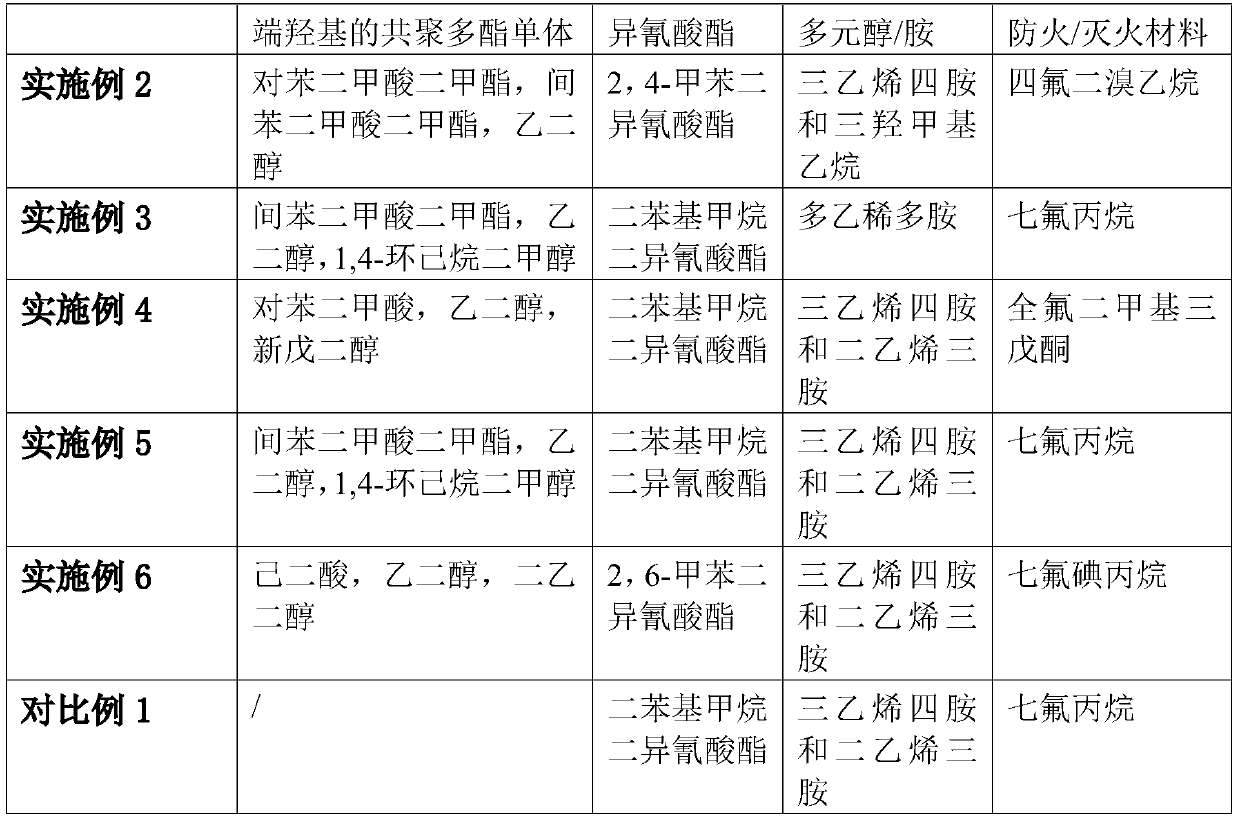

Fireproof and/or fire-extinguishing microcapsule, preparation method thereof and application of microcapsule

ActiveCN109821181AStrengthen physical and chemical propertiesImprove toughnessFire extinguisherPolymer scienceAlcohol

The invention provides a fireproof and / or fire-extinguishing microcapsule, a preparation method thereof and an application of the microcapsule. Modified polyisocyanate prepolymers are mixed with fireproof and / or fire-extinguishing materials, mixture is dispersed in water, and polyhydric alcohols and / or polyamines are added into the water to prepare the fireproof and / or fire-extinguishing microcapsule. High molecular polymerization monomers are designed and selected to synthesize the microcapsule with various enhanced physicochemical properties of shell materials, the strength, the flexibilityand the sealing performance of the microcapsule are greatly improved, so that the microcapsule can be directly and independently used as a fire-extinguishing agent, the microcapsule can also be individually used as a main material or functional additive, added into various composite materials and conveniently and directly used for preparing fireproof and / or self-excitation fire-extinguishing materials in various fields of coatings, adhesives, rubber, plastics and the like, and the applicable range and the application field of gas and liquid fire-extinguishing materials and the fireproof and / orfire-extinguishing microcapsule are greatly widened.

Owner:苏州海云涂层技术有限公司

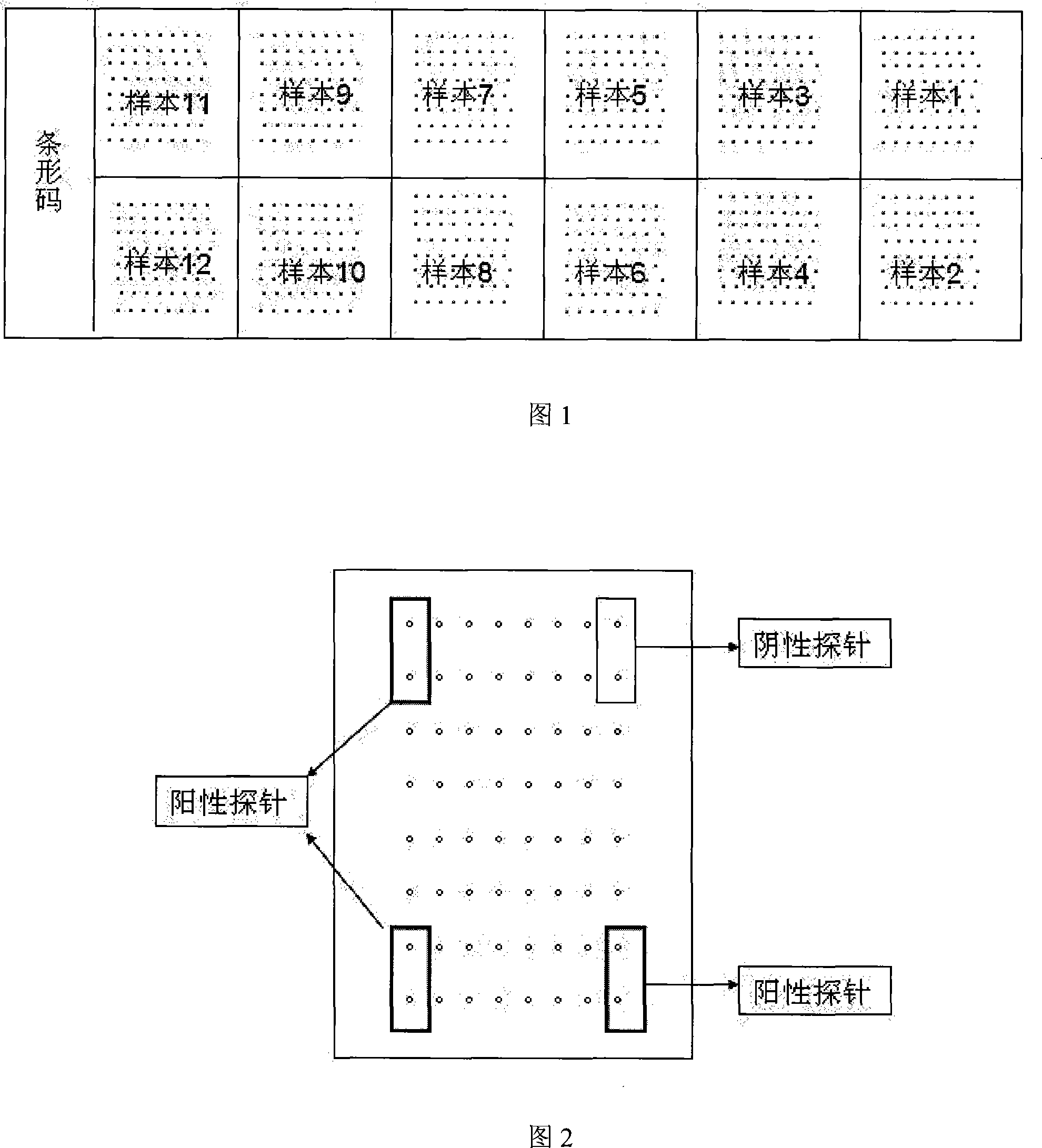

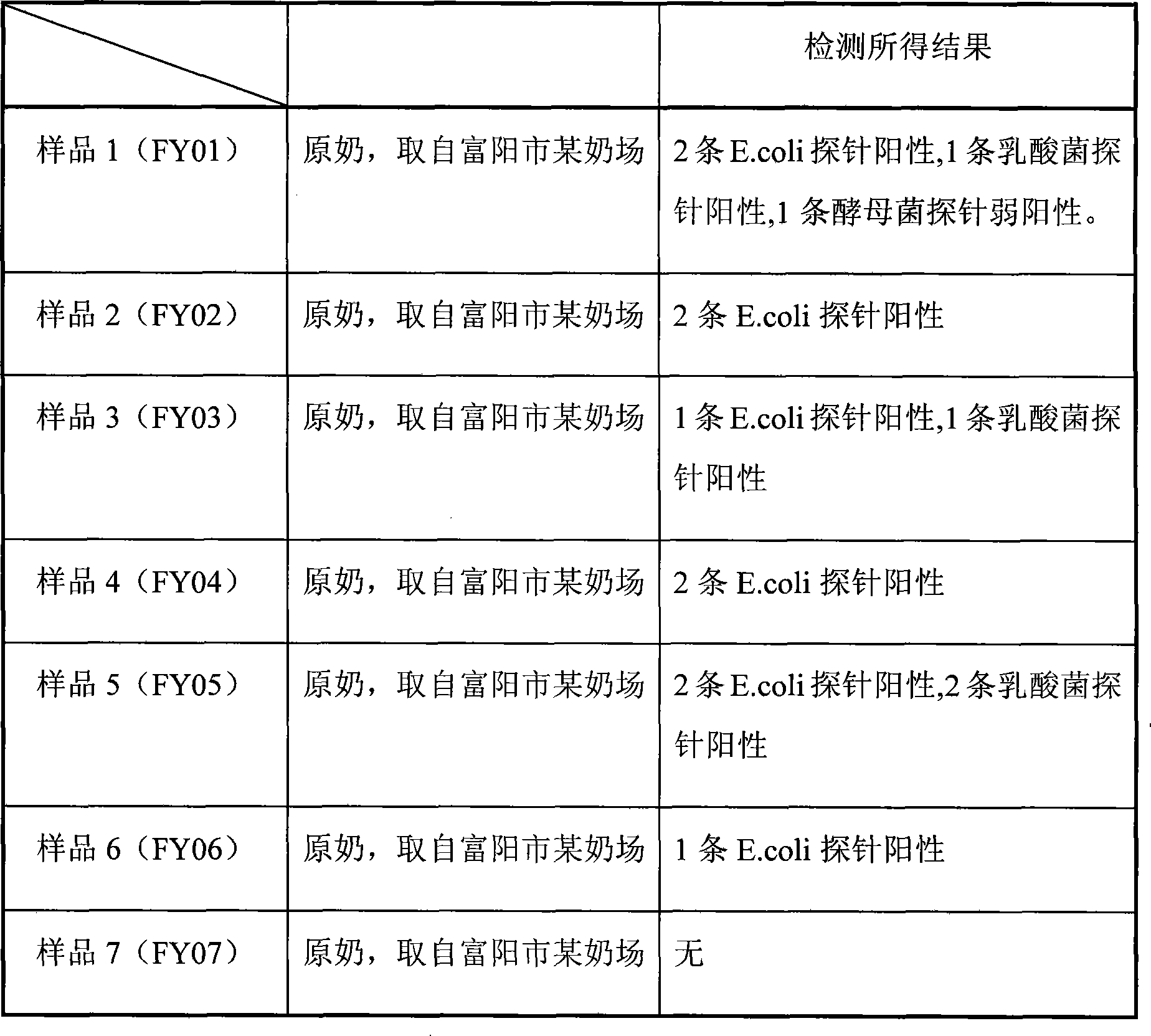

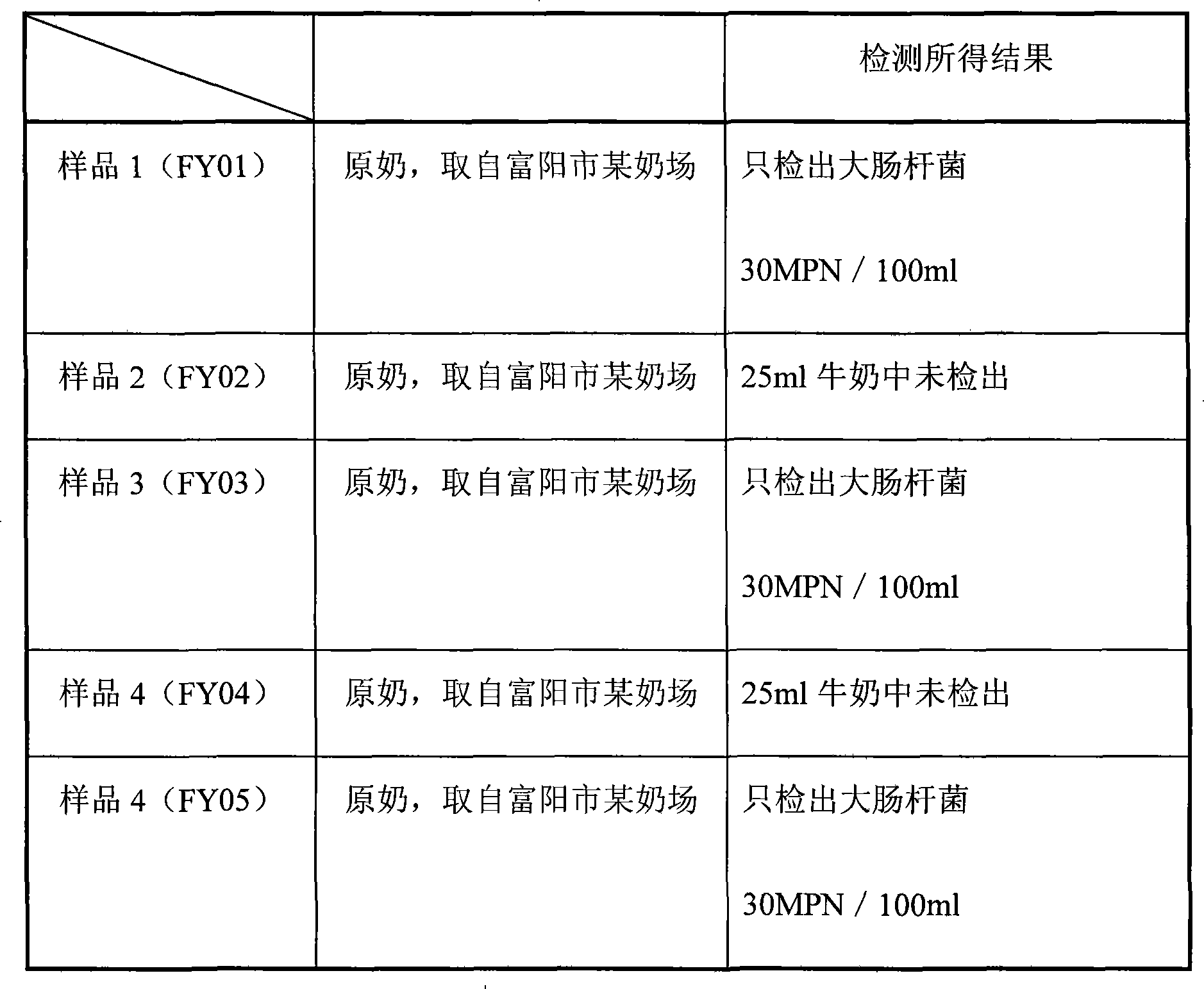

Method for preparing detection chip and method for detecting pathogen by using the same

InactiveCN101240347ANot easy to storeEnhanced signalMicrobiological testing/measurementMultiplex pcrsBiology

The invention discloses a preparation of a detection chip, comprising the steps of: 1) designing oligonucleotide probe of bacteria; 2) preparing the chip. The invention further discloses a method for detecting pathogene in multiple food samples with the detection chip, comprising the following steps: 1) designing a primer; 2) extracting DNA from samples to be detected, and getting extracting solution; 3) multi-PCR amplifying of target gene; 4) hybridization detecting of chip; and 5) detecting and analyzing of hybridization result. The detection step of the invention is simple, easy to operate, and produces high correct rate result.

Owner:ZHEJIANG UNIV

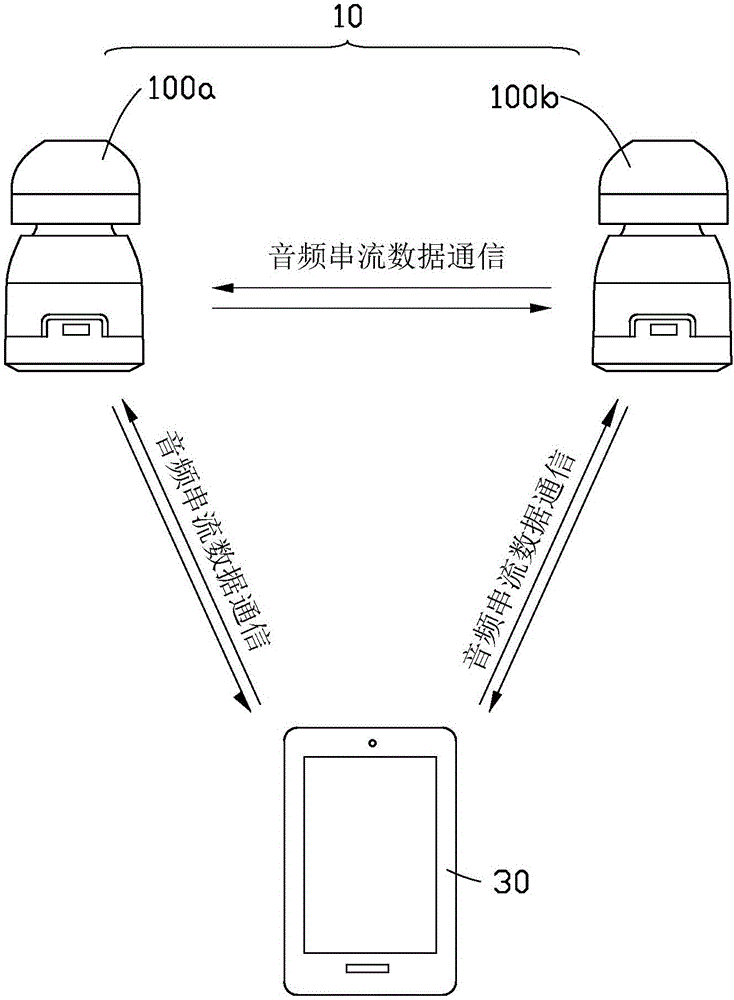

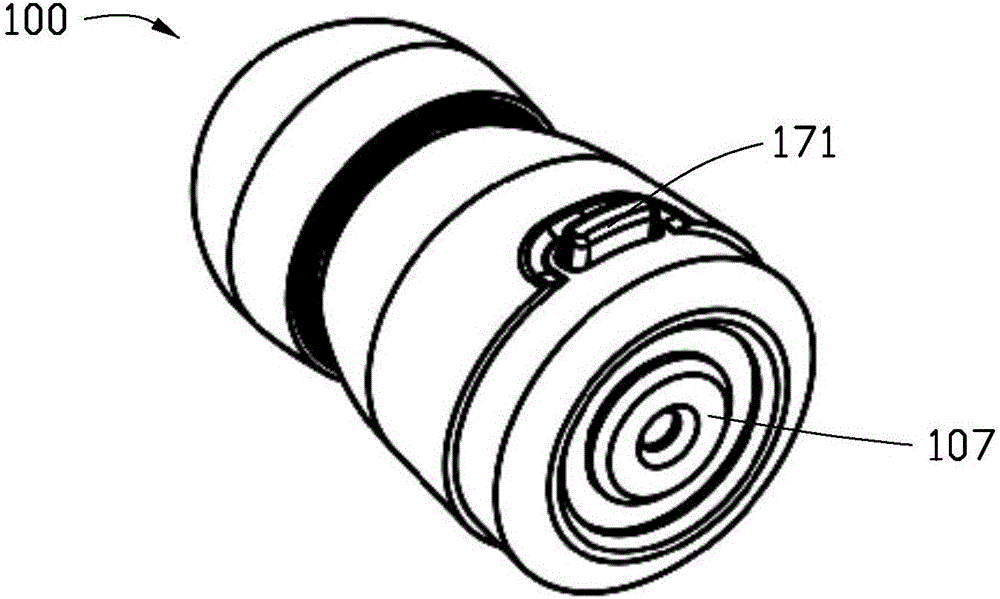

Wireless earphone and controlling method of same

InactiveCN106851452AEasy to knotEasy to storeMicrophonesHeadphones for stereophonic communicationMicrocontrollerHeadphones

The invention provides a wireless earphone and a controlling method of the same. The wireless earphone comprises an input unit and a microcontroller. The controlling method includes: storing a plurality of input modes and a plurality of instructions in the microcontroller; providing relations between the plurality of input modes and the plurality of instructions to a microprocessor; receiving an input applied by the input unit; recognizing one input mode in the plurality of input modes based on the microprocessor; and executing one instruction, corresponding to the recognized input mode, in the plurality of instructions through the microprocessor. According to the wireless earphone and the controlling method, the user experience is improved, the earphone function is improved, and the earphone is more intelligent.

Owner:ERATO CAYMAN HLDG CO LTD +1

Precoated sand mixing process

InactiveCN103600024ASolve the problem of irritating odorReduces pungent odorsFoundry mouldsMould handling/dressing devicesAdhesiveDeodorant

The invention provides a precoated sand mixing process which is characterized by comprising the following steps: (1) heating crude sand, adding the crude sand into a sand mixing machine after the temperature of the crude sand rises to 140 DEG C -160 DEG C, adding and mixing an adhesive with the sand, stirring for 1-2 minutes to obtain adhesive sand, and adding a deodorant while stirring in a stirring process; (2) adding a lubricant into the adhesive sand, mixing with the sand for 1-2 minutes, cooling down the adhesive sand after being mixed, adding a curing agent when the temperature of the adhesive sand is reduced to be 105-110 DEG C, and mixing for 20-40 seconds so as to obtain curing agent sand; and (3) adding the lubricant into the curing agent sand, mixing with the sand for 1-2 minutes, cooling down the curing agent sand after mixing, and discharging the sand when the temperature of the sand is reduced to be less than 70 DEG C so as to obtain precoated sand, wherein the addition amount of the adhesive is 1.5-2.5% of the total weight of the crude sand, the addition amount of the deodorant is 20-40% of the addition amount of the adhesive, the addition amount of the curing agent is 10-20% of the addition amount of the adhesive, and the addition amount of the lubricant is 2-6% of the addition amount of the adhesive. The precoated sand produced by using the precoated sand mixing process has the characteristics that the pungent smell is little, agglomeration is unlikely to happen, the roughness degree is low, and the sand is unlikely to adhere to a cast piece.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Process of preparing hydrogen with biomass fast cracking oil

InactiveCN1706743AIncrease water contentIncrease oxygen contentHydrogenWater vaporReaction temperature

The present invention discloses one process of preparing hydrogen with biomass fast cracking oil. The biomass fast cracking oil as main material and the Ni / Al2O3 catalyst are water vapor catalytically reformed under proper reaction temperature, reaction pressure, reaction time and other technological conditions to prepare synthetic gas with rich hydrogen content. The present invention provides one new way for producing hydrogen and lays foundation for the subsequent processing of biomass cracking oil and the development of biomass resource.

Owner:EAST CHINA UNIV OF SCI & TECH

Polygonatum polysaccharide buccal tablets and preparation method thereof

InactiveCN101715914AEasy to absorb moistureNot easy to formFood preparationFlavouring agentAdditive ingredient

The invention belongs to the field of functional health-care food, and relates to a buccal tablet formula which takes an extracted polygonatum polysaccharide as a main functional component and a preparation method. The preparation method for the polygonatum polysaccharide buccal tablets comprises the following steps: taking polygonatum polysaccharide extracts, a diluent, a binding agent, a lubricant and a flavour agent as raw materials; preparing the polygonatum polysaccharide extracts into polysaccharide powder, and then uniformly dispersing the diluent, the binding agent and the flavour agent into the polysaccharide powder to prepare appropriate dampmass; and performing sieving for granulation, adding the lubricant for uniformly mixing after drying, and performing sieving for granule finishing, tabletting for forming to obtain the polygonatum polysaccharide buccal tablets. The polygonatum polysaccharide buccal tablets have the advantages of comfortable mouthfeel, unique odor of polygonatum, simple process and high repeatability.

Owner:NANJING NORMAL UNIVERSITY

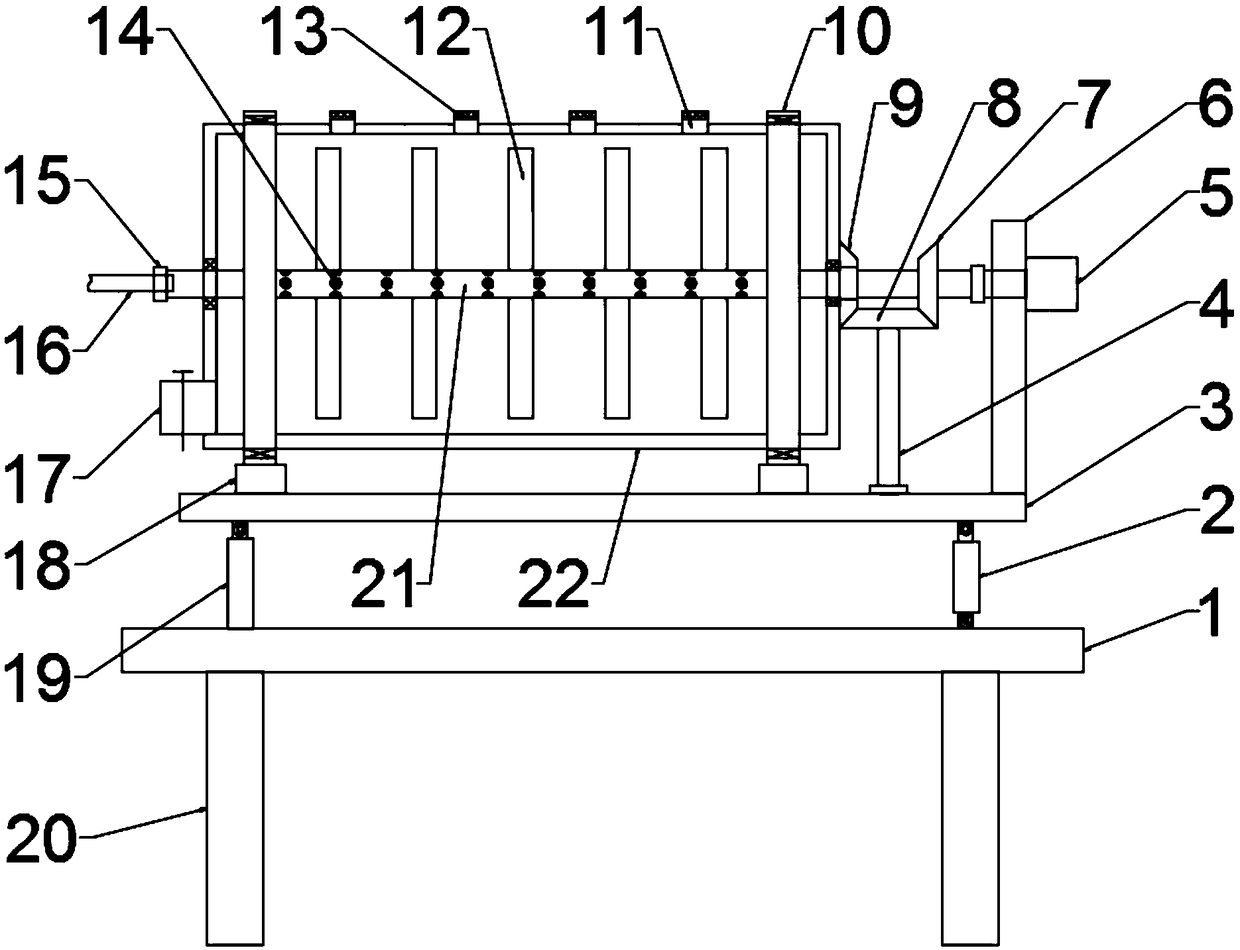

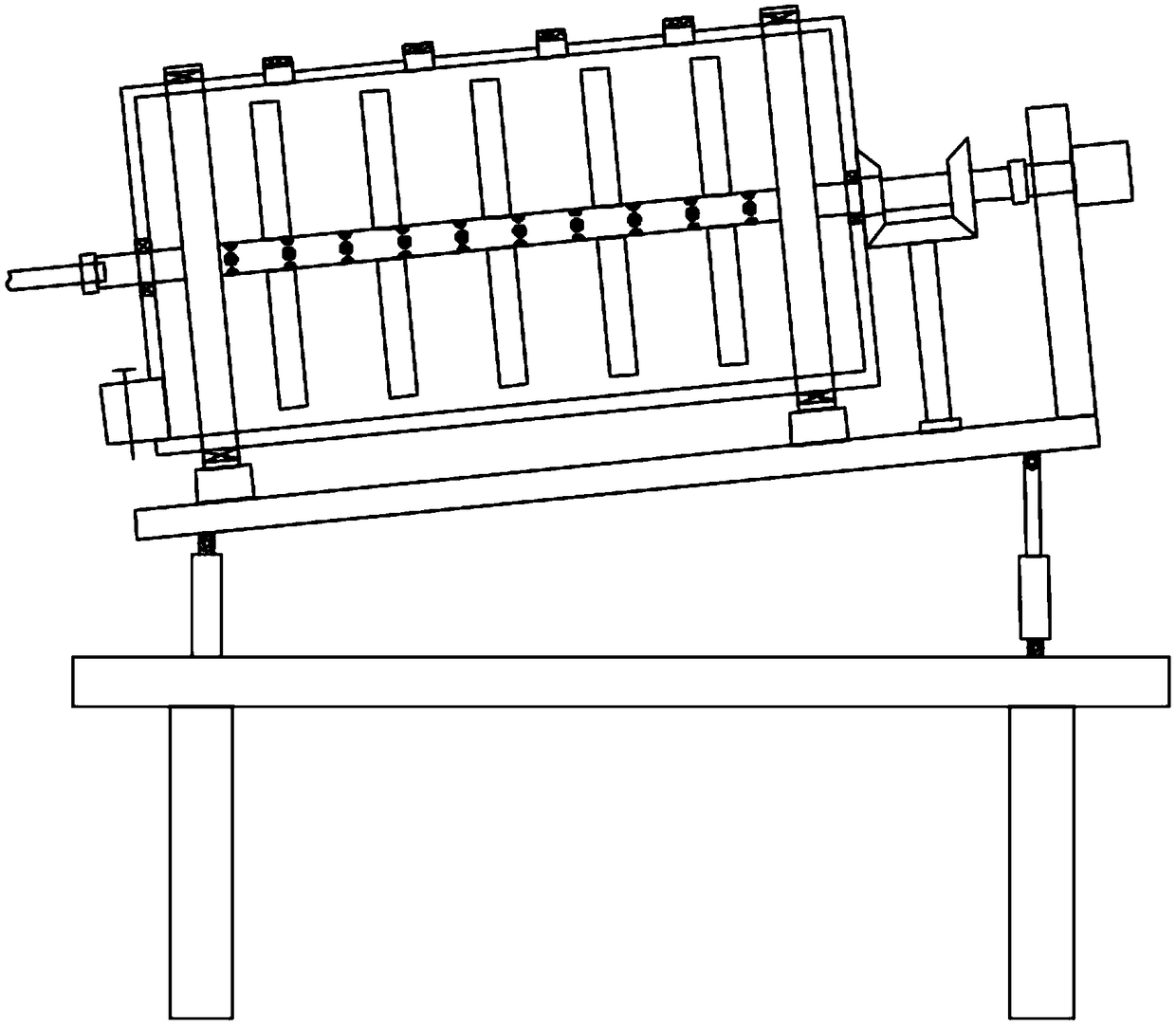

Grain storage drying device for agriculture

InactiveCN108759376AAvoid accumulationEasy dischargeDrying gas arrangementsSeed preservation by dryingMotor driveAgricultural engineering

The invention discloses a grain storage drying device for agriculture. The grain storage drying device comprises a bottom plate, a storage tube, a mounting plate, a lantern ring, a stirring shaft, anair inlet pipe, an air heater, a stirring rod, a first bevel gear, a second bevel gear and a third bevel gear. The grain storage drying device is provided with a motor, the stirring shaft, the stirring rod, the first bevel gear, the second bevel gear and the third bevel gear, the motor drives the stirring shaft to rotate, and the stirring shaft drives the stirring rod and the first bevel gear to rotate. Grain in the storage tube is stirred through the stirring rod to avoid the situations that the grain is stacked, consequently the humidity of the grain is increased, and storage is difficult. Meanwhile, the first bevel gear drives the third bevel gear to rotate through the second bevel gear, the third bevel gear drives the storage tube to rotate, and the rotating direction of the storage tube is opposite to that of the stirring shaft. A supporting rod and an electric push rod are arranged, and a telescopic rod of the electric push rod is controlled to stretch to enable the mounting plate and the storage tube above the mounting plate to incline, so that the grain in the storage tube is discharged.

Owner:史积贵

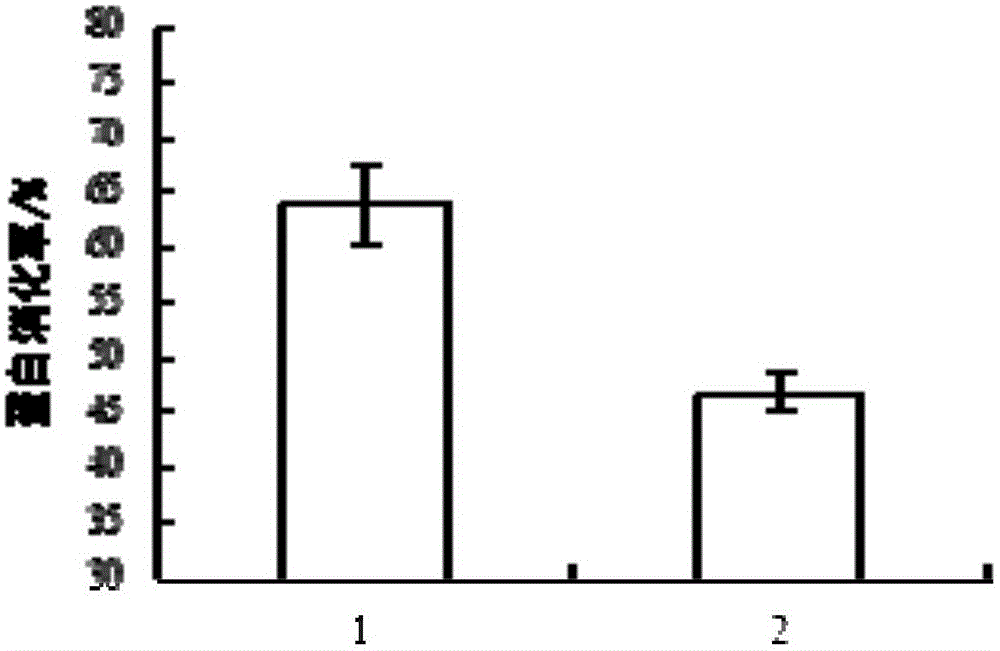

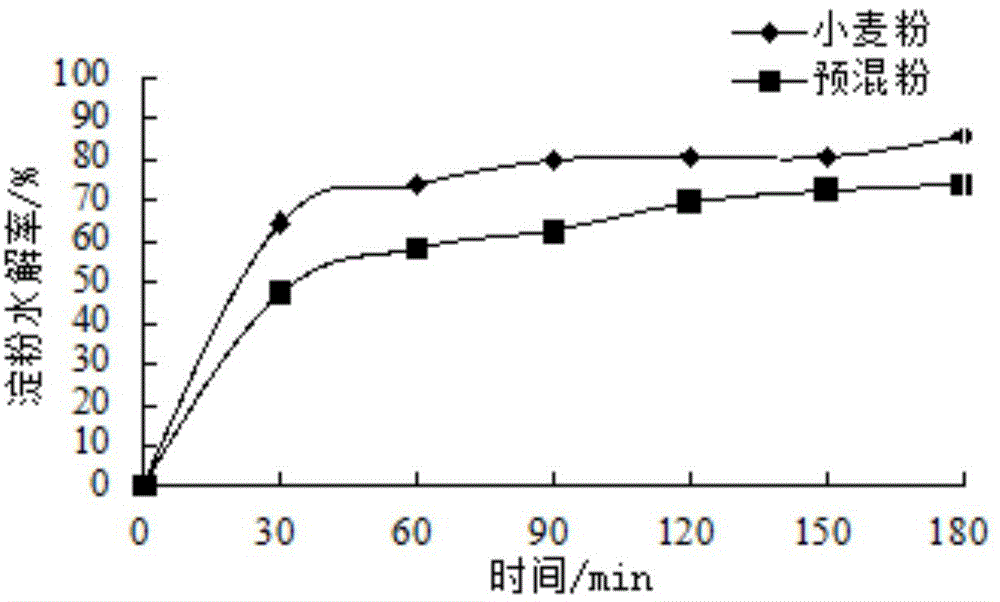

Whole grain premixed dumpling flour containing puffed sorghum, and preparation method thereof

The invention discloses a whole grain premixed dumpling flour containing puffed sorghum and a preparation method thereof. According to the whole grain premixed dumpling flour, wheat flour and whole grain red sorghum puffed powder are taken as total flour materials, wherein weight ratio of wheat flour to the whole grain red sorghum puffed powder ranges from 5:5 to 7:3; and the whole grain premixed dumpling flour is prepared via adding vital gluten, soy isolate protein, and konjac glucomannan for mixing at an appropriate ratio. According to the preparation method, puffing technology is adopted for processing whole grain sorghum powder, so that problems caused by application of whole grain sorghum powder in dumpling wrapper processing are solved, wherein the problems are that: adding ratio is low, molding is difficult to realize, product palatability is poor, and protein digestibility is low. The obtained whole grain premixed dumpling flour possesses unique color and scorch aroma flavor of sorghum puffed powder; mouthfeel of dumpling wrappers prepared from the whole grain premixed dumpling flour is smooth; technology demands of hand made or machine made dumpling wrappers are satisfied; dumpling kinds are increased; application method is simple; and the whole grain premixed dumpling flour is suitable for household dumpling preparation, restaurant fancy cooking, and coarse cereal dumpling production of processing enterprises.

Owner:NORTHWEST A & F UNIV

Nano-encapsulated retinol anti-acne gel and production method thereof

ActiveCN107157966AHygienic complianceAvoid irritationCosmetic preparationsToilet preparationsVitamin CGlycerol

The invention discloses a nano-encapsulated retinol anti-acne gel and a production method thereof. The nano-encapsulated retinol anti-acne gel comprises, by weight, 0.5-5 parts of retinal, 1-3 parts of vitamin C, 1-20 parts of phospholipid, 20-40 parts of polyethylene glycol-20, 10-20 parts of caprylic triglyceride or capric triglyceride, 10-30 parts of glycerol and 5-10 parts of water. The production method of the nano-encapsulated retinol anti-acne gel is simple, and raw materials in the invention accord with cosmetic healthiness standards; and the nano-encapsulated retinol anti-acne gel has an obvious treatment effect on acnes in various stages, and is basically suitable for all people.

Owner:程刚

Citrus residue silage and preparation method and using method thereof

InactiveCN102106456ASlow down fermentationFermentation does not affectFood processingAnimal feeding stuffNutritive valuesMilk cow's

The invention discloses citrus residue silage. The citrus residue silage is characterized by being prepared from the following raw materials based on the percentage of the total weight of the citrus residue silage: 1 to 5 percent of citrus residue feed additive, 10 to 20 percent of lees and 10 to 20 percent of bran, wherein the citrus residue feed additive consists of the following raw materials in percentage by weight: 10 to 40 percent of urea, 10 to 40 percent of yeast, 2 to 8 percent of potassium sorbate and the balance of carrier. The citrus residue silage has good palatability and high nutritional value, is easily stored, and has low production cost; the feeding value of Chinese citrus residues used for pig or cow feed is improved, the grains are saved, and the economic benefit is improved; and the raw materials are easily obtained, a large amount of citrus peel residues produced in factories are successfully utilized, wastes are changed into valuable, the environment is protected and the resources are saved. A preparation method for the citrus residue silage is simple and easy in operation, and effectively reduces the energy consumption of citrus residue feed production.

Owner:CHONGQING ACAD OF ANIMAL SCI

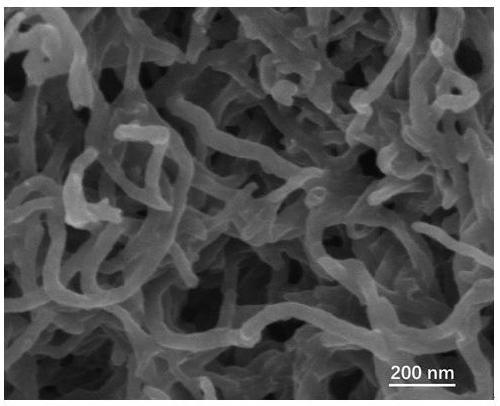

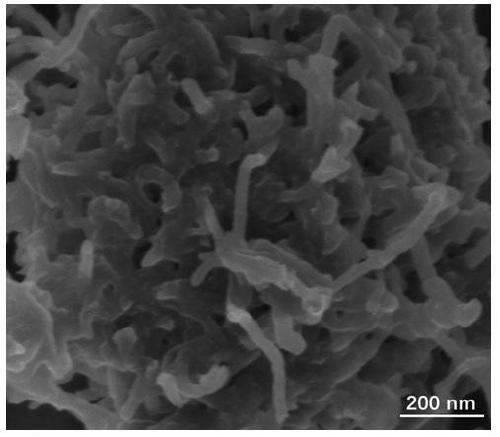

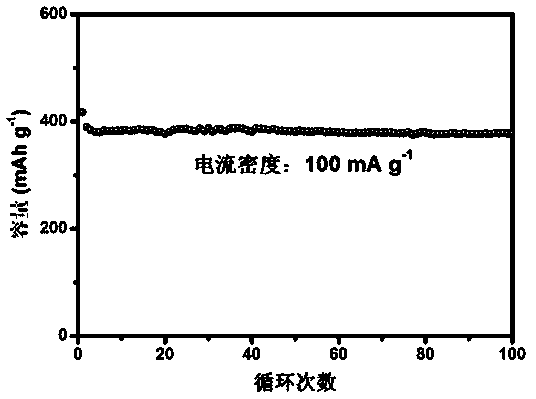

Nitrogen-doped carbon nanotube material

ActiveCN111099577AAvoid the problem of low nitrogen doping efficiencySimple production processCell electrodesSecondary cellsNanotubeNitrogen doped

The invention relates to a nitrogen-doped carbon nanotube material, which is prepared through steps: adopting formaldehyde as a bridge, enabling formaldehyde and melamine to be subjected to moderate crosslinking to form a nitrogen-doped precursor, then performing hydrothermal reaction, enabling the nitrogen-doped precursor and carbon nanotubes to be interacted and uniformly fused, and then performing solvent-free microwave reaction to synthesize high-nitrogen-content doped carbon nanotubes. In the preparation process of the nitrogen-doped carbon nanotube material, the loss caused by sublimation of a nitrogen-doped precursor in the heating process in the traditional nitrogen doping process is avoided, the nitrogen doping efficiency is improved, the reaction conditions are progressively increased from mild to intense, and uniform fusion of interaction of the nitrogen-doped precursor and carbon nanotubes is realized. The prepared nitrogen-doped carbon nanotube material is good in stability, not prone to denaturation in air, easy to store and large in specific surface area, a good channel is provided for lithium ion transmission when the nitrogen-doped carbon nanotube material is usedas a lithium ion battery negative electrode material, and the nitrogen-doped carbon nanotube material has large specific capacity and good cycling stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

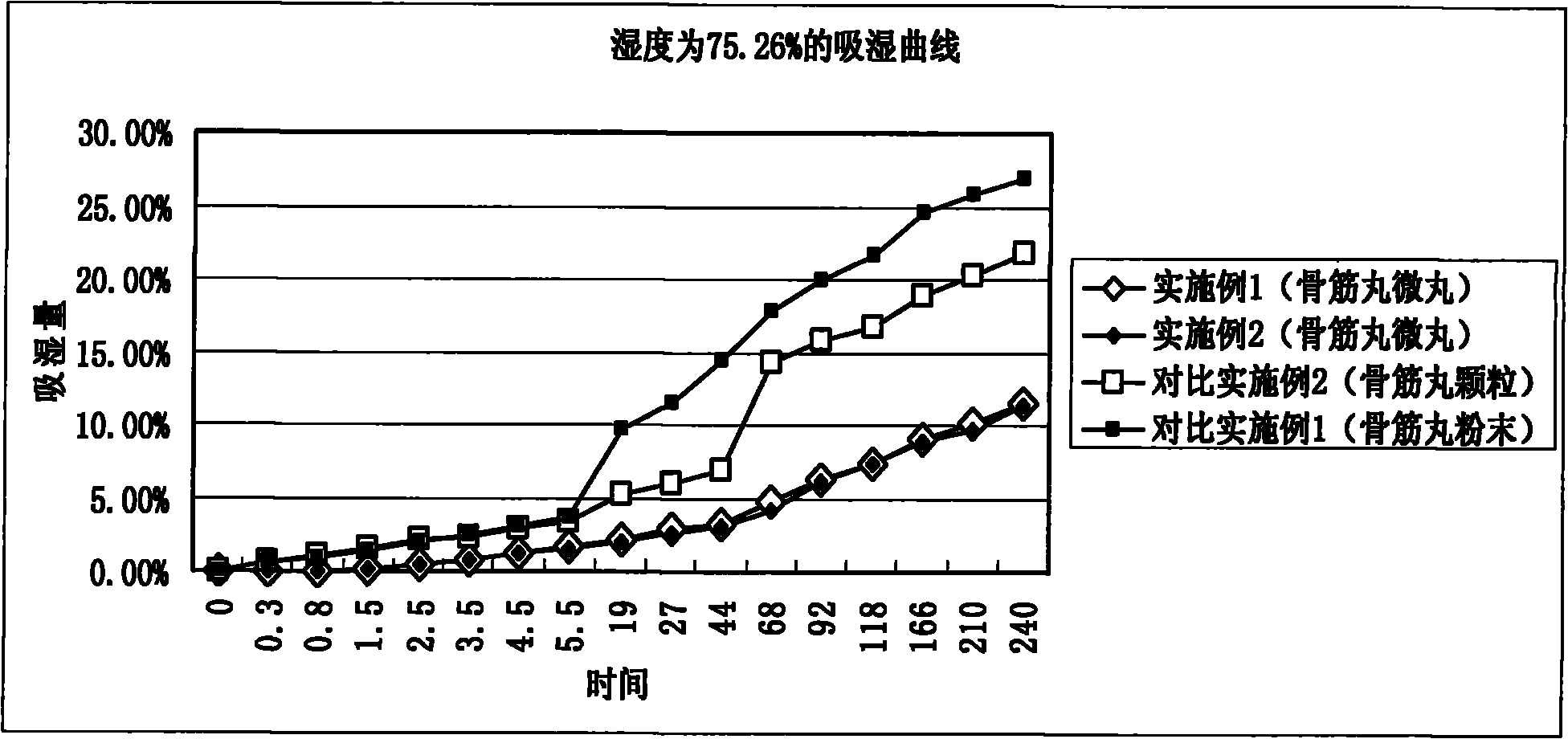

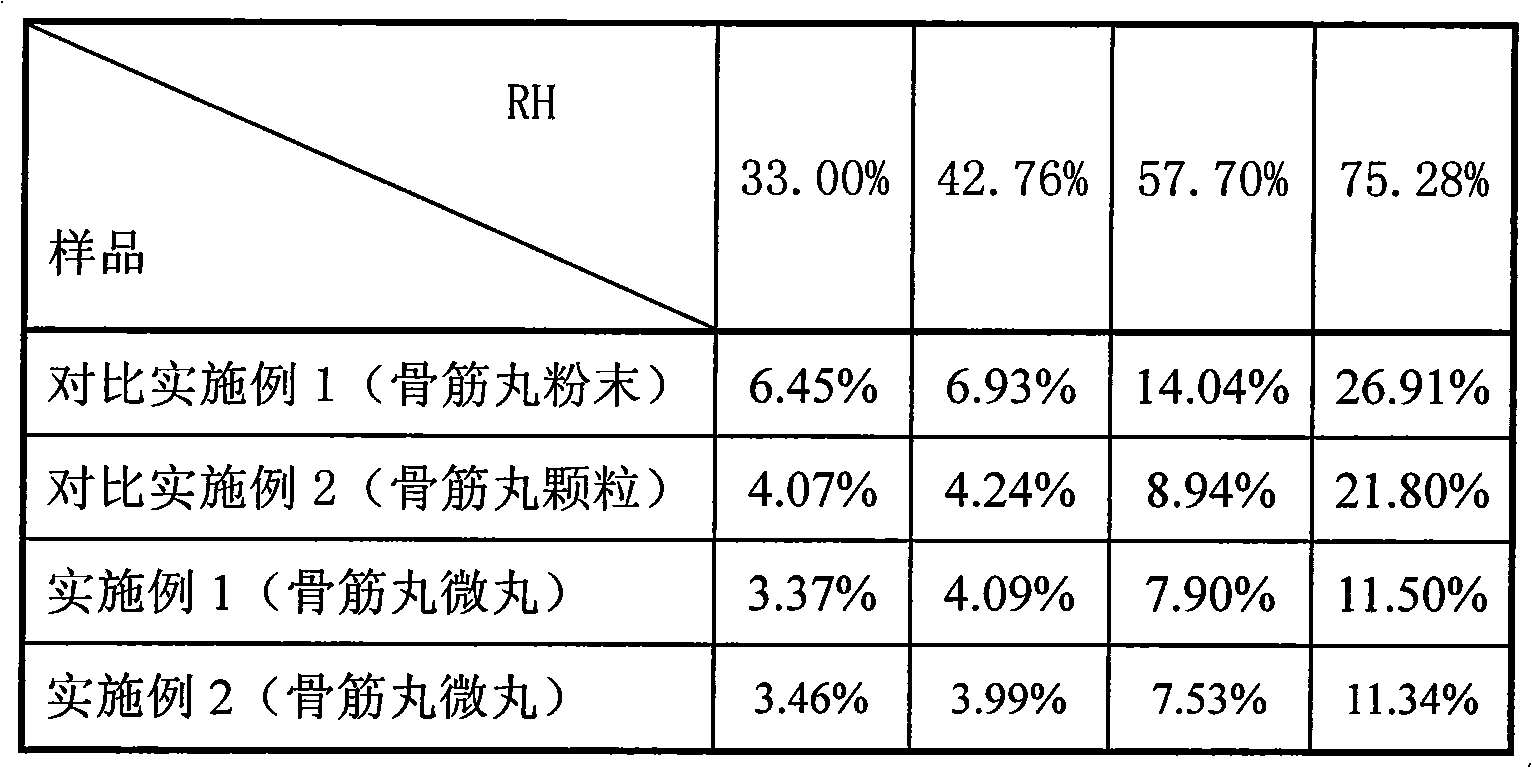

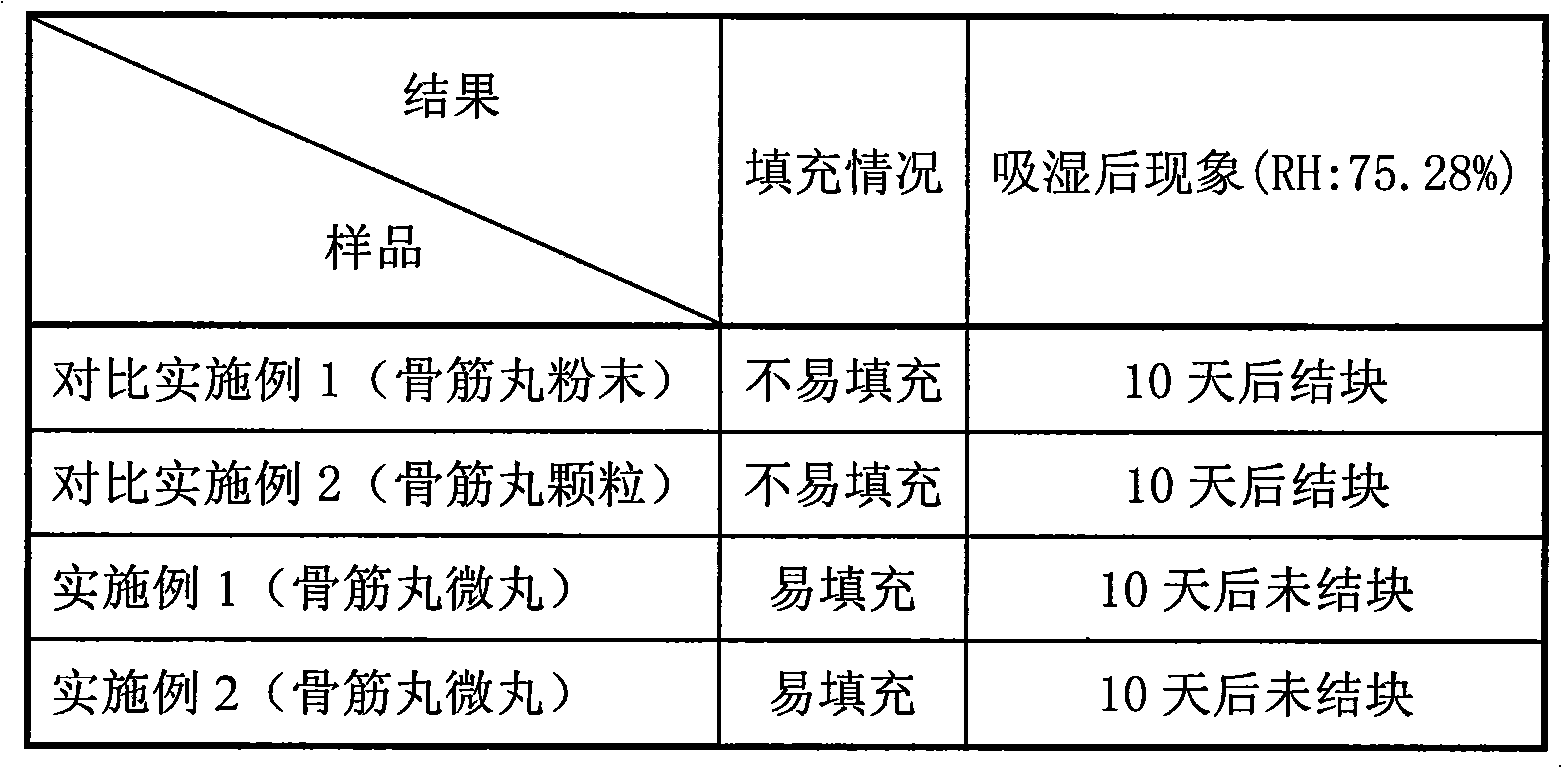

Gujin pill pellet and preparation method thereof

ActiveCN101966316ANot easy to absorb moistureEasy to storeAntipyreticAnalgesicsMedicineMoisture absorption

The invention relates to a Gujin pill pellet and a preparation method thereof. The Gujin pill pellet contains Gujin pill extractum dry powder and Gujin pill mixed powder, wherein the weight ratio of the Gujin pill extractum dry powder to the Gujin pill mixed powder is 3.76-4.00: 1.86-2.14, and the size of the pellet is 16-30 meshes. The Gujin pill pellet is a novel iliacus pill preparation which does not absorb moisture, is easy to store and fill and has stable quality, and can solve the problem of moisture absorption in the traditional iliacus pill.

Owner:GUIZHOU JINGCHENG PHARMA

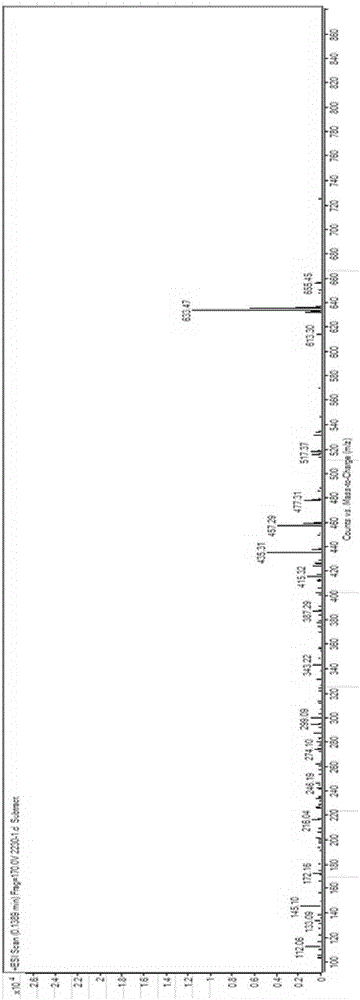

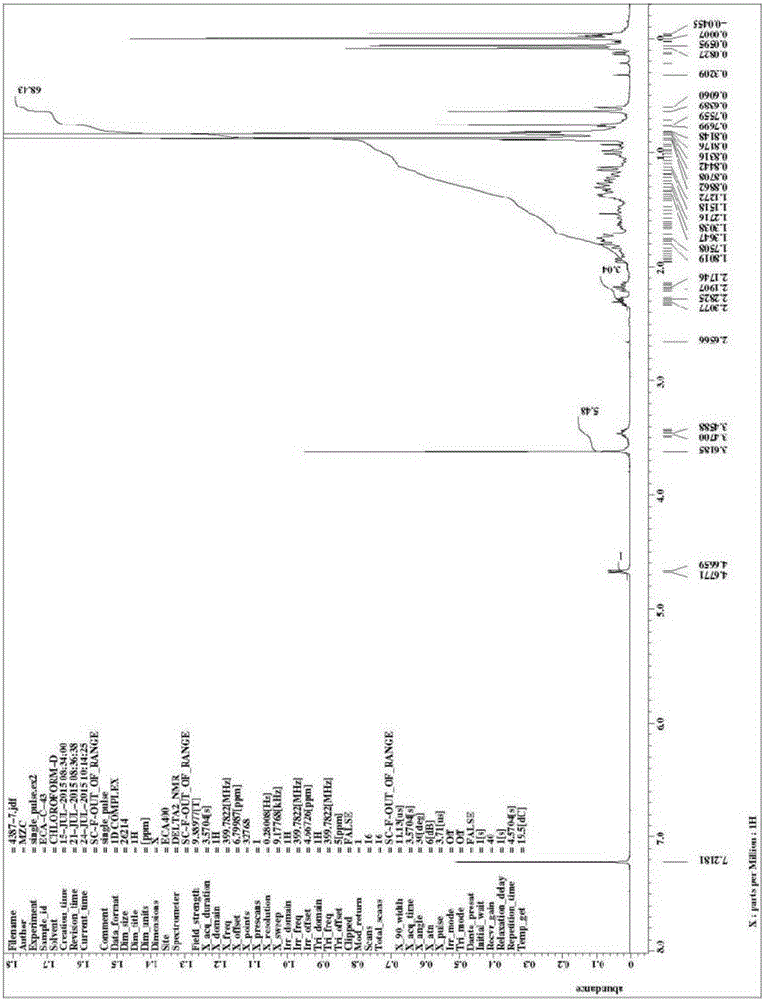

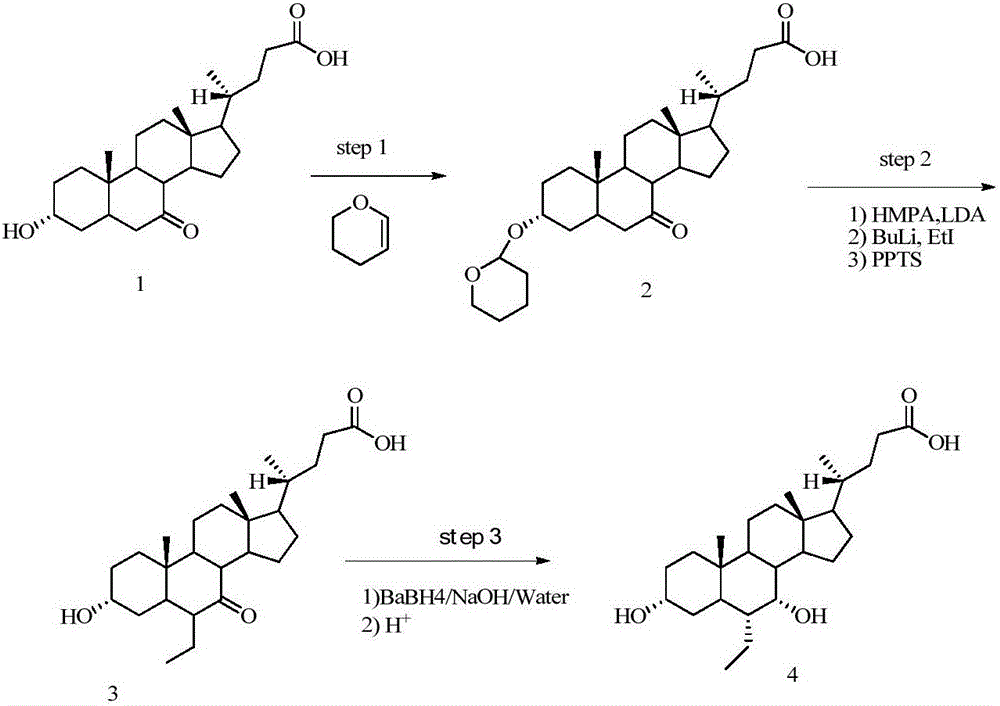

3,7-di(t-butyldimethylsiloxy)-6-ene-5beta-cholan-24-oic acid methyl ester

The invention belongs to the technical field of medicines, relates to a method of preparing obeticholic acid through adopting 3,7-di(t-butyldimethylsiloxy)-6-ene-5beta-cholan-24-oic acid methyl ester as an intermediate, and particularly relates to the 3,7-di(t-butyldimethylsiloxy)-6-ene-5beta-cholan-24-oic acid methyl ester that is a chemical compound, a method of preparing the compound, and a use of the compound for preparation of the obeticholic acid. The invention also relates to a method of preparing the obeticholic acid. The method of preparing the obeticholic acid includes (1) preparing the 3,7-di(t-butyldimethylsiloxy)-6-ene-5beta-cholan-24-oic acid methyl ester and (2) preparing the obeticholic acid through adopting the 3,7-di(t-butyldimethylsiloxy)-6-ene-5beta-cholan-24-oic acid methyl ester as the intermediate.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com