Fireproof and/or fire-extinguishing microcapsule, preparation method thereof and application of microcapsule

A technology of microcapsules and fire extinguishing materials, which is applied in the direction of fire prevention equipment, etc., can solve the problems of instability, structural design, complicated production process, high cost, etc., and achieve the effects of improved sealing, long-term stable storage and use, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] The preparation of the polyisocyanate prepolymer of embodiment 1 modification

[0118] (1) Preparation process

[0119] 1) heating dibasic alcohols, dibasic acids, dibasic acid anhydrides and / or dibasic acid esters in a nitrogen-protected environment to carry out esterification and / or transesterification reactions, and distill off the small molecule by-products generated by the reaction; After the reaction is completed, the by-products and unreacted monomers generated by the reaction are further removed under reduced pressure; the target product obtained by the reaction is separated from the hydroxyl-terminated copolyester. The average molecular weight of the target product copolyester with terminal hydroxyl group is controlled at 300-5000.

[0120] Specifically, the diols include aliphatic diols and / or aromatic diols; more specifically, in this embodiment, the diols are ethylene glycol;

[0121] And / or specifically, the dibasic acid includes aliphatic dibasic acid an...

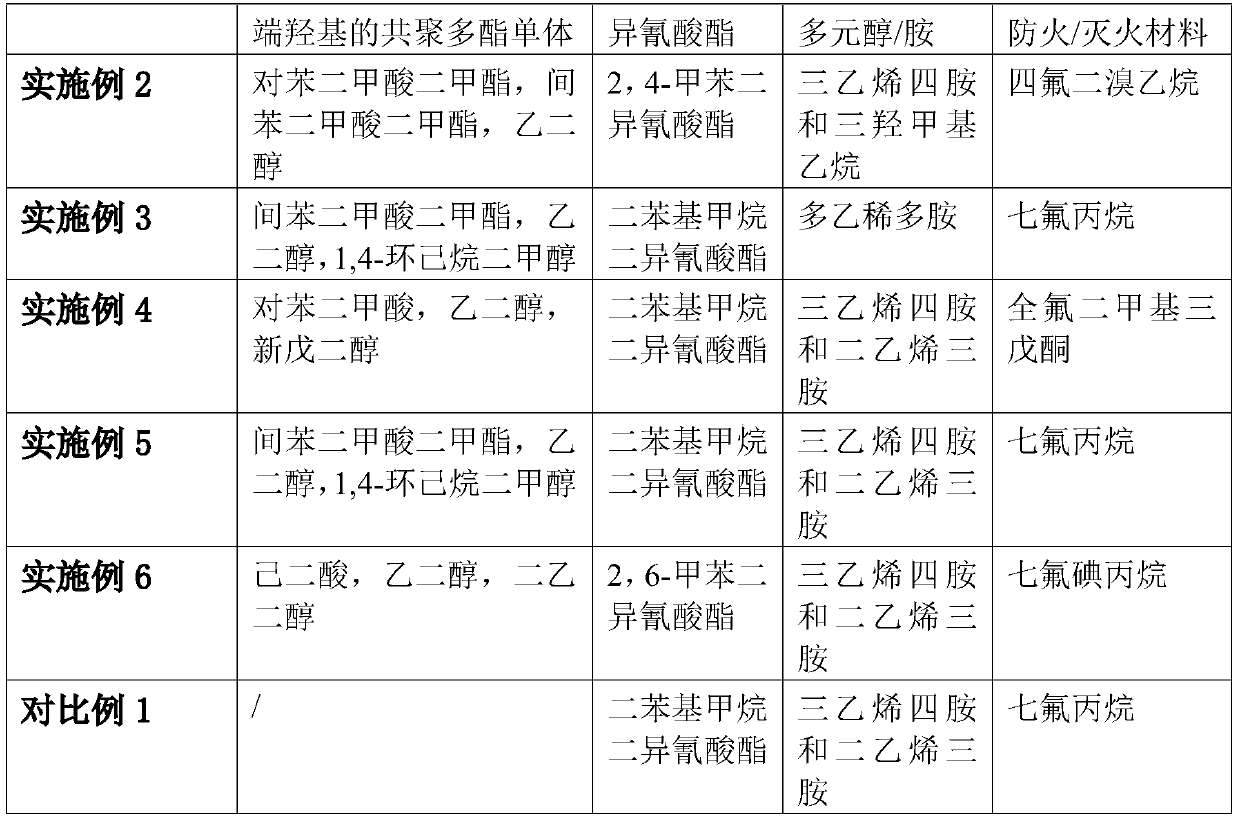

Embodiment 2-6 and comparative example 1

[0150] The preparation process of the fire prevention and / or fire extinguishing microcapsules described in Examples 2-6 and Comparative Example 1 is the same as that of Example 1, except that the replacement and adjustment are carried out according to the following Table 1.

[0151] Table 1

[0152]

[0153] In addition, the mass ratio of the ester group-modified polyisocyanate prepolymer to the fire extinguishing material in Example 2 is 1:18.

[0154] The fire prevention and / or fire extinguishing microcapsules prepared in Examples 2-6 and Comparative Example 1 were tested, and the test results are shown in Table 2 and Table 3.

[0155] Table 2

[0156]

[0157] table 3

[0158]

[0159] Finally, the present invention further prepares the fireproof and / or fire extinguishing microcapsules prepared by the above-mentioned embodiment 2 into fireproof and / or fire extinguishing silk rope according to the preparation method of conventional silk rope; the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com