Hydrocolloid oil yarn and preparation method thereof

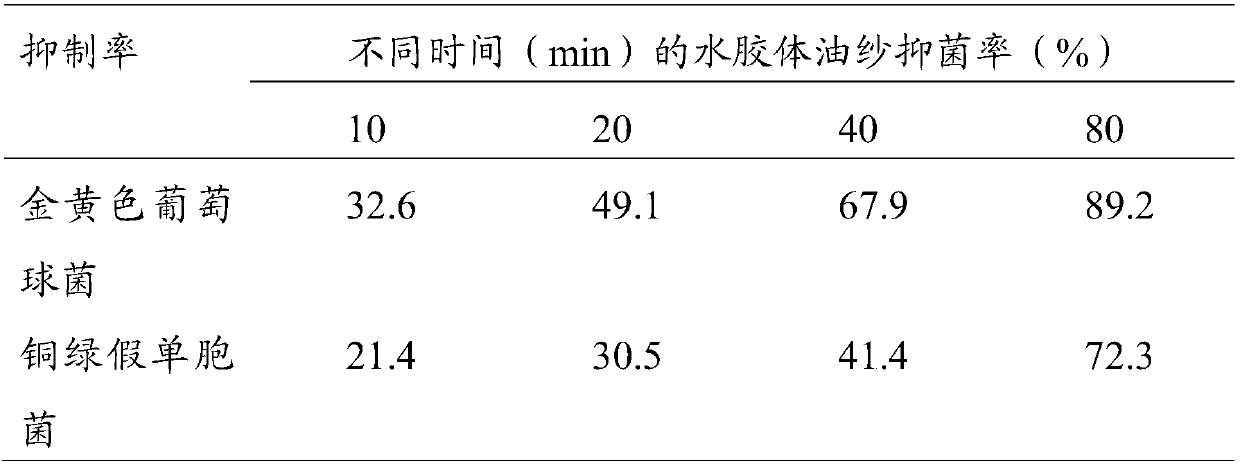

A hydrocolloid and liquid paraffin technology, applied in the field of medical materials, can solve the problems of slow healing of dressing wounds, easy adhesion of wounds, secondary injuries, etc., and achieve good antibacterial effect, good air permeability, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

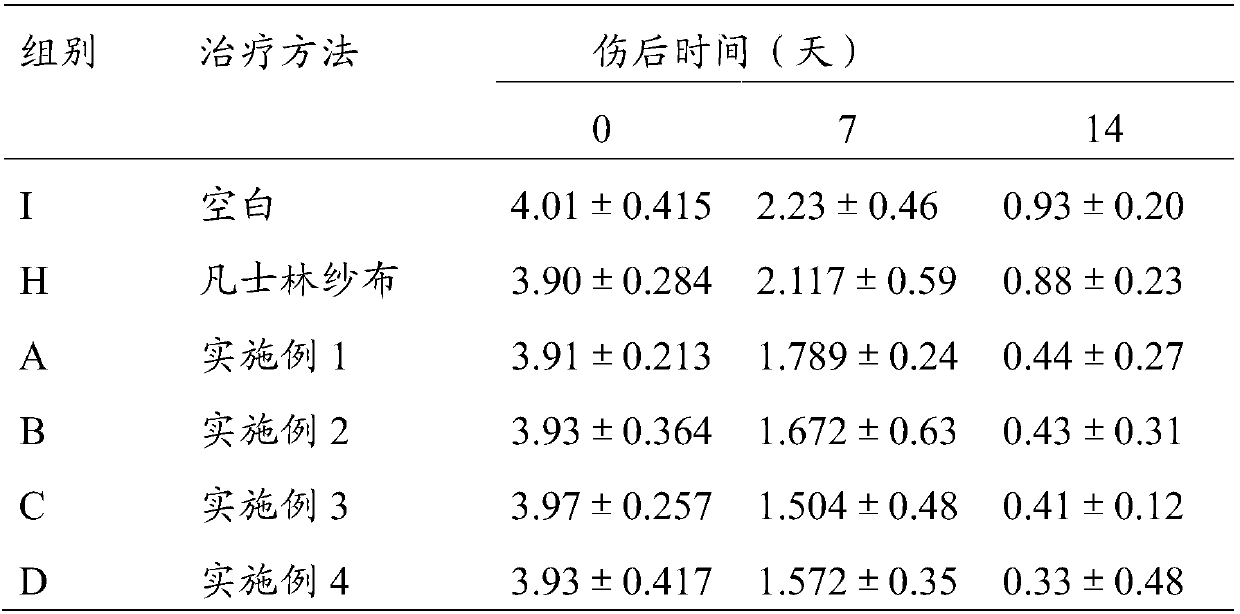

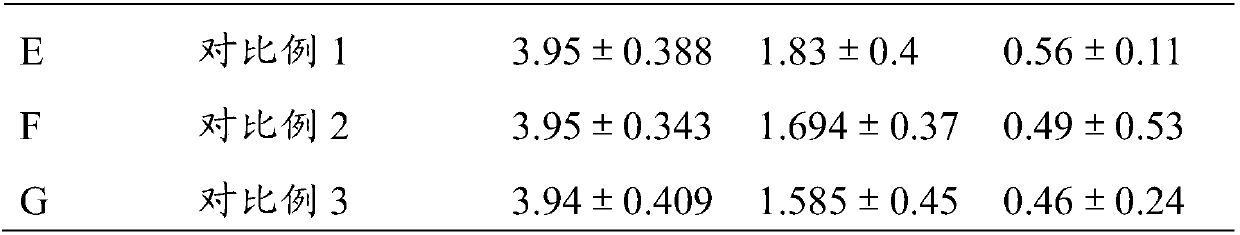

Examples

Embodiment 1

[0052] The present embodiment provides a kind of hydrocolloid oil yarn, and specific scheme is:

[0053] A hydrocolloid oil yarn, consisting of a base material and a hydrocolloid component;

[0054] The base material is reticular polyester fiber,

[0055] The hydrocolloid component is made from the following raw materials in parts by weight:

[0056] 8 parts of G1651, 30 parts of sodium carboxymethylcellulose, 1 part of growth factor microspheres, 1 part of chitosan, 100 parts of liquid paraffin, 30 parts of petrolatum and 5 parts of lanolin.

[0057] The preparation method of the hydrocolloid oil yarn of the present embodiment comprises the following steps:

[0058] Take each raw material by above-mentioned parts by weight;

[0059] Soften G1651, liquid paraffin, vaseline and lanolin in a reaction kettle at a temperature of 200°C for 30 minutes to obtain a mixture;

[0060] In the mixture, add the sodium carboxymethyl cellulose and chitosan, the particle pore size of the ...

Embodiment 2

[0071] The present embodiment provides a kind of hydrocolloid oil yarn, and specific scheme is:

[0072] A hydrocolloid oil yarn, consisting of a base material and a hydrocolloid component;

[0073] The base material is reticular polyester fiber,

[0074] The hydrocolloid component is made from the following raw materials in parts by weight:

[0075] 9 parts of G1651, 25 parts of sodium carboxymethylcellulose, 3 parts of growth factor microspheres, 3 parts of chitosan, 130 parts of liquid paraffin, 30 parts of petrolatum and 7 parts of lanolin.

[0076] The preparation method of the hydrocolloid oil yarn of the present embodiment comprises the following steps:

[0077] Take each raw material by above-mentioned parts by weight;

[0078] Soften G1651, liquid paraffin, vaseline and lanolin in a reaction kettle at a temperature of 200°C for 30 minutes to obtain a mixture;

[0079] In the mixture, add the sodium carboxymethyl cellulose and chitosan, the particle pore size of th...

Embodiment 3

[0090] The present embodiment provides a kind of hydrocolloid oil yarn, and specific scheme is:

[0091] A hydrocolloid oil yarn, consisting of a base material and a hydrocolloid component;

[0092] The base material is reticular polyester fiber,

[0093] The hydrocolloid component is made from the following raw materials in parts by weight:

[0094] 10 parts of G1651, 20 parts of sodium carboxymethylcellulose, 4 parts of growth factor microspheres, 4 parts of chitosan, 150 parts of liquid paraffin, 35 parts of petrolatum and 9 parts of lanolin.

[0095] The preparation method of the hydrocolloid oil yarn of the present embodiment comprises the following steps:

[0096] Take each raw material by above-mentioned parts by weight;

[0097] Soften G1651, liquid paraffin, vaseline and lanolin in a reaction kettle at a temperature of 200°C for 30 minutes to obtain a mixture;

[0098] In the mixture, add the sodium carboxymethyl cellulose and chitosan, the particle pore size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com