Adhesive, preparation method thereof, and epoxy glass fabric prepared from adhesive

A technology of epoxy glass and adhesive, applied in the direction of adhesive, epoxy resin glue, novolac epoxy resin adhesive, etc., can solve the problems of difficult edge trimming, difficult storage, hard and brittle, etc., and achieve easy Effects of storage, ease of procurement, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

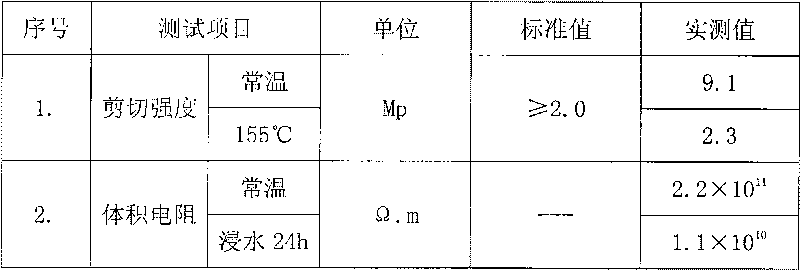

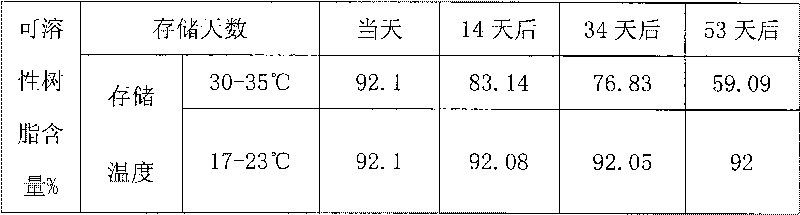

Examples

Embodiment 1

[0023] The preparation of adhesive and epoxy glass gray cloth in the present embodiment is specifically carried out according to the following steps:

[0024] 1) Preparation of curing agent for adhesive:

[0025] First, add tung oil with a mass fraction of 10% into the reactor, start stirring and turn on the steam to raise the temperature. When the temperature rises to 70°C, add maleic anhydride with a mass fraction of 3%, continue to heat up to 100°C, and turn off the steam. The temperature of the material is raised to 148°C by itself, and after 60 minutes of heat preservation reaction, it is cooled to below 80°C to obtain a resin for use;

[0026] Secondly, add toluene with a mass fraction of 14% in the empty reactor, start stirring, then add bismaleimide resin with a mass fraction of 5%, turn on the steam and raise the temperature to 110 ° C, and keep it at this temperature for 50 minutes. , then add the resin prepared above, heat up to 90°C again, and keep it warm for 50 ...

Embodiment 2

[0032] The preparation of adhesive and epoxy glass gray cloth in the present embodiment is specifically carried out according to the following steps:

[0033] 1) Preparation of curing agent for adhesive:

[0034] First, add tung oil with a mass fraction of 10.5% into the reactor, start stirring and turn on the steam to raise the temperature. When the temperature rises to 80°C, add maleic anhydride with a mass fraction of 2%, continue to heat up to 120°C, and turn off the steam. The temperature of the material is raised to 152°C by itself, and after 60 minutes of heat preservation reaction, it is cooled to below 80°C to obtain a resin for use;

[0035] Secondly, add toluene with a mass fraction of 14.2% in the empty reactor, start stirring, then add bismaleimide resin with a mass fraction of 5.3%, turn on the steam and raise the temperature to 120°C, and keep it at this temperature for 70 minutes. , then add the resin prepared above, heat up to 91°C again, and keep it warm for...

Embodiment 3

[0041] The preparation of adhesive and epoxy glass gray cloth in the present embodiment is specifically carried out according to the following steps:

[0042] 1) Preparation of curing agent for adhesive:

[0043] First, add tung oil with a mass fraction of 11% into the reactor, start stirring and turn on the steam to raise the temperature. When the temperature rises to 75°C, add maleic anhydride with a mass fraction of 2.5%, continue to heat up to 110°C, and turn off the steam. The temperature of the material is raised to 150°C by itself, and after the heat preservation reaction for 60 minutes, it is cooled to below 80°C to obtain the resin, which is ready for use;

[0044] Secondly, add toluene with a mass fraction of 14.2% in the empty reactor, start stirring, then add bismaleimide resin with a mass fraction of 5%, turn on the steam and raise the temperature to 115°C, and keep it at this temperature for 60 minutes. , then add the resin prepared above, heat up to 94°C again,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com