High temperature oxidation resistant composite gradient coating on Ti2AlNb alloy surface and preparation method thereof

A technology of high temperature oxidation resistance and gradient coating, applied in chemical instruments and methods, metal material coating processes, coatings, etc., can solve the problems of poor high temperature oxidation resistance, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

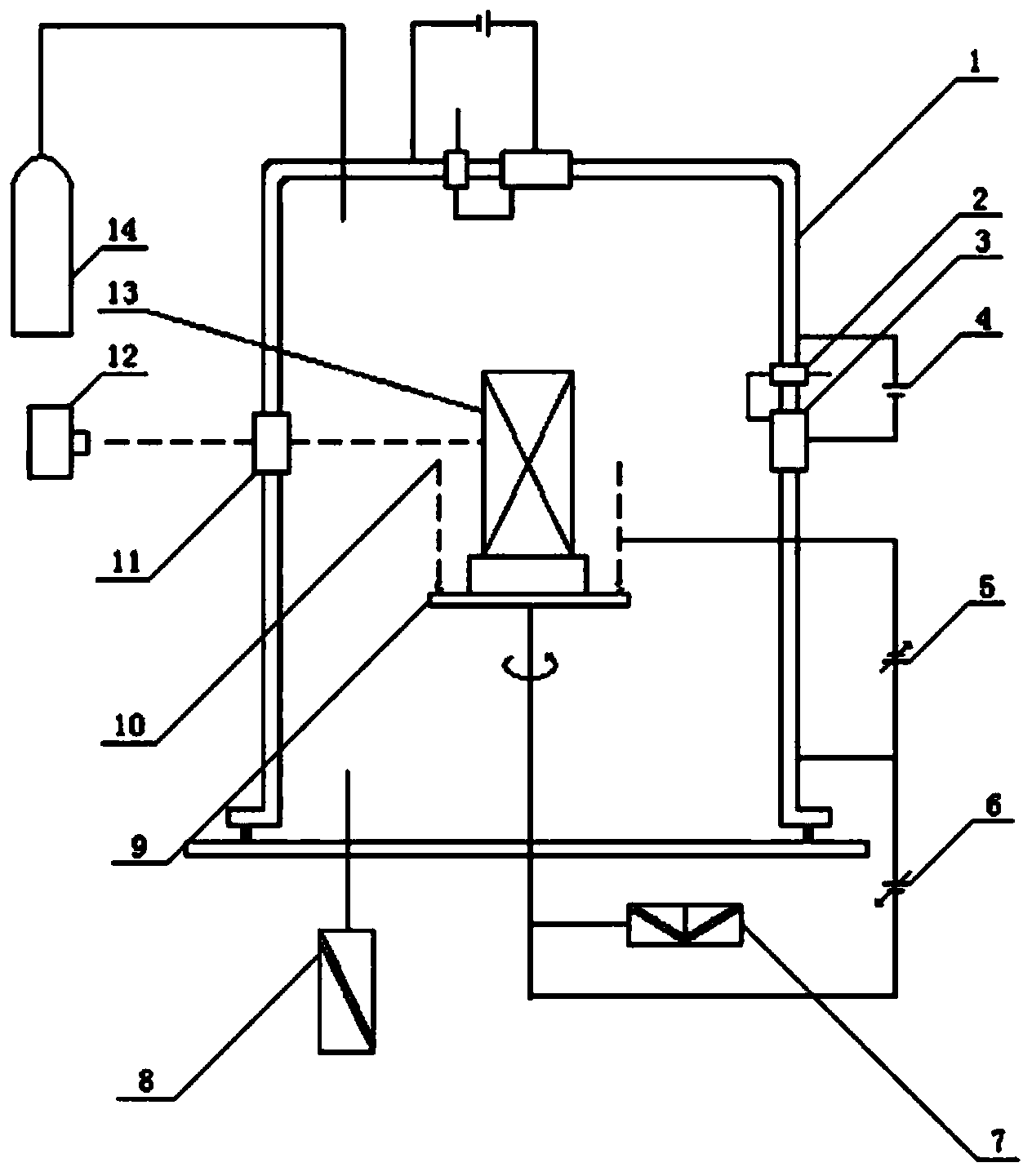

Method used

Image

Examples

Embodiment 1

[0031] 1) Put Ti 2 AlNb-based alloy and Al-Ti alloy targets are put into the arc glow plasma surface alloying device, and Ti 2 The AlNb-based alloy is used as the workpiece electrode, and the Al-Ti alloy target is used as the source electrode. The composition ratio of the Al-Ti alloy target material is: Al accounts for 75wt%, and Ti accounts for 25wt%.

[0032] 2) Evacuate to the ultimate vacuum, feed argon gas, start glow, and debug process parameters are: arc current: 20 A; workpiece bias voltage: 250 V; argon gas pressure: 0.3 Pa; distance between target and workpiece: 200 mm; Duty cycle: 0.2; Holding time: 0.5 h; Working temperature: 840~880℃;

[0033] 3) Stop the glow, cut off the power, and complete the preparation of the Al-Ti infiltrated layer in the middle layer;

[0034] 4) Put the prepared Al-Ti infiltrated layer sample and pure Al alloy target into the arc glow plasma surface alloying device, use the Al-Ti infiltrated layer sample as the workpiece electrode, and...

Embodiment 2

[0041] 1) Put Ti 2 AlNb-based alloy and Al-Ti alloy targets are put into the arc glow plasma surface alloying device, and Ti 2 The AlNb-based alloy is used as the workpiece electrode, and the Al-Ti alloy target is used as the source electrode. The composition ratio of the Al-Ti alloy target material is: Al accounts for 55wt%, and Ti accounts for 45wt%.

[0042] 2) Evacuate to the ultimate vacuum, feed argon gas, start glow, and debug process parameters are: arc current: 30 A; workpiece bias voltage: 350 V; argon gas pressure: 0.5 Pa; distance between target and workpiece: 150 mm; Duty cycle: 0.2; Holding time: 0.5 h; Working temperature: 840~880℃;

[0043] 3) Stop the glow, cut off the power, and complete the preparation of the Al-Ti infiltrated layer in the middle layer;

[0044] 4) Put the prepared Al-Ti infiltrated layer sample and pure Al alloy target into the arc glow plasma surface alloying device, use the Al-Ti infiltrated layer sample as the workpiece electrode, and...

Embodiment 3

[0050] Except following content, all the other are identical with embodiment 1 content:

[0051] Step 1) The composition ratio of the Al-Ti alloy target material is: Al accounts for 45wt%, and Ti accounts for 55wt%.

[0052] The debugging process parameters of step 2) are: arc current: 35A; workpiece bias voltage: 300V; argon gas pressure: 0.4Pa; distance between target and workpiece: 170mm; duty cycle: 0.5; holding time: 1h; working temperature: 840 ~880°C;

[0053] Step 5) Vacuumize to the ultimate vacuum degree, feed argon gas, start glow, and debug process parameters are: arc current: 35 A; workpiece bias voltage: 300 V; argon gas pressure: 0.4Pa; distance between target and workpiece: 170 mm; duty cycle: 0.2; holding time: 0.5 h; working temperature: 840~880℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com