Titanium alloy surface high temperature oxidation resistance and wear resistance oxide gradient coat, and preparation method thereof

A technology of high temperature oxidation resistance and gradient coating, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problem of poor high temperature oxidation resistance, etc. The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

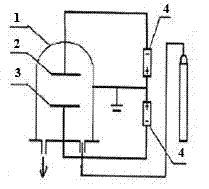

[0036] (1) Put the titanium alloy TC4 and Al-Cr-Ni alloy targets into the double-glow plasma surface alloying device, use the titanium alloy TC4 as the workpiece pole, and use the Al-Cr-Ni alloy target as the source. The composition ratio of Al-Cr-Ni alloy target material is: Al accounts for 50%, Cr accounts for 40%, and Ni accounts for 10%.

[0037] (2) Vacuumize to the ultimate vacuum degree, and send in argon. Start Glow, and adjust the process parameters to the following values:

[0038] Target voltage: 600 V;

[0039] Workpiece voltage: 400 V;

[0040] Argon pressure: 37 Pa;

[0041] Distance between target and workpiece: 10 mm;

[0042] (3) Stop the glow after 4 hours, cut off the power, and break the vacuum to atmospheric pressure.

[0043] (4) Open the device and take out the Al-Cr-Ni alloy target.

[0044] (5) Close the device, evacuate to the ultimate vacuum, and send in argon and oxygen. Start Glow, and adjust the process parameters to the following values: ...

Embodiment 2

[0053] (1) Put the titanium alloy TC11 and the Al-Cr-Ni alloy target into the double-glow plasma surface alloying device, use the titanium alloy TC11 as the workpiece pole, and use the Al-Cr-Ni alloy target as the source. The composition ratio (mass ratio) of the Al-Cr-Ni alloy target material is: Al accounts for 40%, Cr accounts for 30%, and Ni accounts for 30%.

[0054] (2) Vacuumize to the ultimate vacuum degree, and send in argon. Start Glow, and adjust the process parameters to the following values:

[0055] Target voltage: 700 V;

[0056] Workpiece voltage: 500 V;

[0057] Argon pressure: 52 Pa;

[0058] Distance between target and workpiece: 15 mm;

[0059] (3) Stop the glow after 4 hours, cut off the power, and break the vacuum to atmospheric pressure.

[0060] (4) Open the device and take out the Cr-Ni alloy target.

[0061] (5) Close the device, evacuate to the ultimate vacuum, and send in argon and oxygen. Start Glow, and adjust the process parameters to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com