Refined grinding process and grinding medium supplementing device

A technology of grinding medium and double uniform adjustment, applied in the direction of grain processing, etc., to achieve the effect of low investment, reduced grinding cost and more benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

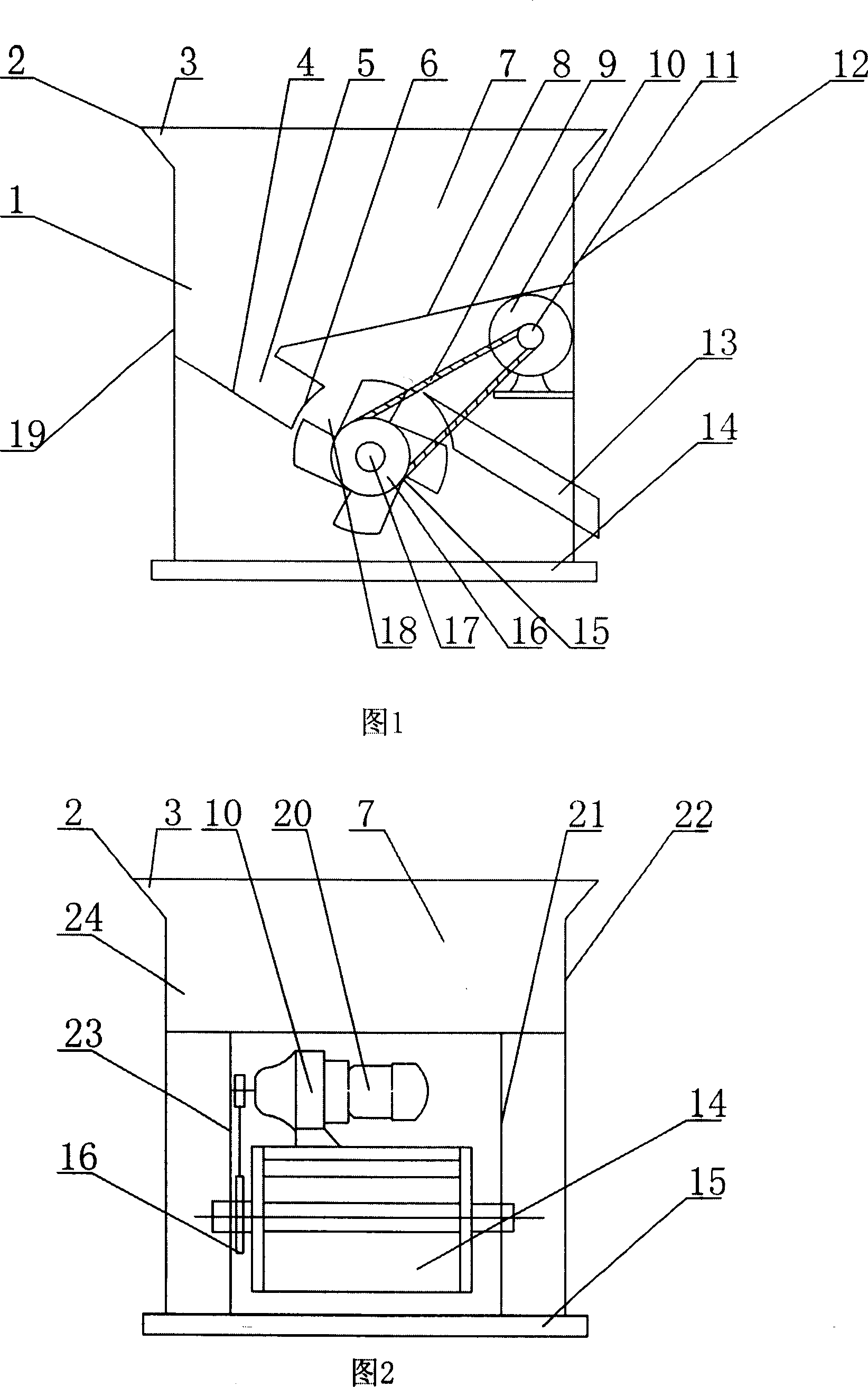

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

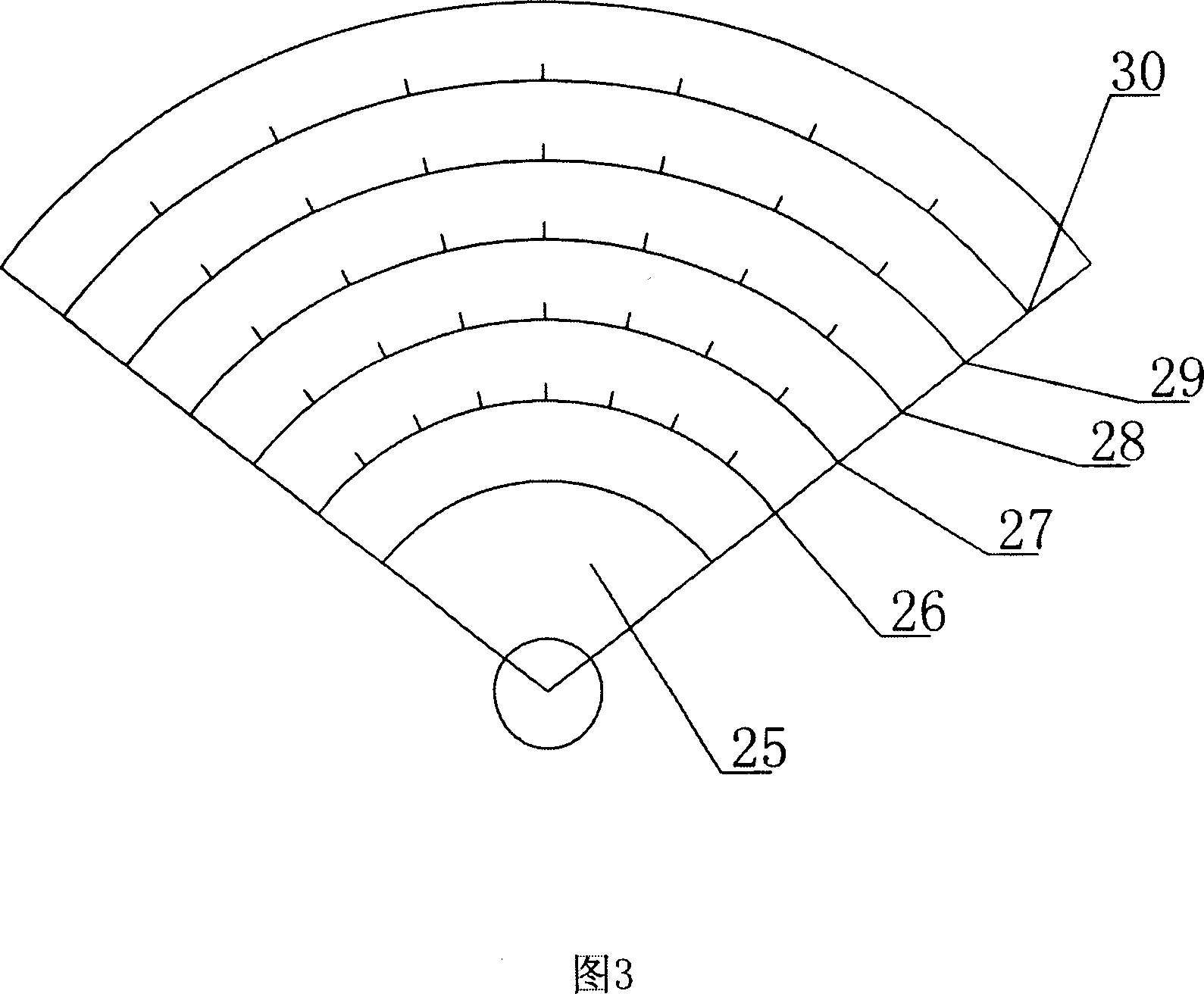

[0024] According to the fine grinding method of "double uniformity and one adjustment" process of the present invention, including the method of controllable and uniform continuous feeding, the appropriate grinding concentration is adjusted by metering water supply, and it is characterized in that it uses timing, quantitative, uniform and continuous recording of shorthand to control the amount of automatic grinding. The ore medium filling device, according to the needs of the grindability of the ore to be ground and the grinding capacity of the grinding medium, fills the grinding medium into the ball mill to achieve a balanced and stable filling rate of the grinding medium and achieve a suitable ratio of medium specifications. It is organically combined with the controllable uniform and continuous feeding to form a "double control and doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com