Method and device for producing artificial crushed sand by means of a thermal treatment using sand in the form of fine sand (fS/FSa) and/or round sand as the starting material

A material, round sand technology, applied in grain processing, mineral processing, pretreatment control, etc., to reduce the risk of natural disasters, reduce the increase, and slow down the expansion of the desert

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

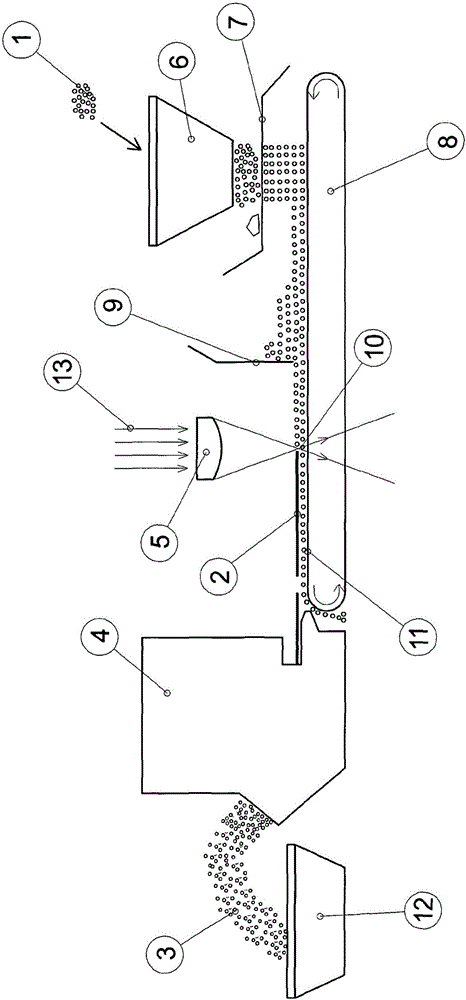

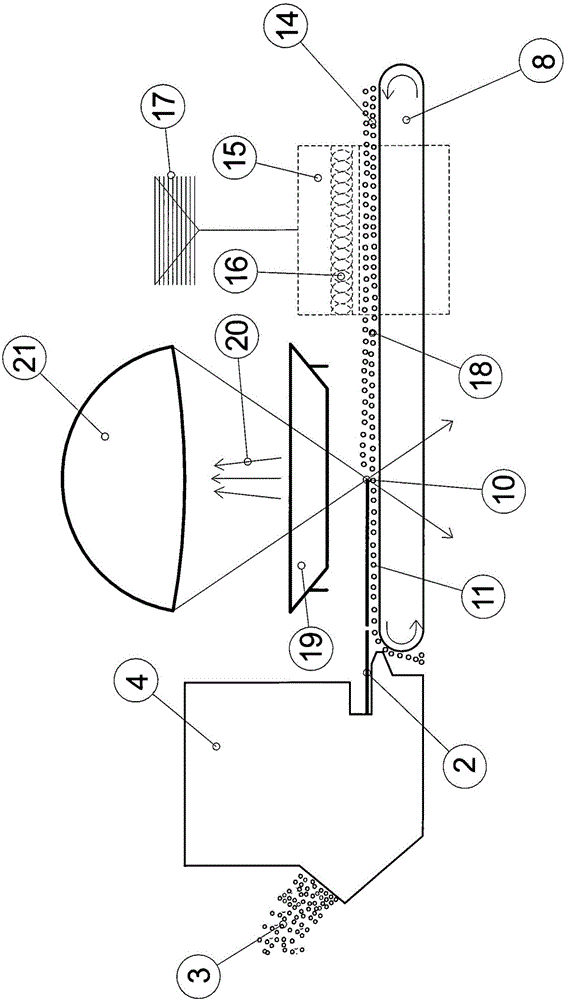

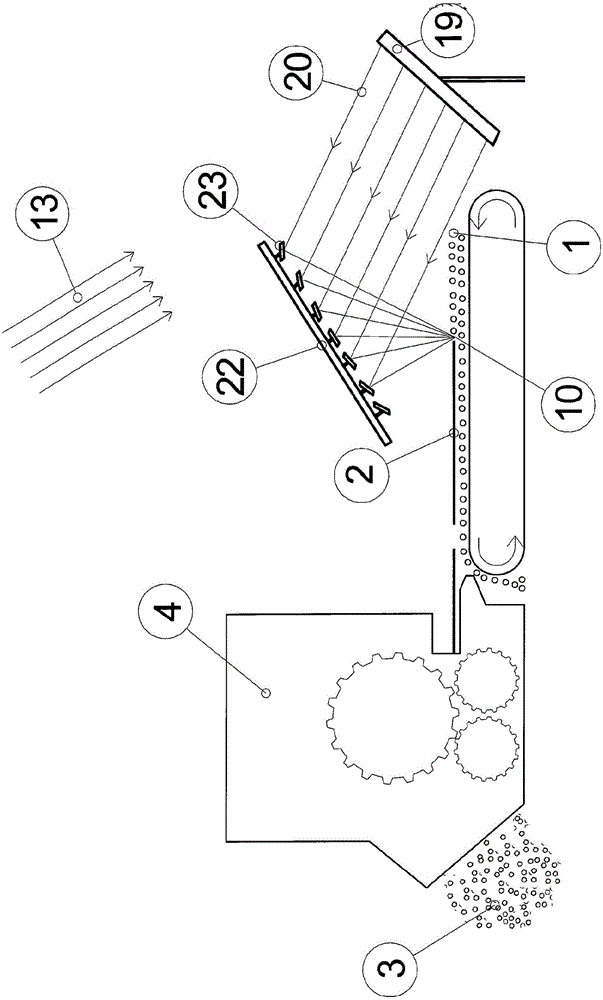

[0040] figure 1 A possible device for carrying out a preferred embodiment of the method according to the invention is shown. In this case, desert sand as a starting material 1 is placed through a storage container 6 (eg, funnel-shaped) on a coarse screen 7 to remove the coarsest impurities from the starting material 1 . After the screening process, the screened starting material 1 is transferred directly to a suitable conveyor belt 8 as support surface. The conveyor belt is provided with a release sheet 9 to produce a uniform layer with a controllable layer thickness. Optionally, the flatness of the material layer can be improved by vibrating belts. The homogeneous sand layer goes further via the conveyor belt 8 to the level of heat treatment, melting the starting material 1 as it is guided past the immediate region of the focal point 10 of the device 5 for concentrating the sun's rays, such as a plano-convex converging lens. The larger the area of the means 5 for concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com