Purification packed tower and purification method of methyl trichlorosilane

A technology of monomethyltrichlorosilane and methyltrichlorosilane, which is applied in separation methods, chemical instruments and methods, silicon organic compounds, etc., can solve problems such as huge maintenance costs and operating costs, difficulty in realistic manufacturing, and high reflux ratio , to achieve the effect of small cooling and heating public works consumption, optimized operating conditions, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

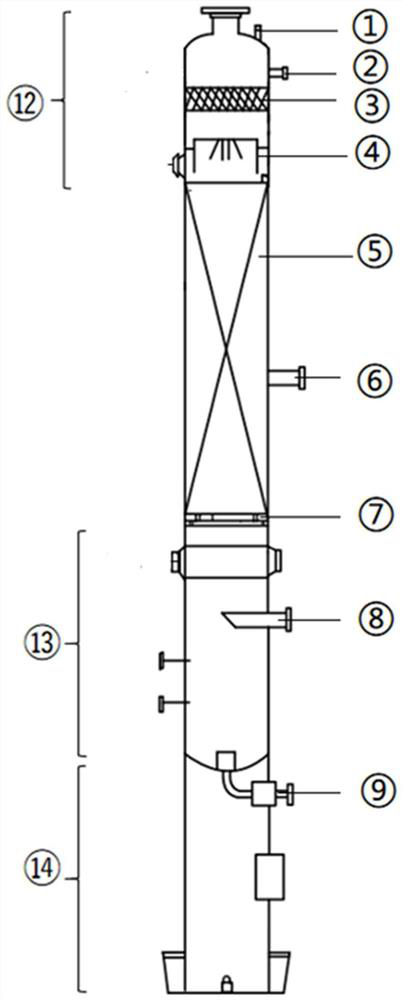

[0039] like figure 1 As shown, the methylchlorosilane mixture with a temperature of 66.9 °C and a flow rate of 370 kg / h obtained from the previous section was 99.4 wt% of monomethyltrichlorosilane, 0.1 wt% of 2-methyl-2-pentene, 3 - Methyl-2-pentene 0.33 wt%, trimethylmonochlorosilane 0.02 wt%, and dimethyldichlorosilane 0.13 wt% are fed from the feed port 6 at a height of 10 m of the filler, and the material is at the filler position 5 and re- The steam rises in the boiler for gas-liquid mass transfer, enters the reboiler and is converted into steam, enters the tower body from the reboiler steam inlet 8, and transfers gas and liquid mass between the packing part and the condensate at the top of the tower and the feed liquid, and is fully transferred. The high-quality gas and liquid phases pass through the defoaming net 3 to reach the discharge port 1 to obtain light components, and part of the gas and liquid phases enter the tower top condenser to condense into liquid, and th...

Embodiment 2

[0041] Methylchlorosilane mixture with a temperature of 66.5°C and a flow rate of 370kg / h obtained from the previous section: monomethyltrichlorosilane 99.4 wt%, 2-methyl-2-pentene 0.07 wt%, 3-methyl -2 Pentene 0.36 wt%, trimethylmonochlorosilane 0.05 wt%, dimethyldichlorosilane 0.12 wt% are fed from the feed port 6 at a height of 10m of the filler, and the material is in the filler part 5 and the reboiler The rising steam transfers gas-liquid mass, enters the reboiler and turns into steam, enters the tower body from the reboiler steam inlet 8, and transfers gas-liquid mass between the packing part and the condensate at the top of the tower and the feed liquid, and the gas with sufficient mass transfer. The liquid phase passes through the defoaming net 3 to reach the discharge port 1 to obtain light components, and part of the gas and liquid phase enters the tower top condenser to be condensed into liquid, and then returns to the tower body through the condenser reflux pipe 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com