A method for producing agglomerates from complex nickel-containing wet materials

A wet material and agglomerate technology is applied in the field of complex nickel-containing wet materials to produce agglomerates, which can solve the problems of increased material processing difficulty, inability to increase the processing capacity, affecting the processing and processing efficiency of enterprises, etc., and achieve the production capacity of metal smelting and recycling. , Improve the production efficiency of enterprises and reduce the effect of large storage and backup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

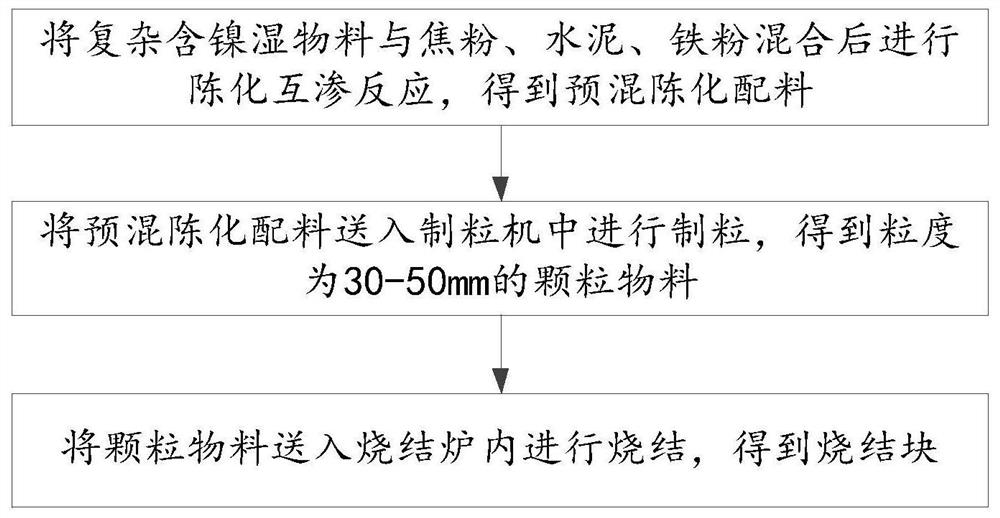

[0043] The invention provides a method for producing agglomerates from complex nickel-containing wet materials, comprising:

[0044] S1. Ingredients:

[0045] The material containing 1% nickel, the material containing 3% nickel, the material containing 5% nickel, and the material containing 7% nickel are respectively mixed according to the ratio of 1:2:2:3 to obtain the complex nickel-containing wet material. The nickel content is 4.75%; then the complex nickel-containing wet materials and reagents such as coke powder, cement, and iron powder are mixed according to the proportions of 5%, 8%, and 10% of the total amount of materials, and are carried out in batches by forklift. The material is evenly mixed for the first time, and then the material is shoveled into the batching bin, automatically metered and fed to the biaxial mixing agitator for mixing, and the nickel-containing material after mixing continues to enter the granulation process according to the production plan of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com