A Saturated Adsorption Process and Device for Pressure Swing Adsorption Decarburization

A pressure swing adsorption and process technology, which is applied in the field of saturated adsorption process and its devices, can solve the problems of large loss of effective components of gas and low CO2 absorption rate, etc., to reduce the loss of effective components, increase CO2 absorption rate, and realize recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

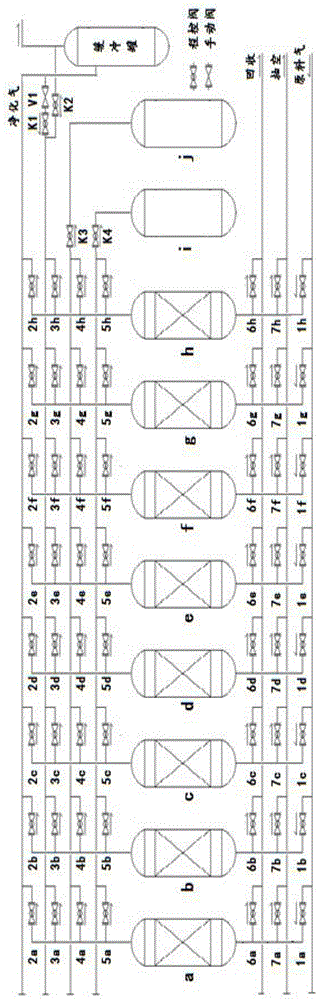

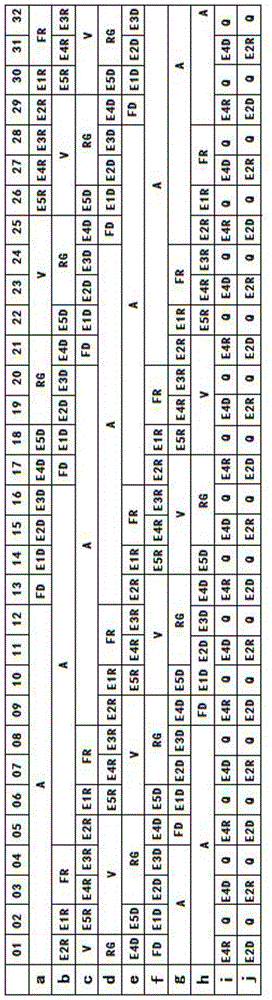

[0050] refer to figure 1 and figure 2 As shown, a saturated adsorption process for pressure swing adsorption decarburization provided by the present invention uses adsorption towers arranged side by side to remove CO2 gas in the raw gas through the adsorbent in the adsorption tower to obtain purified gas. Each cycle of the above adsorption process includes adsorption, equal pressure drop, recovery RG, vacuum V, equal pressure rise, isolation Q and final boost FR, and the described adsorption includes pre-adsorption A1, adsorption A and post-adsorption A2, Among them: the specific process of the pre-adsorption A1 is to input the output gas of other adsorption towers in the post-adsorption A2 stage, and output the purified gas; the specific process of the adsorption A is to input the raw material gas and output the purified gas; the specific process of the post-adsorption A2 is to output more than the purified gas The gas with the gas index is used as the input gas of the pre-...

Embodiment 2

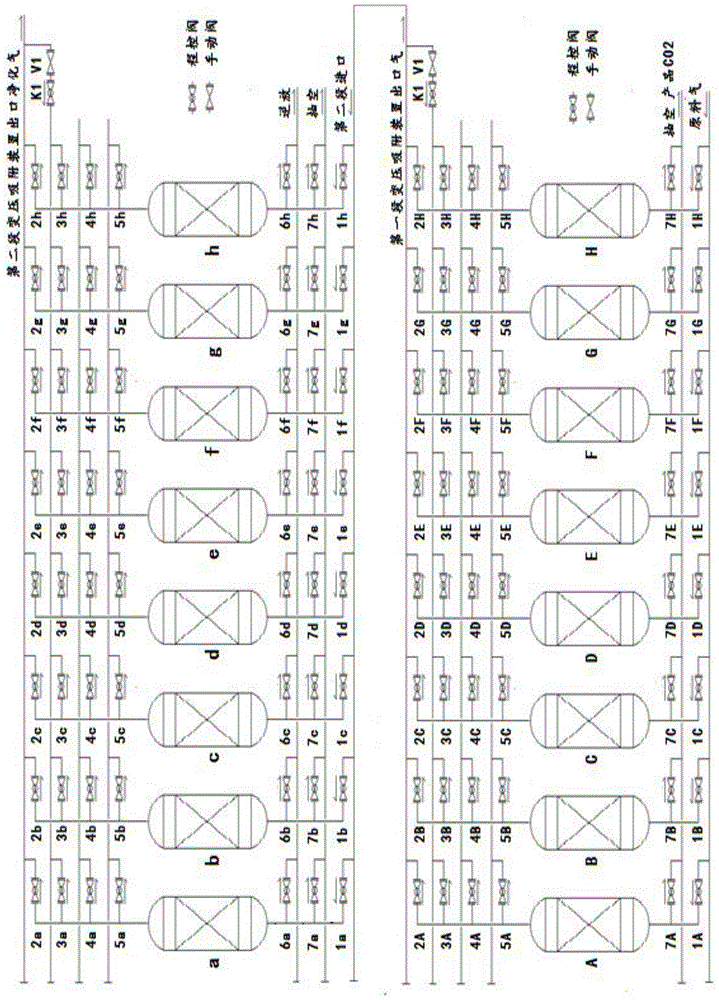

[0073] refer to figure 1 As shown, the present invention also provides a device for realizing the above-mentioned saturated adsorption process of pressure swing adsorption decarburization, comprising multiple groups of adsorption towers (a, b, c...) arranged side by side, and adsorption towers (a, b, The bottom of c...) is connected to the raw material inlet valve (1a, 1b, 1c...) for feeding the raw material gas, and connected to the top of the adsorption tower (a, b, c...) to output the purified gas for the purified gas Gas outlet valve (2a, 2b, 2c...), the first pressure equalizing valve (3a, 3b, 3c...) connected to the top of the adsorption tower (a, b, c...) for pressure equalization and pressure rise, The second pressure equalizing valve (4a, 4b, 4c...) and the third pressure equalizing valve (5a, 5b, 5c...) respectively pass through the first control valve K3 and the second control valve K4 and the second pressure equalizing valve ( 4a, 4b, 4c...) and the third pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com