Recycling and treatment method for waste printing nickel screen

A technology of recovery treatment and nickel mesh, which is applied in the direction of chemical instruments and methods, nickel sulfate, nickel compounds, etc., can solve the problems of low recovery rate, large pollution, high cost, etc., and achieve high recovery rate, low power consumption and added value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

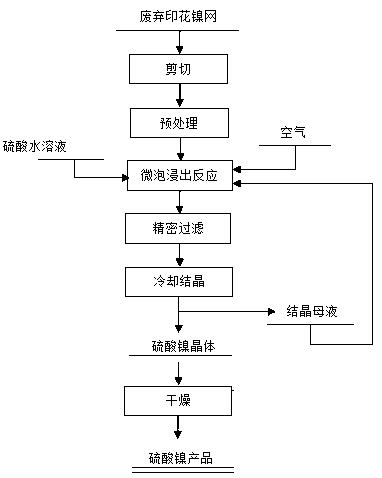

[0025] A method for recycling and processing waste printed nickel mesh, including the following steps:

[0026] 1) The waste printed nickel mesh is cut into fragments about 1×1cm in size, and the fragments are placed in a titanium basket, which enters the pretreatment tank, and is soaked in a small amount of dilute sulfuric acid aqueous solution for about 1 hour for pretreatment. To remove a small amount of iron filings on the fragments obtained in the shearing process, take the fragments from the dilute sulfuric acid aqueous solution for use;

[0027] 2) There is an aqueous sulfuric acid solution inside the microbubble nickel dissolving kettle, the mass concentration of the sulfuric acid aqueous solution is 200g / L, and the temperature is 80°C; the pretreated fragments obtained in step 1) are put into the microbubble nickel dissolving kettle ( The mass ratio of the fragments to the volume of the sulfuric acid aqueous solution is 1:5, the unit of mass is g, and the unit of volume is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com