Medical gauze waste recycling equipment and method

A technology of recycling equipment and recycling methods, applied in recycling technology, decomposition and recovery of textiles, textiles and papermaking, etc., can solve problems such as yarn ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

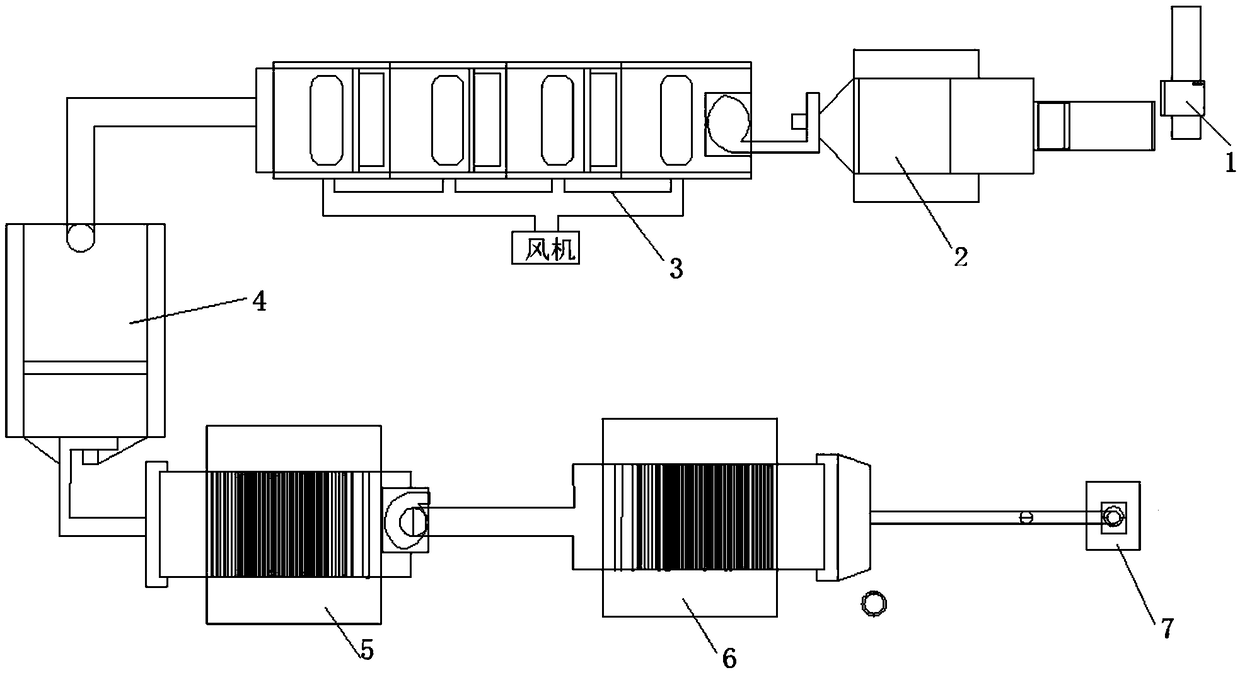

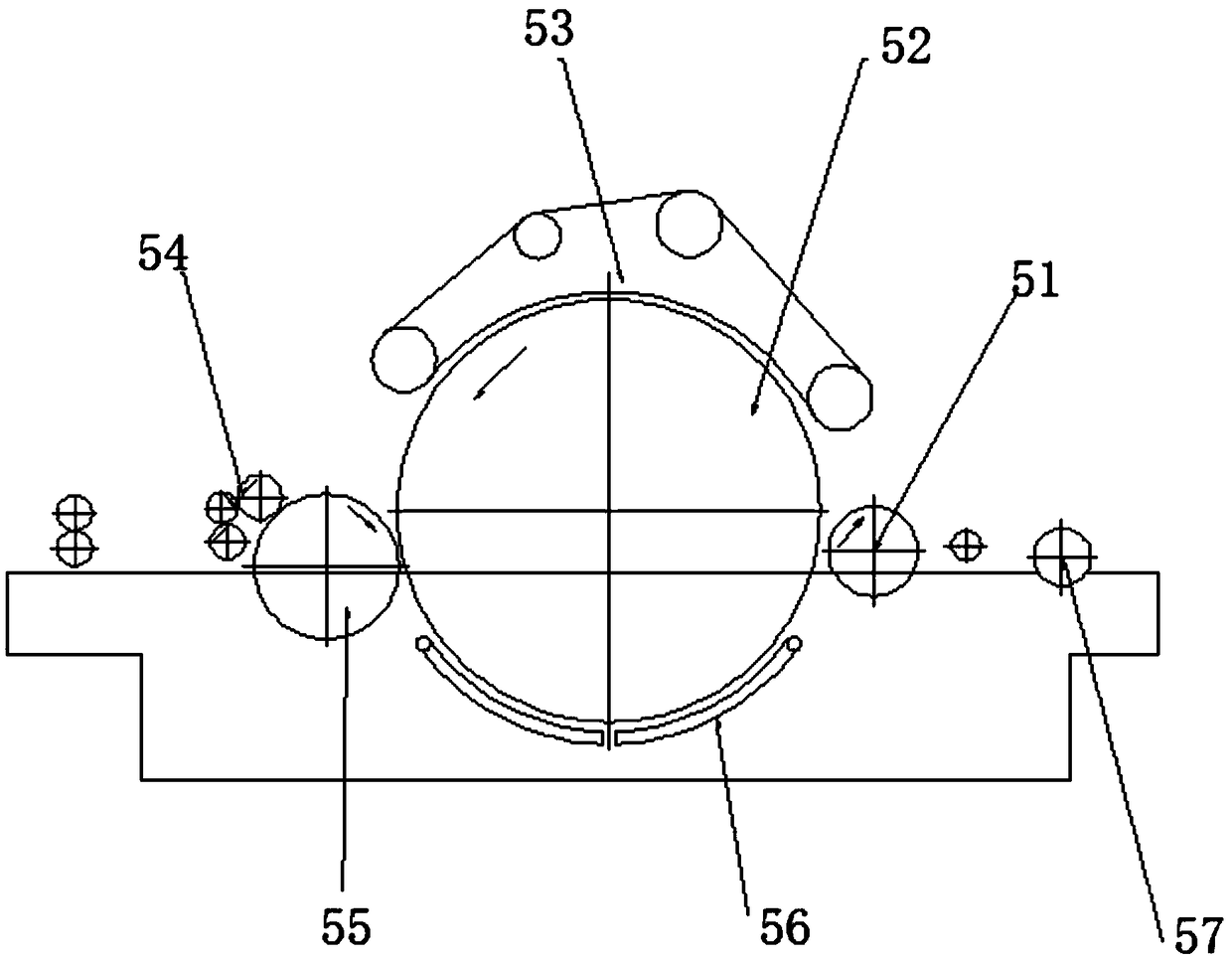

[0033] This embodiment provides a recovery device for medical gauze leftovers, such as figure 1 , the equipment includes a cutting machine 1, a feeding machine 2, a bomb cleaning machine 3, a first carding machine 5 and an air fiber separator 7 connected in sequence through pipelines. Wherein the cutting machine 1 is used for cutting the reclaimed gauze leftovers, cutting the large piece of gauze into small pieces of gauze, so as to prevent the large pieces of gauze from being wound up in the feeder 2 . The cutting machine 1 and the feeding machine 2 are connected through a pipeline, and the cutting machine 1 directly transports the cut small pieces of gauze to the feeding machine 2 through the pipeline for primary opening, so that the small pieces of gauze are opened into yarn ends, and fed Feeder 2 loosens the gauze into yarn ends and sends them to bomb cleaning machine 3 through the blower, and bomb cleaner 3 is used to open the yarn ends loosened by feeder 2 in multiple st...

Embodiment 2

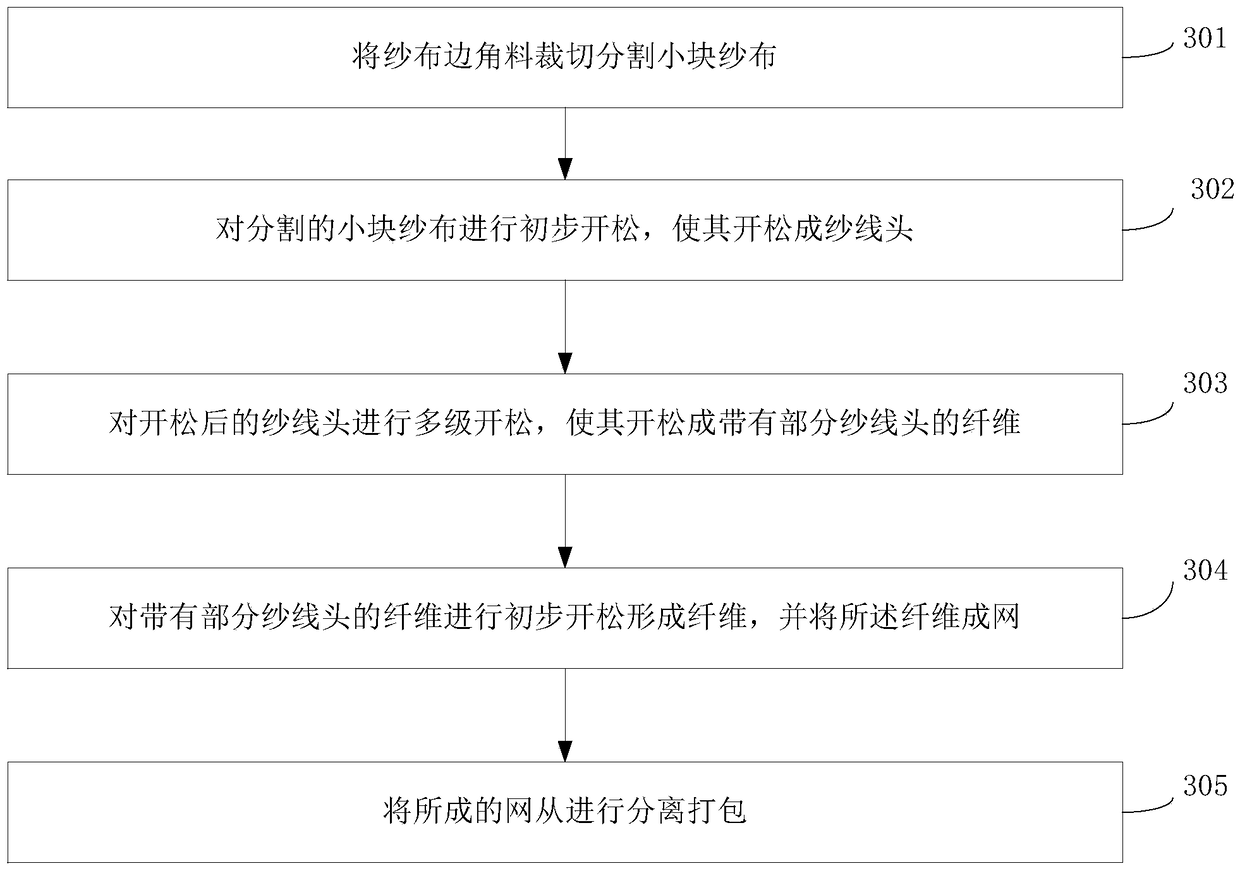

[0040] On the basis of embodiment 1, the present embodiment provides a method for recycling medical gauze leftovers, such as image 3 ,include:

[0041]Step 301: cutting and dividing the leftover gauze into small pieces of gauze;

[0042] Step 302: Preliminarily opening the divided small pieces of gauze to form yarn ends;

[0043] Step 303: performing multi-stage opening on the loosened yarn ends to form fibers with partial yarn ends;

[0044] Step 304: Preliminarily opening the fibers with partial yarn ends to form fibers, and forming the fibers into a web;

[0045] Step 305: Separating and packing the formed fiber web.

[0046] Wherein, in step 301, the present embodiment uses the cutting machine 1 to cut the input gauze leftovers into small pieces of gauze, so as to prevent large pieces of gauze from being entangled in the subsequent opening process.

[0047] Wherein, in step 302, in this embodiment, the small piece of gauze cut in step 301 is preliminarily opened by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com