A kind of preparation method and application of nanofiber/polyurethane hydrophobic sponge

A technology of polyurethane sponge and nanofiber, applied in the direction of separation method, fiber treatment, fiber chemical characteristics, etc., can solve the problems of complex preparation process, etc., and achieve the effect of simple preparation process, good adsorption effect and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this example, 1.8 g of PVDF-HFP and 10 g of DMF were weighed into a 100 ml glass bottle and stirred at room temperature for 4 hours. A transparent spinning solution A was obtained.

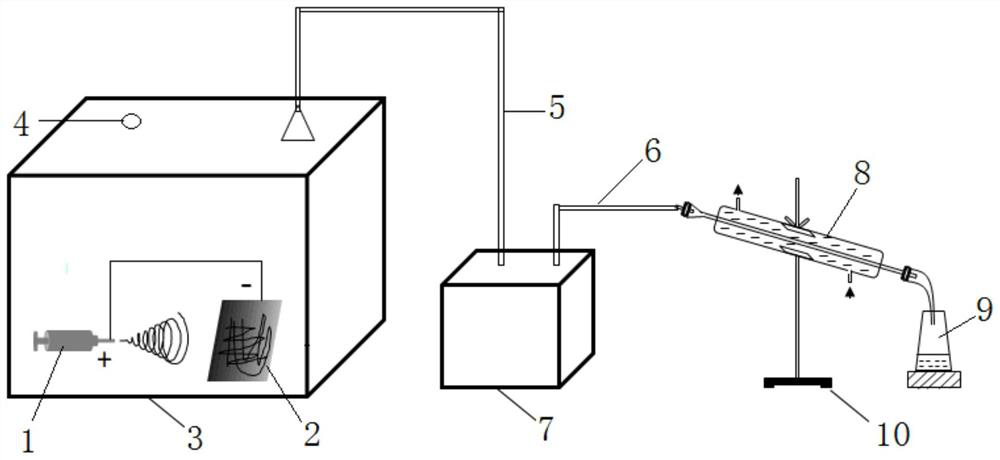

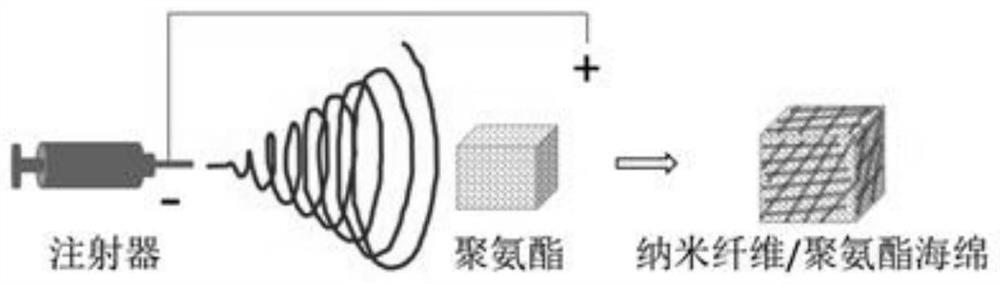

[0051] Such as figure 1 Pour the spinning solution A into the syringe as indicated. The spinning parameters were adjusted as: spinning voltage 18kV, receiving distance 6cm, and the humidity in the spinning box 3 was adjusted to 90%. Place the cut polyurethane sponge between the receiving plate 2 and the needle of the syringe 1. Each side was spun for about 10 minutes, and turned over continuously until all sides of the polyurethane were covered by PVDF-HFP nanofibers. Obtain PVDF-HFP nanofiber / polyurethane hydrophobic sponge initial sample B.

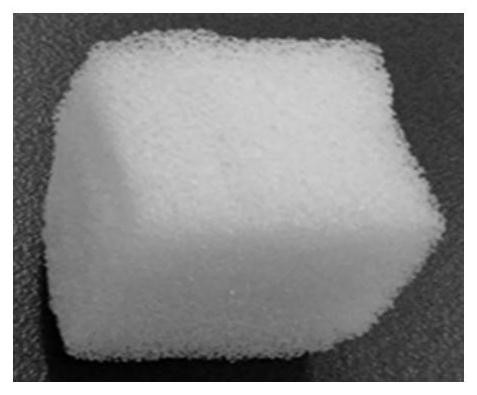

[0052] Move the PVDF-HFP nanofiber / polyurethane hydrophobic sponge initial sample B into the oven. The parameters are set as follows: the temperature is set to 40° C., and the time is 6 hours. Remove residual solvent and water vapor, and fur...

Embodiment 2

[0055] In this example, 2.0 g of PVDF-HFP and 10 g of DMF were weighed into a 100 ml glass bottle and stirred at room temperature for 4 hours. A transparent spinning solution A was obtained.

[0056] Such as figure 1 Pour the spinning solution A into the syringe as indicated. The spinning parameters were adjusted as follows: spinning voltage 18kV, receiving distance 6cm, and the humidity in the spinning box was adjusted to 90%. Place the cut polyurethane sponge between the receiving plate 2 and the needle of the syringe 1. Each side was spun for about 10 minutes, and turned over continuously until all sides of the polyurethane were covered by PVDF-HFP nanofibers. Obtain PVDF-HFP nanofiber / polyurethane hydrophobic sponge initial sample B.

[0057] Move the PVDF-HFP nanofiber / polyurethane hydrophobic sponge initial sample B into the oven. The parameters are set as follows: the temperature is set to 40° C., and the time is 6 hours. Remove residual solvent and water vapor, a...

Embodiment 3

[0059] In this example, 1.8 g of PVDF-HFP and 10 g of DMF were weighed into a 100 ml glass bottle and stirred at room temperature for 4 hours. A transparent spinning solution A was obtained.

[0060] Such as figure 1 Pour the spinning solution A into the syringe as indicated. The spinning parameters were adjusted as follows: spinning voltage 18kV, receiving distance 6cm, and humidity in the spinning box was adjusted to 95%. Place the cut polyurethane sponge between the receiver plate and the needle of the syringe. Each side was spun for about 10 minutes, and turned over continuously until all sides of the polyurethane were covered by PVDF-HFP nanofibers. Obtain PVDF-HFP nanofiber / polyurethane hydrophobic sponge initial sample B.

[0061] Move the PVDF-HFP nanofiber / polyurethane hydrophobic sponge initial sample B into the oven. The parameters are set as follows: the temperature is set to 40° C., and the time is 6 hours. Remove residual solvent and water vapor, and furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com