A purification method for raw materials for production of decorative base paper titanium dioxide

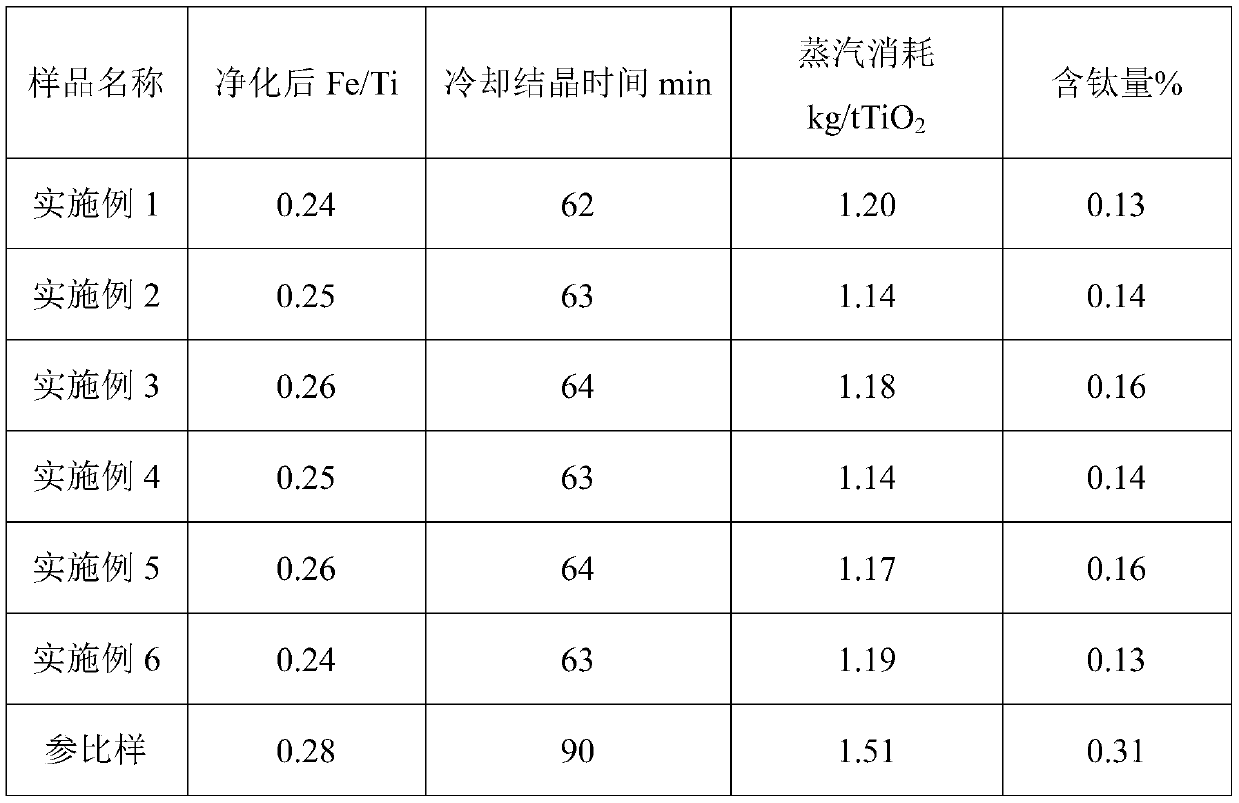

A technology for decorating base paper and titanium dioxide, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve problems such as the separation of ferrous sulfate, achieve the effects of increasing yield, uniform and pure crystallization, and saving cooling crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

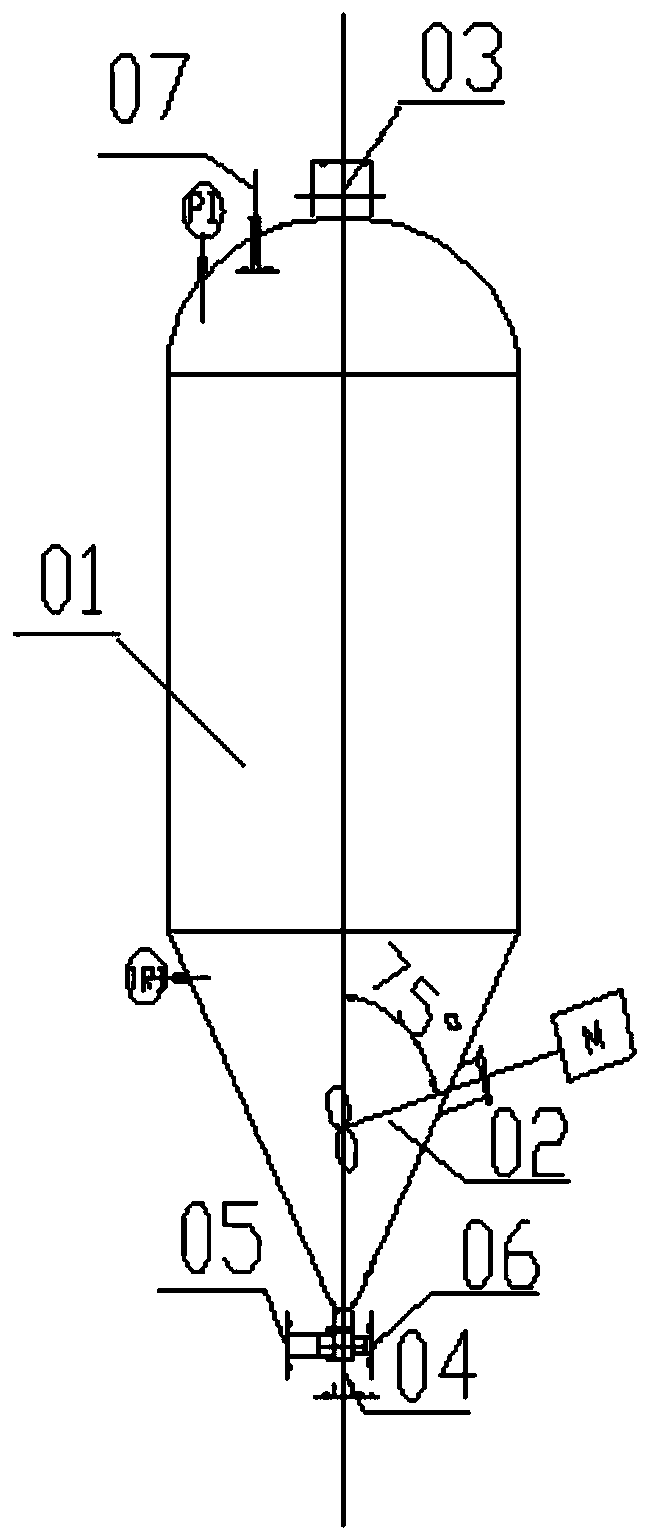

[0030] A method for purifying the raw materials for the production of decorative base paper titanium dioxide, which is processed in a crystallizer with a stirrer, and the volume of the crystallizer used is 56m 3 , The cylinder body is increased by 500mm on the purchased crystallization tank. This design increases the separation space between the secondary steam and the titanium sulfate solution, reduces the amount of secondary steam entrainment, and reduces the loss of the titanium sulfate solution; agitator and level The angle of the direction is 15°. This design increases the radial flow of the materials in the tank, the mixing of materials is more uniform, the crystallization efficiency is improved, the ferrous sulfate crystals are more uniform, and the wall adhesion of the ferrous sulfate crystals is reduced, including the following steps:

[0031] A. Add 25m to the crystallization tank 3 Titanium sulfate solution (concentration TiO 2 121g / L), turn on the stirrer, and control t...

Embodiment 2

[0037] A method for purifying the raw materials for the production of decorative base paper titanium dioxide, which is processed in a crystallizer with a stirrer, and the volume of the crystallizer used is 56m 3 , The cylinder body is increased by 500mm on the purchased crystallization tank. This design increases the separation space between the secondary steam and the titanium sulfate solution, reduces the amount of secondary steam entrainment, and reduces the loss of the titanium sulfate solution; agitator and level The angle of the direction is 15°. This design increases the radial flow of the materials in the tank, the mixing of materials is more uniform, the crystallization efficiency is improved, the ferrous sulfate crystals are more uniform, and the wall adhesion of the ferrous sulfate crystals is reduced, including the following steps:

[0038] A. Add 26m to the crystallization tank 3 Titanium sulfate solution (concentration TiO 2 121g / L), turn on the stirrer, and control t...

Embodiment 3

[0044] A method for purifying the raw materials for the production of decorative base paper titanium dioxide, which is processed in a crystallizer with a stirrer, and the volume of the crystallizer used is 56m 3 , The cylinder body is increased by 500mm on the purchased crystallization tank. This design increases the separation space between the secondary steam and the titanium sulfate solution, reduces the amount of secondary steam entrainment, and reduces the loss of the titanium sulfate solution; agitator and level The angle of the direction is 20°. This design increases the radial flow of the materials in the tank, the mixing of materials is more uniform, the crystallization efficiency is improved, the ferrous sulfate crystals are more uniform, and the adhesion of the ferrous sulfate crystals to the wall is reduced, including the following steps:

[0045] A. Add 25m to the crystallization tank 3 Titanium sulfate solution (concentration TiO 2 121g / L), turn on the stirrer and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com