Patents

Literature

55results about How to "Efficient demulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick oil demulsifier and its prepn

ActiveCN1810933ALow densityIncrease viscosityHydrocarbon oil dewatering/demulsificationEpoxyDemulsifier

The present invention is one kind of thick oil demulsifier and its preparation process, and belongs to the field of petrochemical technology. The present invention features that phenol-amine resin as the initial material is block polymerized with epoxy propane ad epoxy ethane under the action of catalyst to obtain stereo netted macromolecular polyether as the thick oil demulsifier. The polyether as the thick oil demulsifier may be further chain expanded for even high demulsifying effect. The thick oil demulsifier can reach the oil-water interface fast to lower the elasticity and viscosity of the interface film, speed the aggregation of liquid drops and demulsify effectively. The thick oil demulsifier has simple preparation process, is suitable for industrial production, and may be used in the efficient dewatering of oil field produced liquid with different water contents.

Owner:LIAONING OXIRANCHEM INC

Method for preparing multifunctional deemulsifying agent of crude oil and products thereof

InactiveCN1600835AImprove surface activityImprove wettabilityHydrocarbon oil dewatering/demulsificationEpoxyAlkaline earth metal

This invention provides a method for preparing crude oil demulsification agent for crude oil pretreatment in refinery plant. Said multi-functional demulsification agent has betaine structure, being of amphoteric-ion surfactant. Organic amine is used as initiator, and epoxy propane and epoxy ethane are polymerized to produce polyether, then reacting with alpha-halogenated carboxylic acid to produce said betaine structure product. This produced has advantages of: excellent emulsification ability and dewater ability, on the molecule there are quaternary amido and carboxy group, so having excellent wetting function, and having good complexation stability to alkaline earth metals in crude-oil, being of calcium-disperser, and having excellent function for removing magnesium and iron.

Owner:PETROCHINA CO LTD

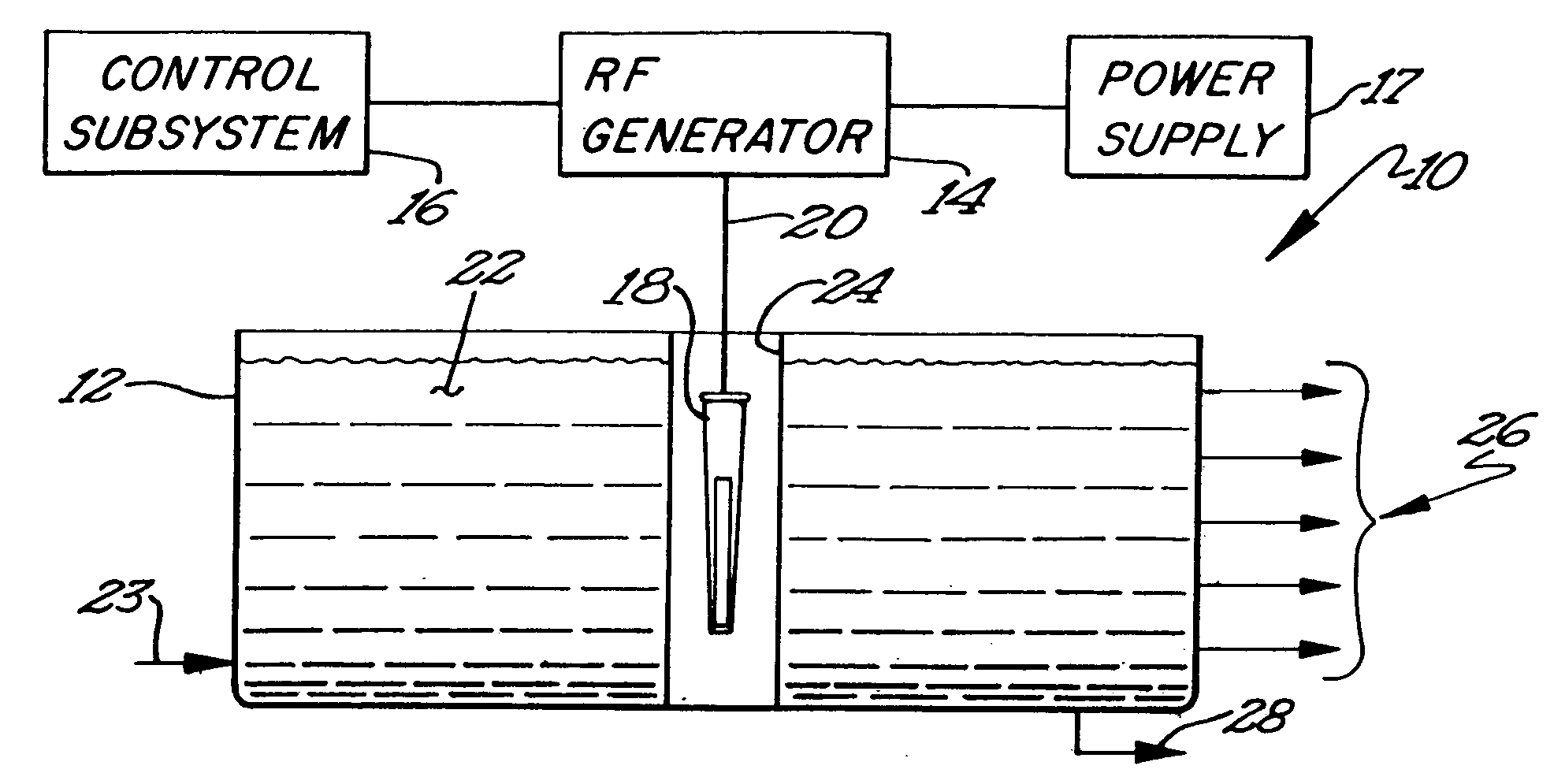

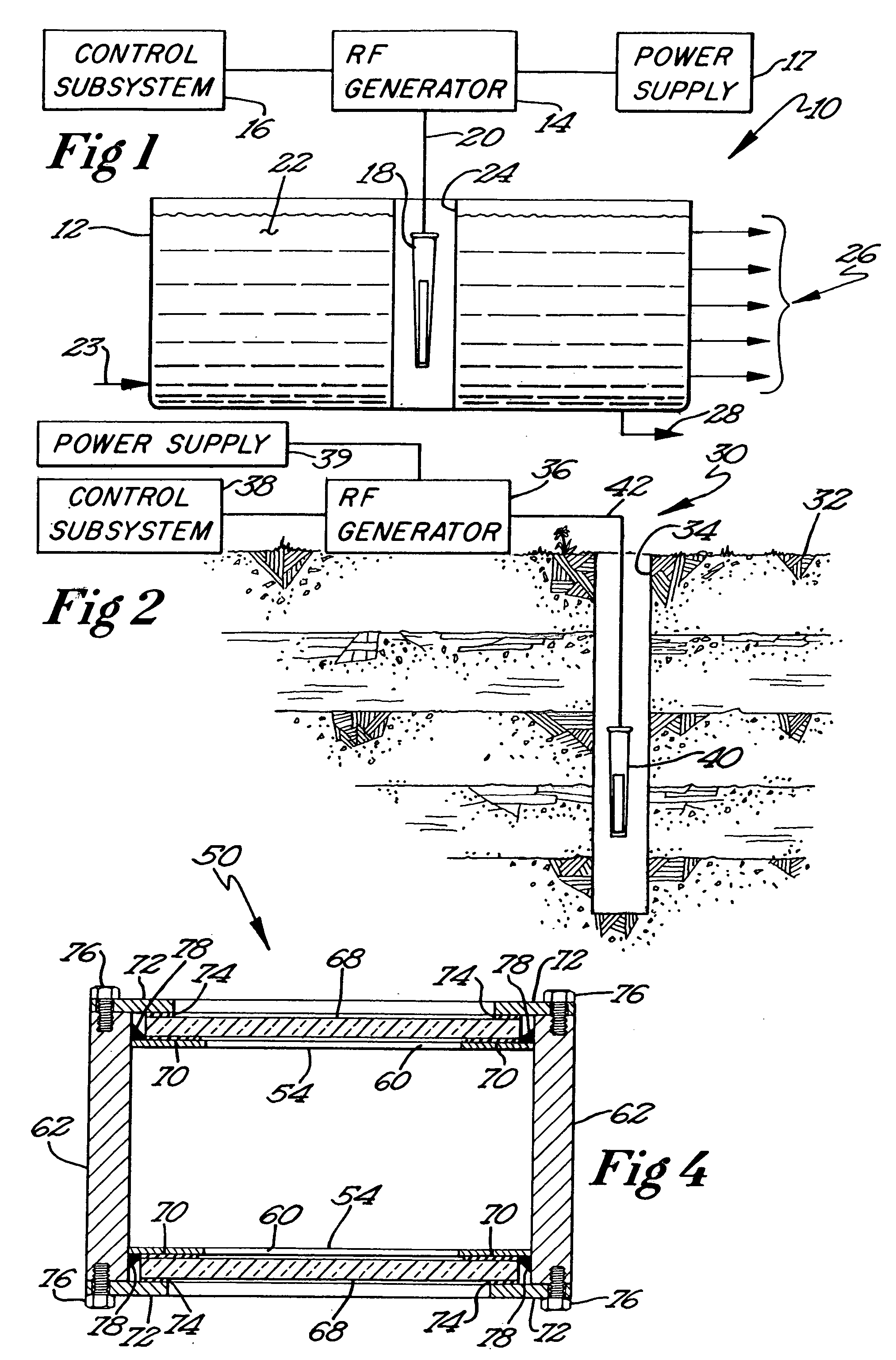

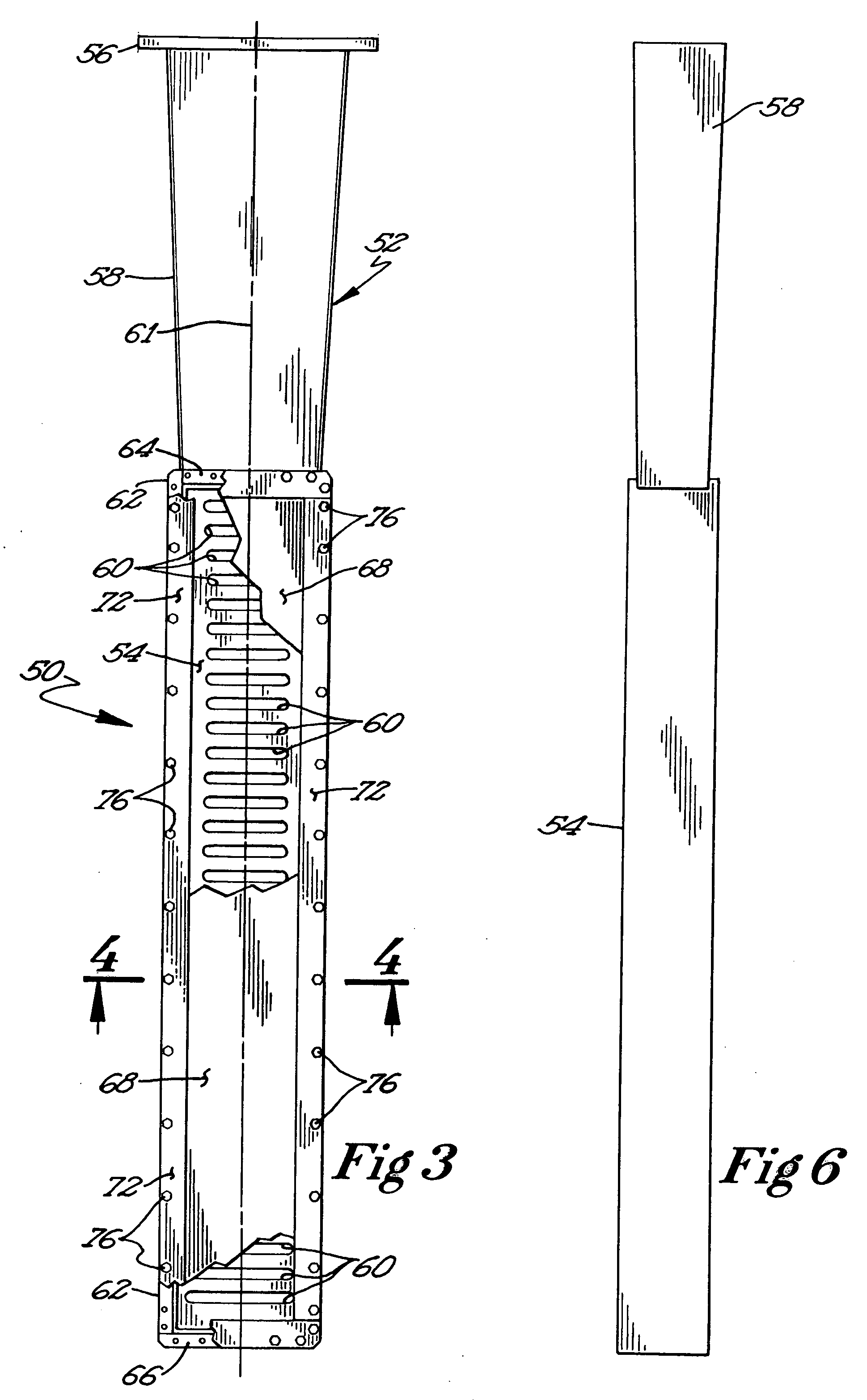

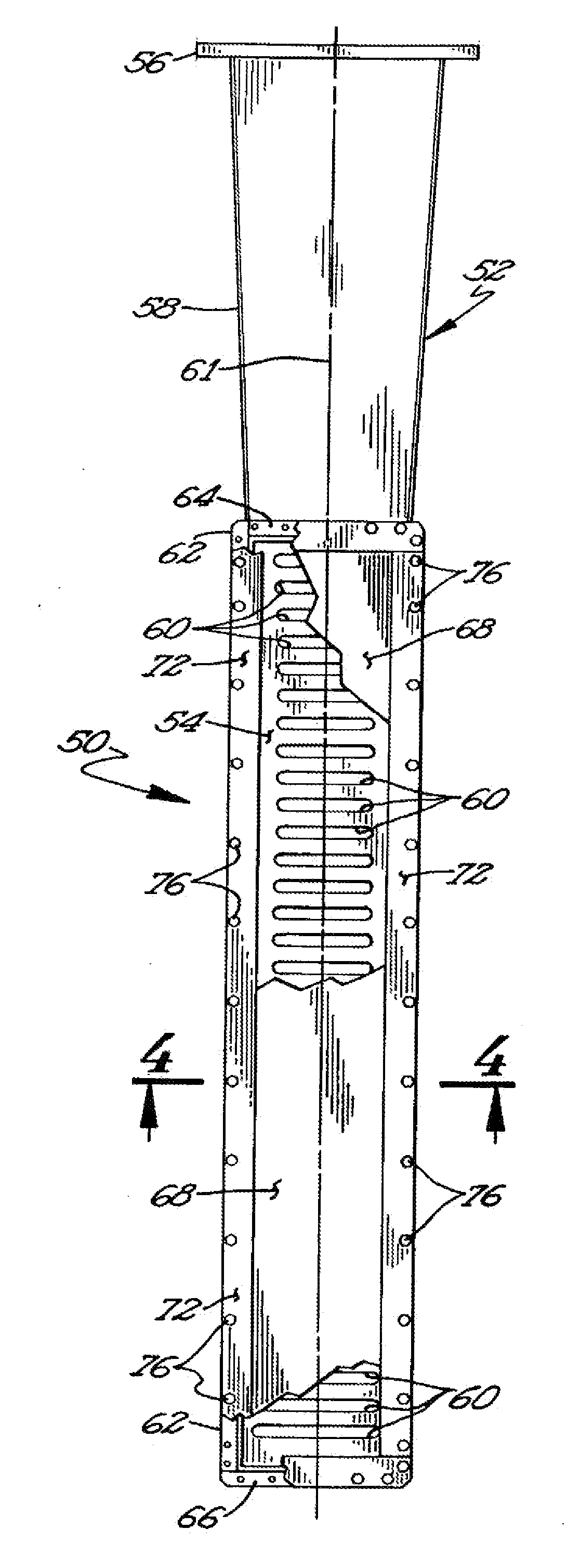

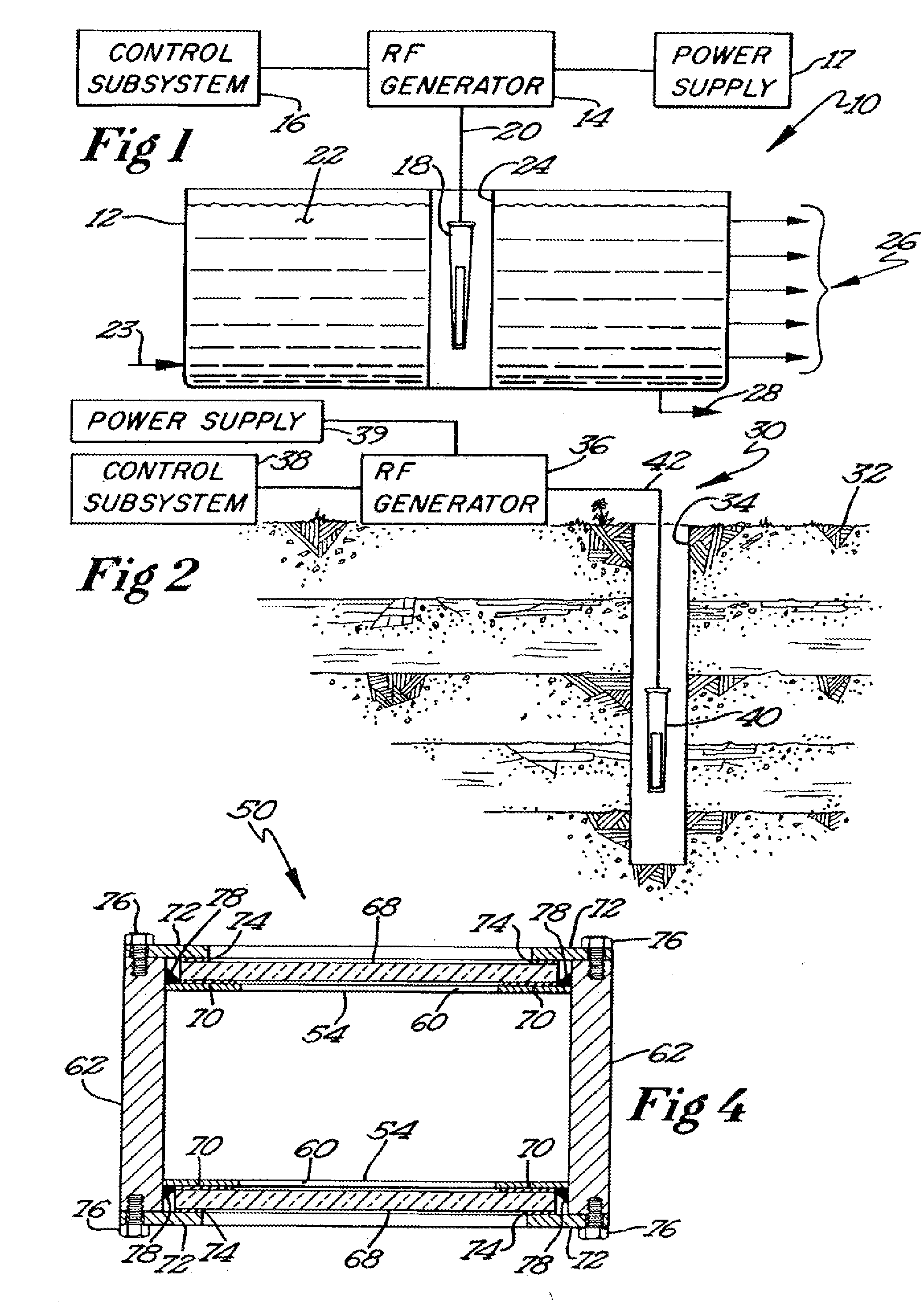

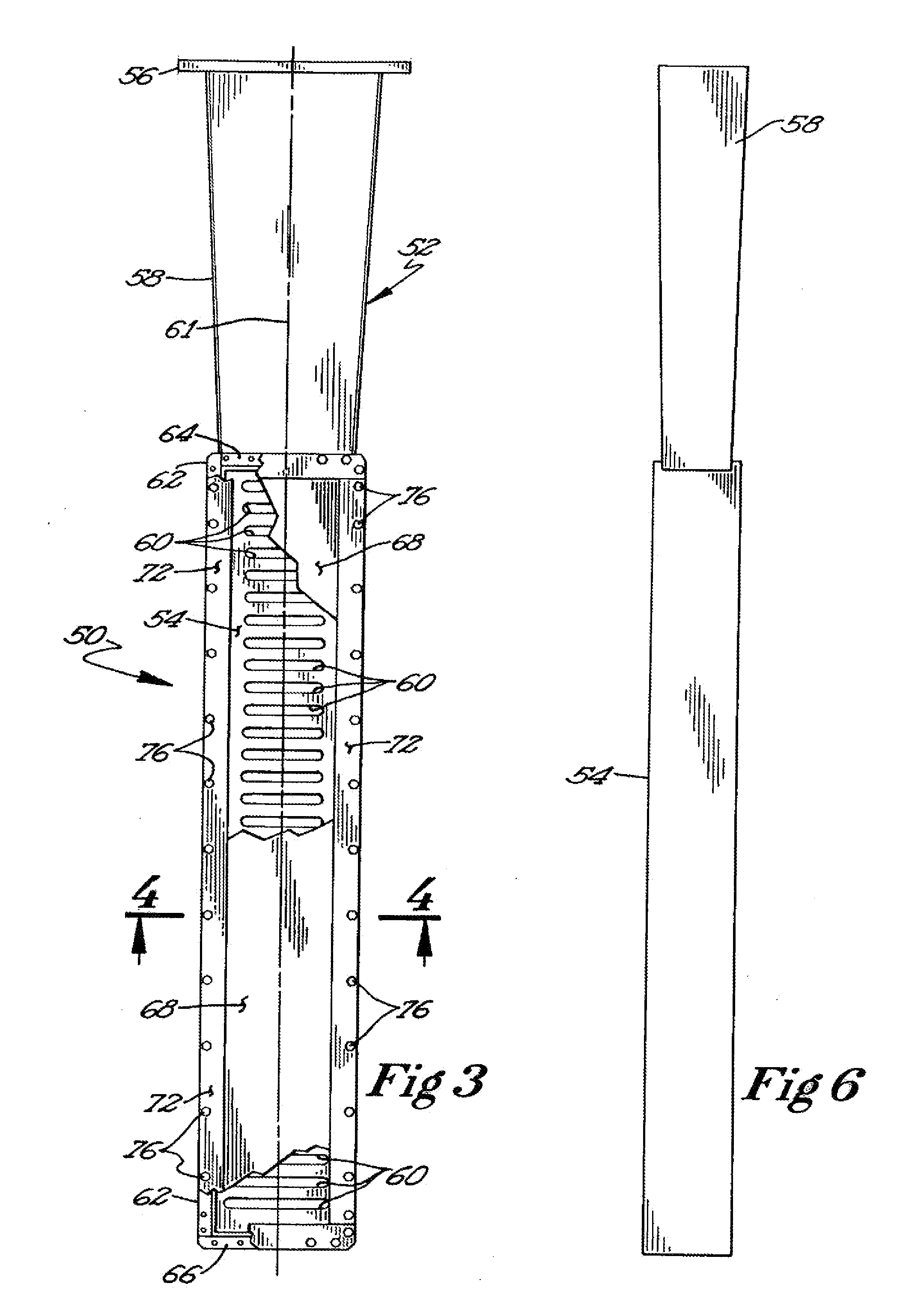

Microwave demulsification of hydrocarbon emulsion

InactiveUS7486248B2Promote demulsificationEfficiently delivers microwave energyWater/sewage treatment by irradiationSubaqueous/subterranean adaptionEmulsionMicrowave

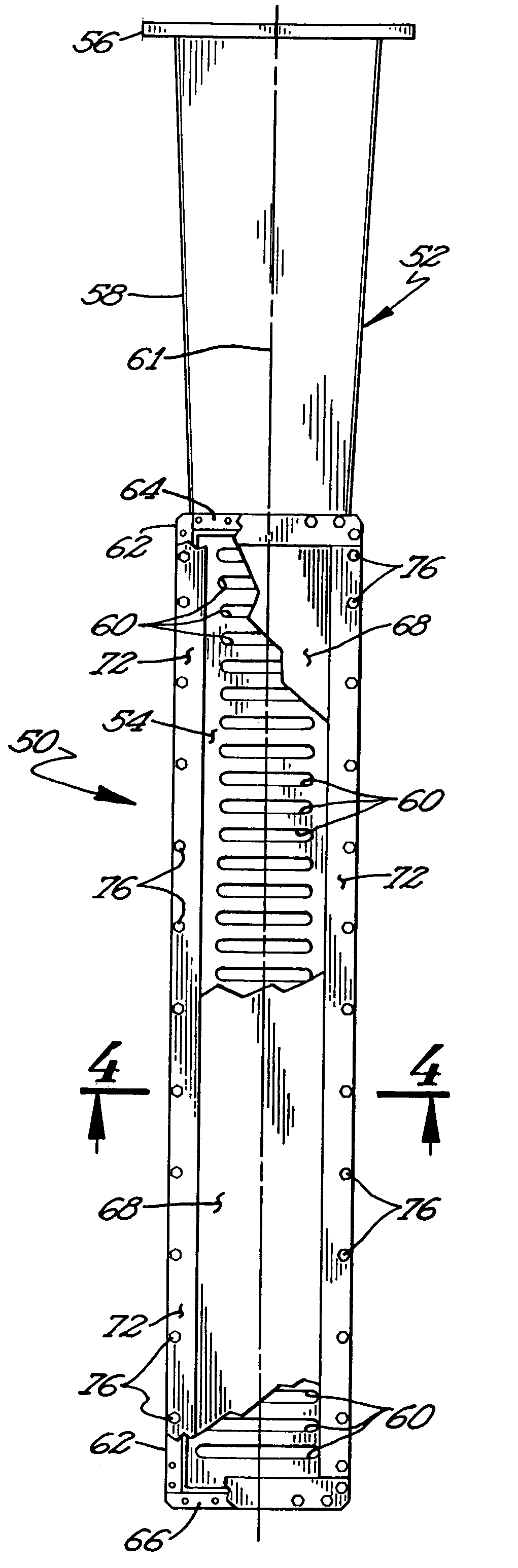

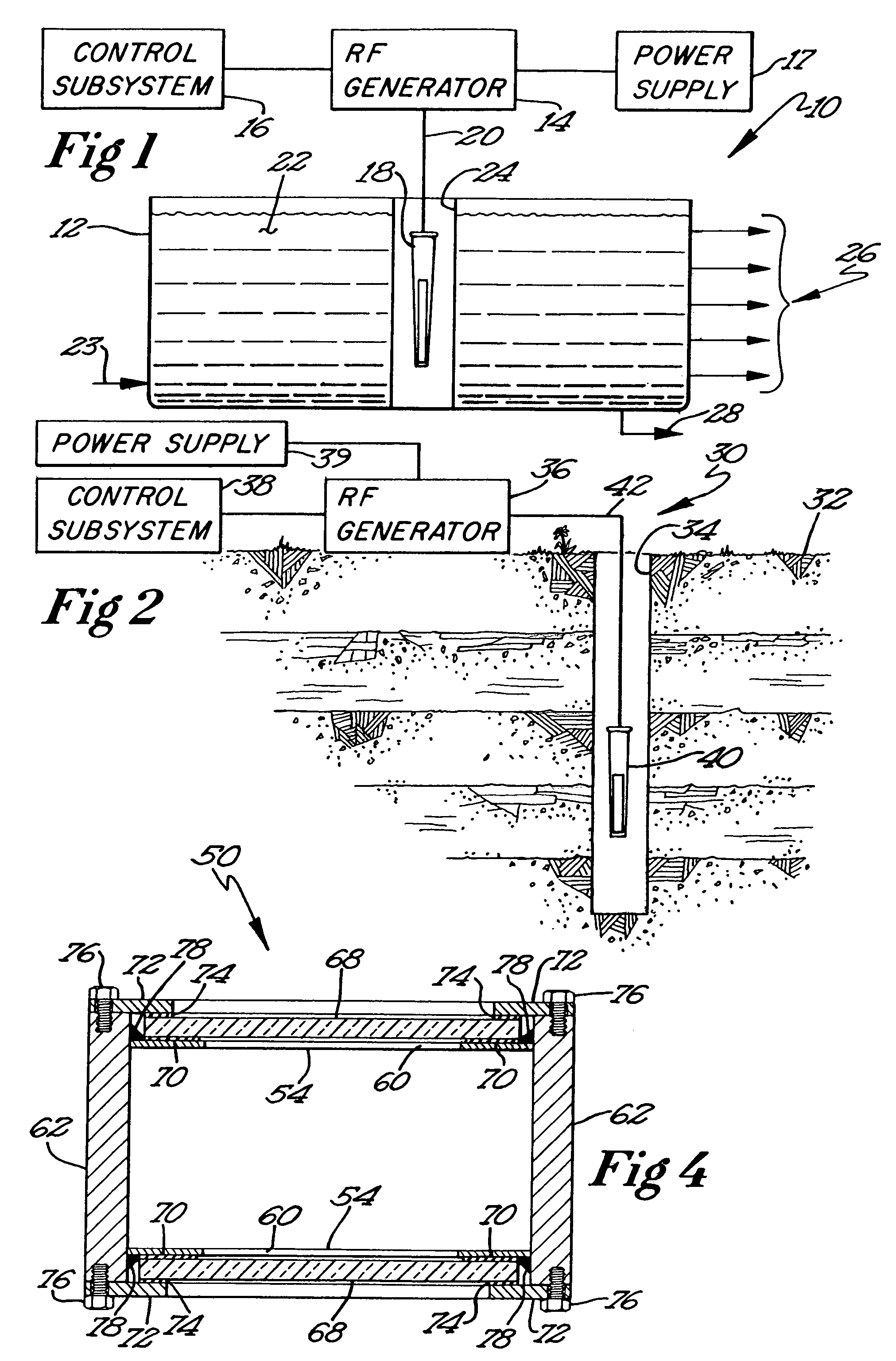

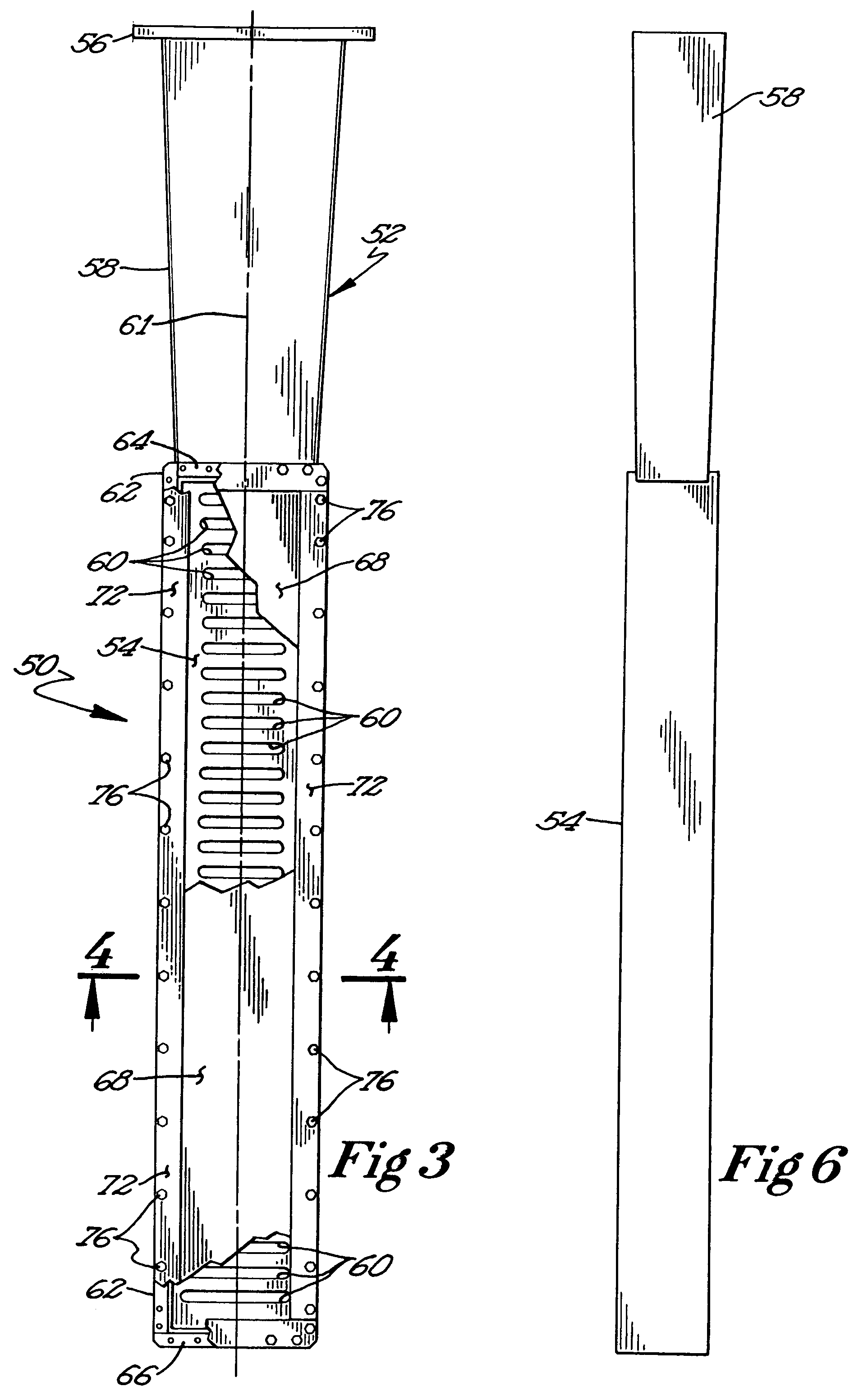

Recovery of hydrocarbons, such as petroleum products, from a liquid or solid substrate is facilitated by the use of microwave energy to energize and separate molecular bonds between the hydrocarbons and the substrate. A radio frequency (RF) applicator delivers microwave energy to a treatment volume containing an emulsion of a hydrocarbon and a substrate. Delivering the microwave energy to the emulsion facilitates separation of the hydrocarbon and substrate molecules into layers. Hydrocarbons and other products can then be recovered from their respective layers. The treatment volume may be located either above or below ground. The RF applicator may include an antenna body with slots formed substantially parallel to one another in a substantially horizontal orientation. The RF applicator efficiently delivers microwave energy into the treatment volume. Substantially all of the power supplied to the RF applicator is radiated, with very little power reflected internally within the RF applicator.

Owner:INTEGRITY DEV

Crude oil electric desalting dewatering process

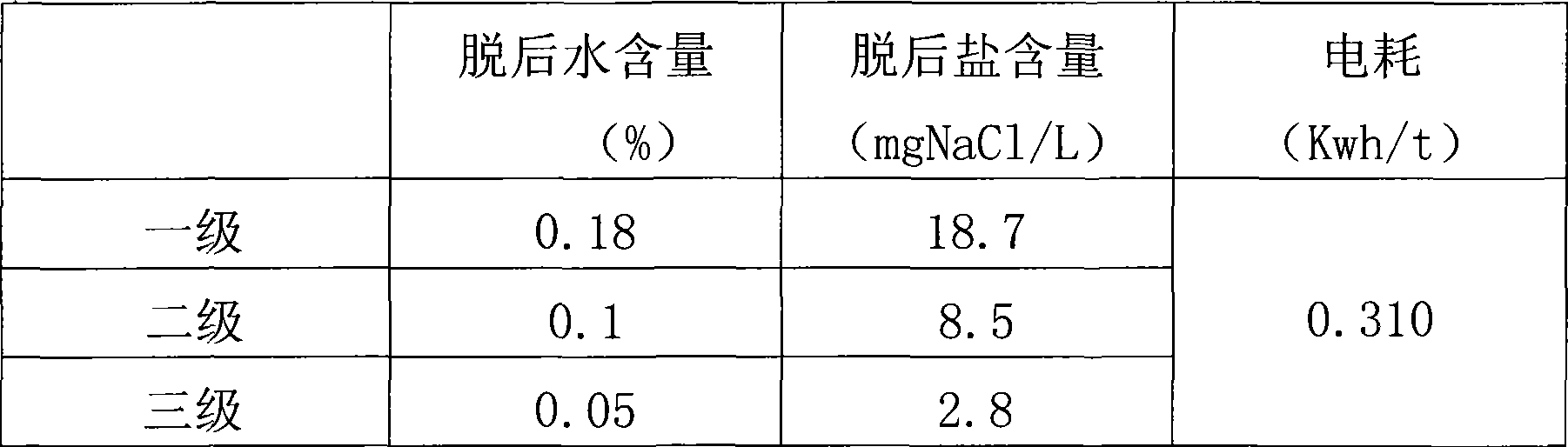

InactiveCN101475832AEnhanced oil-water contactImprove the mixing effectRefining by water treatmentRefining by electric/magnetic meansMicrogramGram

The invention discloses a method for performing electrostatic desalting and dehydration on crude oil, which comprises the following steps: heating the crude oil to a temperature of between 115 and 155 DEG C; pouring water of which the weight is between 3 and 8 percent of the total weight of the crude oil to the crude oil; adding a demulsifier of which the weight between 0 and 25 micrograms per gram of the total weight of the crude oil to the mixture; mixing the materials in an active region with the ultrasonic frequency of between 20 and 40 kHz and the intensity of sound of between 0.5 w / cm<-2> and 0.75 w / cm<-2> for 1 to 5 minutes; keeping the mixture in a desalting and dehydrating tank in an electric field with the pulse electrical field strength of between 600 V / cm and 2,000 V / cm, the duty ratio of between 15 and 50 percent and the frequency of between 100 and 800 Hz for 25 to 50 minutes; and separating out sewage to obtain the purified crude oil which meets the requirement on salt content and is taken out of the device. The method can save more than 50 percent of electric energy.

Owner:CHINA PETROCHEMICAL CORP +1

Microwave demulsification of hydrocarbon emulsion

InactiveUS20050024284A1Promote demulsificationEfficiently delivers microwave energySubaqueous/subterranean adaptionSlot antennasEmulsionPetroleum product

Recovery of hydrocarbons, such as petroleum products, from a liquid or solid substrate is facilitated by the use of microwave energy to energize and separate molecular bonds between the hydrocarbons and the substrate. A radio frequency (RF) applicator delivers microwave energy to a treatment volume containing an emulsion of a hydrocarbon and a substrate. Delivering the microwave energy to the emulsion facilitates separation of the hydrocarbon and substrate molecules into layers. Hydrocarbons and other products can then be recovered from their respective layers. The treatment volume may be located either above or below ground. The RF applicator may include an antenna body with slots formed substantially parallel to one another in a substantially horizontal orientation. The RF applicator efficiently delivers microwave energy into the treatment volume. Substantially all of the power supplied to the RF applicator is radiated, with very little power reflected internally within the RF applicator.

Owner:INTEGRITY DEV

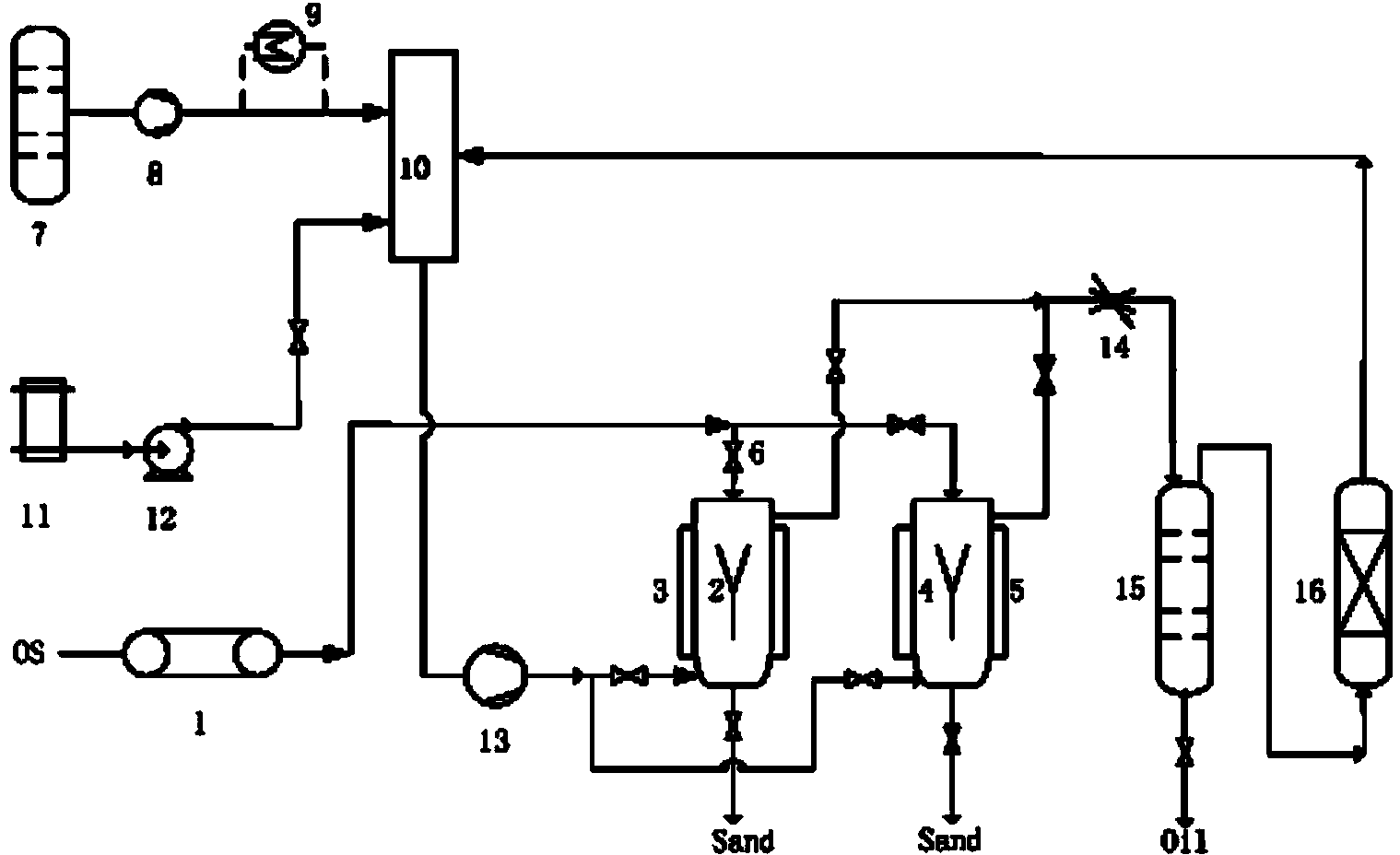

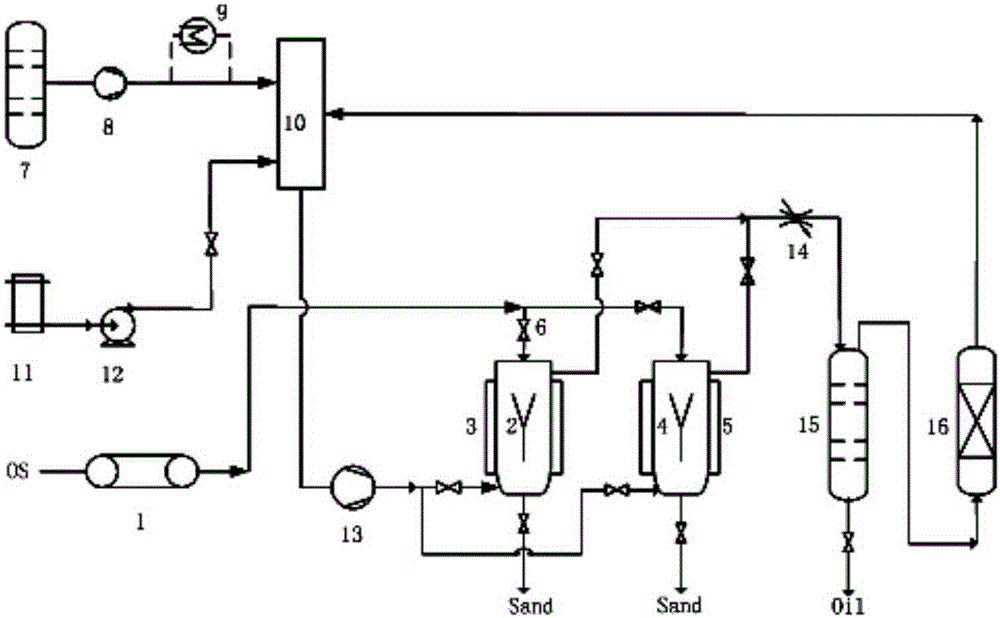

Microwave-assisted supercritical CO2 extraction system and microwave-assisted supercritical CO2 extraction method for crude oil in oil sand

ActiveCN104046375AEfficient separationEfficient developmentLiquid hydrocarbon mixture productionEnergy based chemical/physical/physico-chemical processesGas phaseBuffer tank

The invention discloses a microwave-assisted supercritical CO2 extraction system and a microwave-assisted supercritical CO2 extraction method for crude oil in oil sand. The system comprises at least two extraction kettles, a microwave generator, a separator, a gas purifier, a buffer tank, an entrainer storage tank and the like. The method comprises the following steps: conveying oil sand to each extraction kettle by virtue of a conveying device, meanwhile, feeding CO2 and the entrainer into the buffer tank, enabling the mixture in the buffer tank to enter the extraction kettle, and closing valves at the inlet and outlet ends of the extraction kettle; starting the microwave generator, staying for a period of time after the temperature in the kettle is up to the extraction temperature, opening the valve at the bottom of the kettle, discharging sand, opening the valve at the top outlet of the kettle, and enabling gas-phase fluid to enter the separator through a throttle valve; discharging crude oil from an outlet at the bottom of the separator, and returning the top gas to the buffer tank by virtue of the purifier. The system is provided with the at least two extraction kettles which can be alternately operated to realize continuous operation.

Owner:XI AN JIAOTONG UNIV

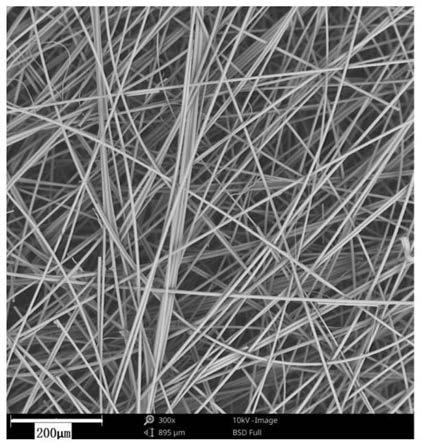

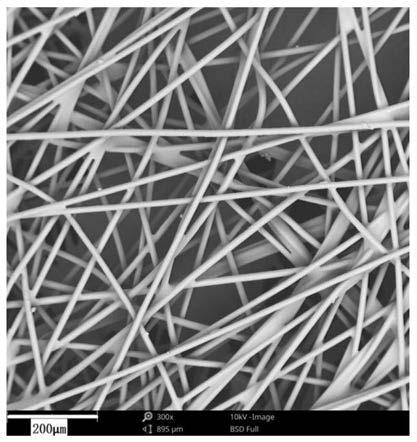

Polymer with emulsifying water demulsifying and coalescence functions, and preparation method and applications thereof

ActiveCN110330586ALong-lastingWon't breakFiltration separationNon-miscible liquid separationPolymeric surfacePolymer science

The invention discloses a polymer with emulsifying water demulsifying and coalescence functions, and a preparation method and applications thereof. The polymer is composed of 100 parts of a monomer, 1to 5 parts of an initiator, 0.5 to 3 parts of a chain transferring agent, and 100 to 900 parts of an organic solvent; the monomer is composed of 5 to 40 parts of a functional monomer containing amphiphilic molecular chain segments, 5 to 30 parts of acrylic acid monomer containing crosslinking groups, 10 to 60 parts of an acrylic ester soft monomer, and 0 to 40 parts of an acrylic ester hard monomer. The polymer possesses relatively high clunging force on a plurality of kinds of porous filter materials, material pore blocking is not caused after drying of the polymer, after contact collision of emulsified water drops with polymer surface, demulsification is caused, and coalescence is induced further, so that large water drops are formed, and it is convenient for separation; and the application prospect of the polymer in the field of oil water separation is promising.

Owner:SOUTH CHINA UNIV OF TECH

Microwave demulsification of hydrocarbon emulsion

InactiveUS20090146897A1Promote demulsificationEfficiently delivers microwave energyRadiating element housingsSubaqueous/subterranean adaptionEmulsionMicrowave

Recovery of hydrocarbons, such as petroleum products, from a liquid or solid substrate is facilitated by the use of microwave energy to energize and separate molecular bonds between the hydrocarbons and the substrate. A radio frequency (RF) applicator delivers microwave energy to a treatment volume containing an emulsion of a hydrocarbon and a substrate. Delivering the microwave energy to the emulsion facilitates separation of the hydrocarbon and substrate molecules into layers. Hydrocarbons and other products can then be recovered from their respective layers. The treatment volume may be located either above or below ground. The RF applicator may include an antenna body with slots formed substantially parallel to one another in a substantially horizontal orientation. The RF applicator efficiently delivers microwave energy into the treatment volume. Substantially all of the power supplied to the RF applicator is radiated, with very little power reflected internally within the RF applicator.

Owner:INTEGRITY DEV

Short-range preprocessing method for cutting effluent

InactiveCN106830422AEasy to separateEfficient demulsificationFatty/oily/floating substances removal devicesWater treatment compoundsLiquid wasteHigh concentration

The invention provides a short-range preprocessing method for cutting effluent. The method is characterized by comprising the following steps: adjusting a pH value of the cutting effluent to 3-4; adding soluble ferrite and hydrogen peroxide; uniformly mixing; reacting for 2-3 hours and then removing oil slick; adjusting a pH value of a bottom clean liquid to 8-9; adding a flocculating agent, stirring, fully precipitating the insoluble substances in the effluent and removing the sediment. According to the short-range preprocessing method provided by the invention, the efficient de-emulsification of the cutting effluent is realized; oil and water separation can be conveniently realized; the organic matters in high-concentration cutting effluent can be efficiently degraded; the COD removal rate is 90% or more and can reach up to 99% or more; the method is simple; the cost is low; the separated oily substances, such as machine oil and mineral oil, can be recycled; the short-range preprocessing method is suitable for large-scale industrial application.

Owner:JIANGSU UNIV OF SCI & TECH

Natural gas well foam draining extraction emulsion demulsifying agent

InactiveCN104498081ASolving Stubborn Emulsion ProblemsAchieve separationDewatering/demulsification with chemical meansNon-miscible liquid separationBenzeneInorganic salts

The invention provides a natural gas well foam draining extraction emulsion demulsifying agent and a preparation method thereof. The foam draining demulsifying agent comprises the following components: functional block polyether, alkyl benzene sulfonic acid, citric acid, organic amine, inorganic salts and other aids. According to the foam draining demulsifying agent provided by the invention, bean curd jelly-shaped gas well foam draining water containing lots of gas condensate can be effectively subjected to oil-water separation, the long-standing knotty problem that the complex foam draining emulsion cannot be demulsified by the traditional demulsifying agent is solved, the recovery rate of the gas condensate is improved, the separated water can be clear, and the pollution of the discharged sewage on the environment is reduced.

Owner:DESHI ENERGY TECH GRP CO LTD

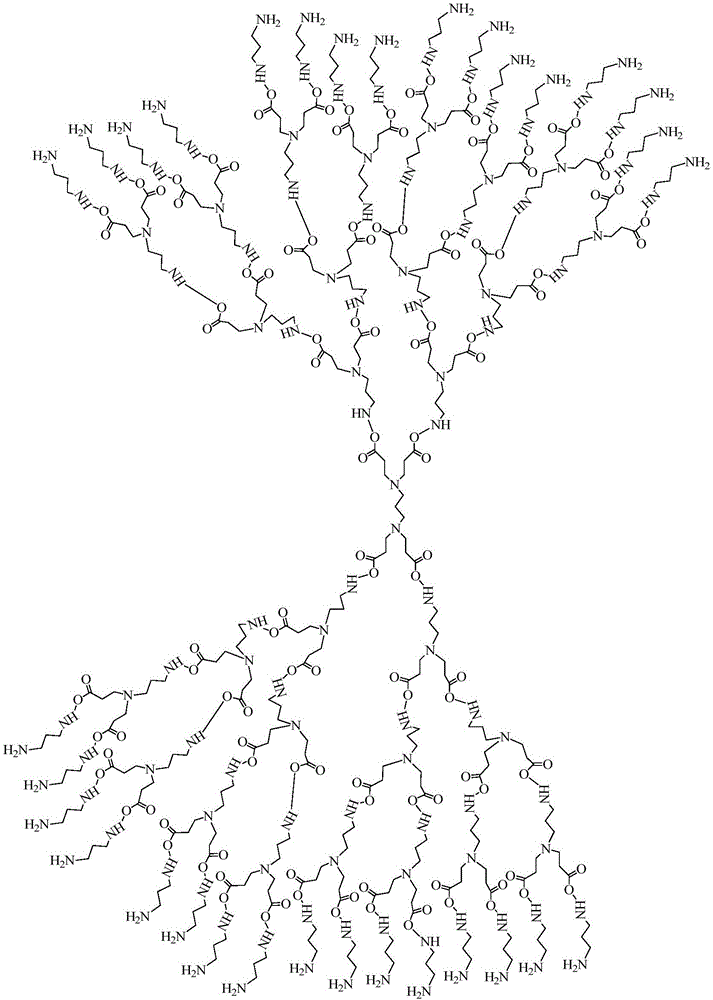

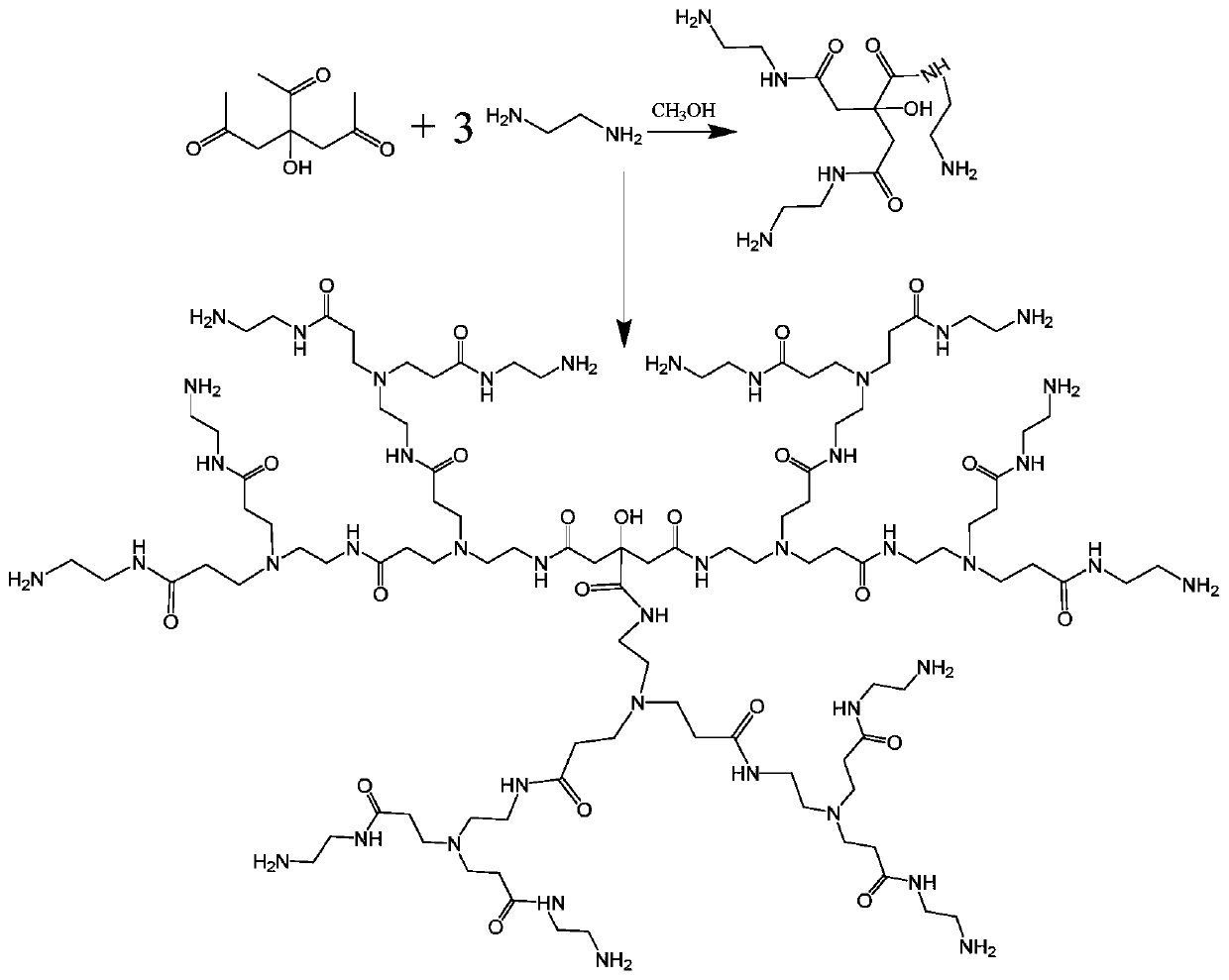

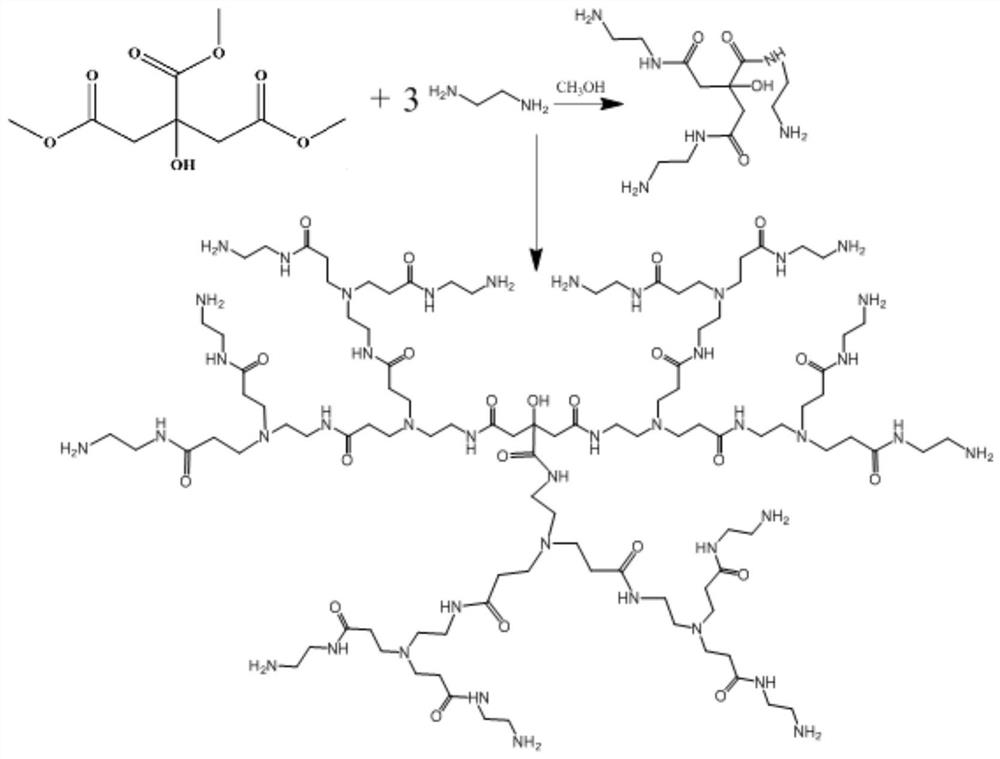

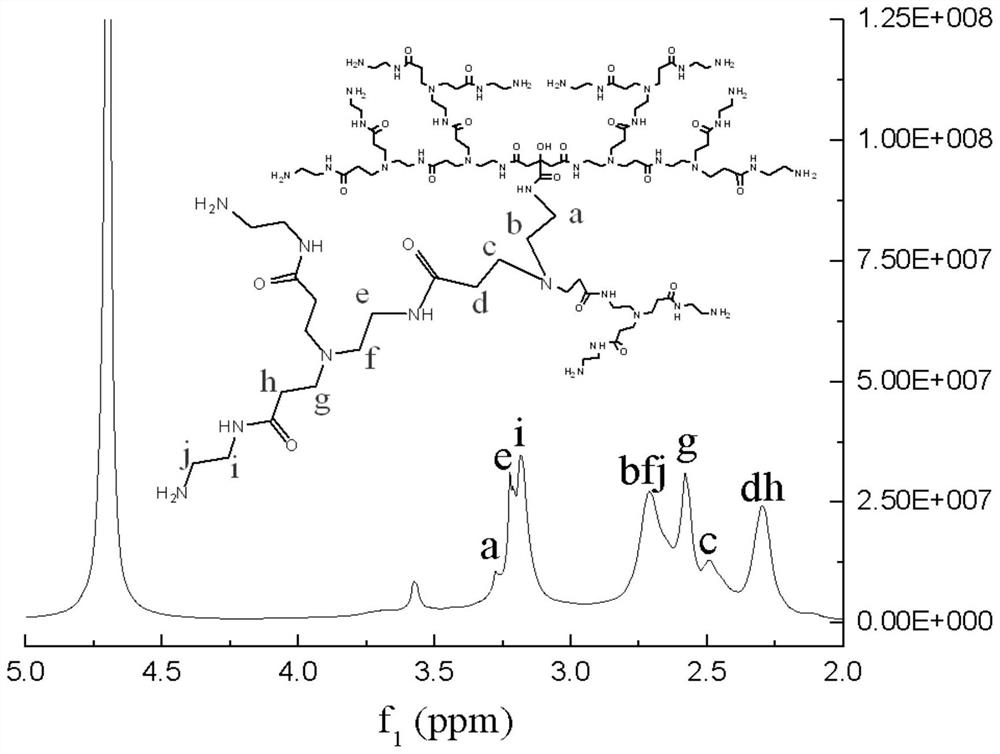

Preparation method and application of hyperbranched polymer with propylene diamine as initiator

ActiveCN106565968ARapid demulsificationTo destroyDewatering/demulsification with chemical meansEnd-groupEvaporation

The invention relates to a preparation method and application of a hyperbranched polymer with propylene diamine as the initiator. The preparation method includes the following steps that firstly, thepropylene diamine is dissolved in organic solvent, then, methyl acrylate is dropwise added, and an intermediate product is obtained through the Michael addition reaction lasting for 40-60 h at the room temperature; secondly, the temperature of the intermediate product obtained in the first step rises to 50-150 DEG C, the reduced pressure condensation reaction is conducted, and a rough product is obtained; and thirdly, the rough product obtained in the second step is subjected to diethyl ether separation and rotary evaporation, and the hyperbranched polymer with the propylene diamine as the initiator is obtained. The end group of the hyperbranched polymer is an amino group, a large number of amide groups and other structures are contained in the framework, a demulsifying agent can rapidly arrive at the oil-water interface due to the strong hydrophily of the amino group, the amide groups can be adsorbed to the oil-water interface in a multipoint manner, the effect of damaging an oil-water interface film is achieved, and the aim of rapid and efficient demulsifying is achieved.

Owner:ZHEJIANG UNIV

Light hydrocarbon fuel composition for vehicle

PendingCN112899044AImprove cleanlinessGood dispersionLiquid carbonaceous fuelsFuel additivesAnti oxidantTrimethylbenzenes

The invention discloses a light hydrocarbon fuel composition for a vehicle. The light hydrocarbon fuel composition comprises the following components in parts by weight: 500-600 parts of stable light hydrocarbon (octane site in a research method is greater than 92 #), 80-120 parts of isobutanol, 180-340 parts of aromatic hydrocarbon, 130-150 parts of xylene, 200-305 parts of isooctane, 0.25-0.5 part of lanthanum isooctanoate, 0.5-0.7 part of biphenyl, 0.1 part of a metal corrosion inhibitor and 0.1 part of an antioxidant. The stable light hydrocarbon is oil refinery downstream byproducts or methanol to olefin (MTO) and coal tar hydrogenation stable light hydrocarbons; the molecular formula of the isobutanol is C4H100; the aromatic hydrocarbon is a mixture of methylbenzene, dimethylbenzene and trimethylbenzene or one or two of methylbenzene, dimethylbenzene and trimethylbenzene for blending gasoline; the isooctane is alkylated oil and is also called isomer octane, and the research octane number is 98-100; and the metal corrosion inhibitor is benzotriazole. The light hydrocarbon fuel composition for the vehicle can improve power and reduce gasoline consumption; and emission of tail gas pollutants is reduced.

Owner:平湖市晨星科技实业有限公司

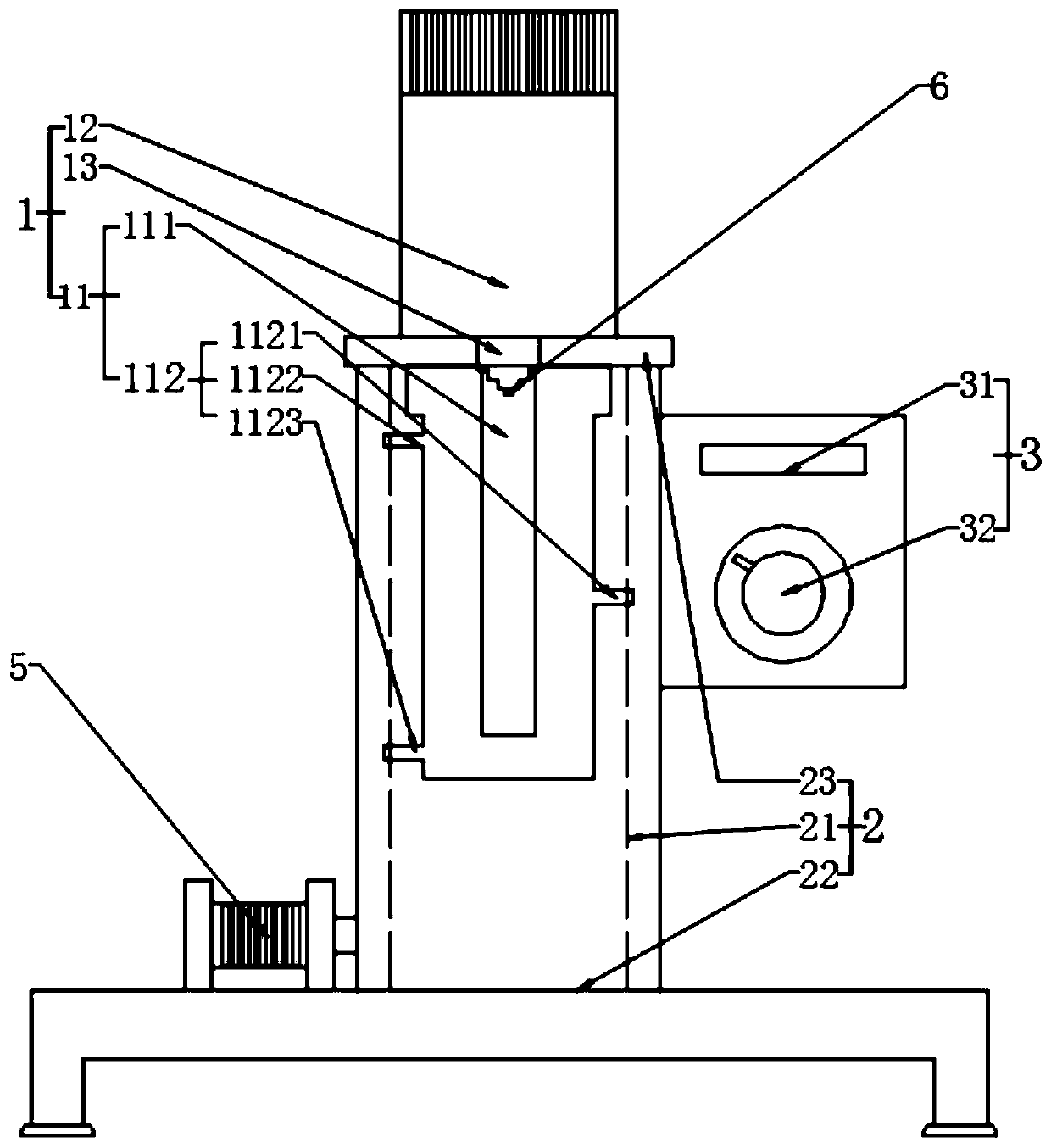

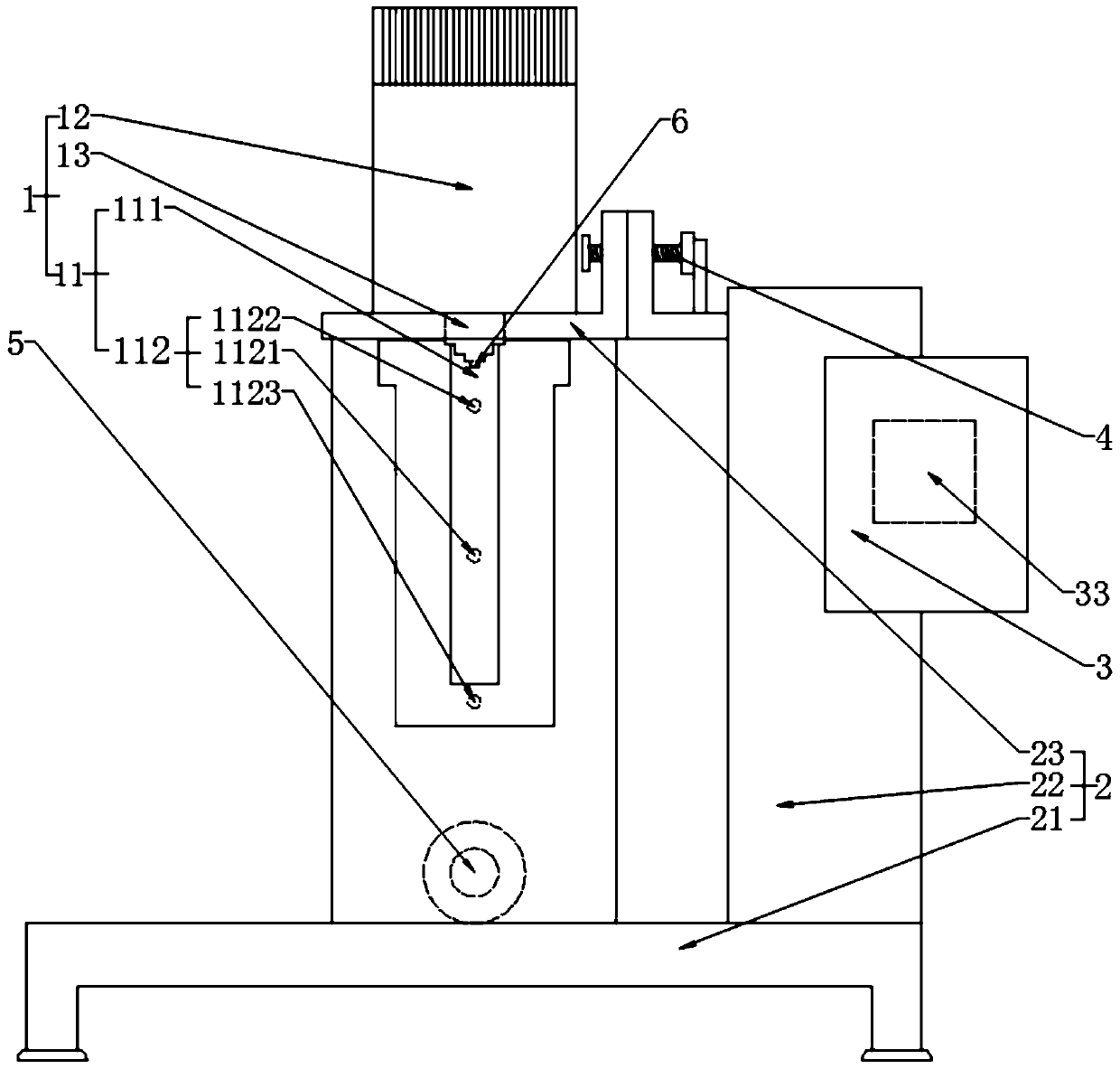

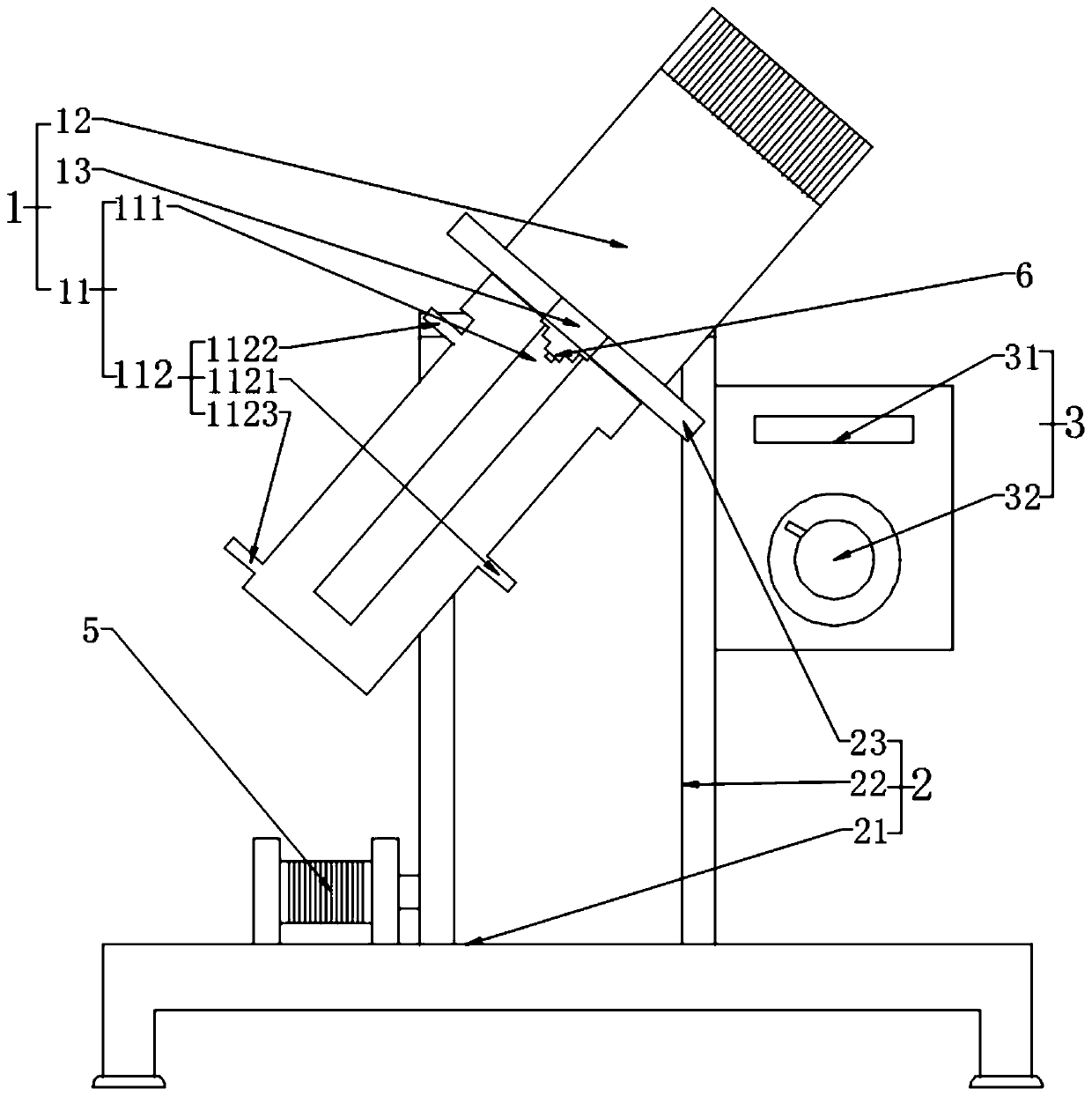

Rotary micro-channel demulsification method

ActiveCN110935198AEasy to separateFast separationNon-miscible liquid separationNumerical controlRotational axis

The invention discloses a rotary micro-channel demulsification method. A rotary demulsification part, a supporting part and a numerical control part are included. The rotary demulsification part comprises a demulsification cylinder, a rotary motor and a rotary shaft, the top of the demulsification cylinder is connected to the rotary motor through the rotary shaft, the demulsification cylinder comprises an inner demulsification cylinder and an outer demulsification cylinder, the outer demulsification cylinder is fixedly connected to the rotary motor through a glass plate, the inner demulsification cylinder is fixedly connected to the rotary shaft, the supporting part comprises a supporting base and a supporting rod, and the side face of the supporting rod is fixedly connected to the numerical control part. The method comprises the following steps: S1, preparing an emulsion, S2, adjusting the device, S3, demulsifying by the device and S4, collecting a demulsified liquid. The outer demulsification cylinder rotates, the demulsification part deflects, polytetrafluoroethylene and organic glass materials are adopted, rapid separation is achieved, efficient demulsification is achieved, andan emulsion feeding hole, an upper discharge hole and a lower discharge hole are limited, so that sufficient and stable demulsification is realized. Different demulsification requirements are met byutilizing an embedding mode.

Owner:SICHUAN UNIV

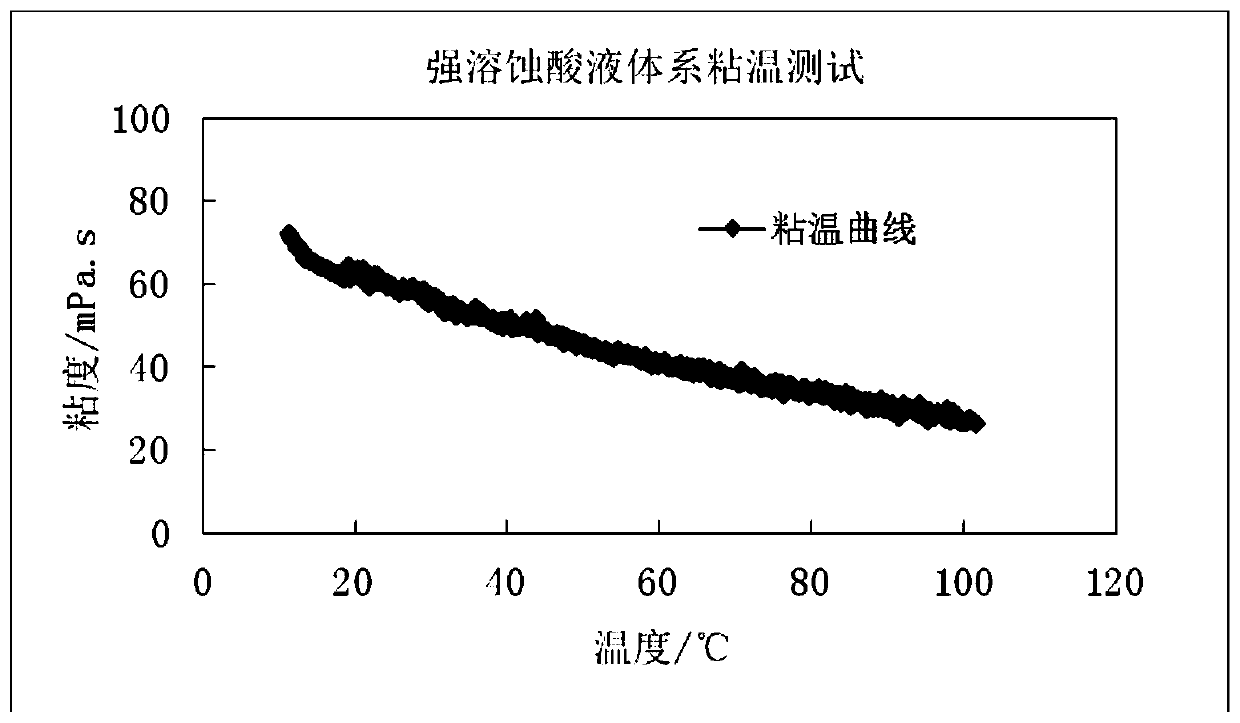

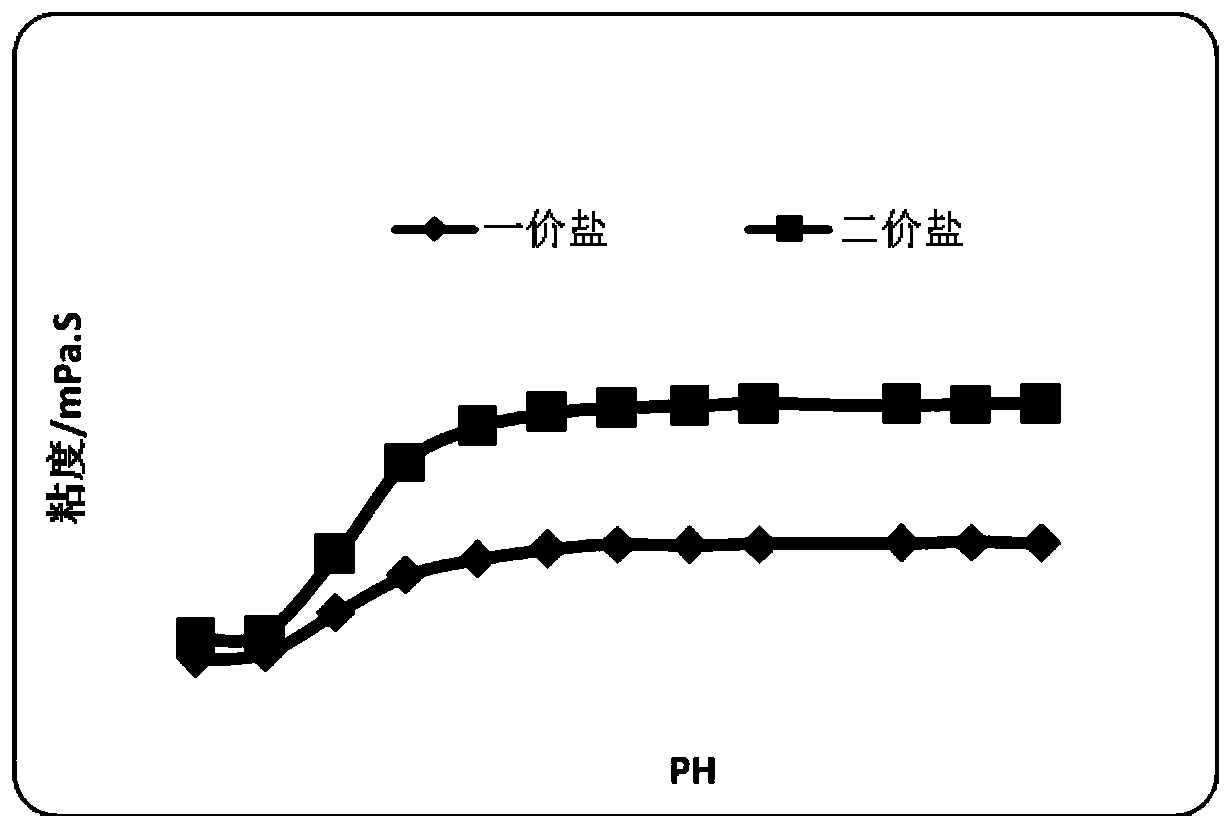

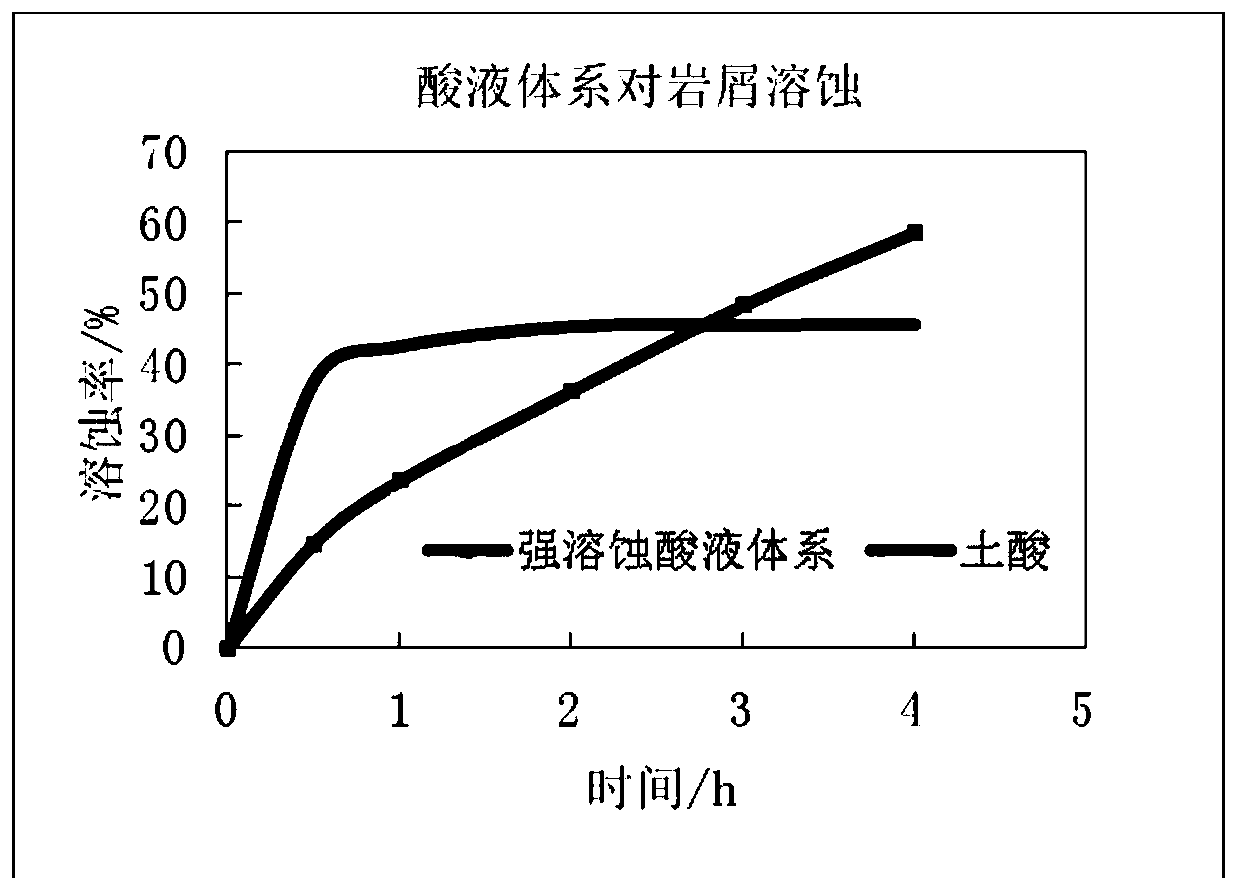

High-viscosity strong-corrosion acid liquid system for low-permeability sandstone oil reservoir

InactiveCN110791279AReduce fluid lossIncrease the effective rangeDrilling compositionDemulsifierFiltration

The invention discloses a high-viscosity strong-corrosion acid liquid system for a low-permeability sandstone oil reservoir. The system comprises the following components in percentage by mass: 6-12%of hydrochloric acid, 1-3% of betaine, 4-8% of a reinforcing agent, 0.05-0.2% of citric acid, 0.5-2% of ammonium chloride, 0.5-2% of a corrosion inhibitor, 0.1-0.4% of a cleanup additive, 0.05-0.2% ofa demulsifier and the balance of water, wherein the sum of the components is 100%. During acidification of the acid liquid system, rise of the viscosity of the acid liquid reduces the filtration lossof the acid liquid, more fresh acid is forced to enter the deep part of a stratum, the effective action distance of the acid liquid is increased, and after acidification is finished, a high-viscosityfluid is automatically broken into a low-viscosity fluid when meeting crude oil in the stratum, so that the stratum is not subjected to secondary damage.

Owner:XI'AN PETROLEUM UNIVERSITY

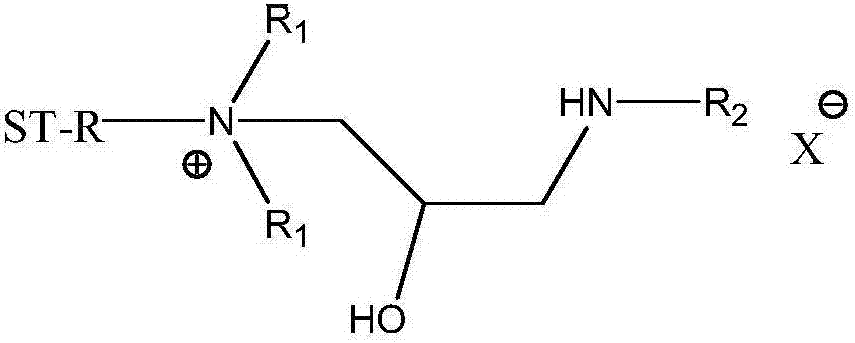

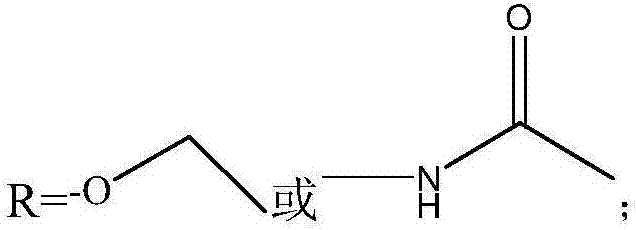

Branched low-temperature high-efficiency quaternary ammonium salt modified starch demulsifying agent and preparation method thereof

ActiveCN107188976AEfficient demulsificationLow priceNon-miscible liquid separationAldehydeBy-product

The invention relates to the technical field of oilfield sewage disposal demulsification flocculation, in particular to a branched low-temperature high-efficiency quaternary ammonium salt modified starch demulsifying agent and a preparation method thereof. The demulsifying agent has a general molecular formula as described in the description, and the preparation method comprises the following steps: (1) adding starch, aldehyde or urea, and dialkyl amine into a reactor one after another to carry out tertiary amine end capping grafting reaction; (2) adding halogeneated epoxyalkane in a reaction product to carry out quaternization grafting reaction; (3) adding a ring-opening reagent in the reaction product to carry out ring-opening grafting reaction to obtain the demulsifying agent. According to the demulsifying agent, under the condition of not using a catalyst, the starch which is low in price, rich in raw materials and can be regenerated is taken as a raw material, the production cost is low, the industrial production is conducive to being realized, the prepared demulsifying agent is characterized in that the dosage is less and the demulsifying efficiency is high, and has a very good demulsifying effect for sewage generated by the tertiary oil recovery technology. Water is the only by-product, the utilization rate of raw materials is high, and the discharge of three wastes does not exist.

Owner:WEIHAI CY DENDRIMER TECH

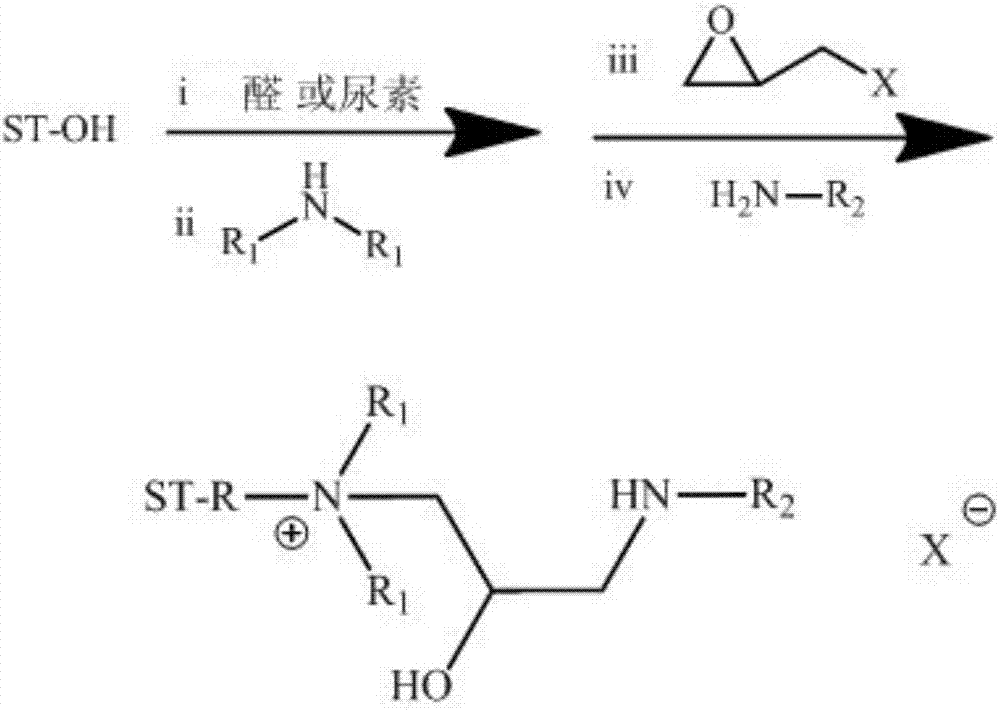

Preparation method of novel multi-branched cationic polyether reverse demulsifier and multi-branched cationic polyether reverse demulsifier

InactiveCN111423903AGood demulsification effectComplex structureDewatering/demulsification with chemical meansPolyamine CompoundPolymer science

The invention discloses a preparation method of a multi-branched cationic polyether reverse demulsifier. Bisphenol A is used as a block polyether initiator, phenolic hydroxyl ortho-hydrogen, formaldehyde and vinylamine undergo an amine methylation reaction to generate a polyamine compound with bisphenol A serving as a core, vinylamine serving as a branch and a phenolic hydroxyl group as a leaf, the polyamine compound and epoxy compounds such as epoxypropane and ethylene oxide undergo a ring opening polymerization reaction to produce a multi-branched polyether, and further the tail end of the multi-branched polyether is subjected to modification with different cationization degrees to obtain the multi-branched cationic polyether reverse demulsifier. The prepared multi-branched cationic polyether reverse demulsifier is higher in deoiling rate and demulsifying efficiency and better in demulsifying capacity, and can well make up for the functional defects of a traditional demulsifier, theoil exploitation cost can be effectively reduced, energy is saved, emission is reduced, and development of an oil exploitation process is facilitated.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

Crude oil electric desalting dewatering process

InactiveCN101475832BImprove separation efficiencyReduce dosageRefining by water treatmentRefining by electric/magnetic meansDemulsifierElectrical field strength

The invention discloses a method for performing electrostatic desalting and dehydration on crude oil, which comprises the following steps: heating the crude oil to a temperature of between 115 and 155 DEG C; pouring water of which the weight is between 3 and 8 percent of the total weight of the crude oil to the crude oil; adding a demulsifier of which the weight between 0 and 25 micrograms per gram of the total weight of the crude oil to the mixture; mixing the materials in an active region with the ultrasonic frequency of between 20 and 40 kHz and the intensity of sound of between 0.5 w / cm<-2> and 0.75 w / cm<-2> for 1 to 5 minutes; keeping the mixture in a desalting and dehydrating tank in an electric field with the pulse electrical field strength of between 600 V / cm and 2,000 V / cm, the duty ratio of between 15 and 50 percent and the frequency of between 100 and 800 Hz for 25 to 50 minutes; and separating out sewage to obtain the purified crude oil which meets the requirement on salt content and is taken out of the device. The method can save more than 50 percent of electric energy.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method of multi-branched cationic polyether microbial demulsifier

PendingCN113637497AEasy to separateImprove EOR indexDewatering/demulsification with chemical meansMicroorganism based processesBiotechnologyCyanide compound

The invention discloses an environment-friendly multi-branched cationic polyether microbial demulsifier synthesized based on a double metal cyanide complex catalyst, bisphenol A is used as a block polyether initiator and reacts with formaldehyde and vinylamine to generate a polyamine compound which takes bisphenol A as a core, vinylamine as a branch and phenolic hydroxyl as a leaf, then ring-opening polymerization is performed on the modified cationic polyether and epoxy compounds including epoxypropane and ethylene oxide to obtain multi-branched polyether, and further the multi-branched polyether reacts with a microbial metabolite and a surfactant to obtain the multi-branched cationic polyether microbial demulsifier. The multi-branched cationic polyether microbial demulsifier prepared by using the double-metal cyanide complex catalyst has no acid-base property problem, has good chemical and biological characteristics and oil and water amphipathy, can effectively reduce the surface tension of water, can be used under the conditions of extreme temperature, pH value and salinity, is non-toxic, environment-friendly and energy-saving, the demulsifier is biodegradable, has higher deoiling rate and demulsification efficiency and better demulsification capability, does not need post-treatment, and overcomes the defects of the traditional demulsifier in function and preparation process; the oil exploitation cost is reduced, and the development of an oil exploitation process is promoted.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

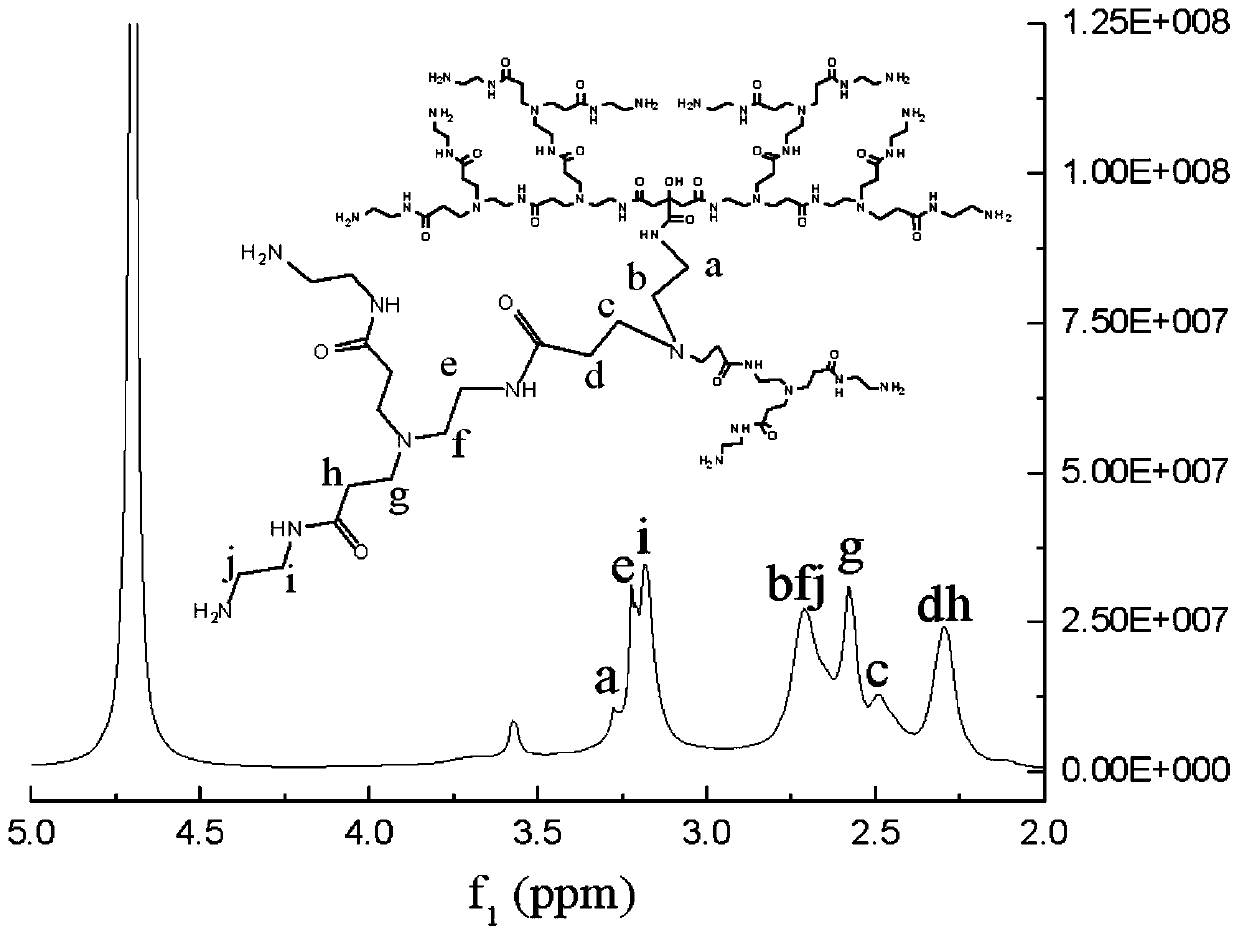

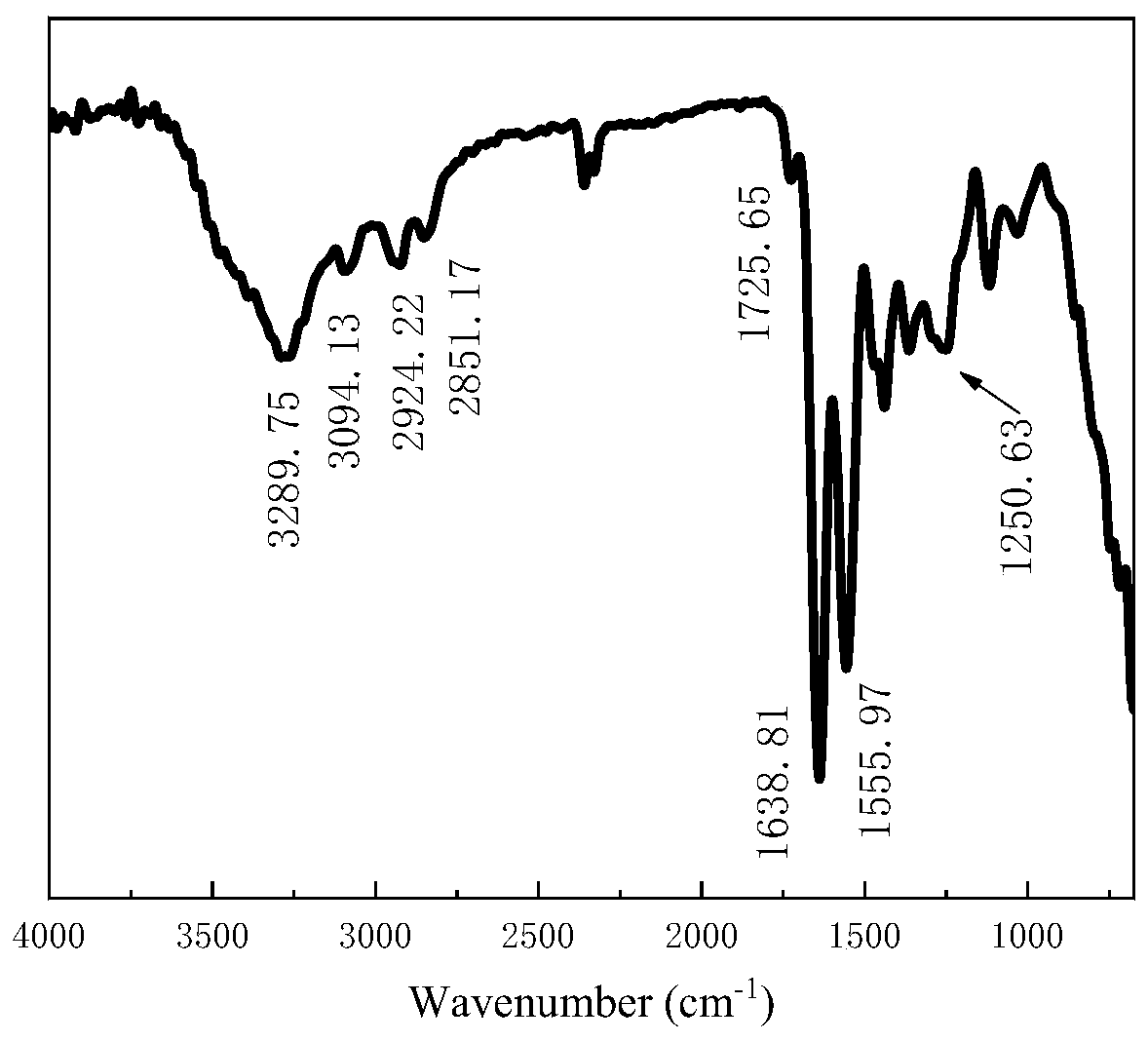

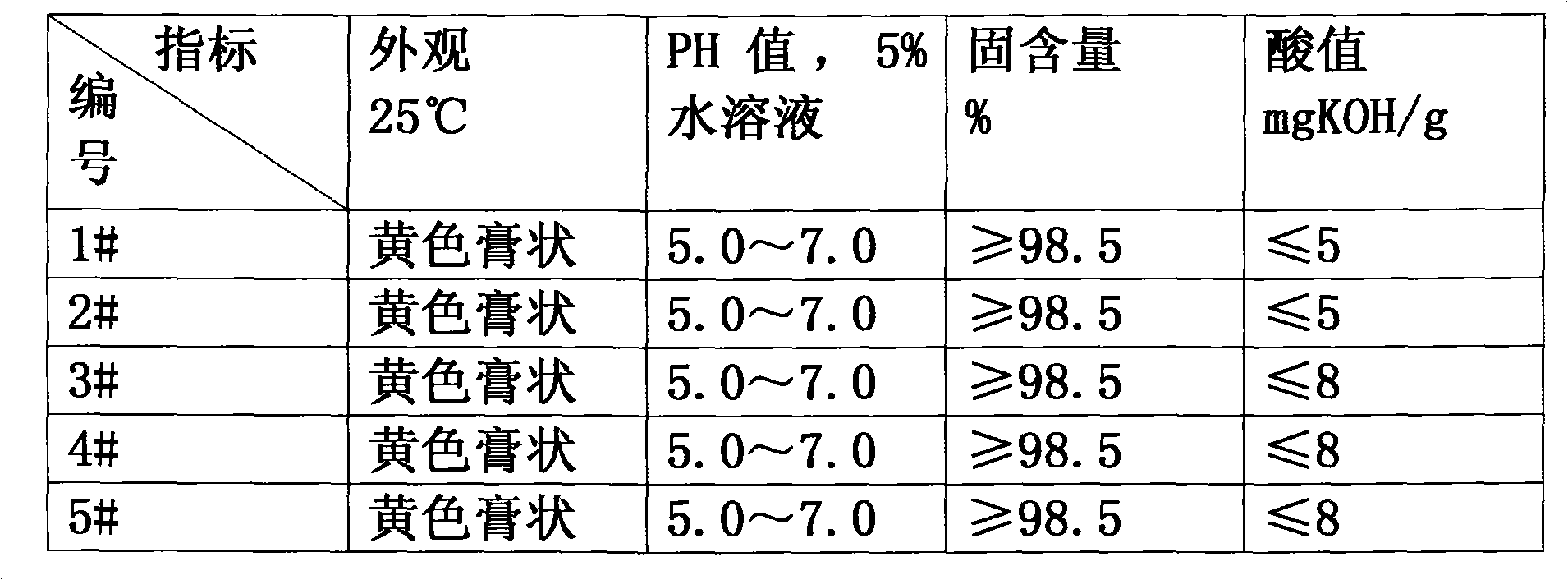

Hyperbranched polymer as well as preparation method and application thereof

ActiveCN111171327AReduce interfacial tensionImprove demulsification efficiencyDewatering/demulsification with chemical meansDemulsifierPolymer science

The invention discloses a hyperbranched polymer which is prepared taking trimethyl citrate as a center and an amino group as an end group. The weight-average molecular weight Mw of the hyperbranched polymer is 10757, and the PDI of the hyperbranched polymer is 5.09. The hyperbranched polymer is prepared by taking trimethyl citrate as the center, and amino group as the terminal group, contains a large number of hydrophilic groups, can remarkably reduce oil-water interfacial tension and improve demulsification efficiency, can be taken as a demulsifier to achieve efficient demulsification of oil-in-water emulsion at normal temperature condition; the demulsification efficiency of 50 mg / L of the hyperbranched polymer on diesel oil emulsion can reach 99.7% at normal temperature, the dosage of the hyperbranched polymer is small, and the demulsification efficiency is high. The invention also provides a preparation method of the hyperbranched polymer and application of the hyperbranched polymeras a demulsifier.

Owner:湖北鑫城普瑞化学科技有限公司

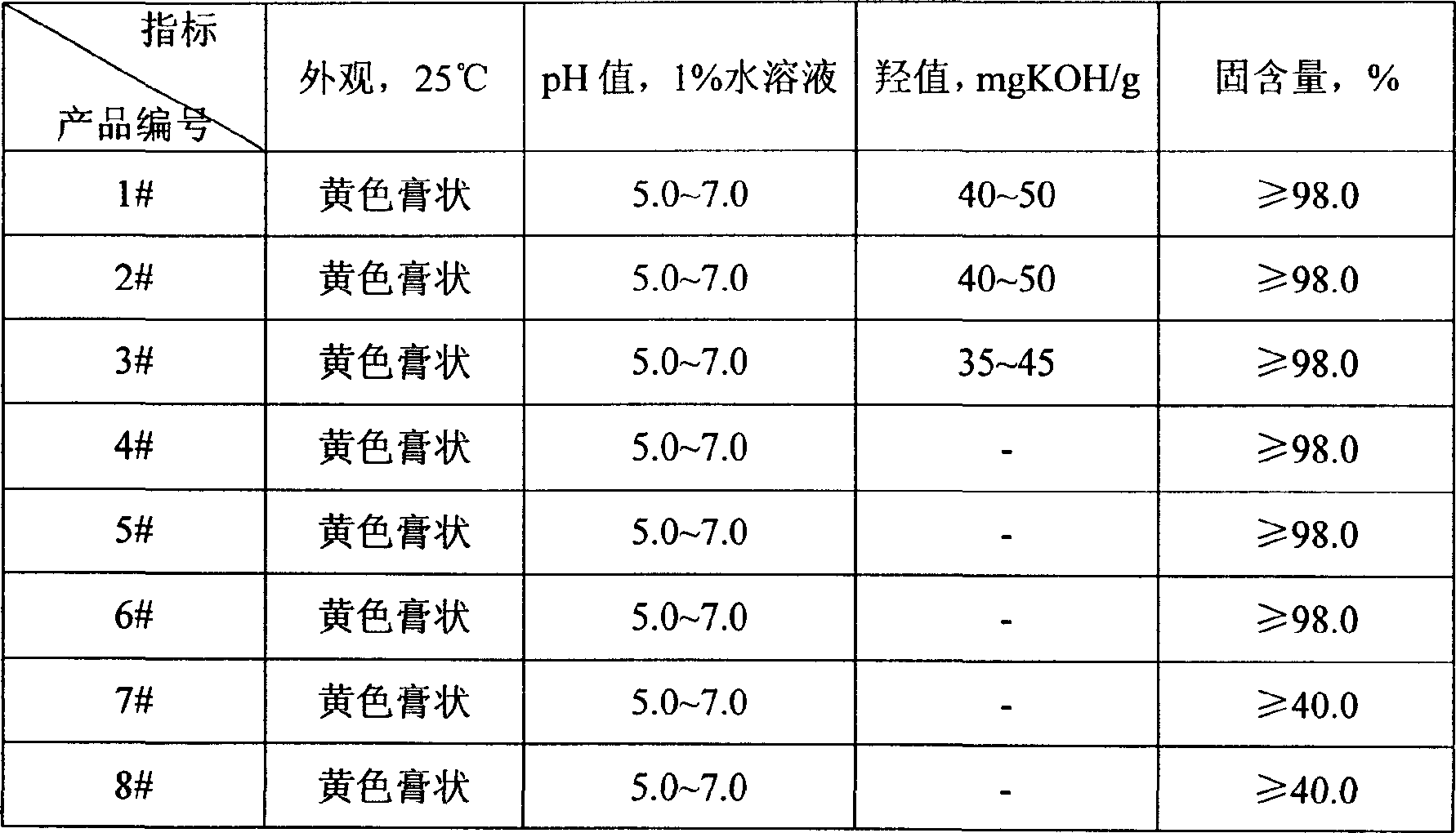

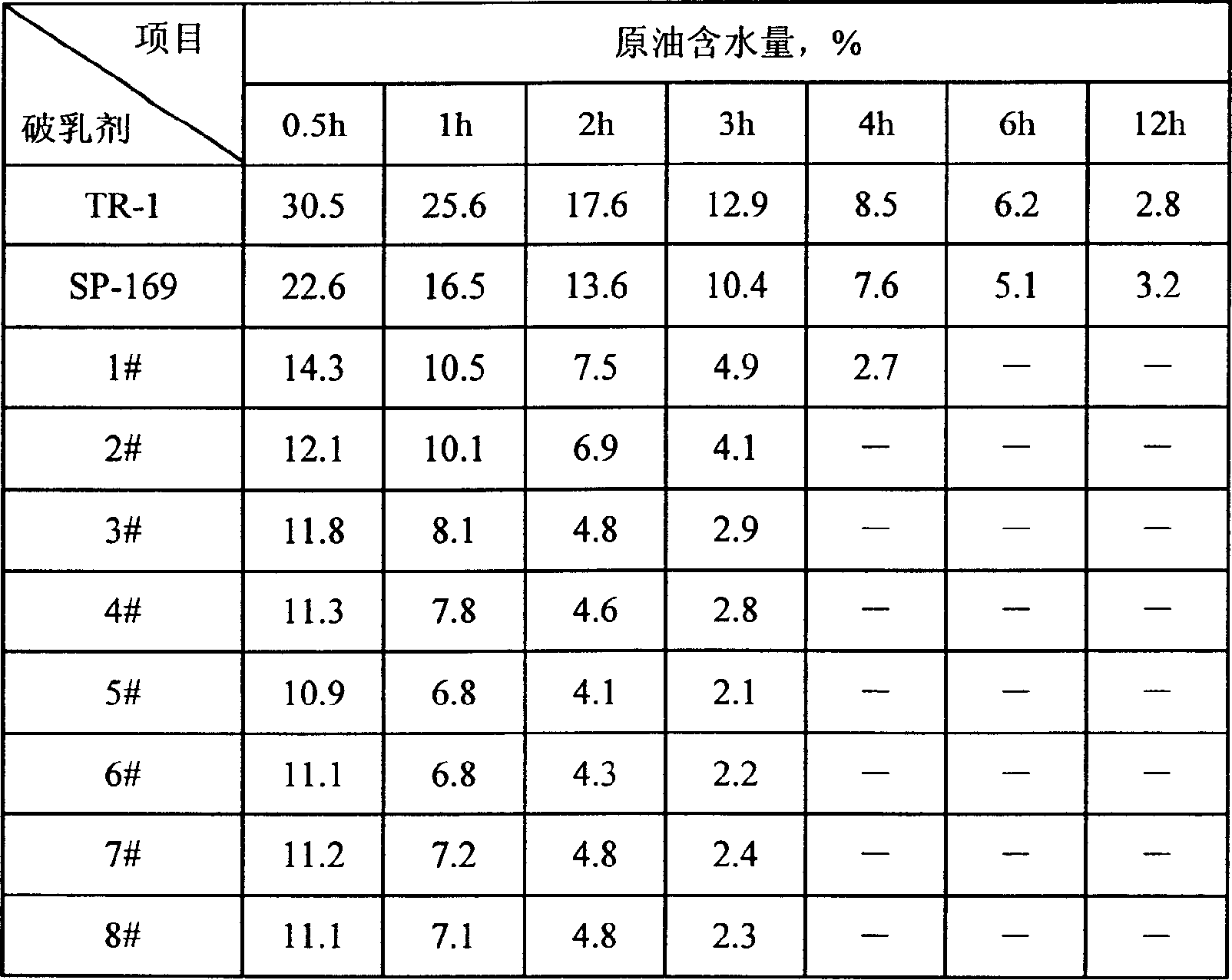

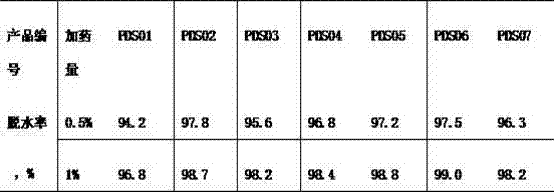

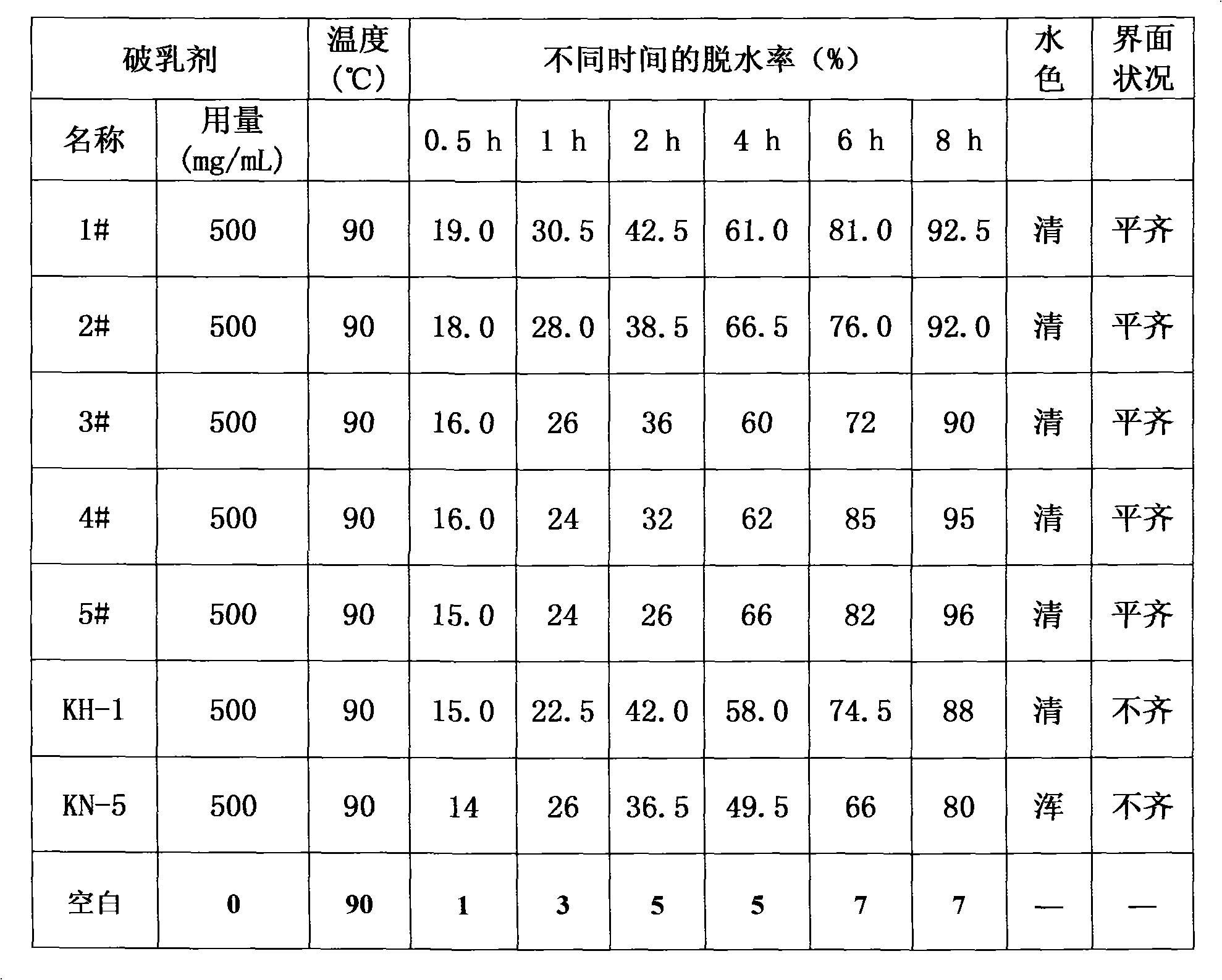

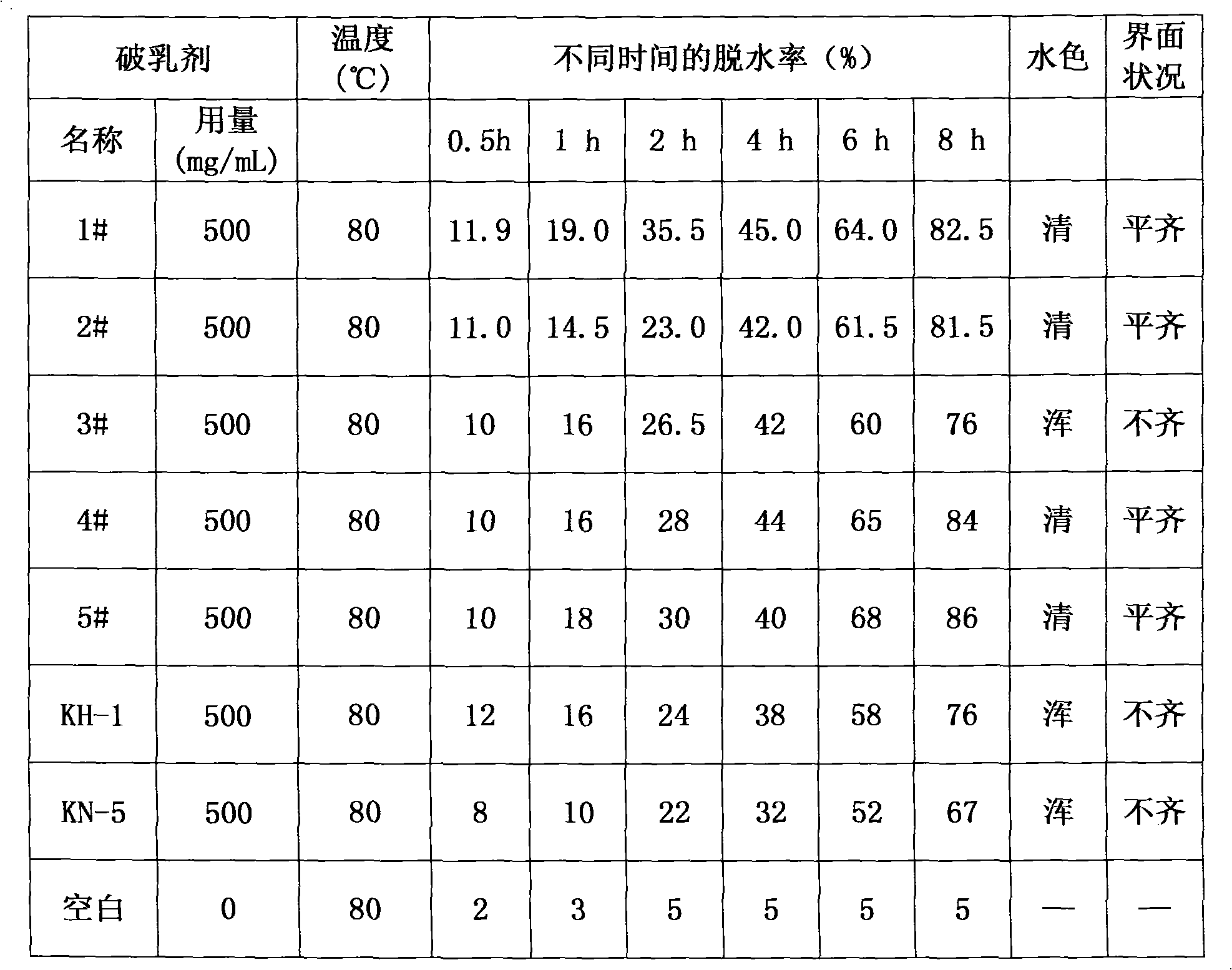

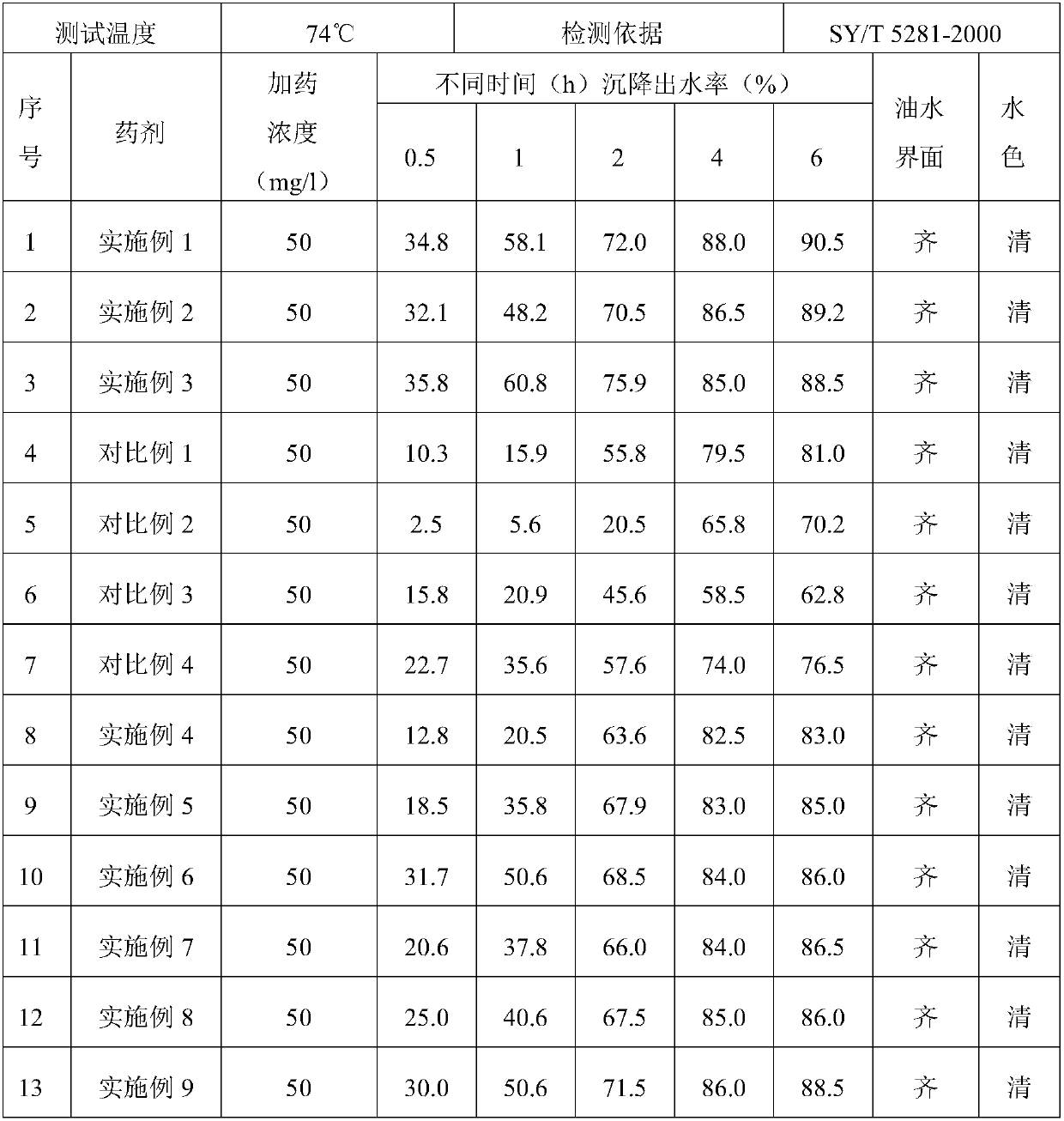

Preparation method of efficient deemulsifier for naphthenic extra heavy oil and product thereof

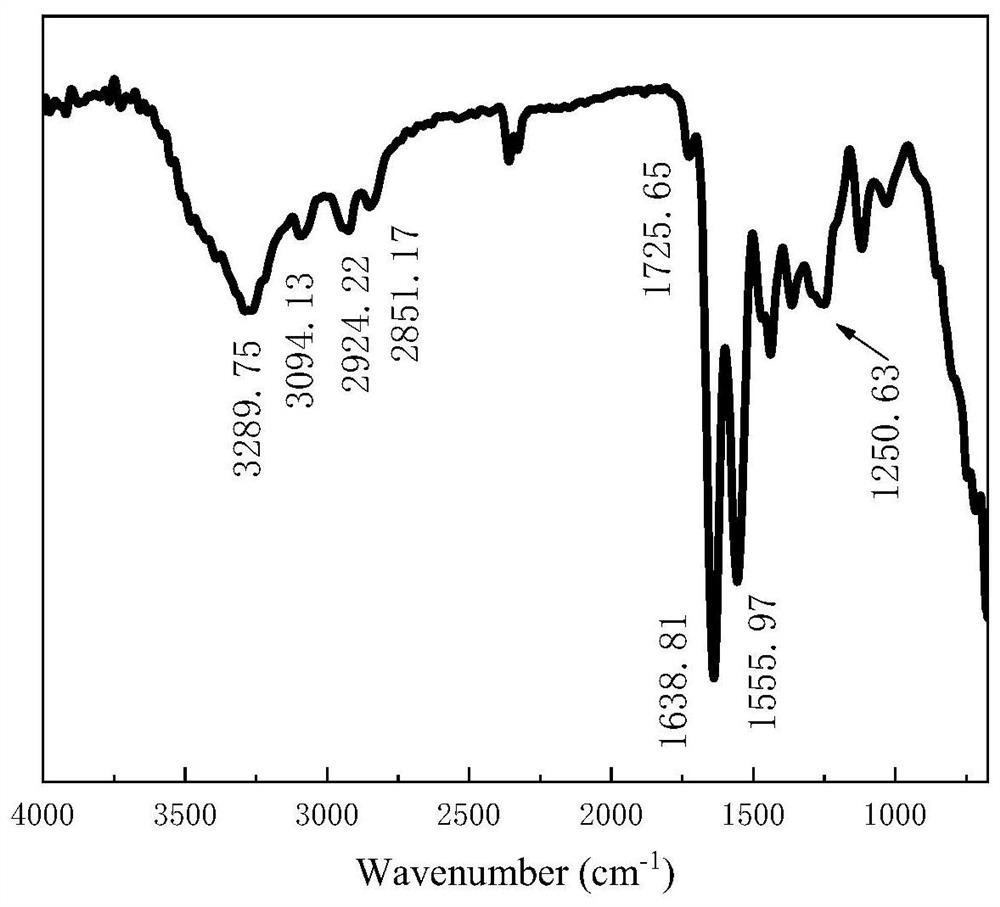

ActiveCN102746470BWeak elasticityReduce viscosityDewatering/demulsification with chemical meansAlkylphenolPhenol

The invention relates to a preparation method of an efficient deemulsifier for naphthenic extra heavy oil and a product thereof, belonging to the technical field of petroleum processing. The efficient deemulsifier is prepared by polymerizing alkylphenol, polyethylene polyamine and formaldehyde to obtain thermoplastic phenol-amine resin as an initiator, polymerizing the initiator with oxirane and epoxypropane to generate polyether blocked copolymer, and then esterifying the polyether blocked copolymer with acrylic acid and other unsaturated acids to generate a modified polyether product by grafting olefine acid. The product prepared by the method has the characteristics of quick dehydration and low dosage. The efficient deemulsifier of the invention is suitable for dehydrating the naphthenic extra heavy oil of Karamay oil fields, meeting the requirements of proper temperature, quick dehydration, high dehydration rate, clear water color, and tidy oil-water interface, and has high efficiency demulsification and dehydration performance.

Owner:克拉玛依市天明化工有限责任公司

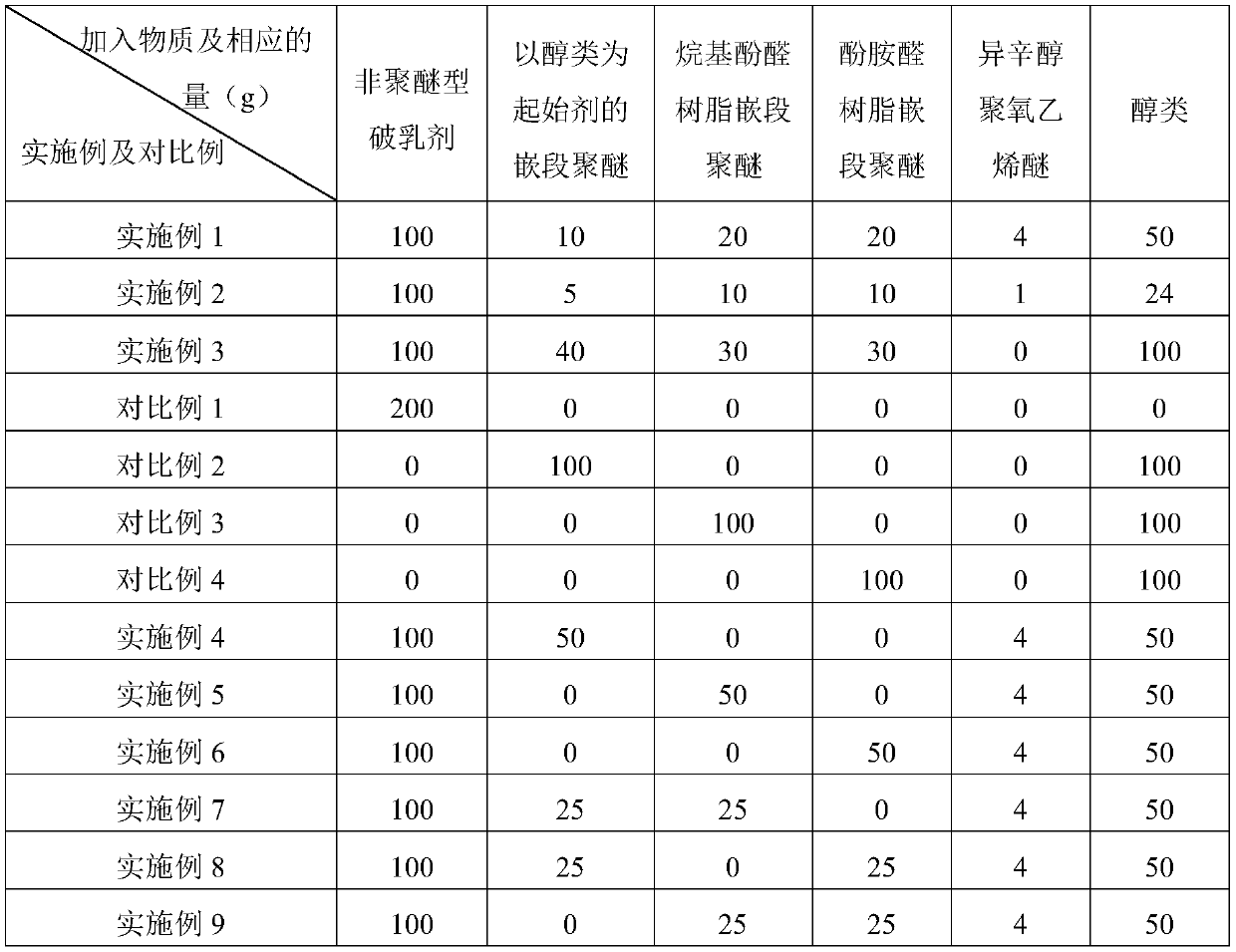

Crude oil demulsifier and preparation method thereof

InactiveCN111088065AImprove surface activityImprove dehydration rateDewatering/demulsification with chemical meansDemulsifierProcess engineering

The invention belongs to the technical field of chemicals for petroleum industry, and particularly relates to a crude oil demulsifier and a preparation method thereof. By utilizing the synergistic effect of a polyether demulsifier and a non-polyether demulsifier, several different types of demulsifiers are compounded to obtain an efficient demulsifier suitable for the thickened oil produced liquid. The crude oil demulsifier provided by the invention has the advantages of small using amount, high dehydration rate, lasting dehydration property, clearness, quick oil-water separation in the demulsification process, clear oil-water interface and few emulsification intermediate layers, and can be used for quickly and efficiently demulsifying heavy oil at a low temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

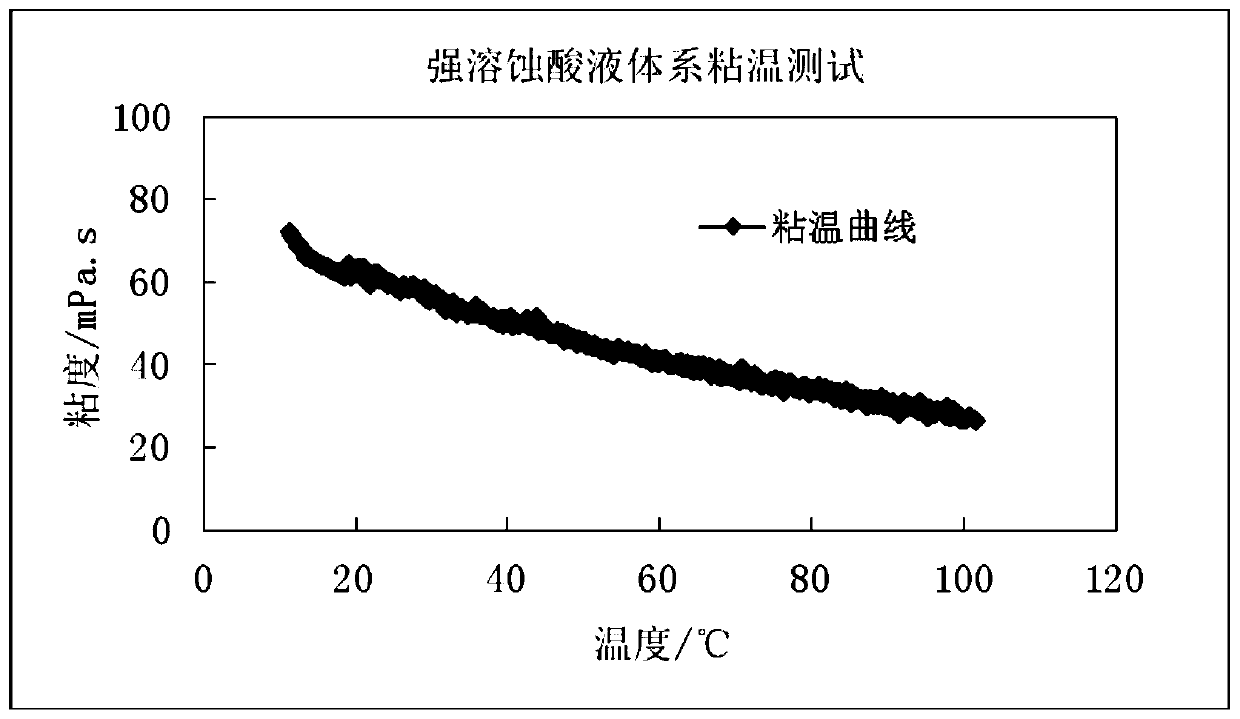

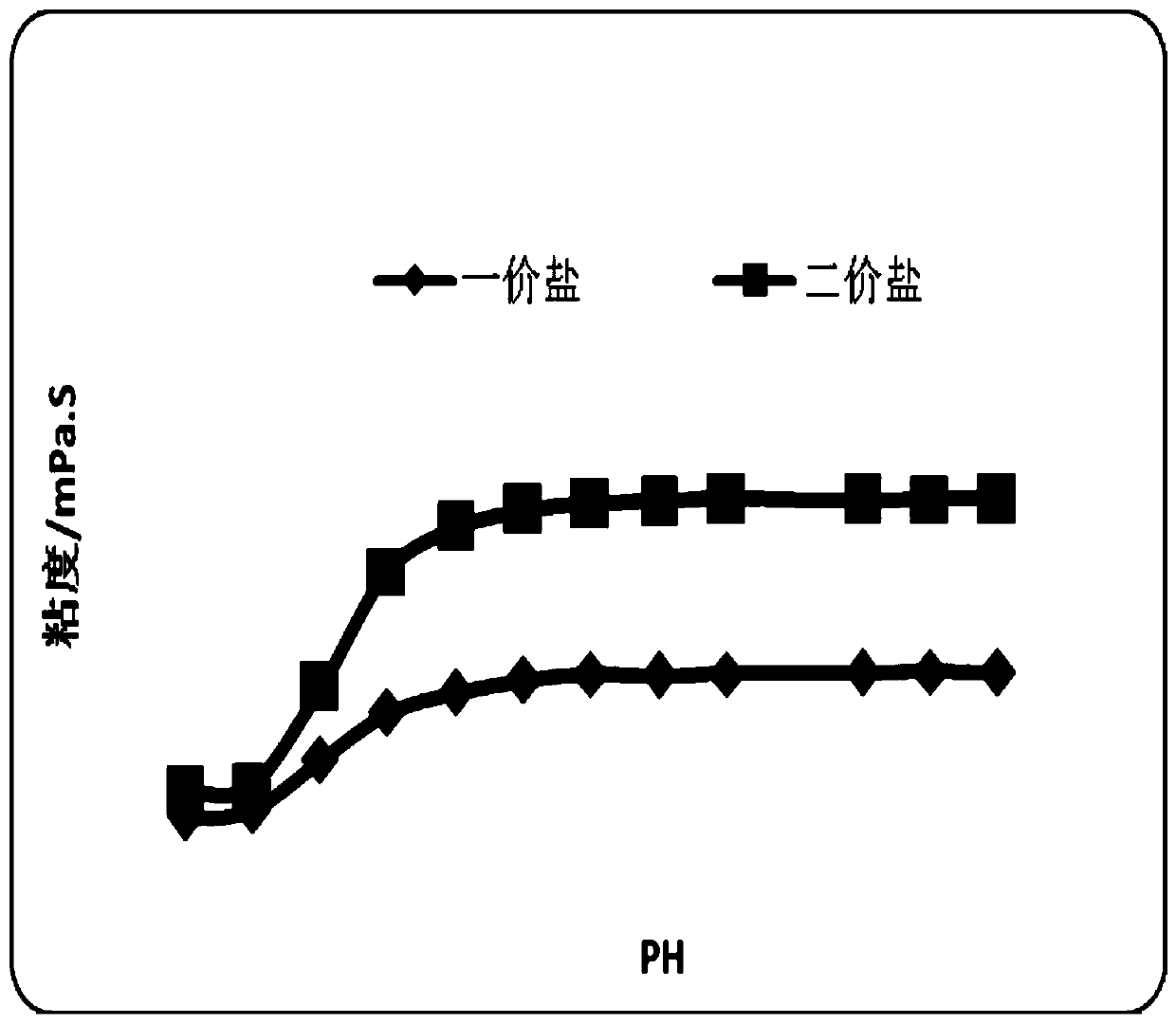

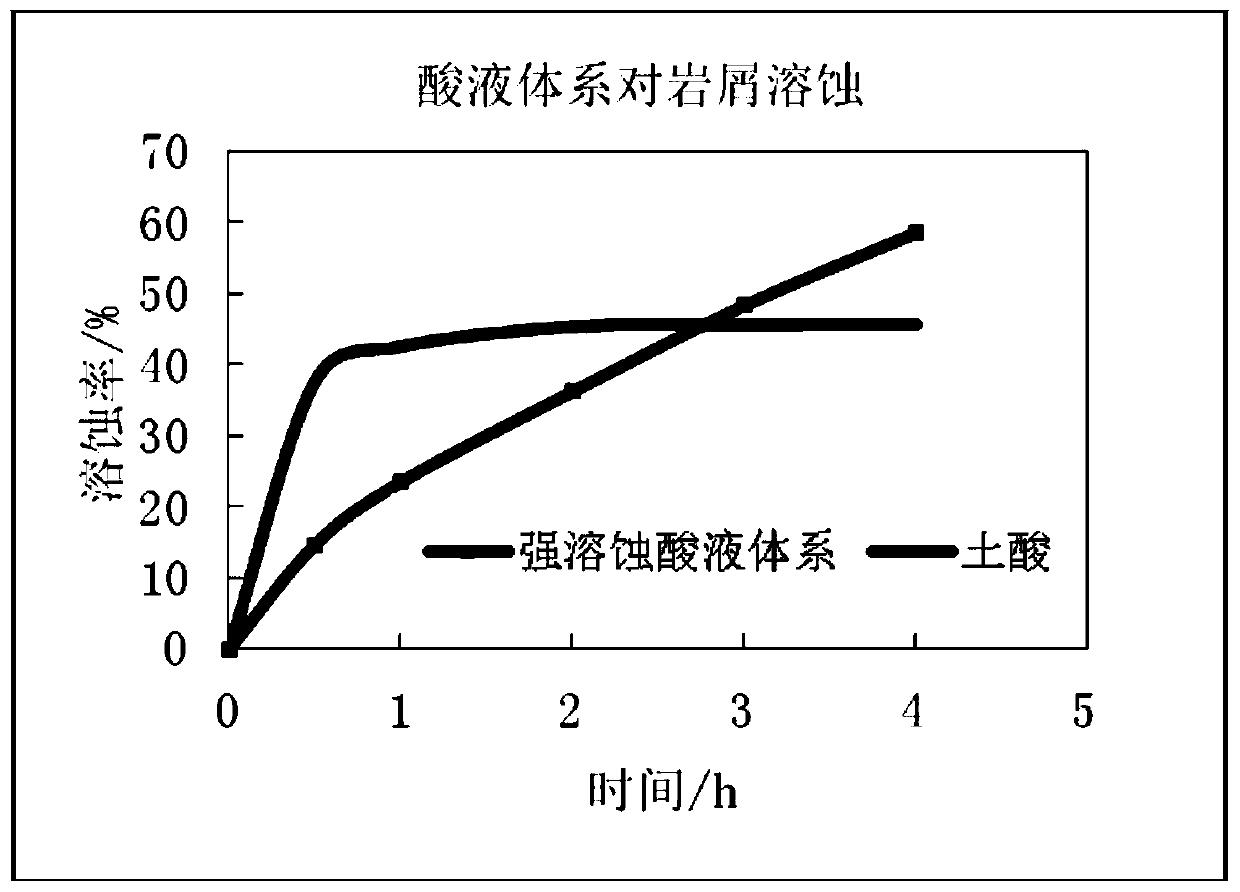

Tight oil reservoir high-viscosity strong-corrosion acid liquid system

ActiveCN110511735AReduce fluid lossIncrease the effective rangeDrilling compositionDemulsifierBetaine

The invention discloses a tight oil reservoir high-viscosity strong-corrosion acid liquid system, which comprises the following components by mass percentage: 6%-12% of hydrochloric acid, 1%-3% of betaine, 4%-8% of a reinforcing agent, 0.05%-0.2% of citric acid, 0.5%-2% of ammonium chloride, 0.5%-2% of a corrosion inhibitor, 0.1%-0.4% of a cleanup additive, 0.05%-0.2% of a demulsifier and the balance water. During acidification of the acid liquid system, the rise of the acid liquid viscosity reduces the acid liquid filtrate loss, thus forcing more fresh acid to enter deep stratum, and increasing the effective action distance of the acid liquid, and at the end of acidification, high-viscosity fluid undergoes automatic gel breaking into a low-viscosity fluid when encountering crude oil in the stratum, so that the stratum is exempt from secondary damage.

Owner:西安石油大油气科技有限公司

System and method for microwave-assisted supercritical CO2 extraction of crude oil in oil sands

ActiveCN104046375BEfficient separationEfficient developmentLiquid hydrocarbon mixture productionEnergy based chemical/physical/physico-chemical processesBuffer tankGas phase

The invention discloses a microwave-assisted supercritical CO2 extraction system and a microwave-assisted supercritical CO2 extraction method for crude oil in oil sand. The system comprises at least two extraction kettles, a microwave generator, a separator, a gas purifier, a buffer tank, an entrainer storage tank and the like. The method comprises the following steps: conveying oil sand to each extraction kettle by virtue of a conveying device, meanwhile, feeding CO2 and the entrainer into the buffer tank, enabling the mixture in the buffer tank to enter the extraction kettle, and closing valves at the inlet and outlet ends of the extraction kettle; starting the microwave generator, staying for a period of time after the temperature in the kettle is up to the extraction temperature, opening the valve at the bottom of the kettle, discharging sand, opening the valve at the top outlet of the kettle, and enabling gas-phase fluid to enter the separator through a throttle valve; discharging crude oil from an outlet at the bottom of the separator, and returning the top gas to the buffer tank by virtue of the purifier. The system is provided with the at least two extraction kettles which can be alternately operated to realize continuous operation.

Owner:XI AN JIAOTONG UNIV

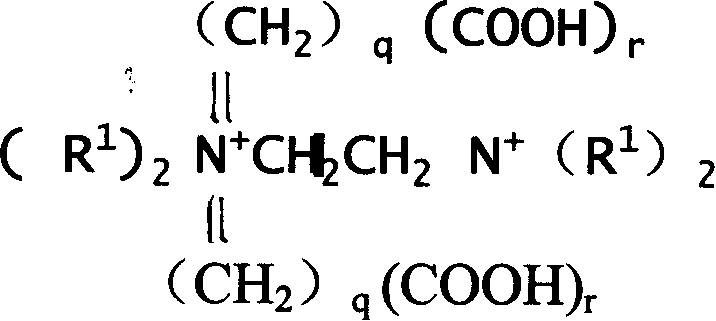

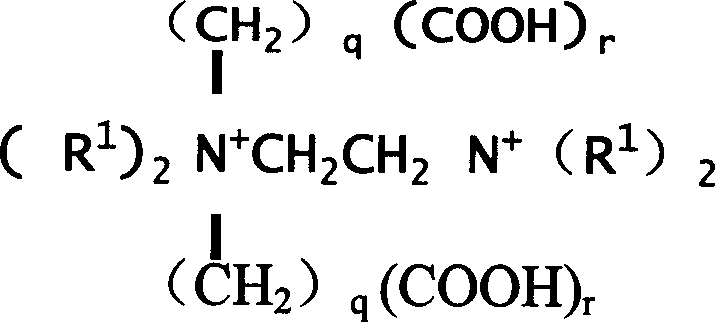

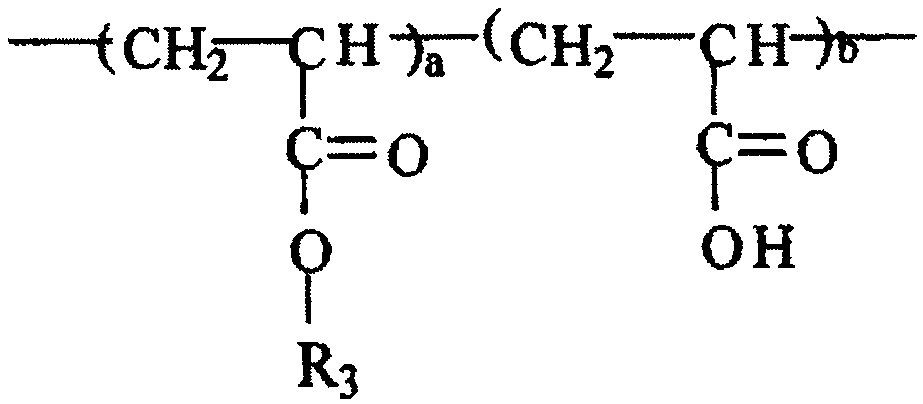

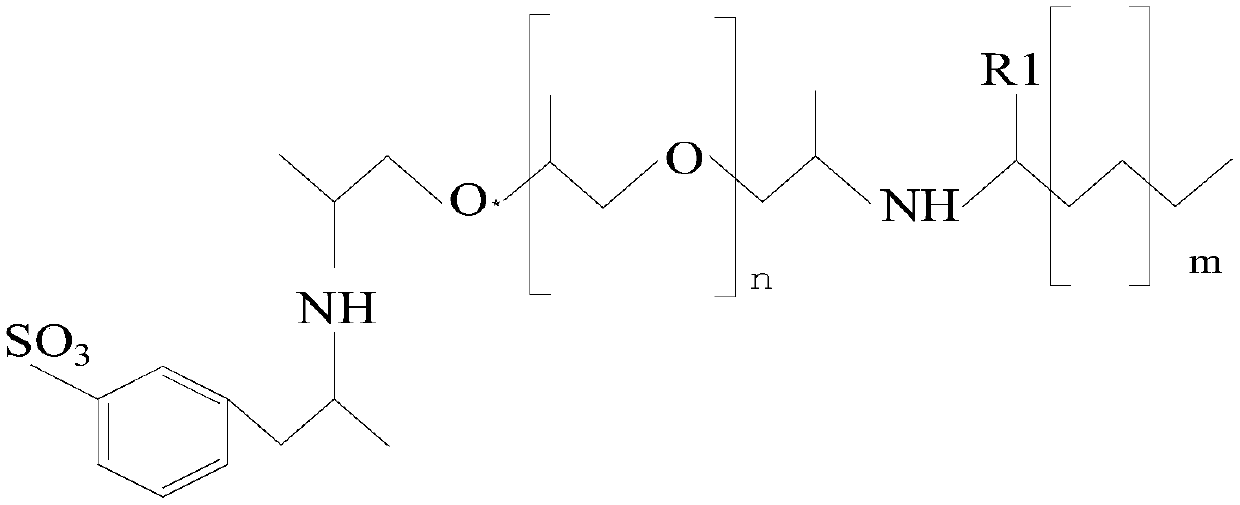

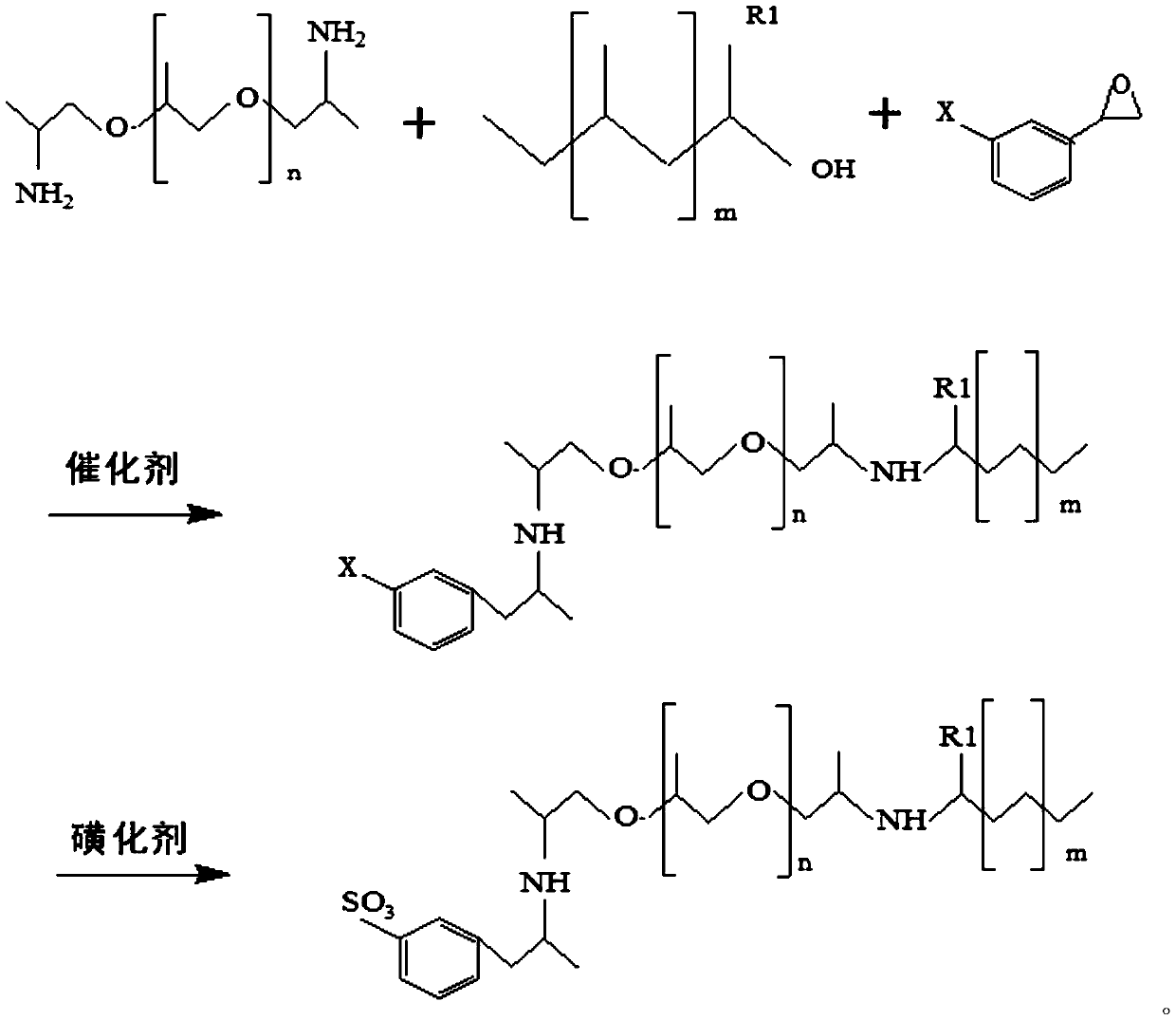

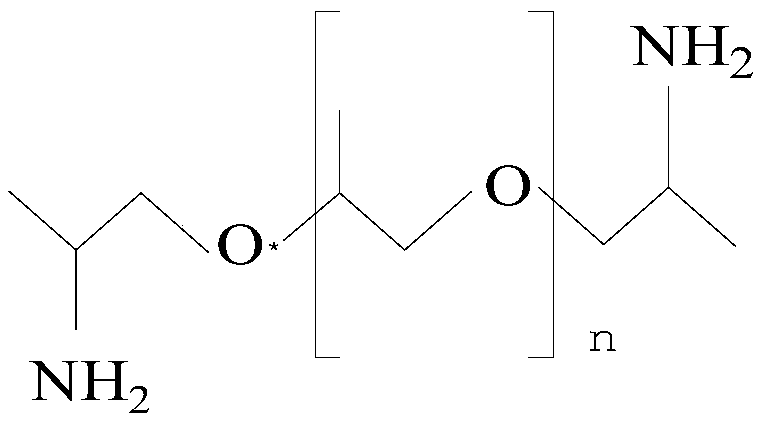

A kind of demulsifier and preparation method of high polymer-containing heavy oil sewage demulsifier

ActiveCN106335968BEfficient demulsificationWaste water treatment from quariesFatty/oily/floating substances removal devicesDemulsifierEther

The invention relates to a demulsifier for sewage high in thickened oil content and a preparation method and belongs to the technical field of chemical agents for oil fields and preparation. The structural formula of the demulsifier for sewage high in thickened oil content is shown in the claim 1, wherein R1 is one of -H, -CH3 and -CH2CH3, m is 5-7, and n is 6-15. The molecular weight of the polymer is 300,000-600,000. Based on the analysis on a demulsification mechanism, the main chain structure of the polymer of the demulsifier is designed on the aspects of a molecular structure, a function effect and the synergistic effect of groups at an equal angle according to the characteristics of the sewage high in thickened oil content, the synergistic effect of amino, sulpho and ether groups in the structural formula of the polymer demulsifier make the thickened oil sewage high in polymer content efficiently demulsified, the oil removal rate of the sewage high in thickened oil content is 95% or above in field application, and the suspended solidremoval rate is 90% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

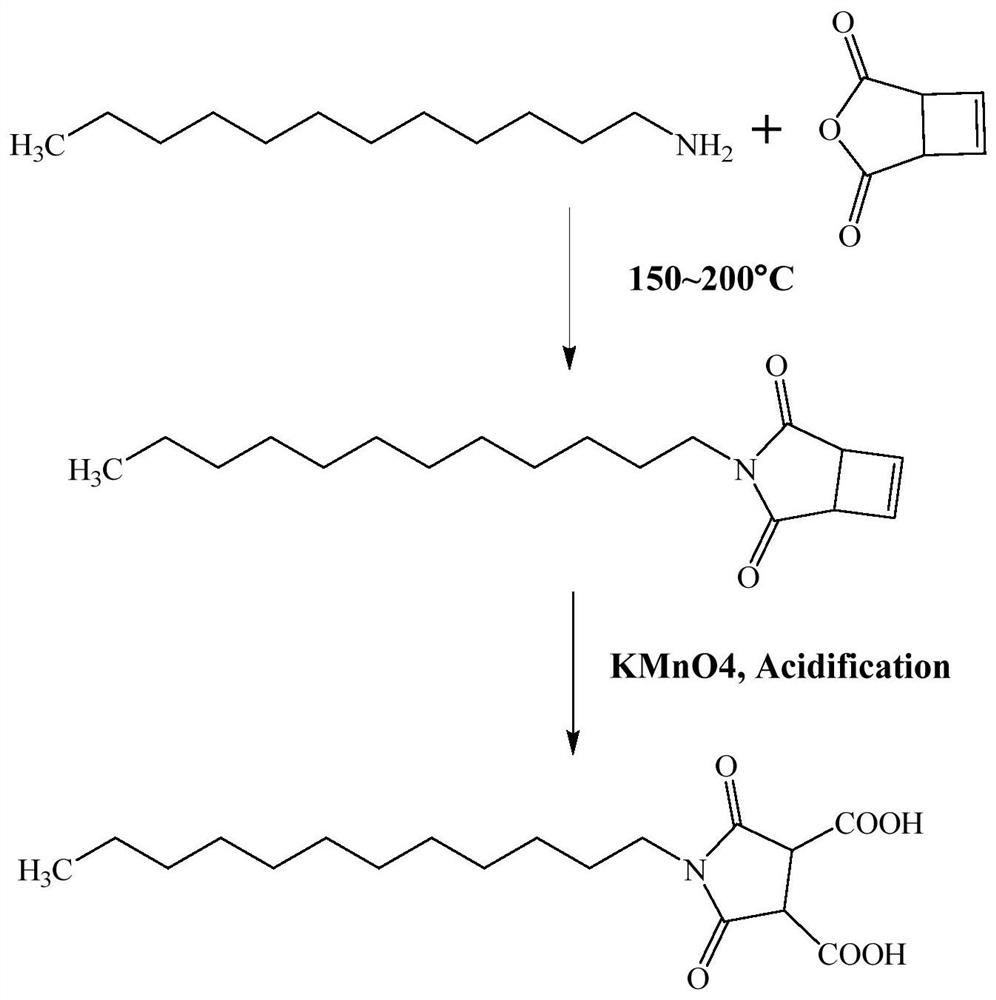

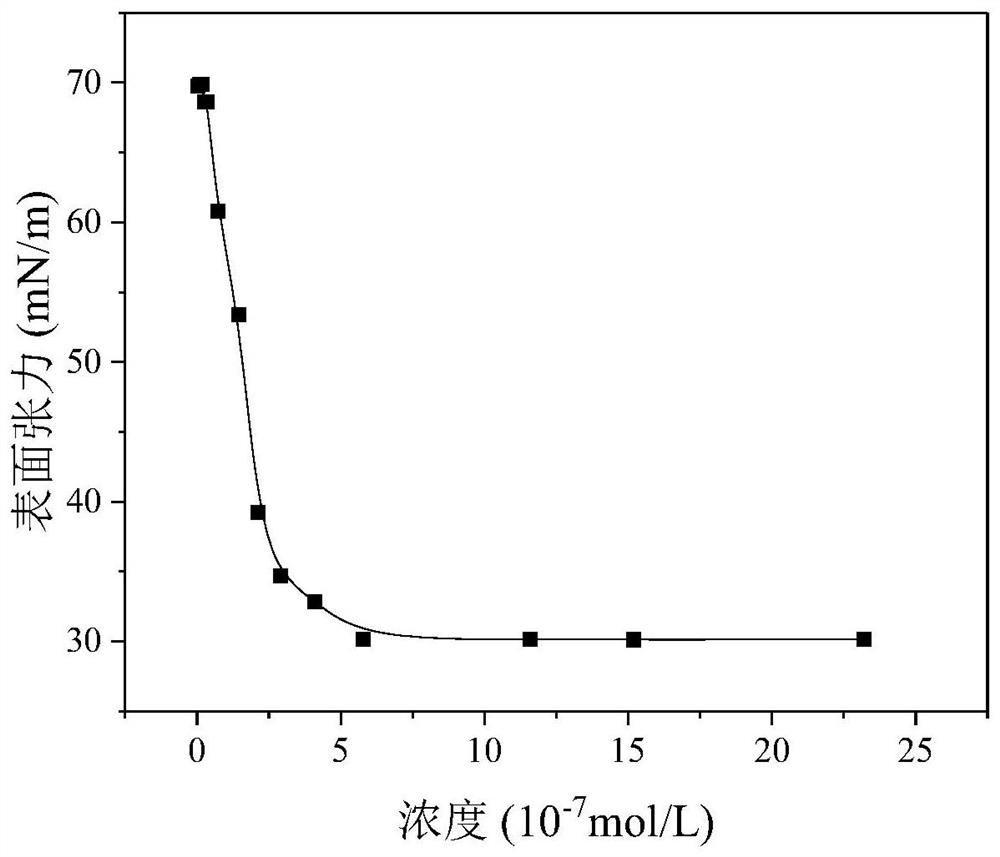

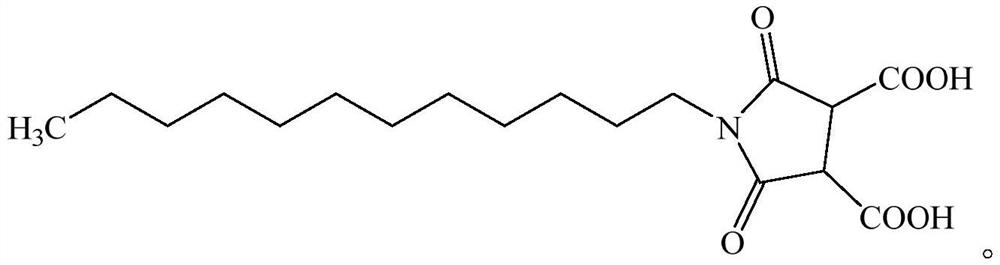

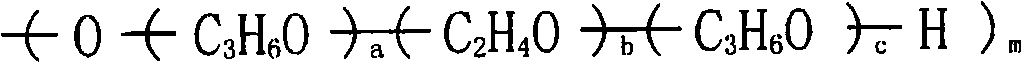

Surfactant with self-demulsification capability as well as preparation method and application of surfactant

ActiveCN112079762AStrong emulsifying abilityExtensive sources of raw materialsDewatering/demulsification with chemical meansOrganic chemistrySulfite saltActive agent

The invention discloses a surfactant with self-demulsification capability as well as a preparation method and application of the surfactant. The method comprises the following steps: 1) sequentially adding dodecylamine and cyclobutane-3-alkene dicarboxylic anhydride into a three-neck flask, introducing nitrogen, carrying out reaction at 150-200 DEG C for 2-5 hours, and carrying out nucleophilic addition elimination reaction to generate imide; and 2) diluting the reaction solution, slowly adding potassium permanganate at 0 DEG C, heating to carry out oxidation reaction to generate carboxyl, andreacting at 90-100 DEG C for 10-12 hours; and after the reaction is finished, adding sodium sulfite to remove excessive potassium permanganate, filtering by adopting a diatomite and extracting impurities by adopting ethyl acetate, collecting a water phase, regulating the pH value to 2-4 to separate out a product, filtering and drying to constant weight to obtain a final product. The surfactant with the self-demulsification capability is applied to thick oil emulsification, the viscosity of thick oil can be reduced, the pH value of emulsified thick oil is increased before the surfactant entersoil refining, and the surfactant can realize demulsification of the emulsified thick oil due to hydrolysis inactivation.

Owner:宁夏宇航油田工程有限公司

Preparation method of diesel vehicle water-based carbon remover

InactiveCN111117777ASimple preparation processEasy to operateInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphoric Acid EstersAromatic solvent

The invention discloses a preparation method of a water-based carbon remover for a diesel vehicle. The preparation method comprises the following specific steps: S1, respectively weighing deionized water, aromatic solvent oil, petroleum ether and a lactic acid solution in parts by weight to obtain a mixed solution A; S2, weighing polyether amine in parts by weight, and adding the polyether amine into the mixed solution A to obtain a mixed solution B; S3, weighing alcohol ether phosphate in parts by weight, and adding the alcohol ether phosphate into the mixed solution B to obtain a mixed solution C; S4, weighing triethanolamine dodecylbenzene sulfonate in parts by weight, and adding the triethanolamine dodecylbenzene sulfonate into the mixed solution C to obtain a mixed solution D; S5, weighing an alkaline solution, and adding the alkaline solution into the mixed solution D until the mixed solution is neutral to obtain a mixed solution E; and S6, weighing hydrotalcite, A-type zeolite powder and a surfactant in parts by weight, adding the hydrotalcite, the A-type zeolite powder and the surfactant into the mixed solution E, and uniformly mixing all the components to obtain the water-based carbon remover F. The method is simple in process, simple to operate, short in production period, low in industrial cost and worthy of popularization; the prepared water-based carbon remover F can be used for effectively cleaning deposited carbon of a diesel vehicle engine.

Owner:深圳市朗迅实业有限公司

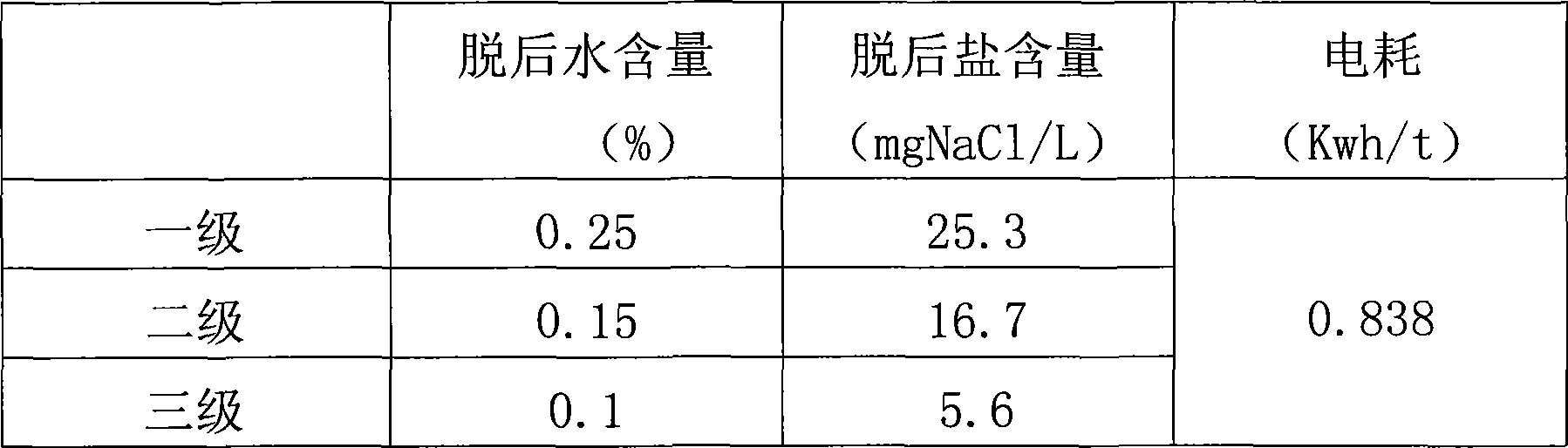

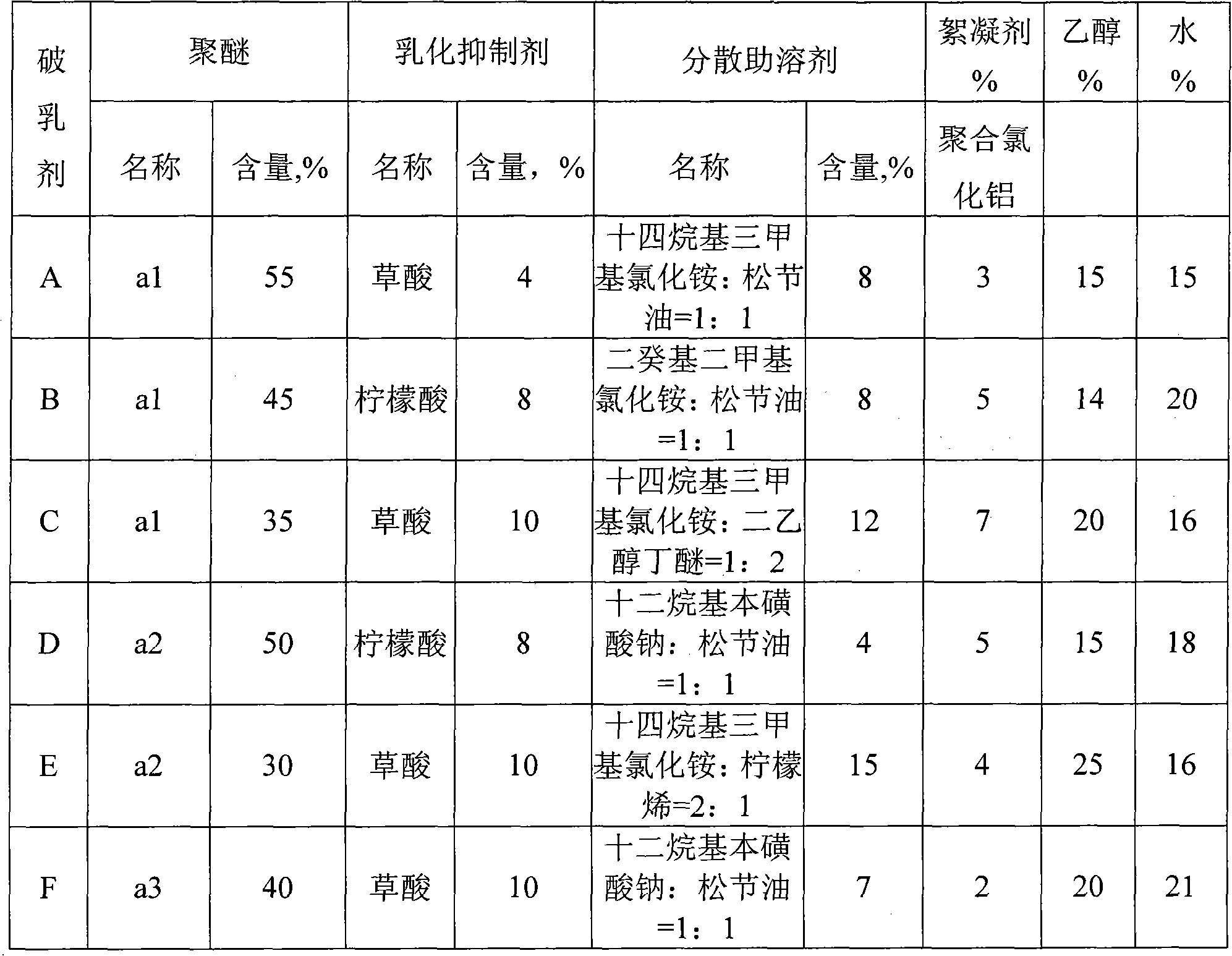

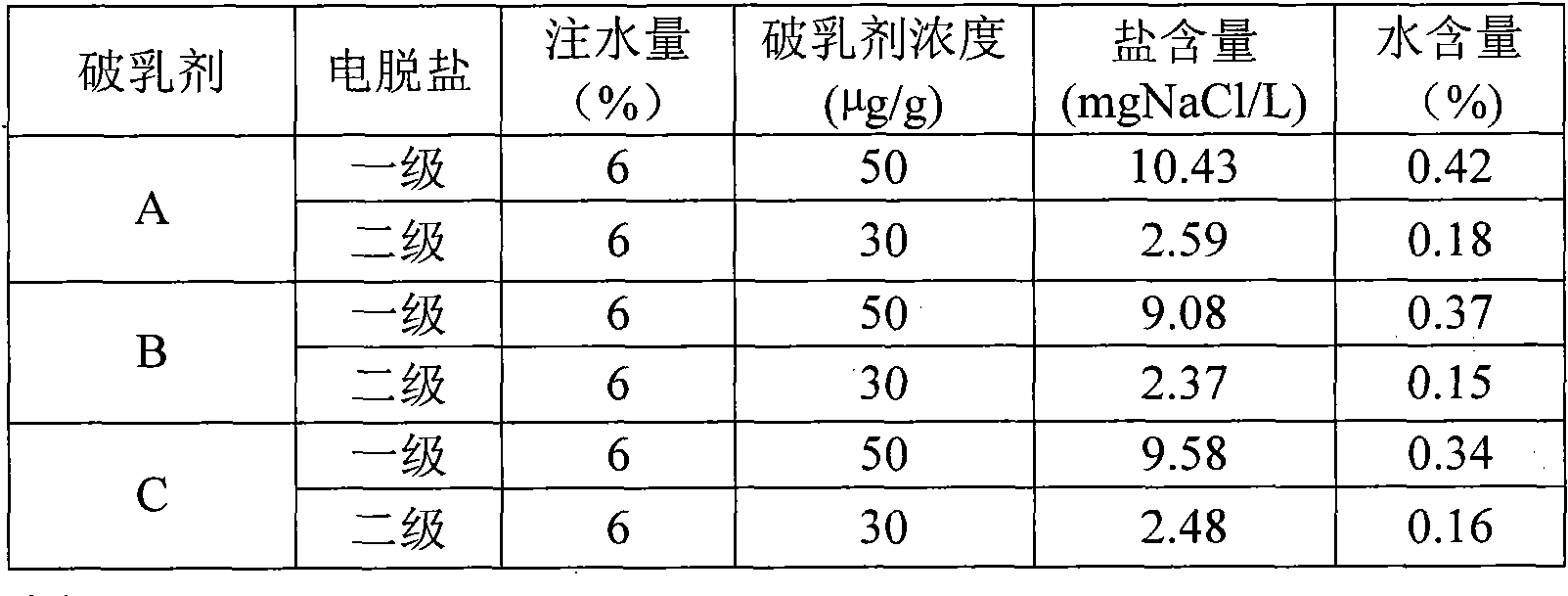

Acid-containing crude oil demulsifying agent and preparation method thereof

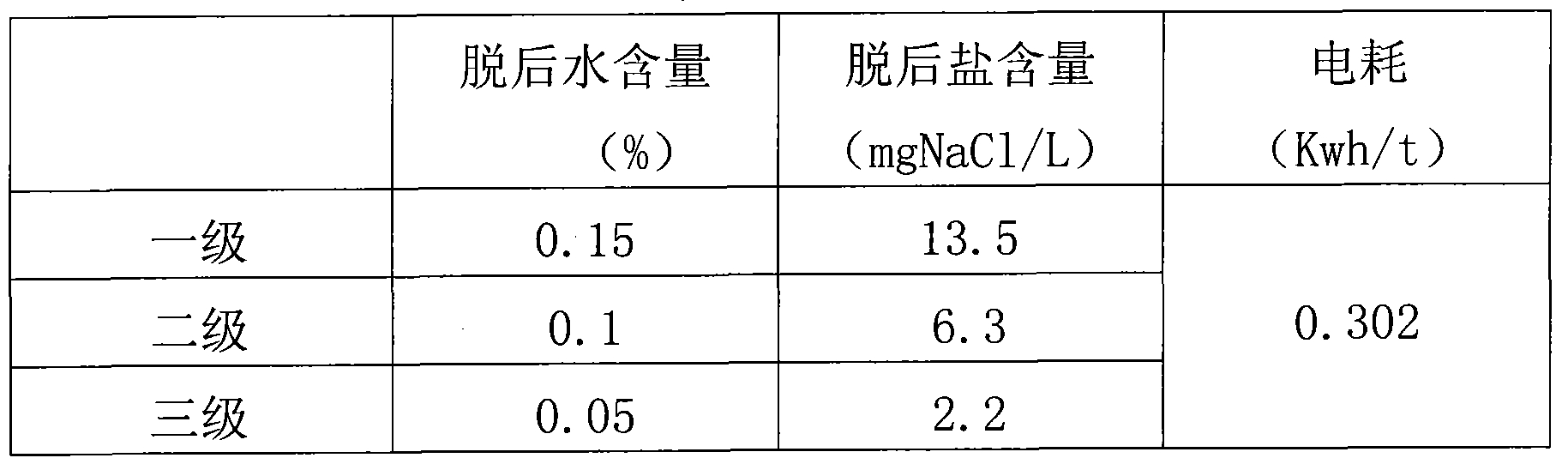

ActiveCN102140365BInhibition dispersionGood desalination effectDewatering/demulsification with chemical meansTransportation and packagingDesalinationEther

The invention discloses an acid-containing crude oil demulsifying agent and a preparation method thereof. The effects of eliminating oil water emulsification, reaching deep desalination and dehydration and reducing oil in drained water are achieved. The demulsifying agent consists of 30 to 60 weight percent of polyvinyl polyamine polyoxyethylene polyoxypropylene ether, 1 to 10 weight percent of emulsifying inhibitor, 1 to 10 weight percent of flocculating agent, 1 to 15 weight percent of dispersion cosolvent and 20 to 50 weight percent of solvent. The demulsifying agent can be used for electric desalination and dehydration processes of acid-containing crude oil and acidified crude oil, the adding amount is 10 to 100mug / g, the salt content of the acid-containing crude oil after electric desalination can be reduced to be less than 3mgNaCl / L, and the water content can be reduced to be less than 0.3 weight percent.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of hyperbranched polymer and its preparation method and application

ActiveCN111171327BReduce interfacial tensionImprove demulsification efficiencyDewatering/demulsification with chemical meansDemulsifierPolymer science

The invention discloses a hyperbranched polymer. The hyperbranched polymer is centered on trimethyl citrate and the amine group is an end group; the weight average molecular weight M of the hyperbranched polymer is w is 10757 and the PDI is 5.09. The hyperbranched polymer is centered on trimethyl citrate, and the amine group is the end group. It contains a large number of hydrophilic groups, which can significantly reduce the oil-water interfacial tension and improve the demulsification efficiency. Efficient demulsification of oil-in-water emulsions can be achieved under a low temperature. At room temperature, the demulsification efficiency of 50mg / L hyperbranched polymers for diesel oil emulsions can reach 99.7%. Milk efficiency is high. The invention also provides a preparation method of the hyperbranched polymer and its application as a demulsifier.

Owner:湖北鑫城普瑞化学科技有限公司

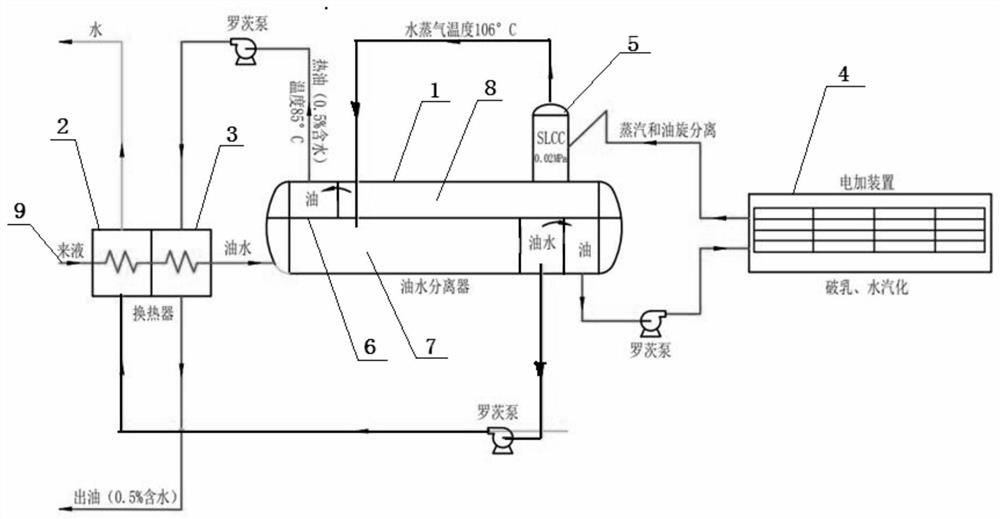

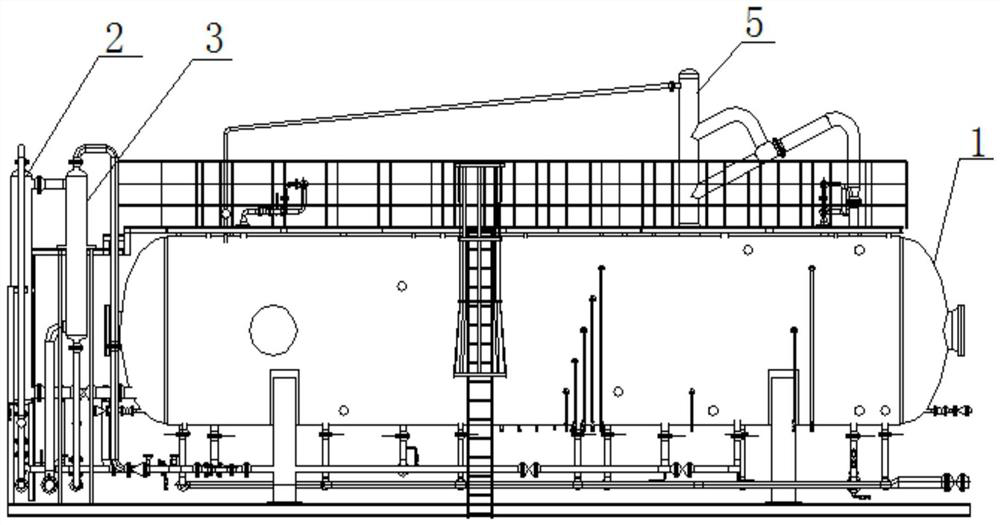

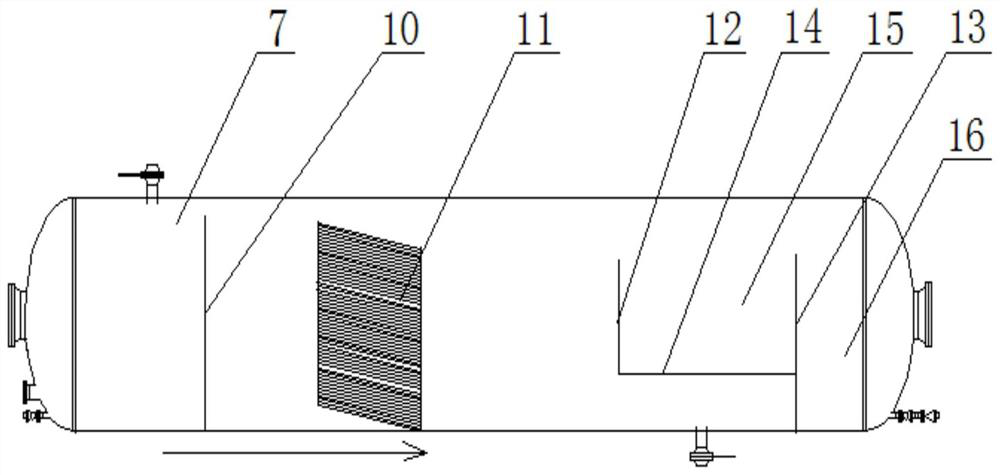

A device and method for oil-water demulsification separation of heavy oil

ActiveCN110643387BPromote boilingEfficient vaporizationDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansPhysical chemistryOil separation

The invention discloses a heavy oil oil-water demulsification separation equipment and method, comprising an oil-water separation tank, and is characterized in that it also includes an electromagnetic induction heater and a vapor-liquid cyclone separator. The oil-water separation tank is divided into a first-stage oil-water separation chamber and a second-stage oil-water separation chamber. The first-stage oil-water separation chamber is connected to the second-stage oil-water separation chamber through an electromagnetic induction heater and a vapor-liquid cyclone in turn. The separation method includes the following steps to mix the oil-water and send the liquid to the first-stage oil-water separation tank. The oil-water separation chamber is used for oil-water separation, and the oil phase separated in the first-stage oil-water separation chamber is sent to the electromagnetic induction heater for treatment. The liquid mixture obtained after flow separation enters the secondary oil-water separation chamber for oil-water separation again to obtain refined oil with a water content of less than 0.5%. The advantages are high oil-water separation efficiency, low energy consumption and high product purity.

Owner:新疆中亚石油天然气有限公司

Clean lubricant for gasoline and diesel direct injection engine and preparation method thereof

InactiveCN111117741AGood dispersionEfficient demulsificationLubricant compositionGasolineProcess engineering

The invention discloses a clean lubricant for a gasoline and diesel direct injection engine. The clean lubricant comprises the following raw materials in parts by weight: 60-80 parts of polyether amine, 20-30 parts of soybean oleic acid, 1-2 parts of alkenyl succinate and 10-20 parts of D100 solvent oil. The polyether amine has a dissolving effect on deposited carbon, particularly has very high dissolving capacity on the deposited carbon in a low-temperature area at the front end of an engine, and the deposited carbon burns away along with oil after being dissolved; the soybean oleic acid canform a layer of adsorption film on the metal surface, the lubricating capacity of the film is very high, and after the lubricating performance is improved, abrasion of a gasoline injection system is reduced, and shaking of an engine can also be reduced. The alkenyl succinate is an antirust agent of an oil product and can inhibit rusting of an oil path system; and the D100 solvent oil is high in flash point, is not inflammable after being blended with the polyether amine, soybean oleic acid and alkenyl succinate, is clearer in product color, and is used for improving the product quality.

Owner:JIANGSU CHUANGXIN PETROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com