Preparation method of novel multi-branched cationic polyether reverse demulsifier and multi-branched cationic polyether reverse demulsifier

An inverse demulsifier and cationic polymerization technology, applied in the direction of chemical dehydration/demulsification, etc., can solve problems such as difficulty in meeting the production needs of efficient and rapid demulsification in oil fields, unclear use effect, and slow dehydration speed. Achieve superior demulsification performance, reduced surface tension and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

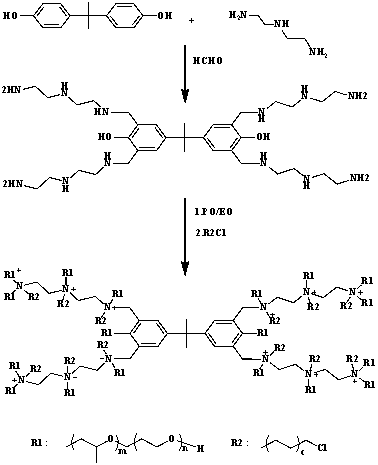

[0026] The invention discloses a preparation method of a novel multi-branched cationic polyether inverse demulsifier, comprising the following steps:

[0027] (1) Reflux reaction of bisphenol A, diethylenetriamine and formaldehyde in a certain molar ratio under the action of alkali catalyst for 1 hour, the molar ratio of bisphenol A, diethylenetriamine, alkali catalyst and formaldehyde is 1:8 :1:20.

[0028] (2) Add the branched polyamine compound and alkali catalyst obtained in the step (1) into the high pressure cap, heat up and vacuumize after sealing. The molar ratio of branched polyamine compound to base catalyst is 1:1, and the temperature is 120 °C.

[0029] (3) Slowly and continuously add PO and EO into the high-pressure cap according to a certain proportion, and continue to react for 2 hours after the addition, and obtain hyperbranched polyether compounds after distillation. The mole fraction ratio of PO and EO is 1:1, the reaction cover pressure is 0.3 MPa, and the...

Embodiment 2

[0032] The invention discloses a preparation method of a novel multi-branched cationic polyether inverse demulsifier, comprising the following steps:

[0033] (1) Reflux reaction of bisphenol A, diethylenetriamine and formaldehyde in a certain molar ratio under the action of an alkali catalyst for 5 hours, the molar ratio of bisphenol A, diethylenetriamine, alkali catalyst and formaldehyde is 1:8 :1:20.

[0034] (2) Add the branched polyamine compound and alkali catalyst obtained in the step (1) into the high pressure cap, heat up and vacuumize after sealing. The molar ratio of branched polyamine compound to base catalyst is 1:1, and the temperature is 120 °C.

[0035] (3) Slowly and continuously add PO and EO into the high-pressure cap according to a certain proportion, and continue to react for 4 hours after the addition, and obtain hyperbranched polyether compounds after distillation. The mole fraction ratio of PO and EO is 1:2, the reaction cover pressure is 0.3 MPa, and...

Embodiment 3

[0038] The invention discloses a preparation method of a novel multi-branched cationic polyether inverse demulsifier, comprising the following steps:

[0039] (1) Reflux reaction of bisphenol A, diethylenetriamine and formaldehyde in a certain molar ratio under the action of alkali catalyst for 6h, the molar ratio of bisphenol A, diethylenetriamine, alkali catalyst and formaldehyde is 1:8 :1:20.

[0040] (2) Add the branched polyamine compound and alkali catalyst obtained in the step (1) into the high pressure cap, heat up and vacuumize after sealing. The molar ratio of branched polyamine compound to base catalyst is 1:1, and the temperature is 120 °C.

[0041] (3) Slowly and continuously add PO and EO into the high-pressure cap according to a certain proportion, and continue to react for 5 hours after the addition, and obtain hyperbranched polyether compounds after distillation. The mole fraction ratio of PO and EO is 2:3, the reaction cover pressure is 0.3 MPa, and the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com