Preparation method and application of hyperbranched polymer with propylene diamine as initiator

A technology of hyperbranched polymer and propylenediamine, which is applied in the field of petroleum additives, can solve the problems of increasing oil production costs, corroding oilfield pipelines, etc., and achieve the effect of high-efficiency demulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

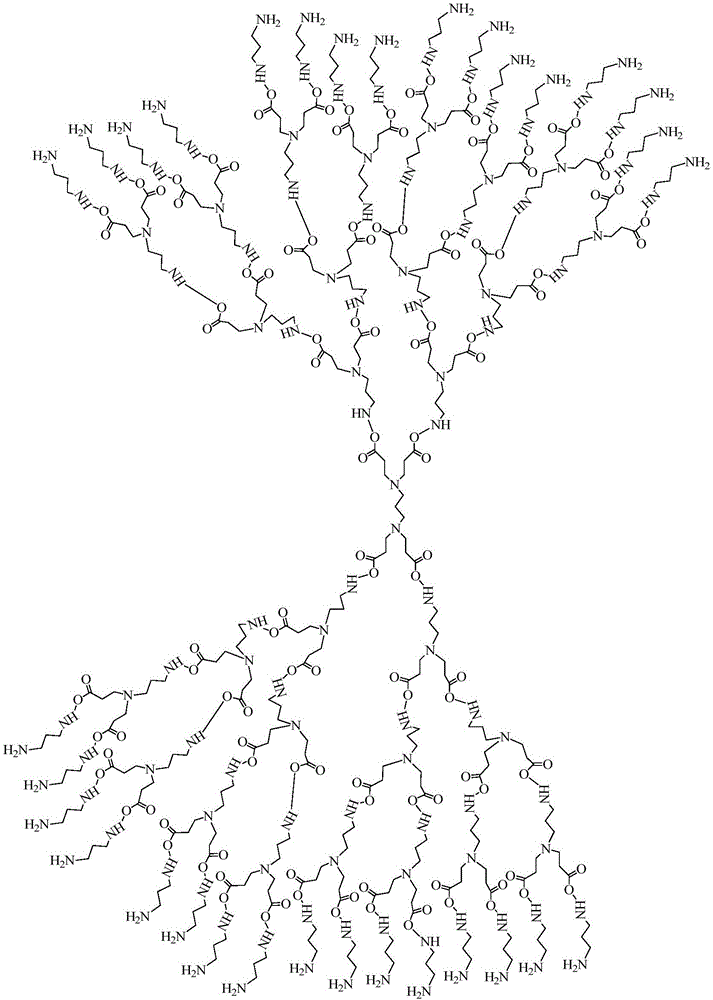

[0028] Embodiment 1: take propylene diamine as the hyperbranched polymer (h-PAMAM) preparation of initiator

[0029] Dissolve 14.2 g of propylenediamine in 25 mL of anhydrous methanol, weigh 17.2 g of methyl acrylate dropwise into the reaction system, and vigorously stir at room temperature for 48 h. The reaction product was subjected to decompression and compression reaction to obtain a product with a high degree of polymerization. The temperature rise program was set from 50°C to 140°C, and the reaction time was 8h; then, the crude product was cooled to room temperature and poured into 200mL ether and stirred for 30min. The yellow transparent viscous liquid sank to the lower layer, discarded the upper layer of ether, repeated the precipitation twice, and rotary evaporated at 60°C under vacuum to obtain h-PAMAM.

[0030] The structural representation of the hyperbranched polymer (h-PAMAM) with propylenediamine as the initiator is as follows: figure 1 (It should be noted that...

Embodiment 2

[0031] Embodiment 2: take propylene diamine as the hyperbranched polymer (h-PAMAM) preparation of initiator

[0032] Dissolve 14.8 g of propylenediamine in 25 mL of anhydrous methanol, weigh 22.2 g of methyl acrylate dropwise into the reaction system, and vigorously stir at room temperature for 60 h. The reaction product was subjected to decompression and compression reaction to obtain a product with a high degree of polymerization. The temperature rise program was set from 60°C to 140°C, and the reaction time was 10h; then, the crude product was cooled to room temperature and then poured into 300mL ether and stirred for 60min. The yellow transparent viscous liquid sank to the lower layer, discarded the upper layer of ether, repeated the precipitation twice, and rotary evaporated at 60°C under vacuum to obtain h-PAMAM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com