Tight oil reservoir high-viscosity strong-corrosion acid liquid system

A technology for tight oil reservoirs and high viscosity, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced production, increased production and increased injection, unsatisfactory effects of increased injection, and inability to completely remove blockages, etc., to achieve increased The effect of the effective range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high-viscosity and strong-corrosion acid liquid system for tight oil reservoirs, comprising:

[0032] 6% hydrochloric acid, 1% betaine, 4% enhancer, 0.05% citric acid, 0.5% ammonium chloride, 0.5% corrosion inhibitor, 0.1% drainage aid, 0.05% demulsifier, the balance is water, the above groups The sum of the points is 100%;

[0033] Described strengthening agent is JD-30B strengthening agent (Sichuan Kaier Oil and Gas Field Technical Service Co., Ltd. has sale);

[0034] Described corrosion inhibitor is sodium nitrate;

[0035] The drainage aid is polyoxyethylene fatty acid ester;

[0036] The demulsifier is demulsifier MQ801 (available from Guangzhou Miaoqing Environmental Protection Technology Co., Ltd.).

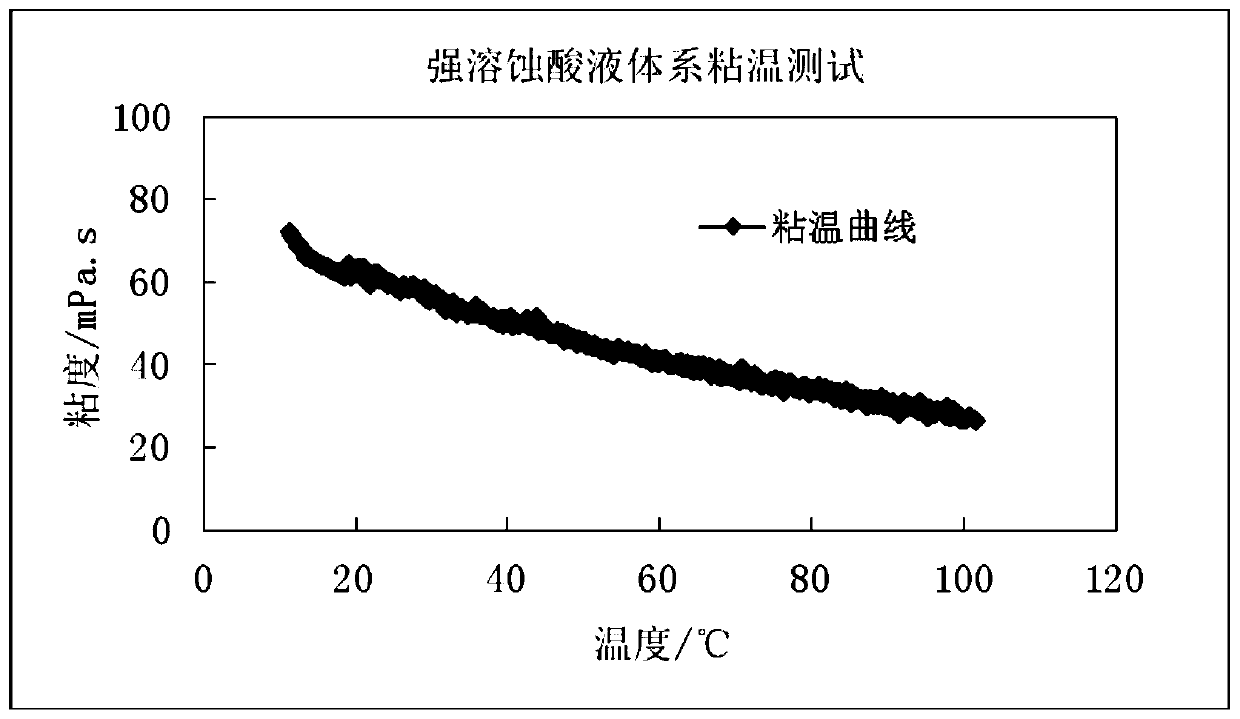

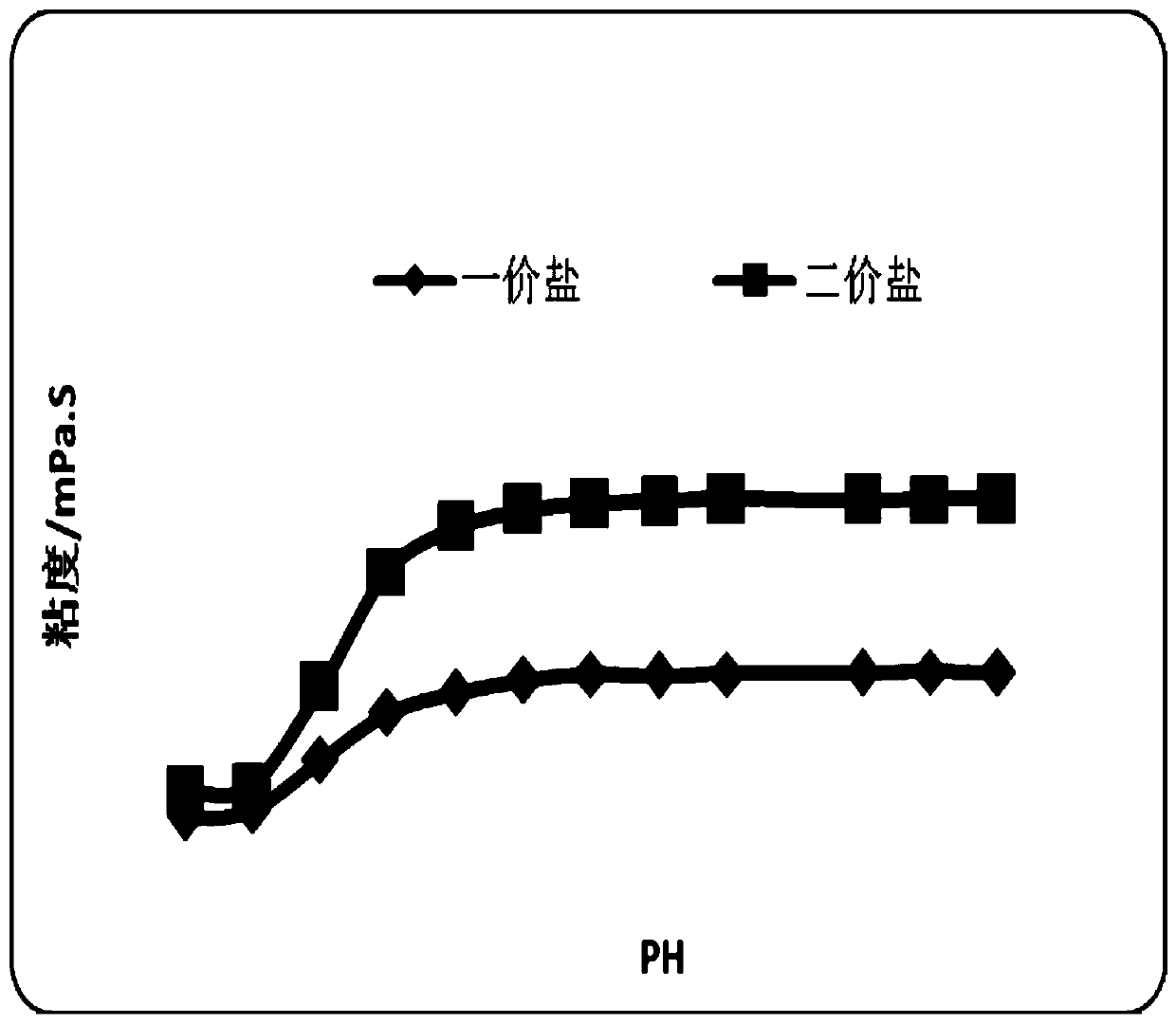

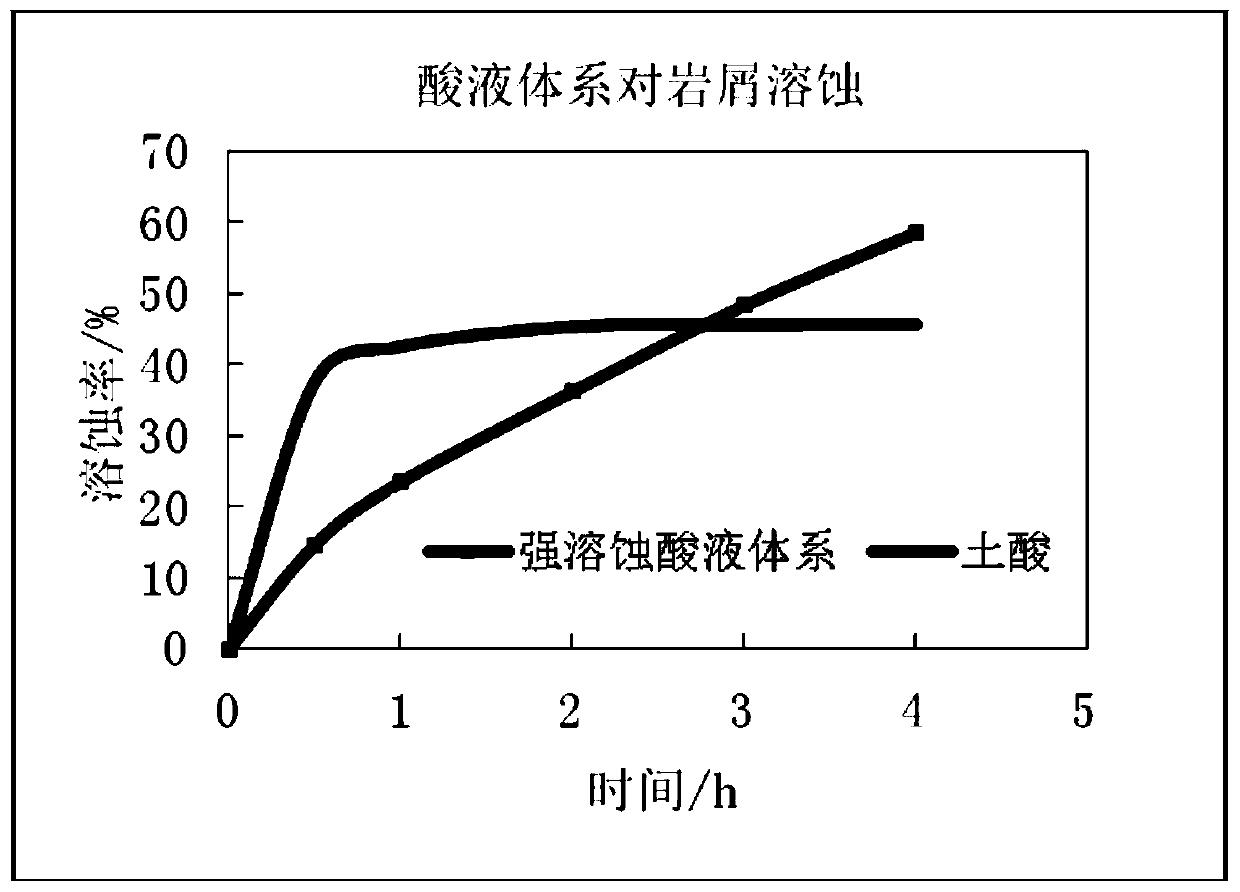

[0037] The acid solution formula has good stability at room temperature and reservoir temperature, strong dissolution ability; good slowing effect, when the residual acid concentration of the high-viscosity and strong corrosion acid solution system drops to ha...

Embodiment 2

[0039] A high-viscosity and strong-corrosion acid liquid system for tight oil reservoirs, comprising:

[0040] 12% hydrochloric acid, 3% betaine, 8% enhancer, 0.2% citric acid, 2% ammonium chloride, 2% corrosion inhibitor, 0.4% drainage aid, 0.2% demulsifier, the balance is water, the above groups The sum of the points is 100%;

[0041] Described strengthening agent is JD-30B strengthening agent (Sichuan Kaier Oil and Gas Field Technical Service Co., Ltd. has sale);

[0042] The corrosion inhibitor is potassium fluoride;

[0043] The drainage aid is polyoxyethylene alkylamine;

[0044] The demulsifier is demulsifier MQ801 (available from Guangzhou Miaoqing Environmental Protection Technology Co., Ltd.).

[0045] The acid solution formula has good stability at room temperature and reservoir temperature, strong dissolution ability; good slowing effect, when the residual acid concentration of the high-viscosity and strong corrosion acid solution system drops to half, the time ...

Embodiment 3

[0047] A high-viscosity and strong-corrosion acid liquid system for tight oil reservoirs, comprising:

[0048] 8%% hydrochloric acid, 1% betaine, 5% JD-30B enhancer, 0.05% citric acid, 0.5% ammonium chloride, 0.5% sodium nitrate, 0.2% polyoxyethylene alkylamide, 0.05% demulsifier MQ801, the rest The amount is water, and the sum of the above components is 100%.

[0049] The acid solution formula has good stability at room temperature and reservoir temperature, strong dissolution ability; good slowing effect, when the residual acid concentration of the high-viscosity and strong corrosion acid solution system drops to half, the time for the residual acid concentration of soil acid to drop to half 8 to 13 times longer than the normal time; the viscosity is moderate and has the characteristics of diversion and diversion, which can reduce the "fingering" phenomenon of acid liquid. After the viscosity rises and reaches the barrier function in the fracture, the high-viscosity and stro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com