Surfactant with self-demulsification capability as well as preparation method and application of surfactant

A surfactant and capacity technology, applied in the field of surfactants with self-demulsification ability and its preparation, can solve the problems such as ineffective effects, and achieve the effects of reducing the viscosity of heavy oil, strong emulsifying ability, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

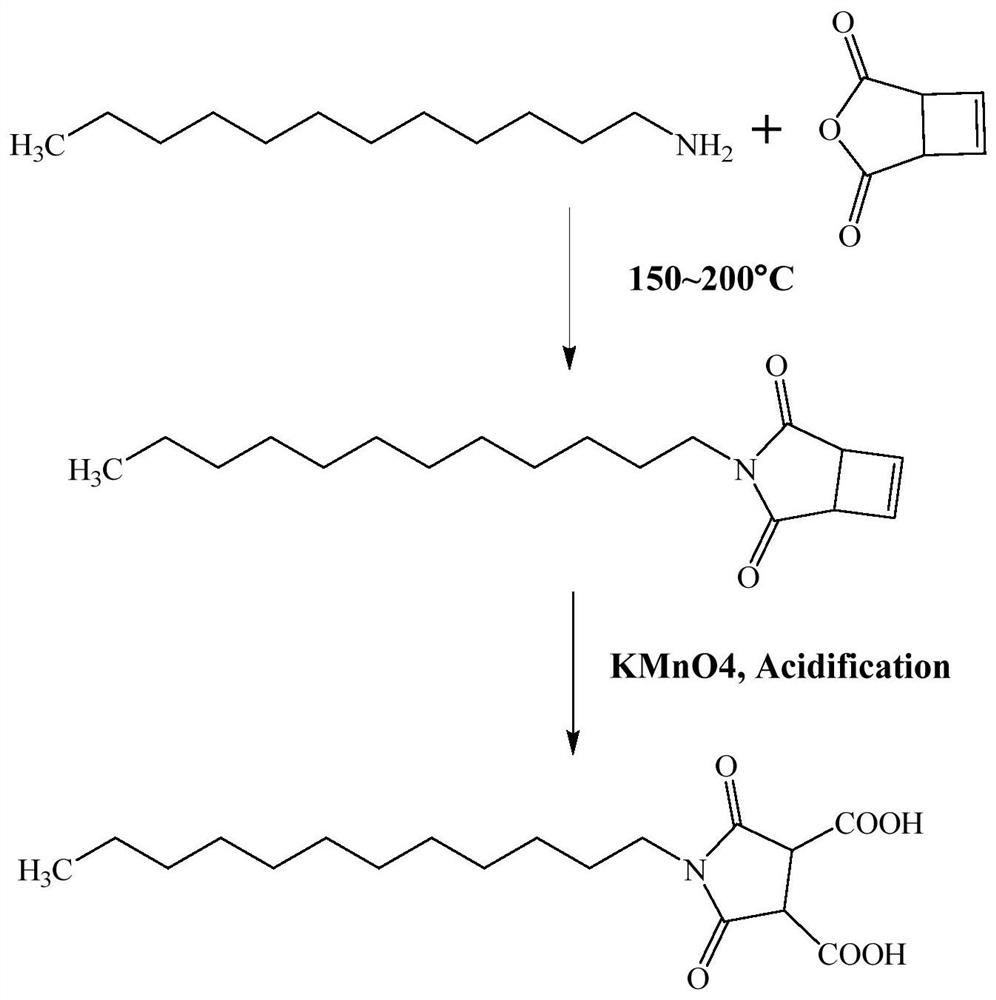

[0036] (1) Add dodecylamine (18.5g, 0.1mol) and cyclobut-3-ene dicarboxylic anhydride (24.8g, 0.2mol) dropwise successively in a 250mL three-necked flask equipped with a reflux condenser, nitrogen gas 3 times, Then heated to 180° C. for 3 h, and TLC (Thin Layer Chromatography, thin layer chromatography) monitored the completion of the reaction. After the reaction was completed, it was cooled to room temperature, 50 mL of distilled water was added, extracted three times with 80 mL of ethyl acetate, dried over anhydrous magnesium sulfate, filtered, concentrated under reduced pressure to obtain a crude product, and finally separated by a column to obtain a colorless oily imide.

[0037] (2) Add imide and 40mL distilled water into a 250mL three-necked flask, place in an ice-salt bath and cool to 0°C, slowly add potassium permanganate KMnO 4 (20g, the addition time is 40min), after all the addition is completed, the temperature is slowly raised to 90°C for 12h. Add 80 mL of satura...

Embodiment 2

[0040] (1) Add dodecylamine (18.5g, 0.1mol) and cyclobut-3-ene dicarboxylic anhydride (24.8g, 0.2mol) dropwise successively in a 250mL three-necked flask equipped with a reflux condenser, nitrogen gas 3 times, Then heated to 150° C. for 2 h, and TLC (Thin Layer Chromatography, thin layer chromatography) monitored the completion of the reaction. After the reaction was completed, it was cooled to room temperature, 50 mL of distilled water was added, extracted three times with 80 mL of ethyl acetate, dried over anhydrous magnesium sulfate, filtered, concentrated under reduced pressure to obtain a crude product, and finally separated by a column to obtain a colorless oily imide.

[0041] (2) Add imide and 40mL distilled water into a 250mL three-necked flask, place in an ice-salt bath and cool to 0°C, slowly add potassium permanganate KMnO 4 (15.8g, the addition time is 40min), after all the addition is completed, the temperature is slowly raised to 100°C for 10h. Add 80 mL of sat...

Embodiment 3

[0044] (1) Add dodecylamine (18.5g, 0.1mol) and cyclobut-3-ene dicarboxylic anhydride (24.8g, 0.2mol) dropwise successively in a 250mL three-necked flask equipped with a reflux condenser, nitrogen gas 3 times, Then heated to 200° C. for 5 h, and TLC (Thin Layer Chromatography, thin layer chromatography) monitored the completion of the reaction. After the reaction was completed, it was cooled to room temperature, 50 mL of distilled water was added, extracted three times with 80 mL of ethyl acetate, dried over anhydrous magnesium sulfate, filtered, concentrated under reduced pressure to obtain a crude product, and finally separated by a column to obtain a colorless oily imide.

[0045] (2) Add imide and 40mL distilled water into a 250mL three-necked flask, place in an ice-salt bath and cool to 0°C, slowly add potassium permanganate KMnO 4 (25g, the addition time is 40min), after all the addition is completed, the temperature is slowly raised to 90°C for 12h. Add 80 mL of satura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com