Rotary micro-channel demulsification method

A demulsification and channel technology, applied in the field of microchannel demulsification, can solve the problems of huge difference in time for complete demulsification, increased demulsification time cost, unstable demulsification efficiency, etc., and achieves rapid demulsification, convenient demulsification, The effect of improving the demulsification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

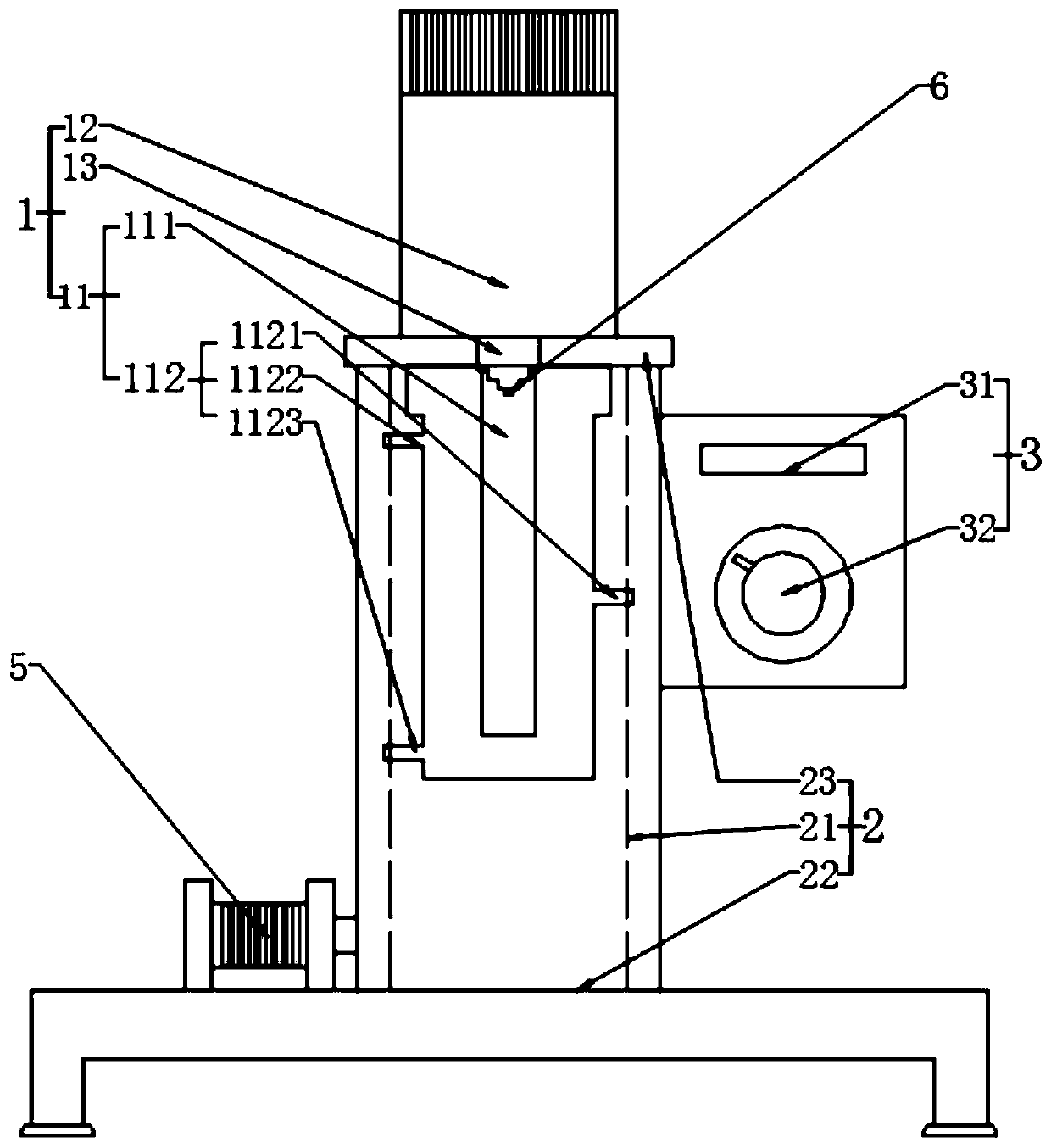

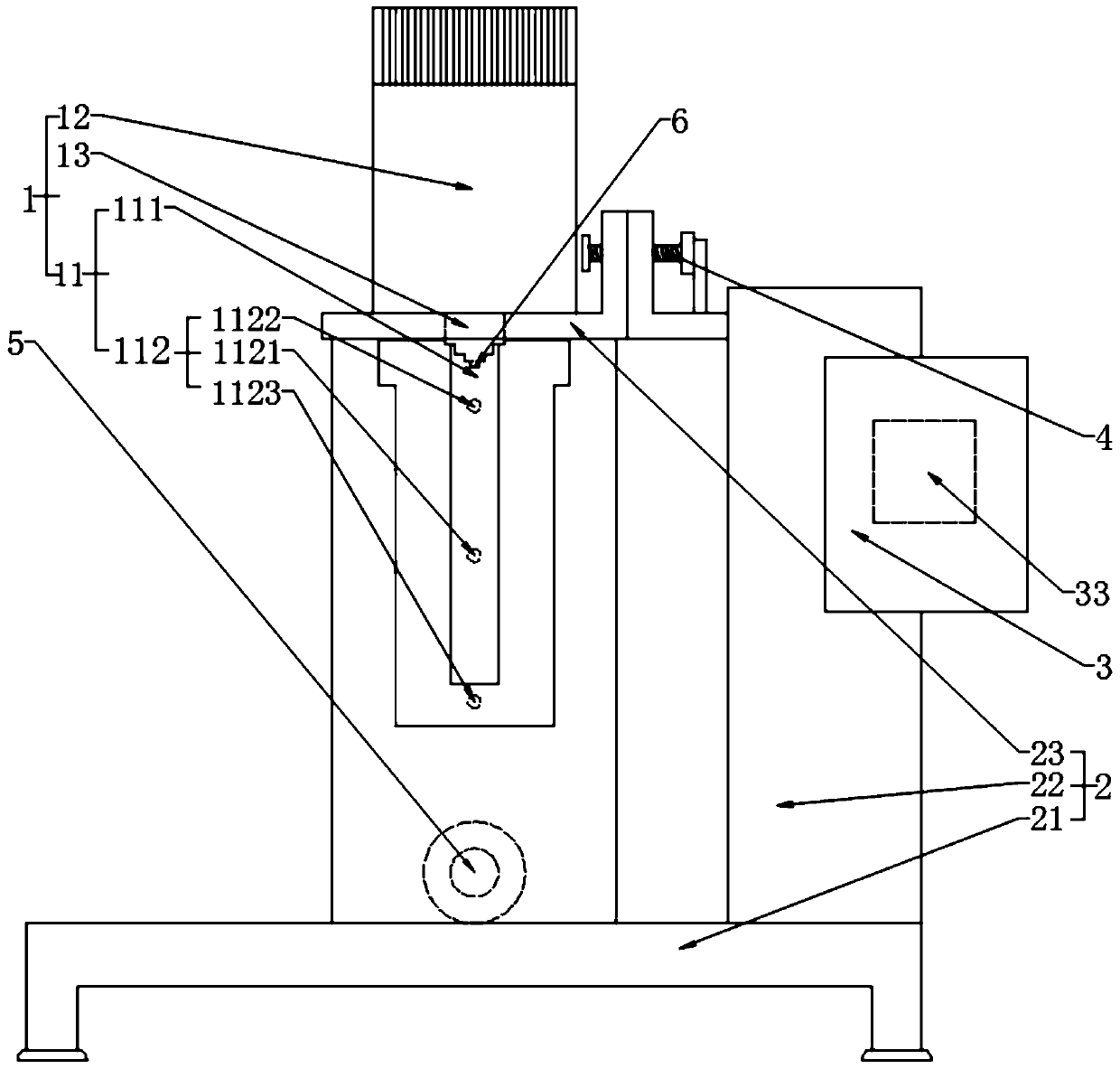

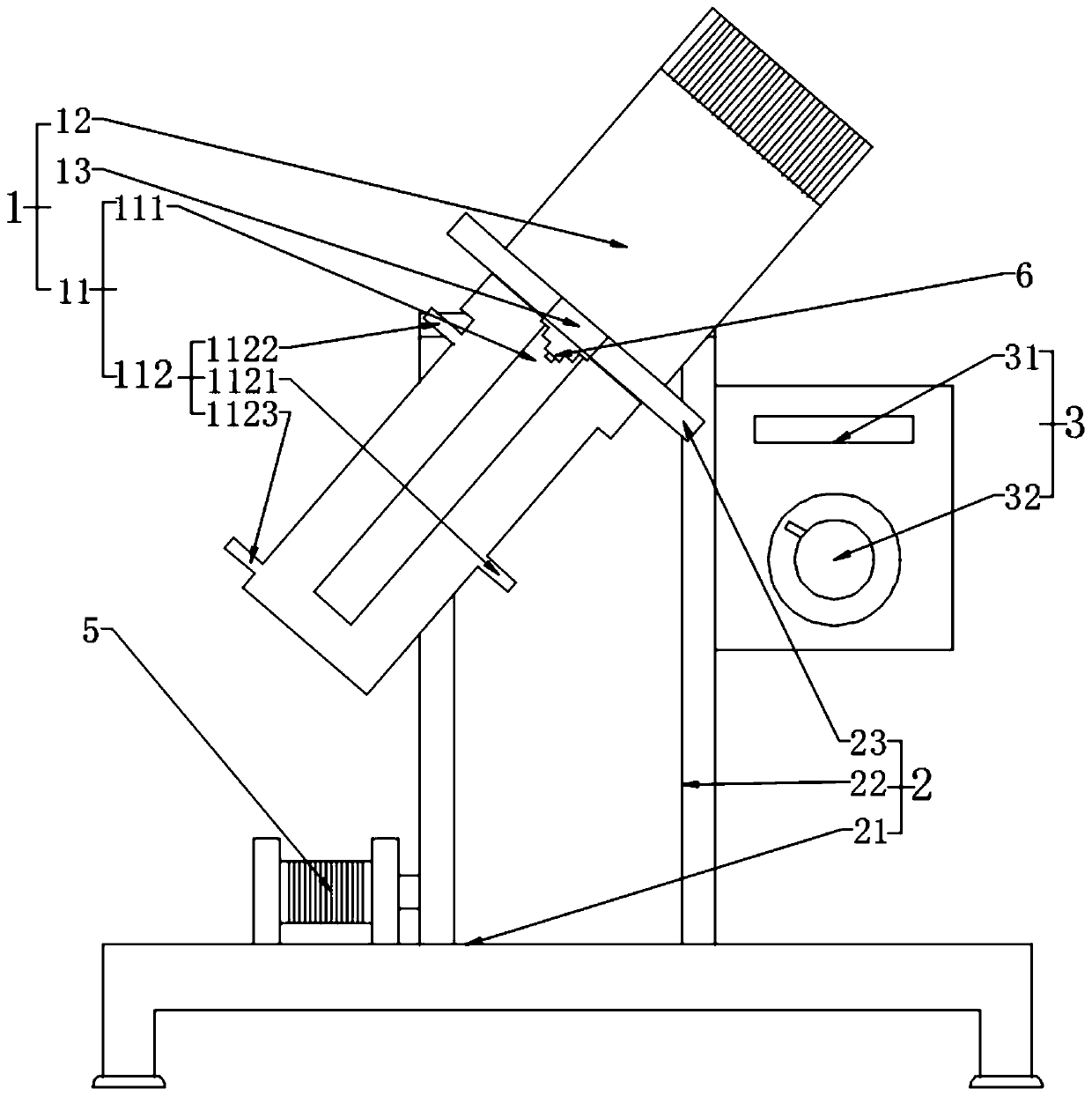

Embodiment 1

[0040] Adopt the method for above-mentioned rotary microchannel demulsification, comprise the following steps:

[0041] S1 utilizes the organic phase and water to mix uniformly to prepare an emulsion; in order to further realize the high efficiency of demulsification, the extractant is prepared by ethylhexyl phosphate mono-2-ethylhexyl ester and kerosene in a volume ratio of 2:8, through Ethylhexyl phosphate mono-2-ethylhexyl ester is mixed with kerosene as the extractant, so as to increase the capacity of the extractant and use the mixed solution as the extractant to extract the extract more comprehensively; in order to further mix the emulsion evenly , to facilitate late-stage demulsification, the uniform mixing is that the extractant and water are placed on a high-speed shear according to a volume ratio of 4:6, and cut for 2 minutes according to a speed of 13000r / min, and the extractant and water are sheared by a high-speed shear Mixtures to make it fully compatible and for...

Embodiment 2

[0046] After uniformly mixing the extractant and water at a ratio of 3:6, the angle between the support part 1 and the support rod 22 is 60°, and the remaining devices, formulas and steps are the same as in Example 1.

Embodiment 3

[0048] After the extraction agent and water are evenly mixed according to 8:6, the angle between the support part 1 and the support rod 22 is 0°, that is, the axis line of the support part 1 coincides with the support rod 22, and the demulsification inner cylinder 111 and the support rod 22 are limited. The gap distance between the demulsification outer cylinders 112 is 0.25 mm, and the rest of the devices, formulations and steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com