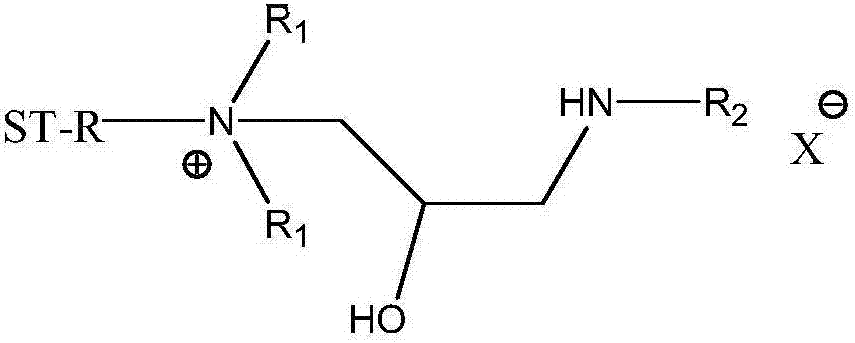

Branched low-temperature high-efficiency quaternary ammonium salt modified starch demulsifying agent and preparation method thereof

A technology of quaternary ammonium salt and demulsifier is applied in the field of branched low-temperature and high-efficiency quaternary ammonium salt modified starch demulsifier and its preparation field, which can solve the problems of high production cost and unfavorable industrialization, and achieves low production cost and raw material utilization rate. High and demulsification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

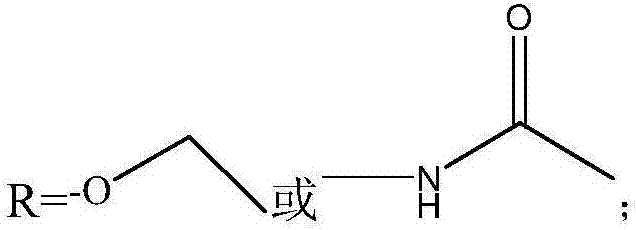

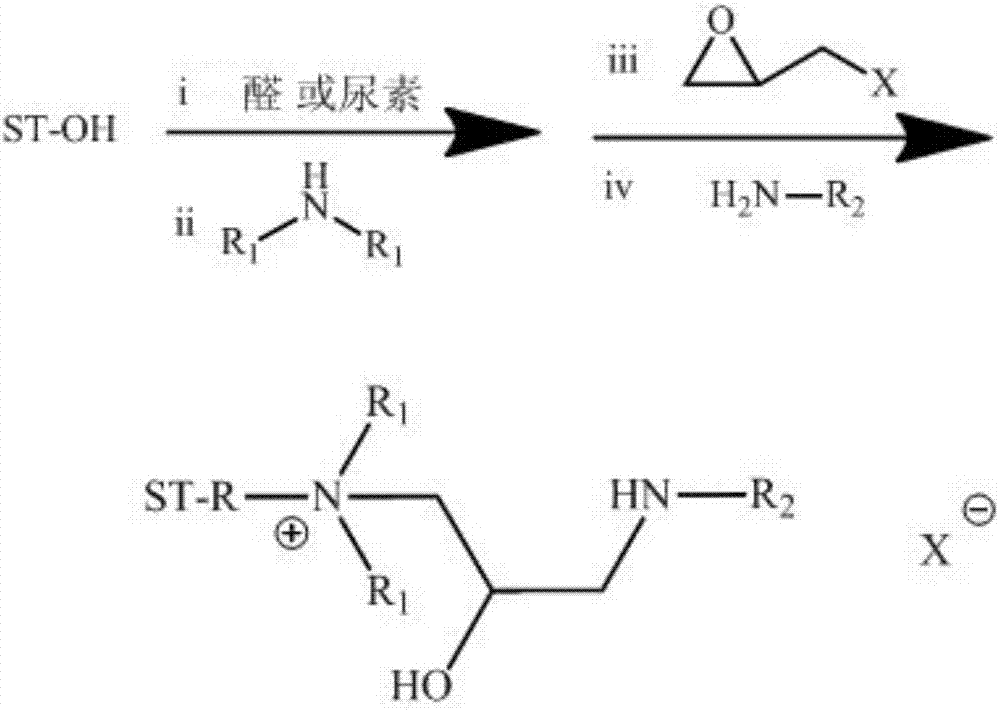

Method used

Image

Examples

Embodiment 1

[0053] Add 1.62g soluble starch (0.01mol according to monomer), 3.37g (0.04mol) formaldehyde aqueous solution (37%) and 5.46g (0.04mol) dimethylamine aqueous solution (33%) to a 100mL round bottom flask , the temperature was raised to 30°C, the starch was dissolved after 30 minutes of reaction, and the reaction was continued at this temperature for 10 hours to obtain a light yellow solution. 3.7g (0.04mol) of epichlorohydrin was slowly added dropwise to the above solution, the reaction temperature was controlled at 50°C, and the reaction was kept at this temperature for 5h to obtain a light yellow solution. Take 2.92g (0.04mol) of n-butylamine and slowly add it dropwise to the above solution, the reaction temperature is controlled at 40°C, and the reaction is kept at this temperature for 6h, and adjusted by adding water to obtain a light yellow solution with a solid content of 50%.

Embodiment 2

[0055] 1.62g wheat starch (0.01mol according to monomer calculation), 0.9g (0.01mol) paraformaldehyde and 6.65g (0.03mol) diethylamine aqueous solution (33%) were successively added in a 100mL round-bottomed flask, and the temperature was raised to After reacting for 30 minutes at 90°C, the starch dissolved, and continued to react at this temperature for 1 hour to obtain a light yellow solution. Take 4.11 g (0.03 mol) of epibromohydrin and slowly add it dropwise to the above solution, the reaction temperature is raised to 100° C., and the reaction is kept at this temperature for 1 h to obtain a light yellow solution. Take 3.88g (0.03mol) of n-octylamine and slowly add it dropwise to the above solution, the reaction temperature is controlled at 90°C, and the reaction is kept at this temperature for 1h, and adjusted by adding water to obtain a light yellow solution with a solid content of 50%.

Embodiment 3

[0057] Add 1.62g cornstarch, 0.20g (3.3mmol, can generate formaldehyde 0.01mol) paraformaldehyde and 3.06g (0.01mol) dipropylamine aqueous solution (33%) into a 100mL round bottom flask successively, heat up to 55°C, After reacting for 30 minutes, the starch dissolved, and continued to react at this temperature for 2 hours to obtain a light yellow solution. Take 0.92g (0.01mol) of epichlorohydrin and slowly add it dropwise to the above solution, the reaction temperature is raised to 95°C, and the reaction is kept at this temperature for 2h to obtain a light yellow solution. Take 2.69g (0.01mol) of n-octadecylamine and slowly add it dropwise to the above solution, the reaction temperature is controlled at 60°C, and the reaction is kept at this temperature for 2.5h, and water is added to adjust to obtain a milky white emulsion with a solid content of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com