Thick oil demulsifier and its prepn

A demulsifier and viscous oil technology, applied in the direction of hydrocarbon oil dehydration/demulsification, petroleum industry, etc., to facilitate industrial production, speed up demulsification and dehydration, and reduce elasticity and viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

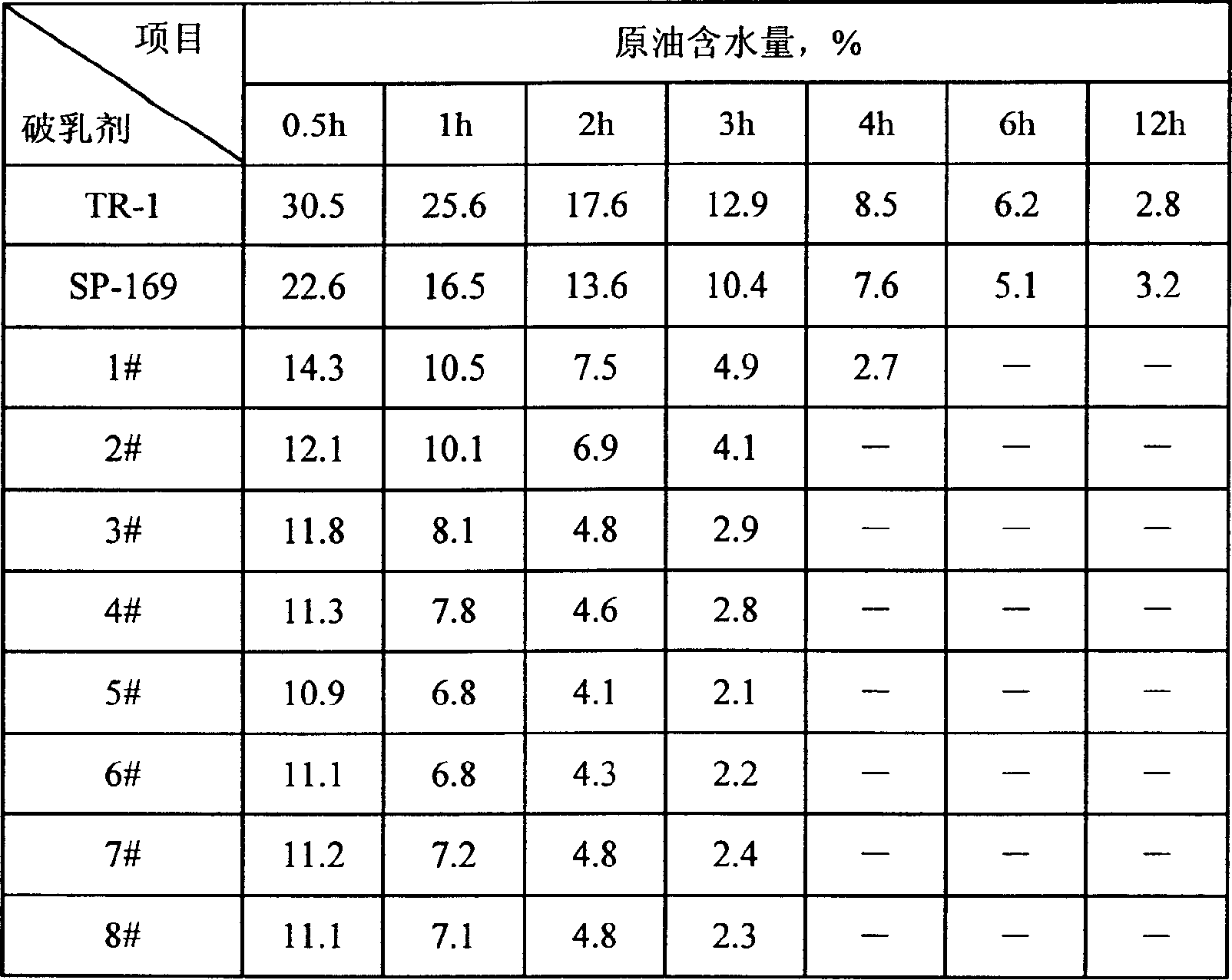

Embodiment 1

[0024] Example 1 Put 120kg of naphthol and 650kg of diethylenetriamine into the reaction kettle, raise the temperature to 80°C, stir evenly, slowly add 230kg of 37% formaldehyde solution dropwise, and the dropping time is 60min. The time is 60 minutes. Then dehydrate at a temperature of 180°C, a pressure of -0.09Mpa, and a reaction time of 180 minutes. After the reaction is completed, a reddish-brown viscous phenolamine resin is obtained. Add 50kg of this phenolic amine resin and 30kg of catalyst (compounded by calcium oxide and silicon dioxide with a weight ratio of 9.5:0.5) into the autoclave, seal it, replace it with nitrogen, raise the temperature and start stirring. When the temperature in the kettle reaches 130-140°C, add 670kg of propylene oxide and 250kg of ethylene oxide, and control the reaction temperature at 160-180°C and the pressure in the kettle at 0.3-0.6MPa. When the proportioning amount of propylene oxide and propylene oxide is added, the reaction is complet...

Embodiment 2

[0025] Example 2 Put 100kg of octylphenol and 650kg of tetraethylenepentamine into the reaction kettle, raise the temperature to 50°C, stir evenly, slowly add 250kg of 40% formaldehyde solution dropwise, the dropping time is 60min, and keep the temperature at 60°C after the addition. The reaction time is 60min. Then dehydrate at a temperature of 100°C and a pressure of -0.08Mpa, and the reaction time is 160 minutes. After the reaction is completed, a reddish-brown viscous phenolamine resin is obtained. Add 130kg of phenolamine resin and 20kg of catalyst (compounded by calcium hydroxide and oxalic acid with a weight ratio of 9:1) into the autoclave, seal and replace with nitrogen, heat up and start stirring, when the temperature in the still reaches 80 At ~90°C, add 590kg of propylene oxide and 260kg of ethylene oxide, control the reaction temperature at 80-100°C and the pressure in the kettle at 0.3-0.6Mpa, when the proportioning amount of propylene oxide and ethylene oxide is...

Embodiment 3

[0026]Example 3 150kg of bisphenol A and 550kg of tetraethylenepentamine were heated up to 70°C, stirred evenly, and 300kg of 35% formaldehyde solution was slowly added for 60 minutes. After the addition, the constant temperature was 80°C, and the reaction time was 60 minutes. Then dehydrate at a temperature of 120°C and a pressure of -0.09Mpa, and the reaction time is 160 minutes. After the reaction is completed, a reddish-brown viscous phenolamine resin is obtained. Add 70kg of phenolamine resin and 20kg of catalyst (compounded by calcium sulfate and tartaric acid with a weight ratio of 9.59:10.5) into the autoclave. After sealing and nitrogen replacement, heat up and start stirring. When the temperature in the autoclave reaches 130~ At 140°C, add 550kg of propylene oxide and 360kg of ethylene oxide, control the reaction temperature at 140-150°C and the pressure inside the kettle at 0.3-0.6Mpa. When the pressure is gradually lowered until it stops falling for 30 minutes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com