A kind of demulsifier and preparation method of high polymer-containing heavy oil sewage demulsifier

A technology of water demulsifier and oil pollution, which is applied in the field of demulsifier and preparation of heavy oily sewage with high polymer content, and can solve the problems of low degreasing rate of heavy oily sewage with high poly content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

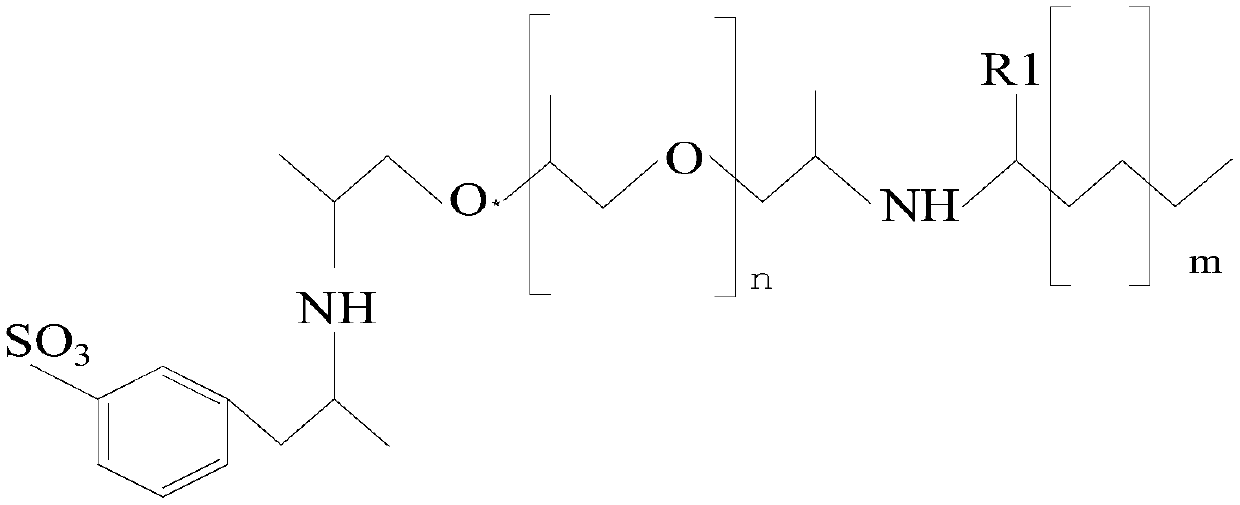

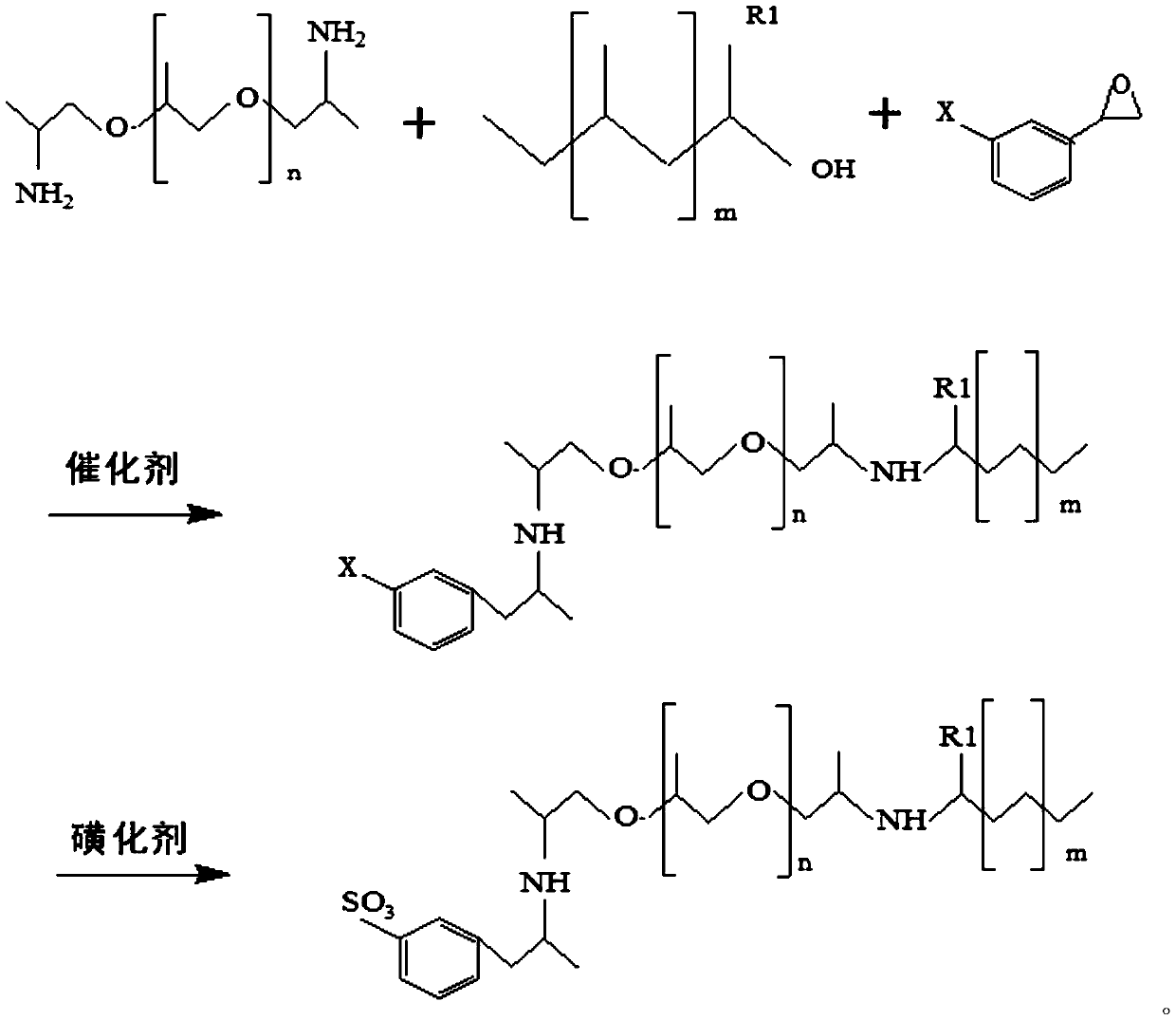

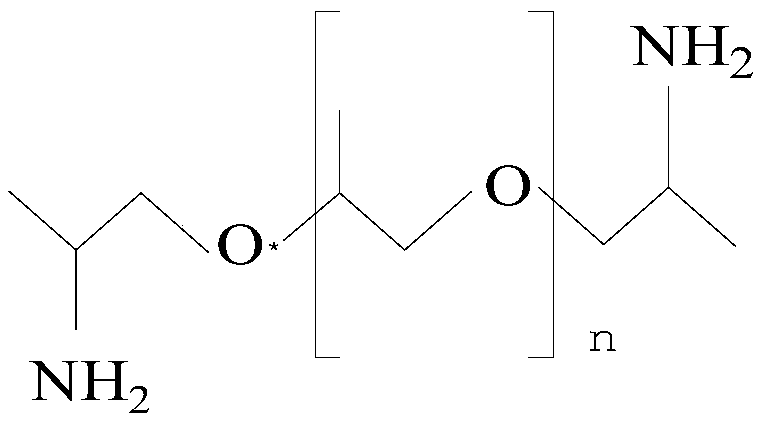

[0031] Add 10g of methanol, 6g of polyetheramine, 1.6g of higher alcohol and 1.5g of (R)-3-chlorophenyloxirane into a reactor with a stirrer, stir well, then add 0.01g of titanocene dichloride , stirred and reacted at 80°C and 0.5MPa for 1h, then added 1g of sodium bisulfite, adjusted the temperature to 70°C, and the pressure was 0.1MPa, stirred and reacted for 0.5h, and then lowered to normal temperature and pressure to obtain high-polyhesy oily sewage broken Emulsion, its chemical reaction structural formula is as follows:

[0032]

Embodiment 2

[0034] Add 20g of ethanol, 8g of polyetheramine, 2g of higher alcohol and 2g of 3-bromophenyloxirane into a reactor with a stirrer. After stirring evenly, add 0.05g of zirconocene dichloride. Stir and react for 4 hours under the same conditions, then add 1.5g of sodium sulfite, adjust the temperature to 90°C, pressure 0.3MPa, stir and react for 3 hours, and then lower to normal temperature and pressure to obtain a demulsifier for sewage with high polymer content. Its chemical reaction structure is as follows:

[0035]

[0036] Embodiment 3~8 steps are identical with embodiment 1 or 2, and each composition and test condition are as shown in table 1:

[0037] Table 1 Embodiment 3~8 formula composition and polymerization condition (unit: g)

[0038]

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com