Crude oil electric desalting dewatering process

A technology of electric desalination and dehydration of crude oil, which is applied in the field of ultrasonic and pulse removal of salt and water in hydrocarbon oil, which can solve the problems of high electric field strength, failure to deal with inferior high-density crude oil, and easy emulsification, etc., to achieve enhanced mixing effect , Improve the efficiency of oil-water separation, and the effect of fast oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

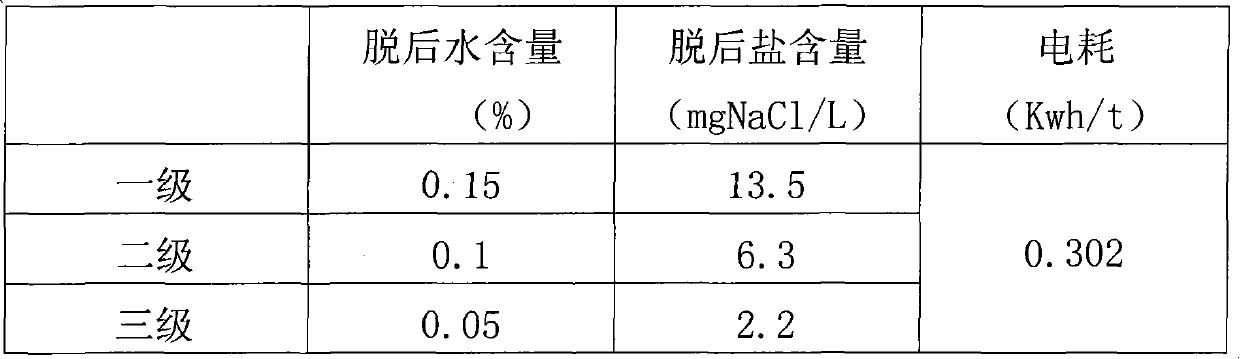

[0022] Crude oil density is 934.1Kg / m 3 , the water content is 0.05%, the salt content is 132.6mgNaCl / L, the demulsifier is water-soluble ERI1160, the water injection is fresh water PH=7, and the desalination temperature is 135°C.

[0023] The dosage of primary desalination demulsifier is 20μg / g, water injection is 8%, the mixing frequency is 20kHz, and the sound intensity is 0.6w / cm 2 Ultrasonic wave for 1 minute, plus an electric field intensity of 800V / cm, a duty ratio of 50%, and a pulse frequency of 100Hz for 40 minutes; the addition of the secondary desalination demulsifier is 10μg / g, water injection is 6%, and the frequency after mixing is 20kHz , the sound intensity is 0.6w / cm 2 Ultrasonic wave for 1 minute, plus an electric field intensity of 800V / cm, a duty cycle of 50%, and a pulse frequency of 100Hz for 40 minutes; the addition of the three-stage desalination demulsifier is 10μg / g, water injection is 5%, and the frequency after mixing is 20kHz , the sound intensi...

Embodiment 2

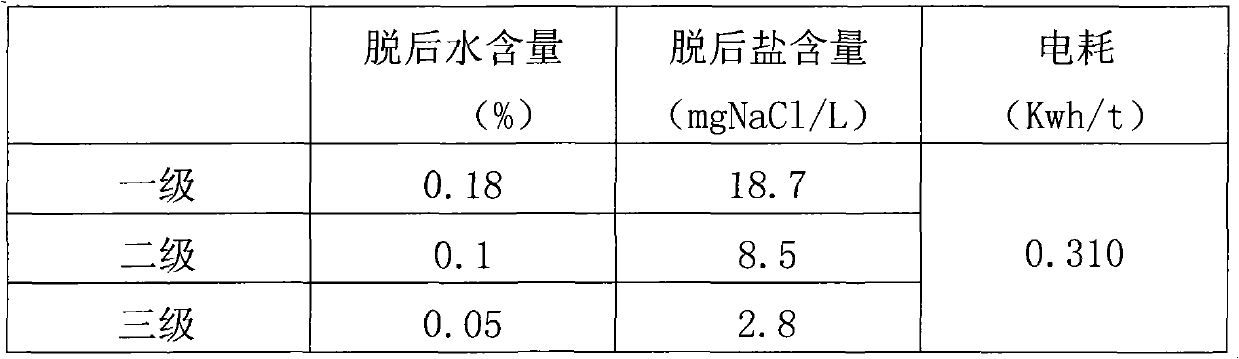

[0027] The density of a crude oil is 934.1Kg / m 3 , the water content is 0.05%, the salt content is 132.6mgNaCl / L, the demulsifier is water-soluble ERI1160, the water injection is fresh water PH=7, and the desalination temperature is 135°C.

[0028] The dosage of primary desalination demulsifier is 15μg / g, water injection is 8%, the frequency after mixing is 20kHz, and the sound intensity is 0.6w / cm 2 Ultrasonic wave for 1 minute, plus an electric field intensity of 800V / cm, a duty cycle of 50%, and a pulse frequency of 100Hz for 40 minutes; the addition of the secondary desalination demulsifier is 8μg / g, water injection is 6%, and the frequency after mixing is 20kHz , the sound intensity is 0.6w / cm 2 Ultrasonic wave for 1 minute, plus an electric field intensity of 800V / cm, a duty cycle of 50%, and a pulse frequency of 100Hz for 40 minutes; the addition of the three-stage desalination demulsifier is 5μg / g, water injection is 5%, and the frequency after mixing is 20kHz , the ...

Embodiment 3

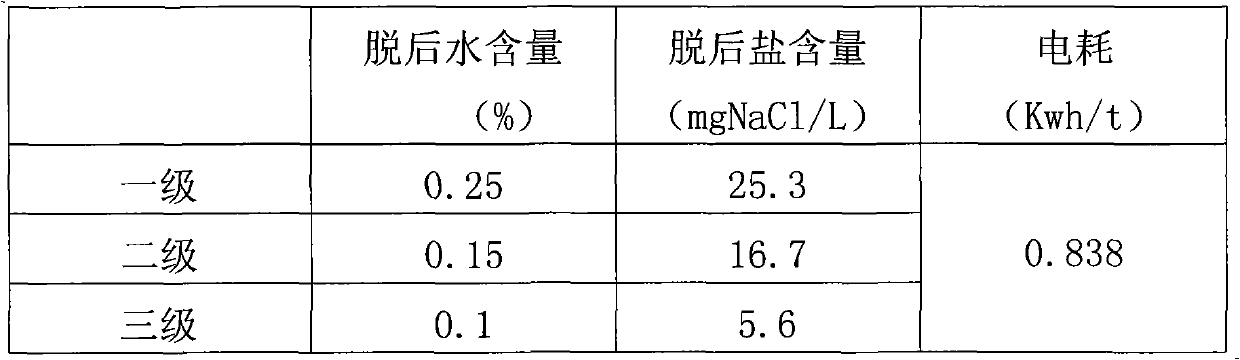

[0031] Embodiment 3 (comparative example)

[0032] The desalination in this example uses an ordinary full-impedance transformer to apply an electric field to the crude oil, and compares it with the new combined electric desalination technology, mainly comparing the injection amount of demulsifier, desalination rate and power consumption.

[0033] The density of a crude oil is 934.1Kg / m 3 , the water content is 0.05%, the salt content is 132.6mgNaCl / L, the demulsifier is water-soluble ERI1160, the water injection is fresh water PH=7, and the desalination temperature is 135°C.

[0034] The amount of the primary desalting demulsifier is 20 μg / g, inject 8% of water, and apply an alternating current with an electric field strength of 800V / cm for 40 minutes after mixing; the amount of the secondary desalting demulsifier is 10 μg / g, inject 6% of water, and apply an electric field after mixing Alternating current with an intensity of 800V / cm for 40 minutes; the amount of three-stage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com