Surface treatment method for CPU cover

A technology of surface treatment and sintering treatment, which is applied in the direction of coating, metal material coating process, manufacturing tools, etc., can solve the problem of insufficient boiling performance of the CPU cover, and achieve the effects of lowering temperature, strengthening boiling performance and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

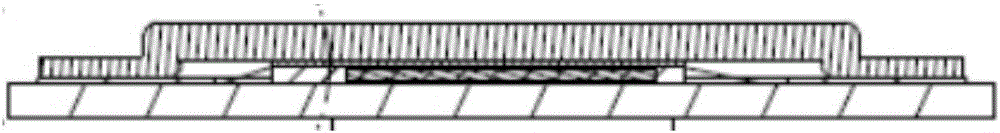

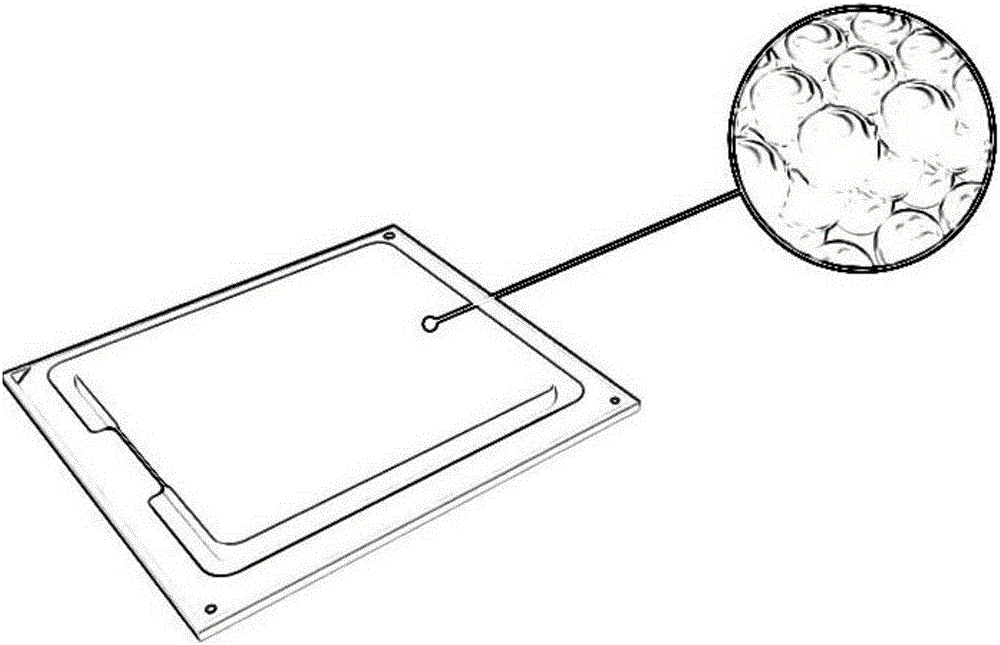

[0027] Remove the rust and grease on the surface of the copper sheet, and then apply a layer of binder solution, and evenly stick the silver powder on the surface of the copper sheet. When the binder solution is air-dried, place it in a sintering furnace. Heating under the protection of hydrogen until the surface of the silver powder tends to melt, and then keep the temperature for 15 minutes to disperse and volatilize the binder, and the silver powder is sintered into one and sintered on the surface of the copper sheet, thereby forming a layer of porous metal overlay. Wherein, the thickness of the porous metal covering layer is less than 3mm, and the porosity is 40%-65%. The copper sheet is welded on the CPU cover.

Embodiment 2

[0029] Remove the rust and grease on the surface of the silver sheet, and then apply a layer of binder solution, and evenly stick the copper powder on the surface of the silver sheet. When the binder solution is air-dried, place it in a sintering furnace. Heating under the protection of hydrogen until the surface of the copper powder tends to melt, and then keep the temperature for 20 minutes to disperse and volatilize the binder, and the copper powder is sintered into one and sintered on the surface of the silver sheet, thereby forming a layer of porous metal overlay. Wherein, the thickness of the porous metal covering layer is less than 3mm, and the porosity is 40%-65%. The silver sheet is welded on the CPU cover.

Embodiment 3

[0031] Remove the rust and grease on the surface of the gold sheet, and then apply a layer of binder solution, and evenly stick the copper powder on the surface of the gold sheet. After the binder solution is air-dried, place it in a sintering furnace. Heating under the protection of hydrogen until the surface of the copper powder tends to melt, and then keep the temperature for 18 minutes to disperse and volatilize the binder, and the copper powder is sintered into one and sintered on the surface of the gold sheet, thereby forming an layer of porous metal overlay. Wherein, the thickness of the porous metal covering layer is less than 3mm, and the porosity is 40%-65%, and the gold sheet is welded on the CPU cover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com