heat exchanger

A technology of heat exchangers and heat generators, applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., to achieve the effects of reliability improvement, optimization of boiling and condensation performance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

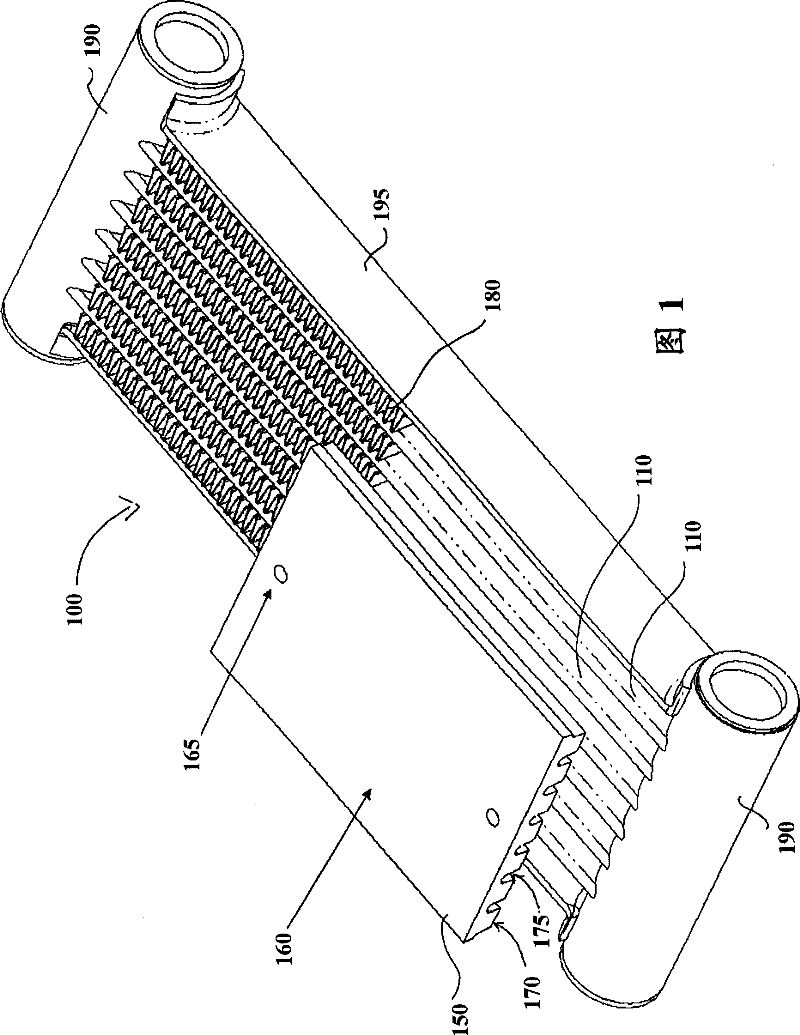

[0055] refer to figure 1 A heat exchanger 100 according to a first preferred embodiment of the present invention is described.

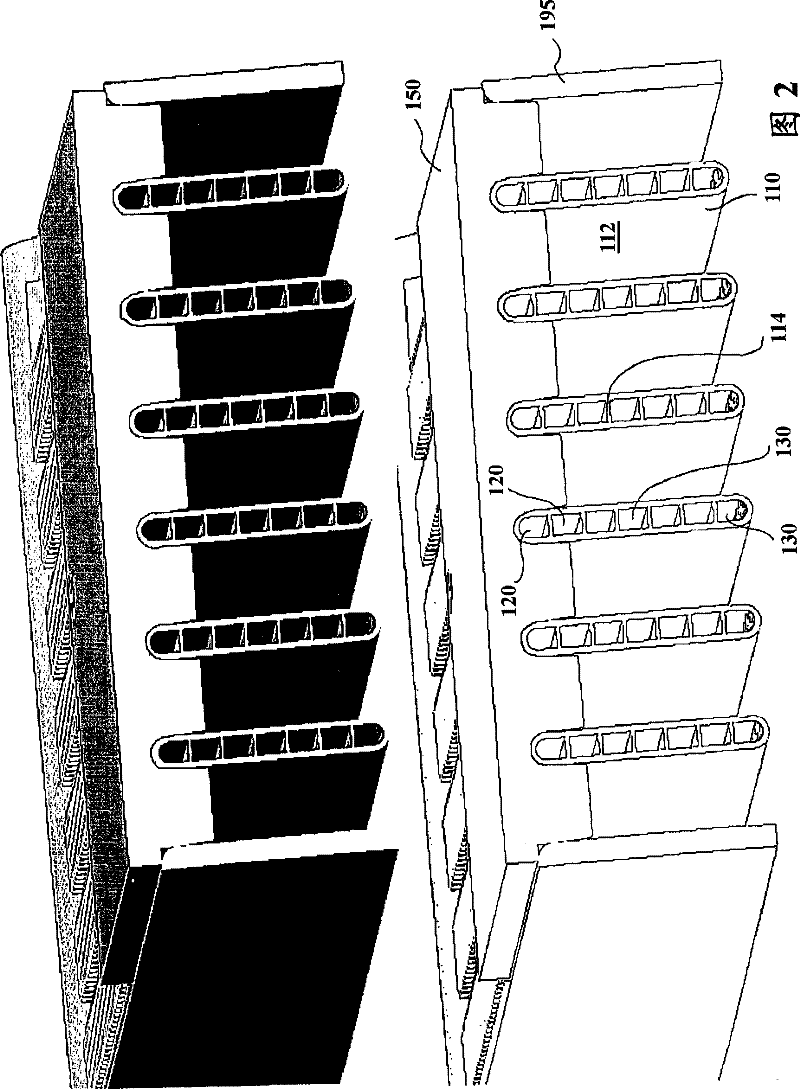

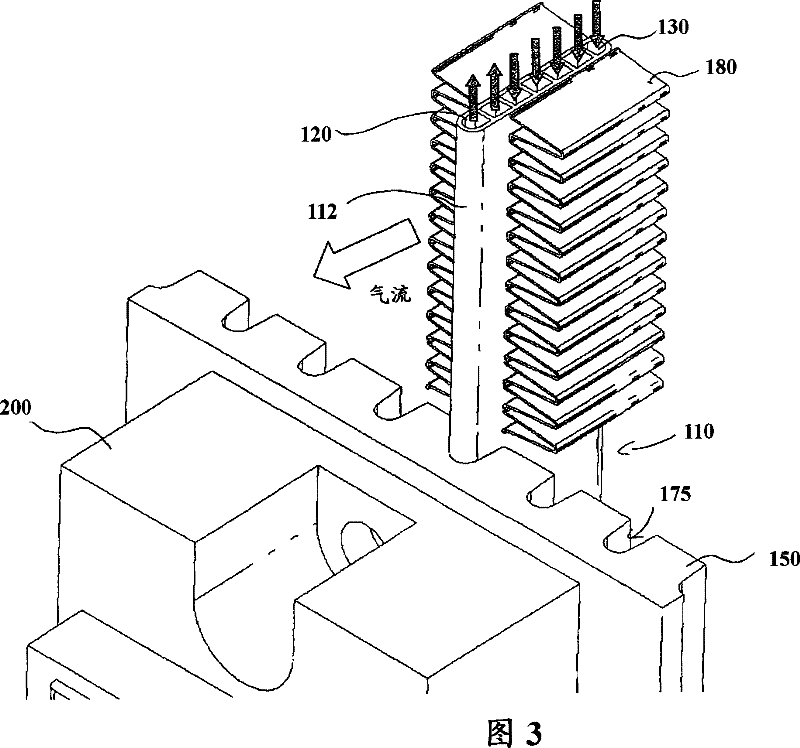

[0056] Such as figure 1 As shown, the heat exchanger 100 includes a plurality of conduits 110 for the working fluid, each conduit 110 has an outer wall 112, and each conduit 110 has a structure for forming at least one evaporation channel 120 and at least one condensation channel in the conduit 110. The inner wall 114 of the road 130 (refer to figure 2 ). Furthermore, the heat exchanger comprises a first heat transfer element 150 for transferring heat to the evaporation channel and a second heat transfer element 180 for transferring heat away from the condensation channel. The conduit 110 is arranged in a vertical position, but other positions of at least 45° are also possible. The evaporation channels 120 and the condensation channels 130 are aligned in parallel within the conduit 110 .

[0057] exist figure 1 In the illustrated embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com