Micro loop heat pipe and method

A loop heat pipe and micro technology, applied in the field of heat pipes, can solve problems such as affecting the heat transfer performance of the micro loop heat pipe, and achieve the effect of strengthening heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

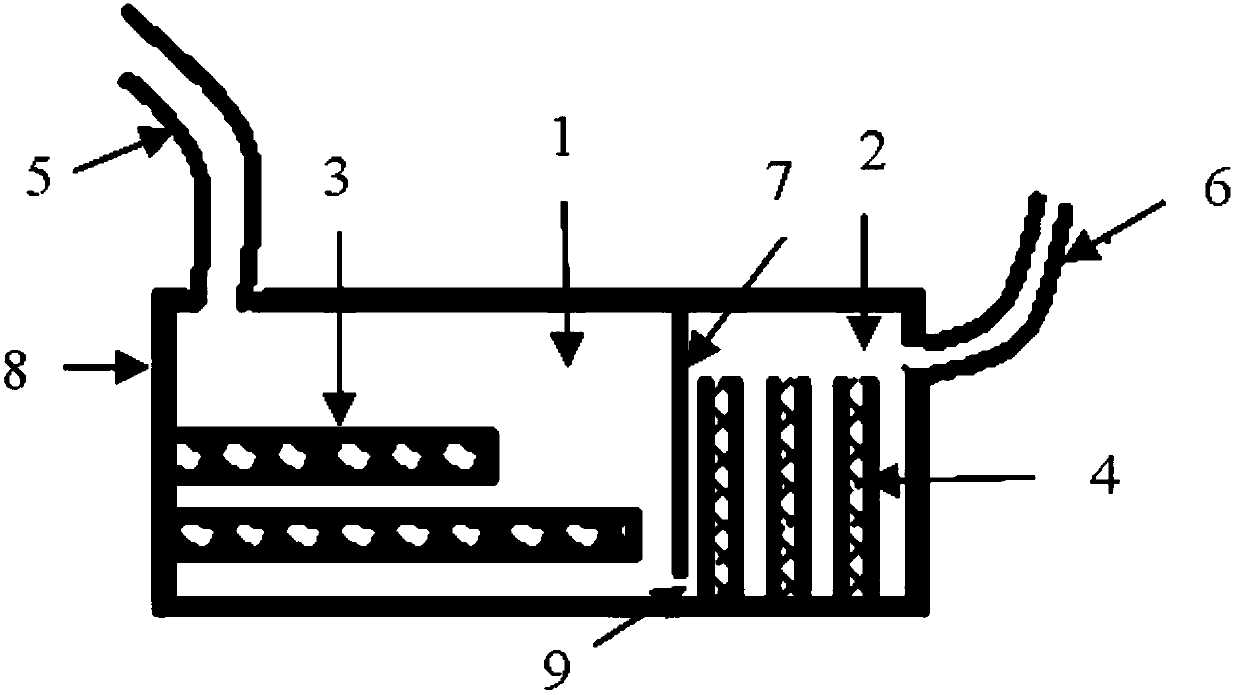

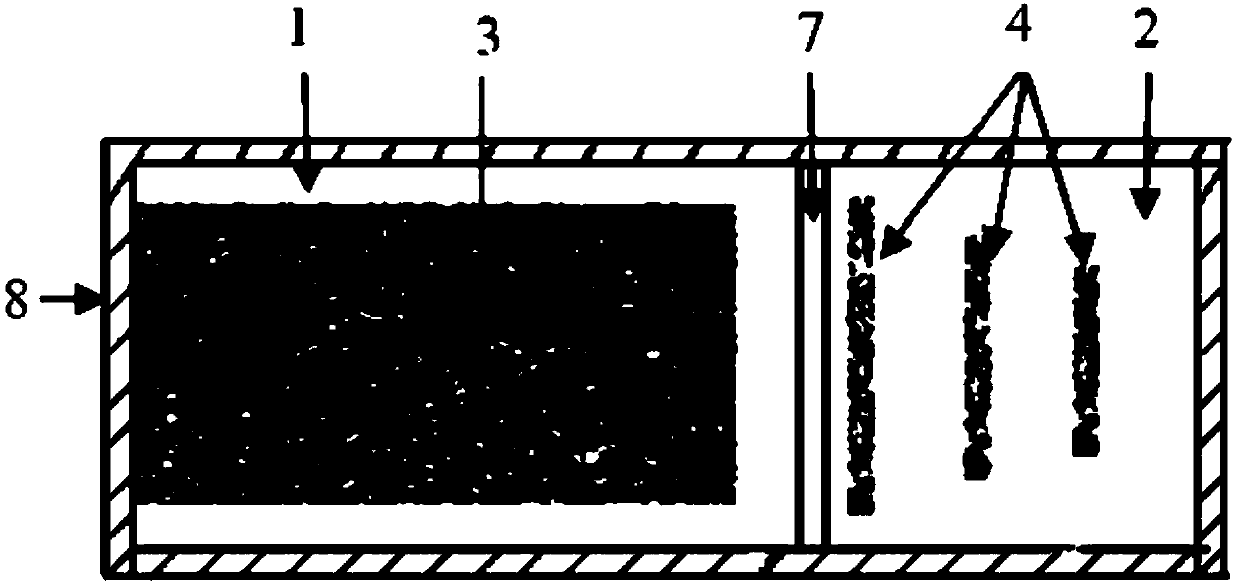

[0037] like Figures 1 to 2 shown. The invention discloses a micro loop heat pipe, which comprises an evaporation chamber, one end of the evaporation chamber is connected to the inlet of the condensation chamber through a steam pipe 5, and the other end of the evaporation chamber is connected to the outlet of the condensation chamber through a liquid return pipe 6; the evaporation chamber is filled with nano Fluid working medium;

[0038] The inside of the evaporation chamber is divided into two interconnected evaporation spaces 1 and reflux liquid storage spaces 2 through a heat-insulating partition 7 made of heat-insulating material;

[0039] In the evaporation space 1 and the return liquid storage space 2, there are respectively provided with multiple layers of capillary core layers with different apertures; the planes of the capillary core layers in the evaporation space 1 and the return liquid storage space 2 are perpendicular to each other;

[0040] When the external h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com