Patents

Literature

34results about How to "Increase cycle power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pure natural beverage capable of not only perfecting dietary structure but also regulating dietary property and flavor

InactiveCN103371227AGreat tasteSimple production processMilk preparationMilk substitutesSolubilityFlavor

The invention discloses a pure natural beverage capable of improving dietary structure and conditioning diet property and flavor. According to the invention, a natural surfactant forming o / w emulsion in vegetable milk and / or animal milk is adopted as an emulsifying agent and suspension needed in a grain-cereal beverage production, such that harms to human body caused by non-natural foodstuff additives are reduced. The grains and cereals are puffed and crushed, such that the taste of the grains and cereals are improved, the production process of the grain-cereal beverage is simplified, and water-solubility and suspension property of the grain-cereal suspended solids in the beverage are improved. Pungent plants are added to the pure natural beverage to enhance yang, and to help the consumers escape the ill condition or sub-healthy state caused by cold body constitution, and to provide the consumers with the healthy state wherein yang serves as the master and yin serves as the slave.

Owner:丛繁滋

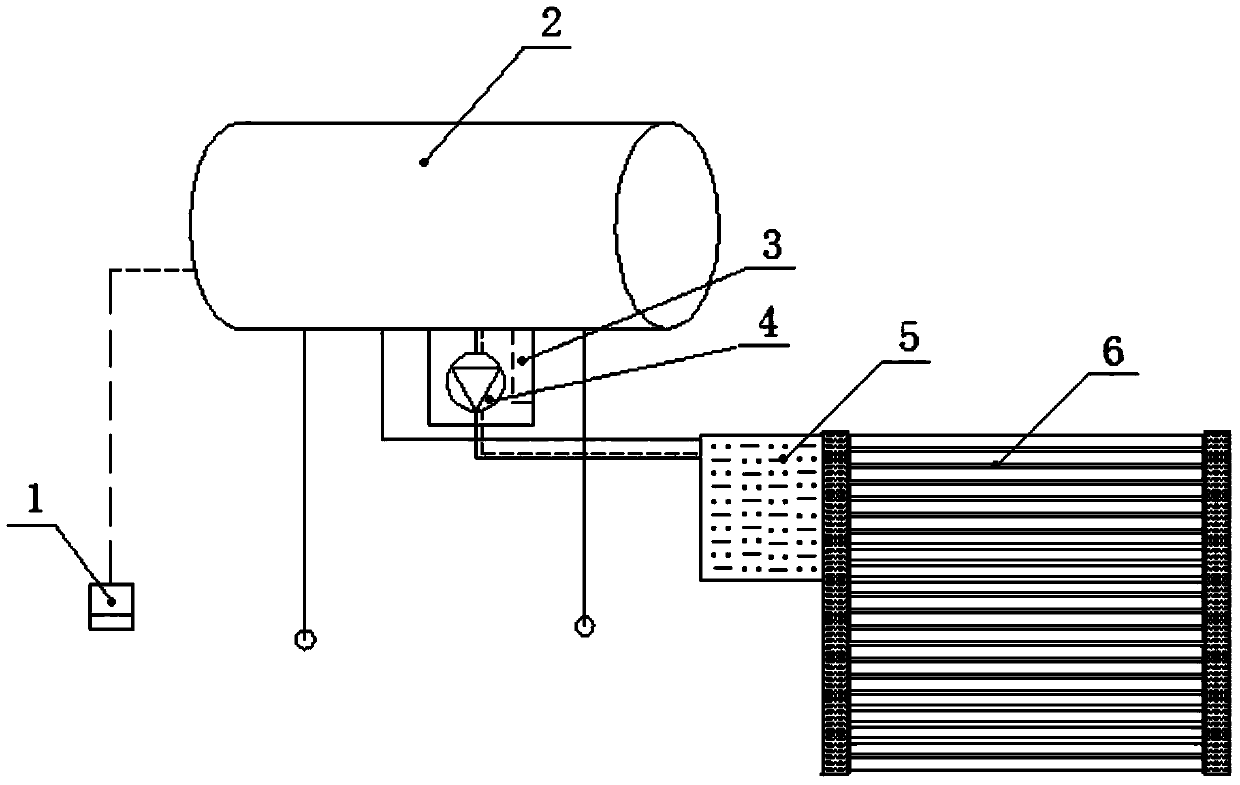

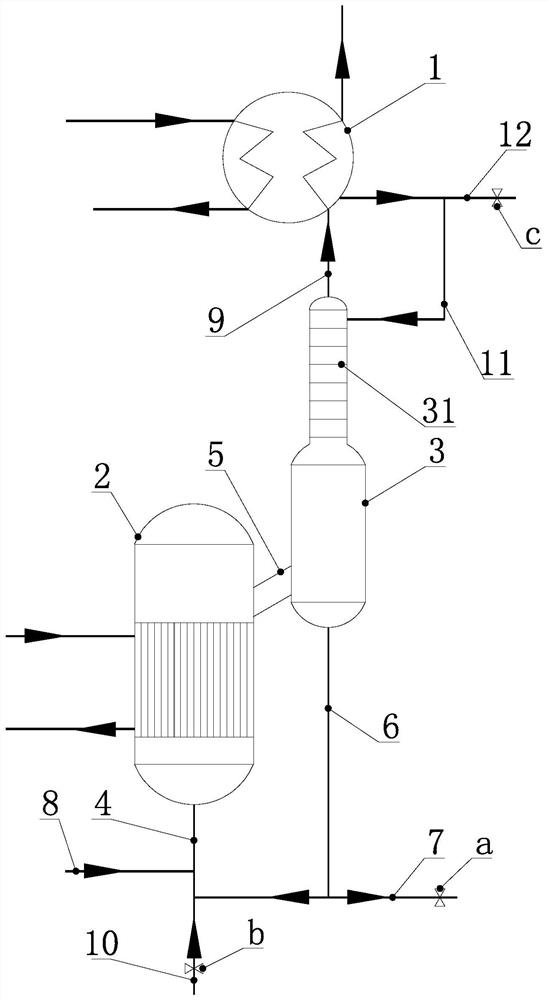

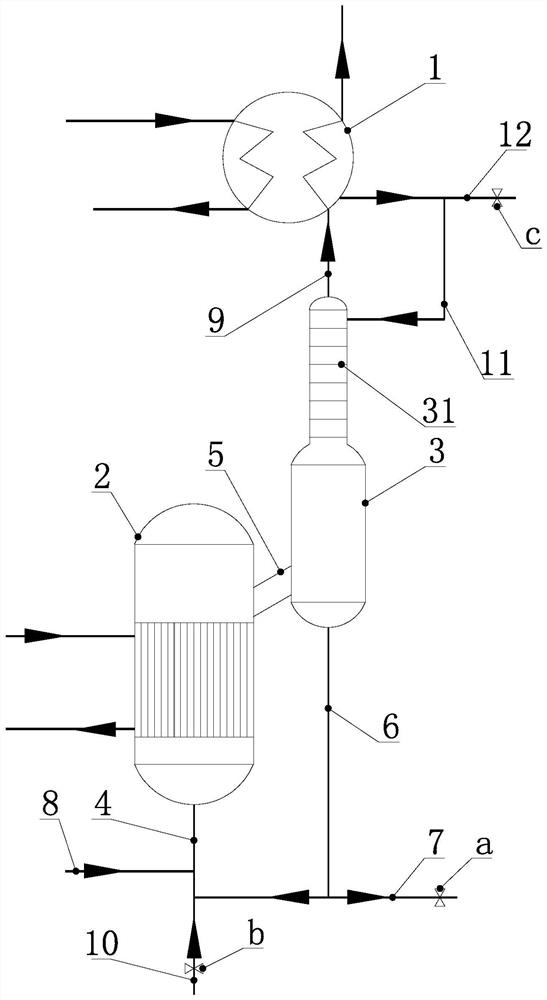

Siphonic water-cooled screw low-temperature solution unit

ActiveCN105674611AImprove operational efficiencyIncrease oil return temperatureMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorEngineering

The invention discloses a siphonic water-cooled screw low-temperature solution unit, which comprises a screw compressor, a built-in oil condenser, a gas-liquid separator circulation tank and a siphonic evaporator; a gas outlet of the gas-liquid separator circulation tank communicates with a gas inlet of the screw compressor through a suction pipeline; the gas-liquid separator circulation tank and a delivery valve of the built-in oil condenser communicate with the suction pipeline through an oil return system; a liquid outlet of the built-in oil condenser separately communicates with the gas-liquid separator circulation tank and the siphonic evaporator through a liquid supply system; and the liquid supply system comprises a plurality of sections of liquid supply pipelines, an oil return heat exchanger and an economizer. According to the siphonic water-cooled screw low-temperature solution unit disclosed by the invention, by installing the oil return heat exchanger and the economizer, oil return temperature of the evaporator is increased, and oil return viscosity is reduced, so that oil return of the evaporator is more smooth; meanwhile, liquid refrigerant coming out from the condenser is lowered in temperature to realize a certain supercooling degree, therefore operating efficiency of the unit is increased.

Owner:JIANGXI HAOJIN OUBO AIR CONDITIONING MFG CO LTD

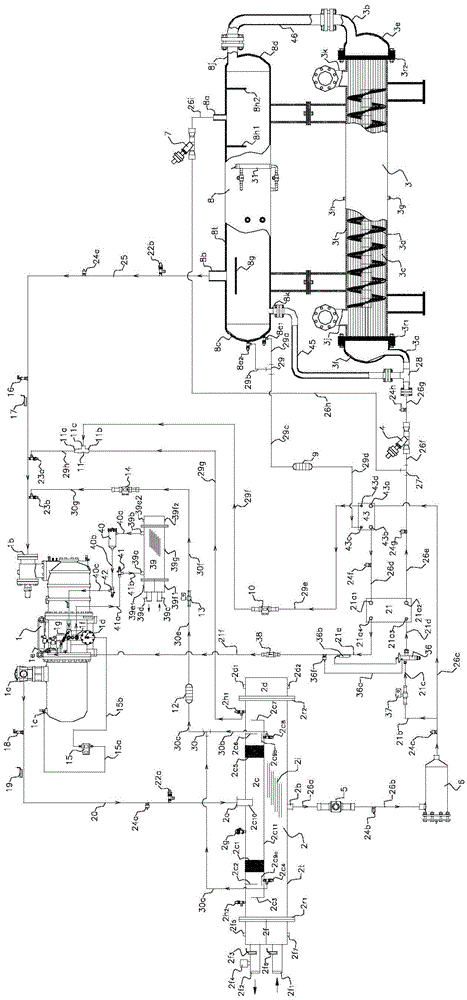

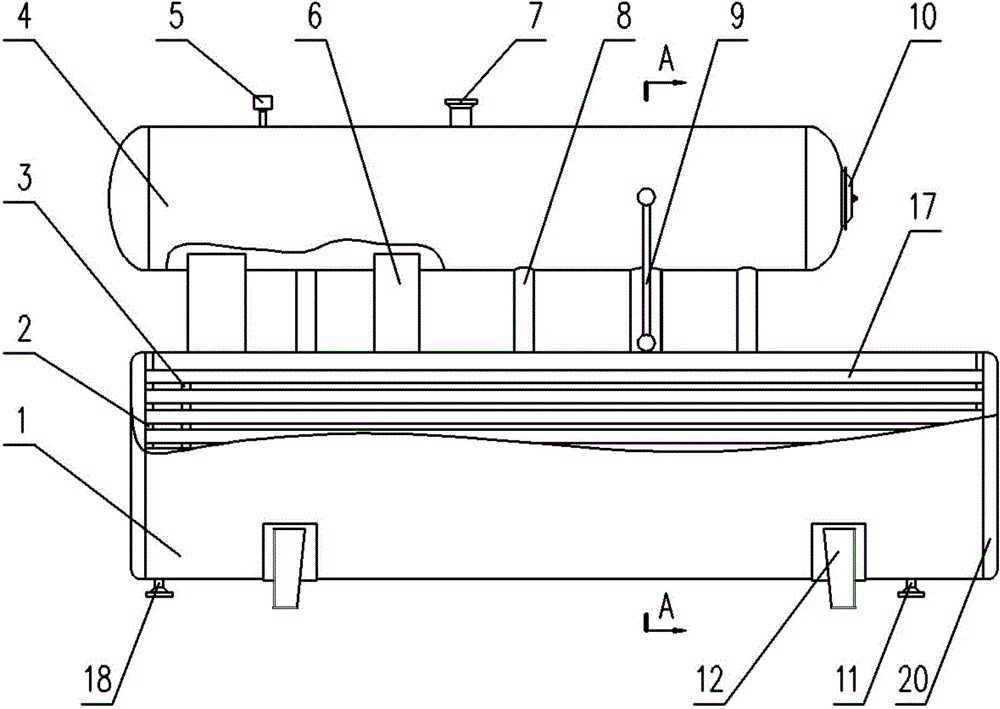

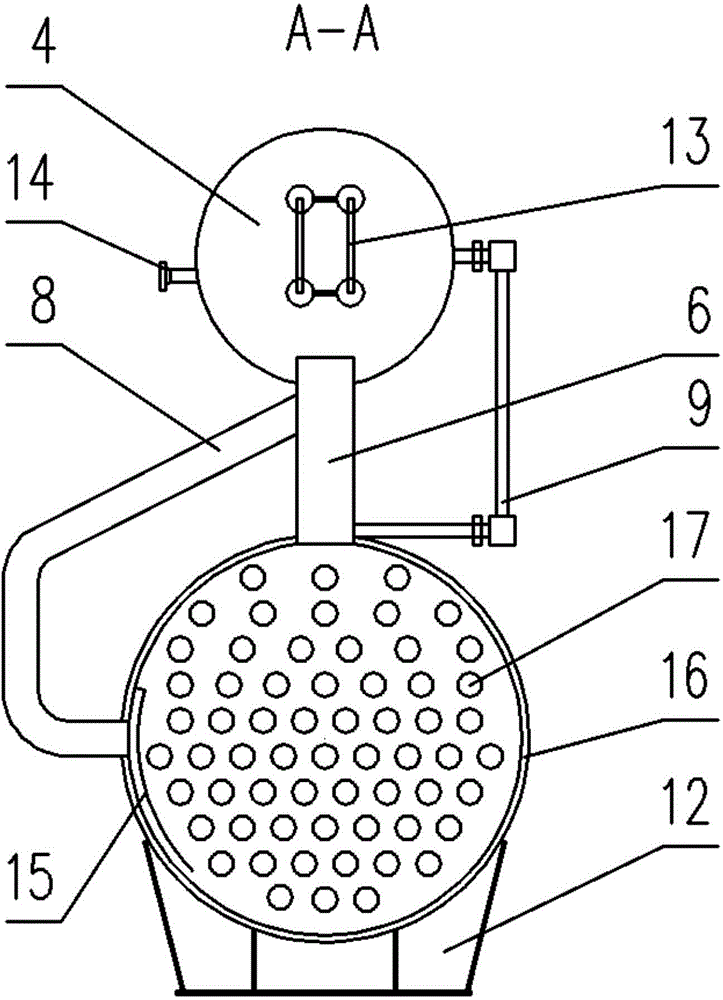

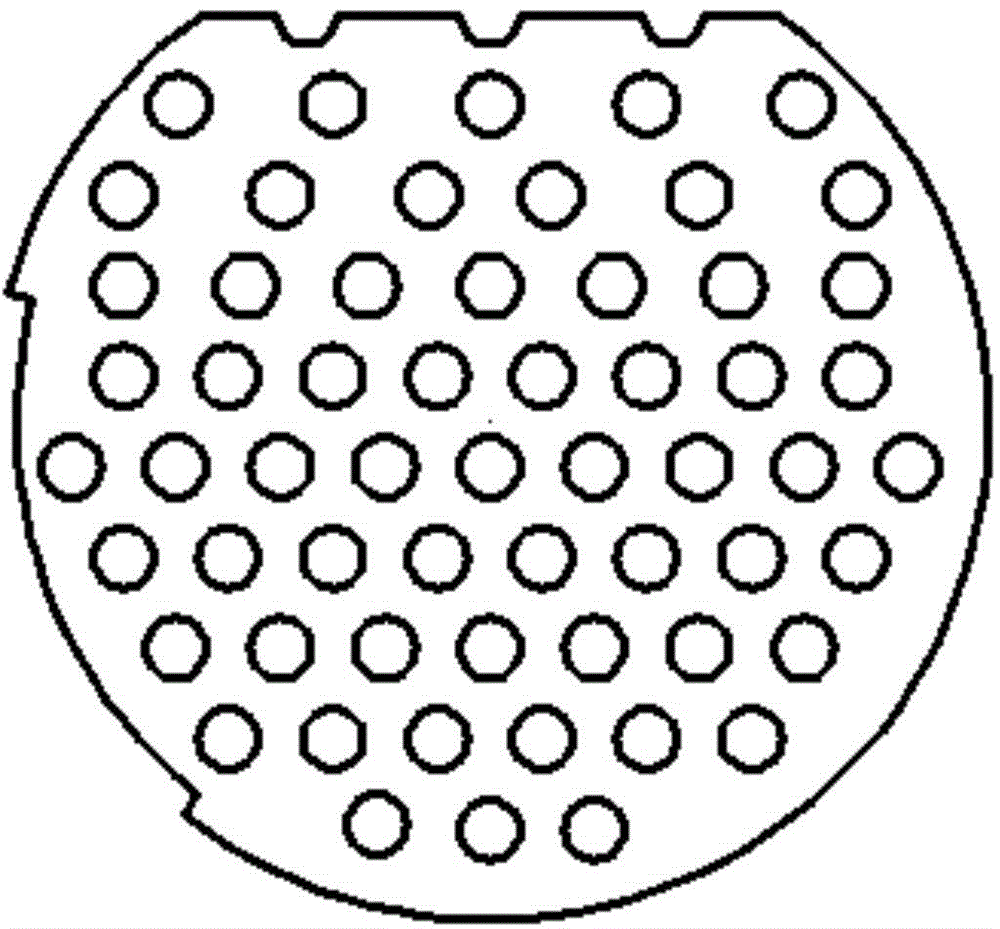

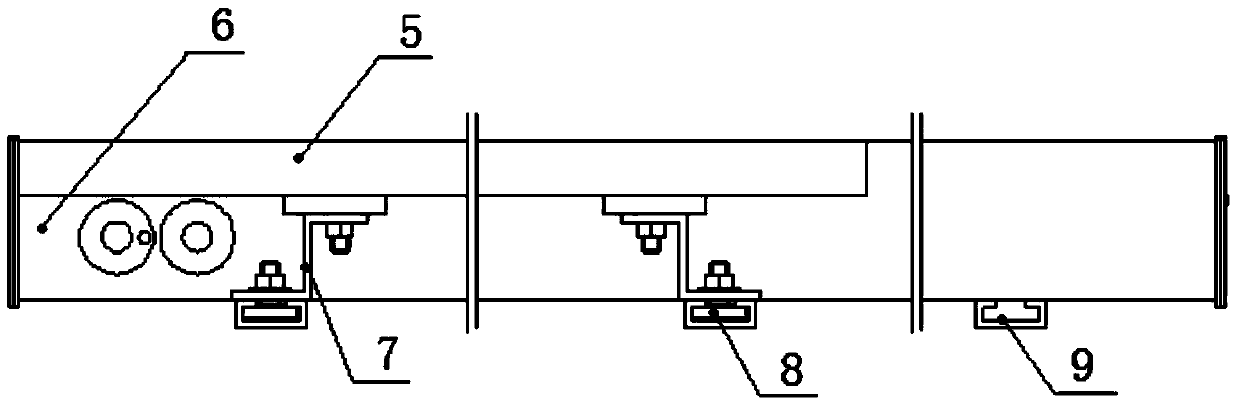

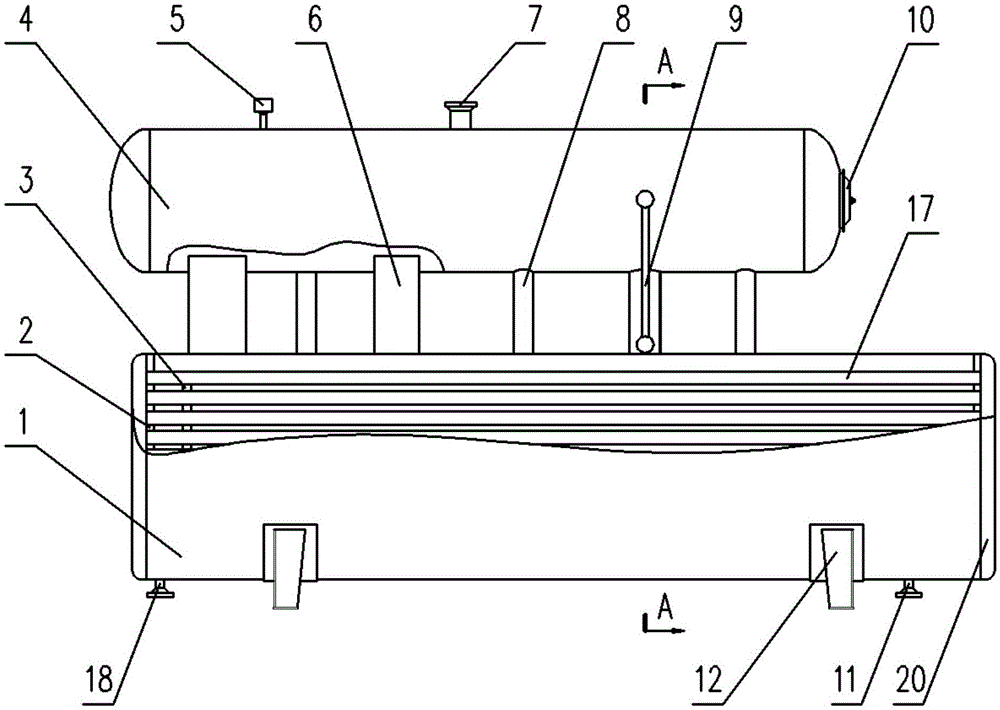

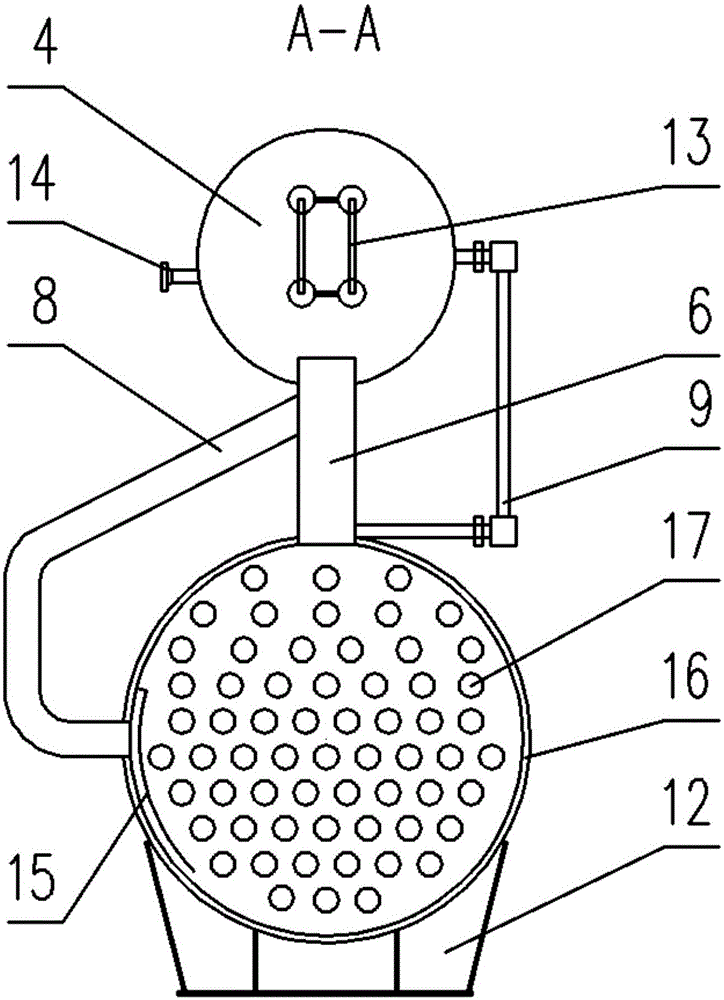

Partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler

ActiveCN103982886AImprove uniformityLow flow resistanceChemical industryStationary tubular conduit assembliesFlue gasEvaporation

The invention discloses a partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler. The partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler comprises a boiler cylinder and a pipe casing type evaporation heat exchanger which are vertically arranged; the boiler cylinder and the pipe casing type evaporation heat exchanger are arranged in a horizontal type; the boiler cylinder and the pipe casing type evaporation heat exchanger are connected through an ascending pipe assembly and a declining pipe assembly; the boiler cylinder is connected with a water inlet connecting opening formed in the pipe casing type evaporation heat exchanger through a high temperature high pressure water pipe; a high temperature high pressure water pump is arranged on the high temperature water pipe. The partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler has the advantages of being small in circulating ratio, efficient and energy saving, long in service life, small in occupied space, benefited to site installation and original facility reconstruction and reasonably utilizing high temperature flue gas waste heat in the chemical engineering field.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD +1

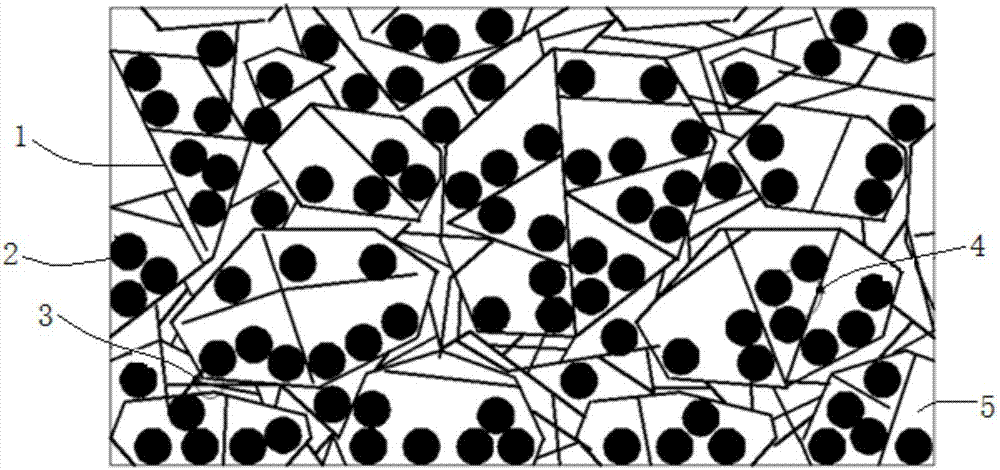

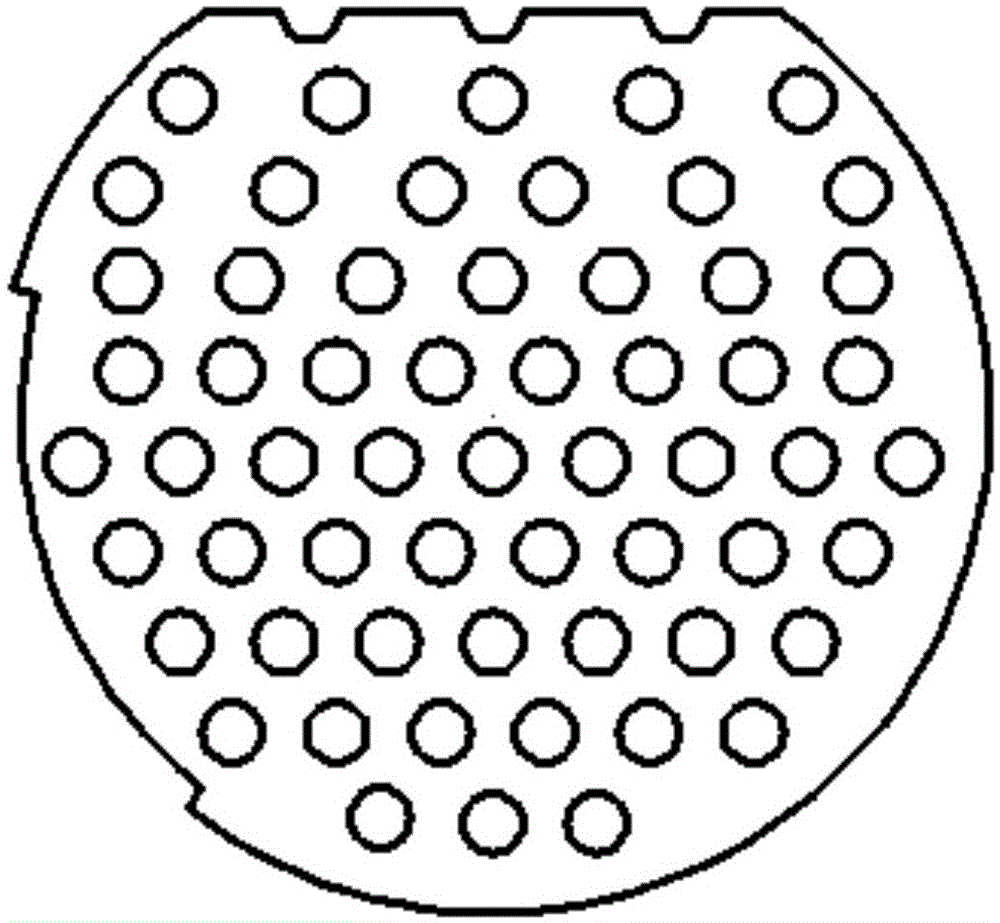

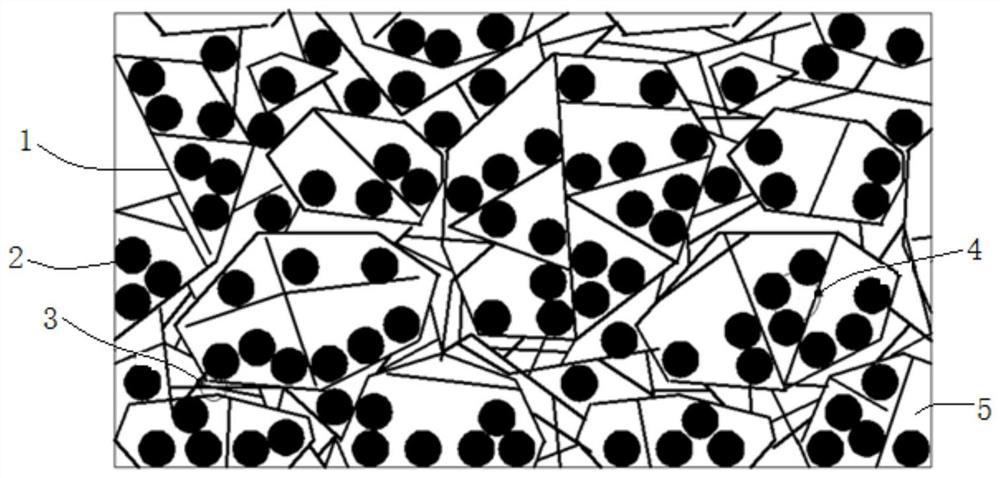

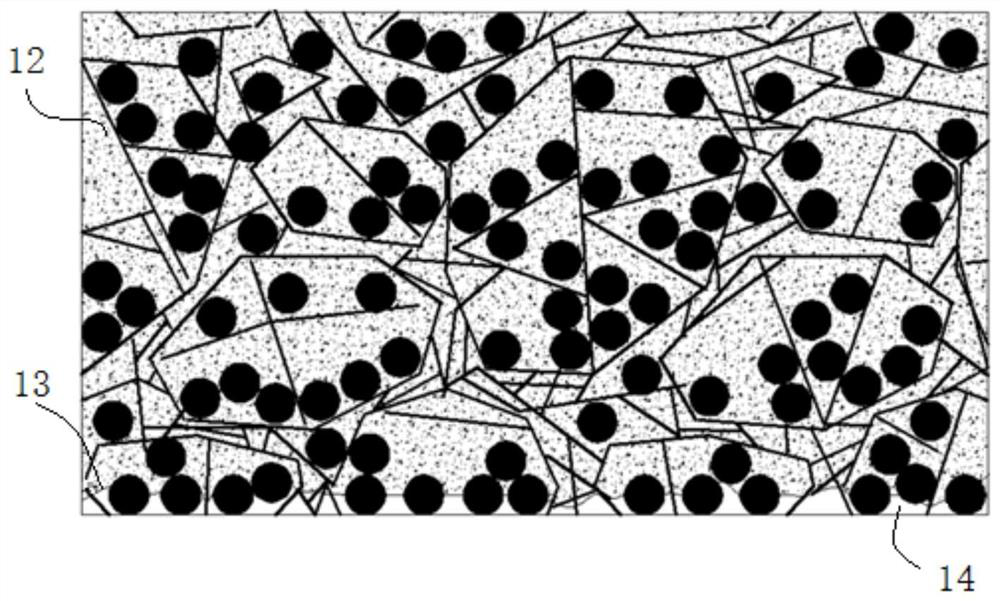

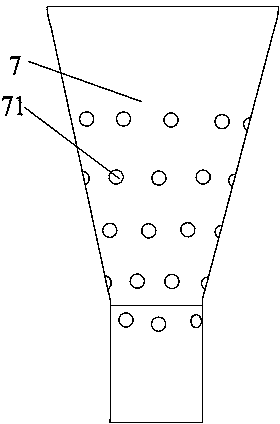

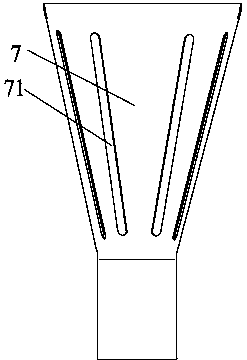

Variable-pore-diameter capillary core applied to loop heat pipe system, and machining method thereof

ActiveCN107462097AQuickly meet suction power requirementsLow flow resistanceIndirect heat exchangersFiberSuction force

The invention discloses a variable-pore-diameter capillary core applied to a loop heat pipe system, and a machining method thereof, and belongs to the field of porous medium phase-change heat transfer and flowing. The capillary core disclosed by the invention is formed through mixed sintering for high-melting-point powder particles and low-melting-point fibers, a temperature is controlled to completely sinter the fibers to form a capillary core framework, and the powder particles are not sintered and capable of moving in the space of a fiber framework according to a heat load to automatically adjust pore diameters. The capillary core is applied to a loop heat pipe, the pore diameters of the powder particles are automatically adjusted under different heat loads, and a suction force of the capillary core is adjusted to prevent a phase-change interface from stretching in the capillary core, and reduce heat transfer resistance during the working of the capillary core; and meanwhile, flowing resistance can be reduced, so that the running performance of the loop heat pipe is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

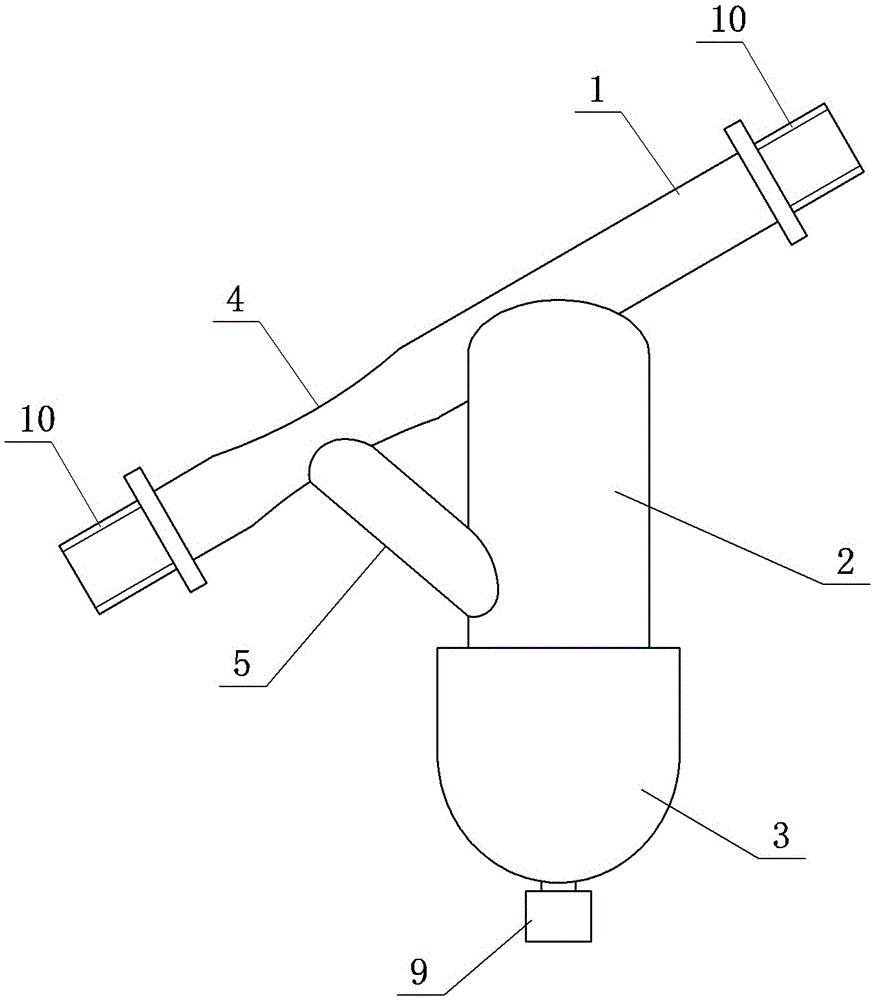

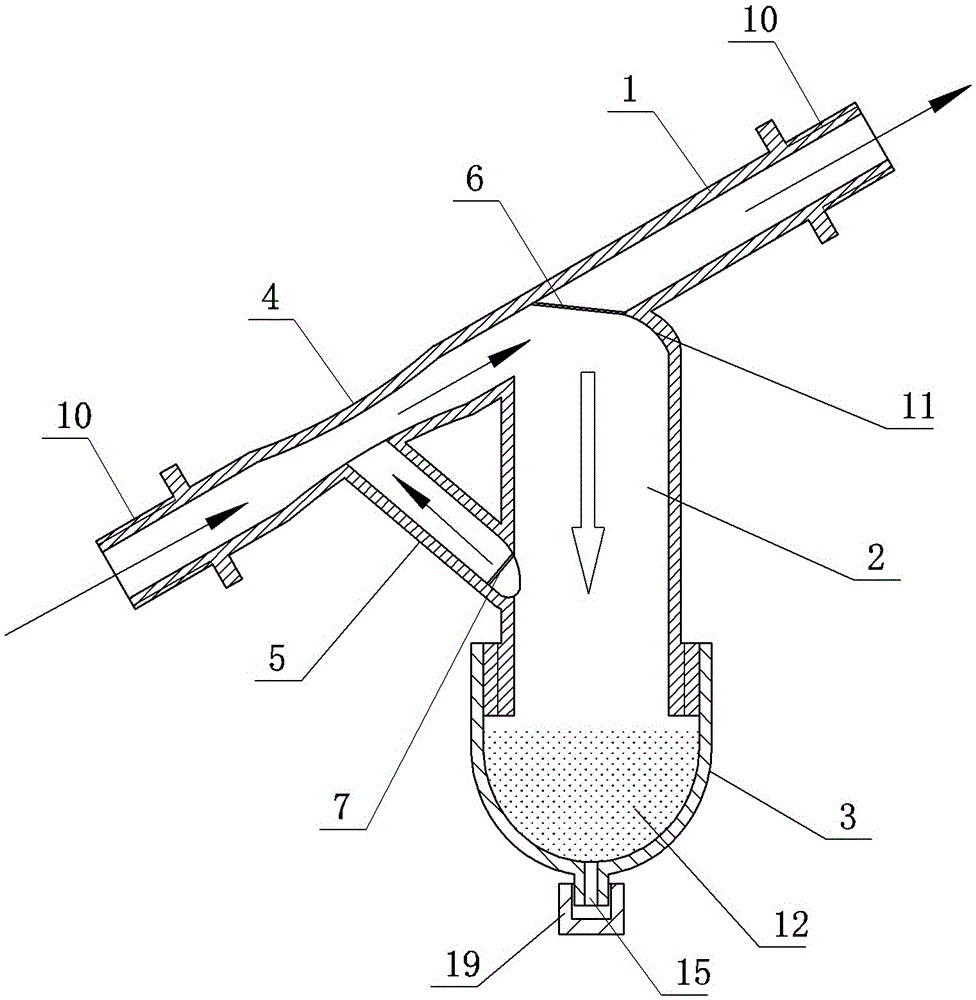

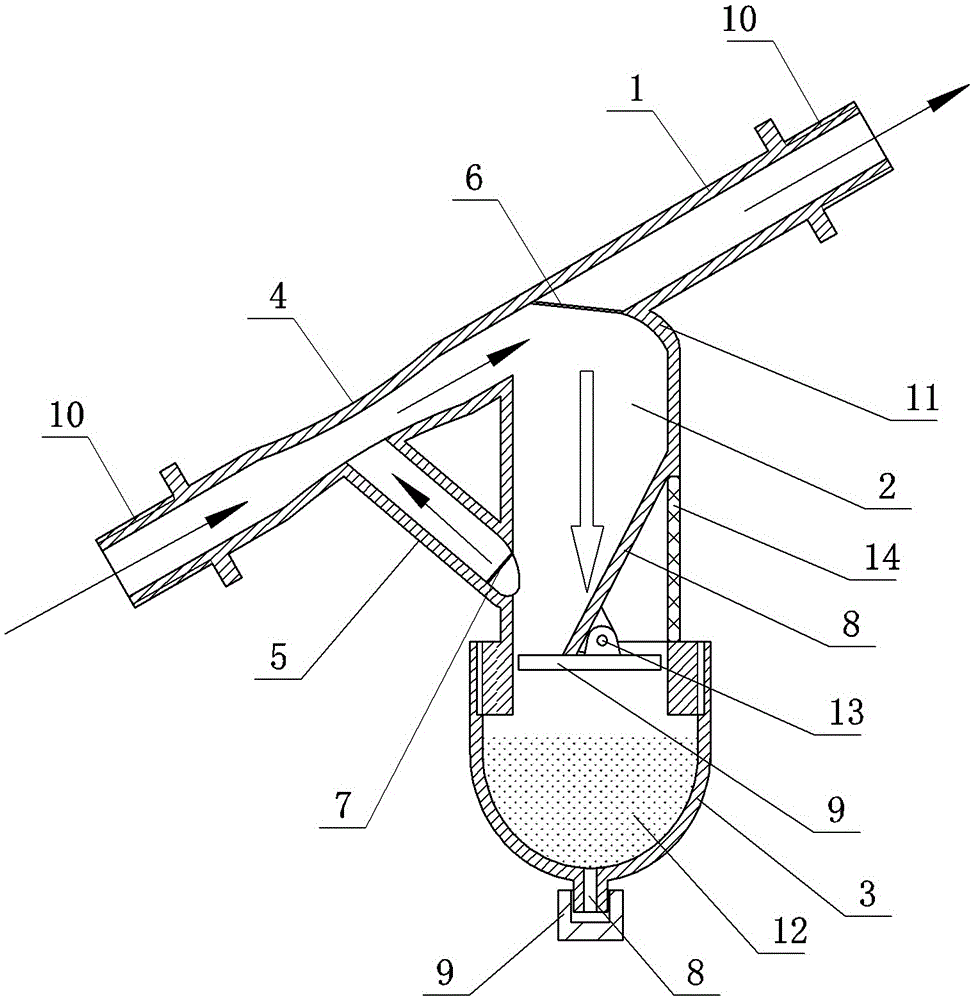

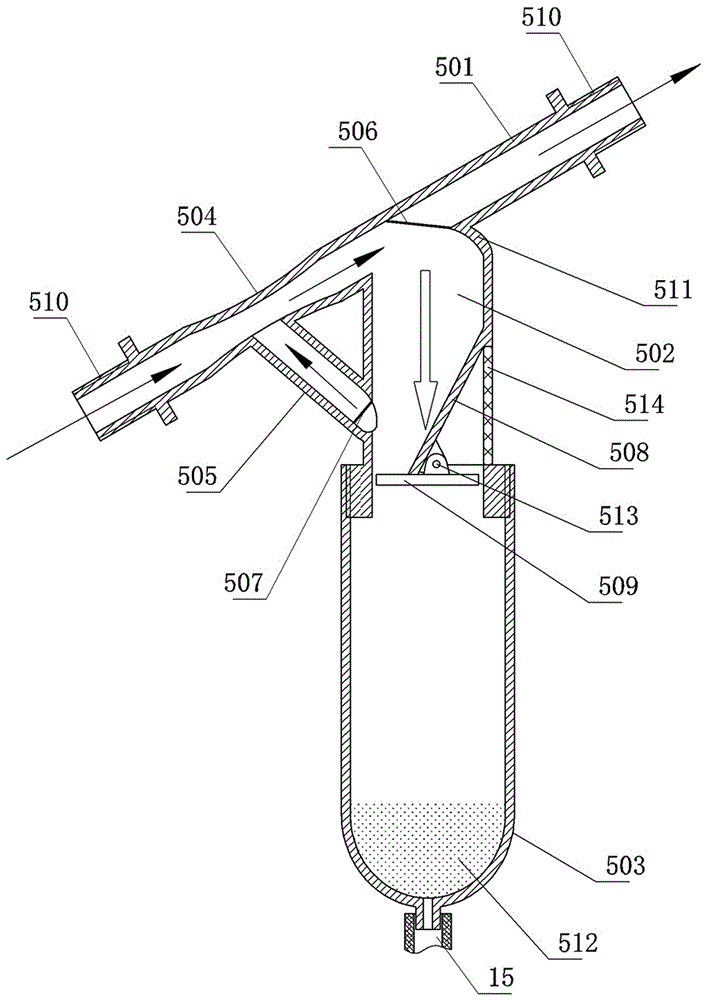

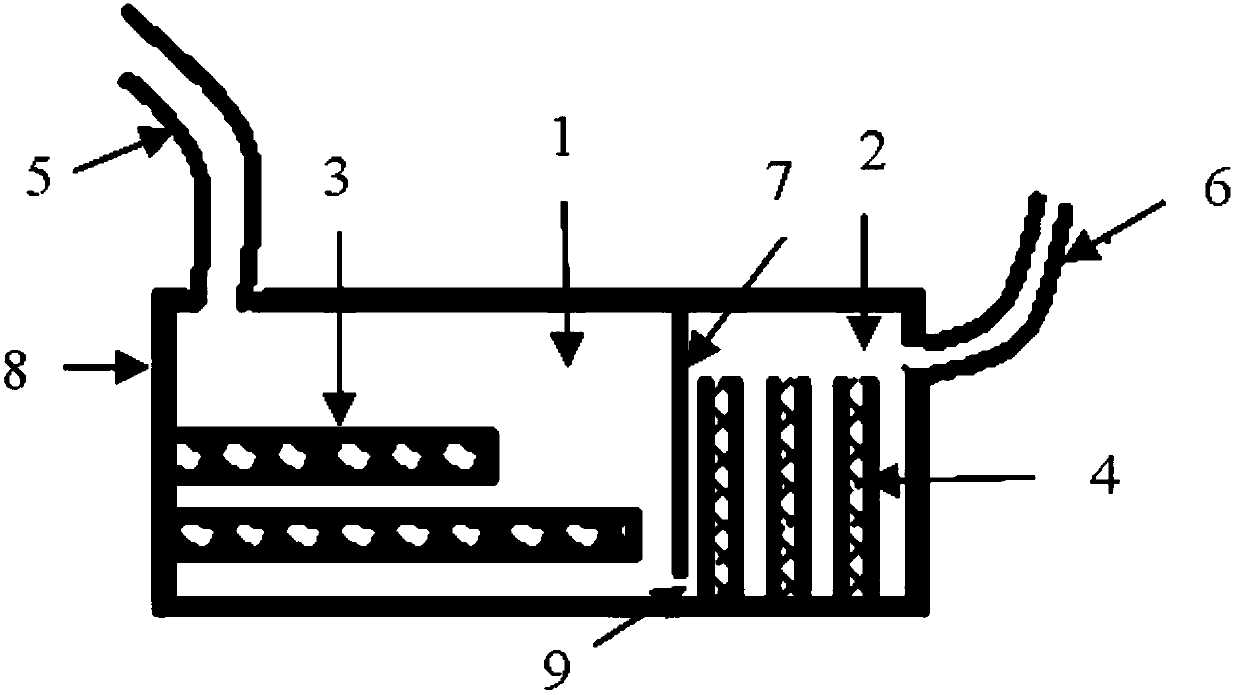

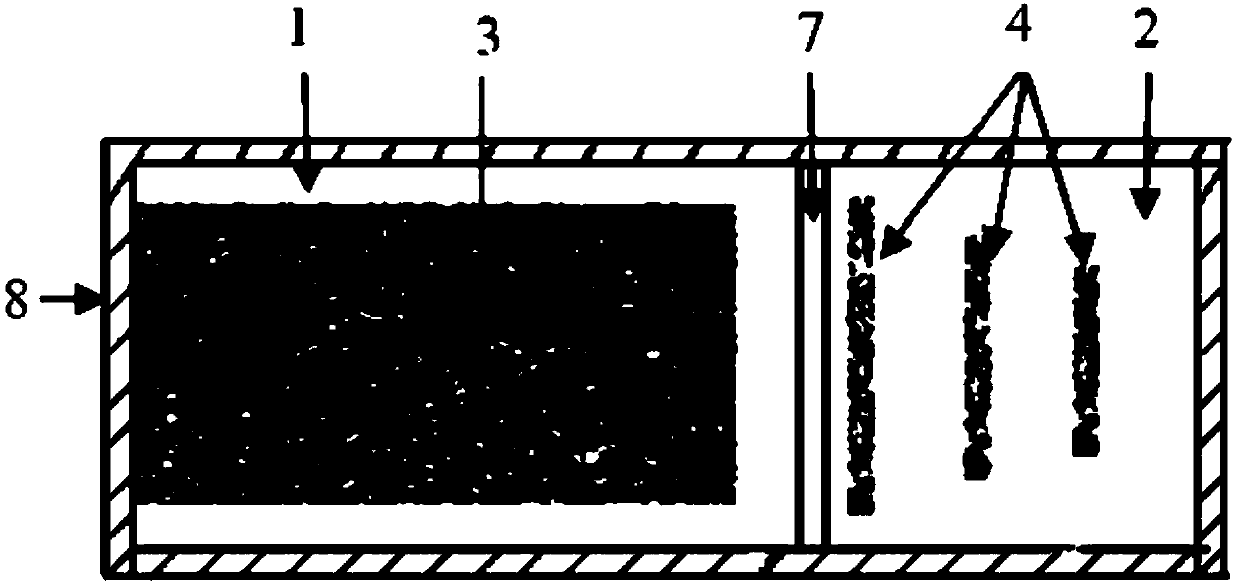

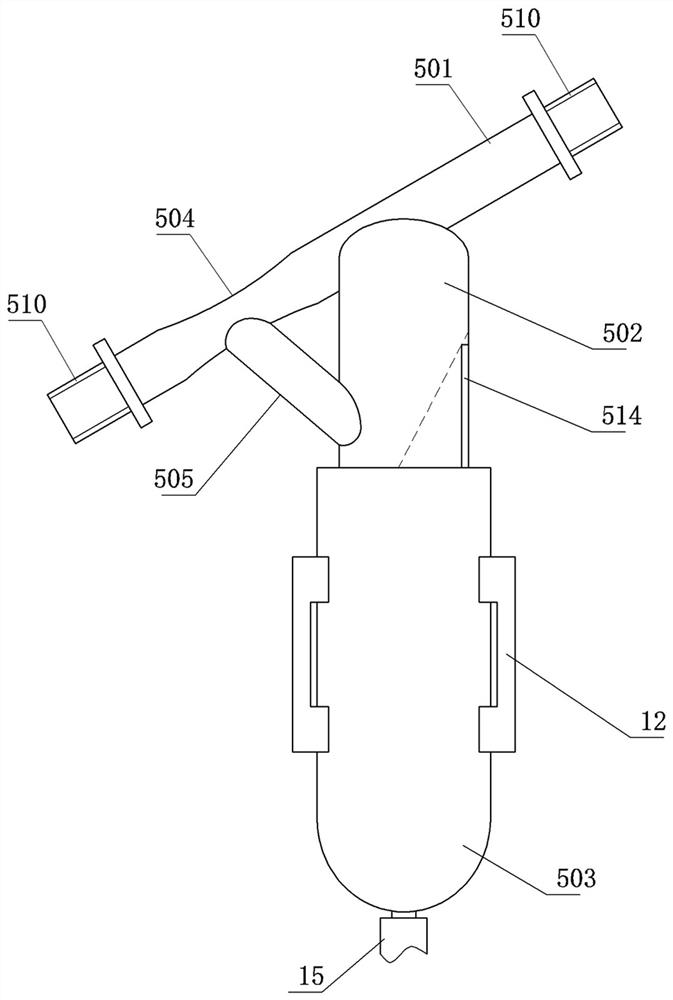

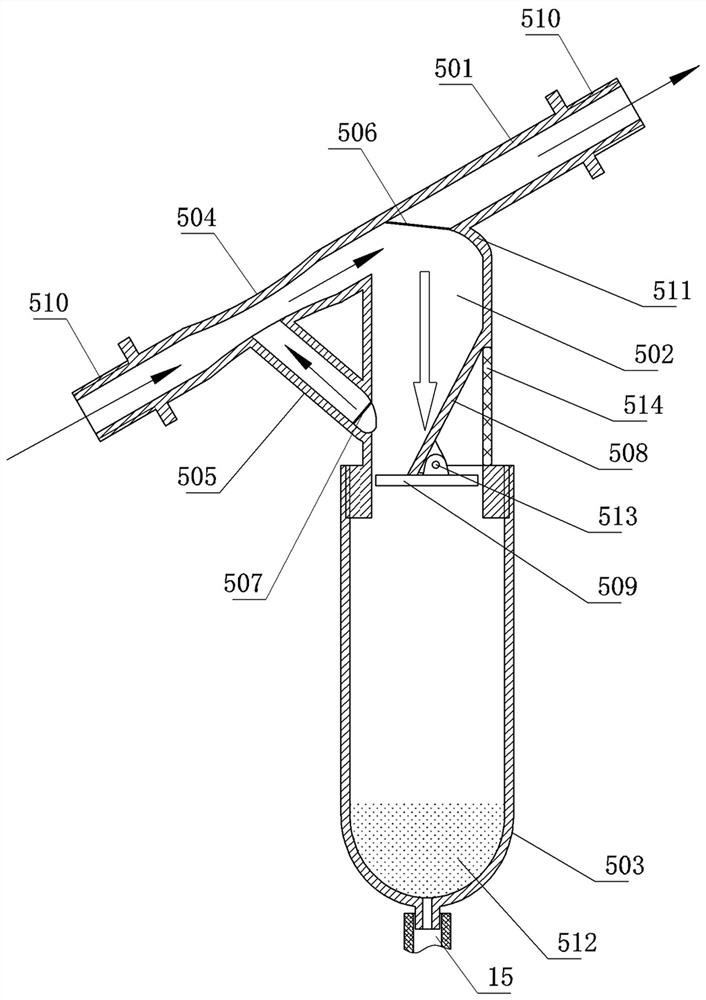

Efficient circulating and filtering device for chemical experiments

InactiveCN105642015AAccelerated precipitationMake sure to fall intoSeparation devicesMembrane filtersEngineeringFilter effect

The invention discloses an efficient circulating and filtering device for chemical experiments. The efficient circulating and filtering device comprises a main tube and a vertical precipitation tube, the main tube is obliquely communicated with the vertical precipitation tube which is kept downward vertically, a water inlet of the main tube is lower than a water outlet thereof, and a first communication port is formed between the main tube and the vertical precipitation tube. A backflow tube is communicated between the vertical precipitation tube and the main tube, a second communicated port is formed between the backflow tube and the main tube and is lower than the first communication port, a third communication port is formed between the backflow tube and the vertical precipitation tube, a main filter screen is arranged at a downflow position of the first communication port, and an auxiliary filter screen is arranged at a downflow position of the third communication port. The efficient circulating and filtering device for the chemical experiments has the advantages that the backflow tube is arranged between the main tube and the vertical precipitation tube, so that solid precipitation is promoted, and most of solids are blocked on the lower side of the main filter screen; during circulation, filtering effects can be further improved through the auxiliary filter screen, so that the solids can fall into the vertical precipitation tube.

Owner:HUANGHE S & T COLLEGE

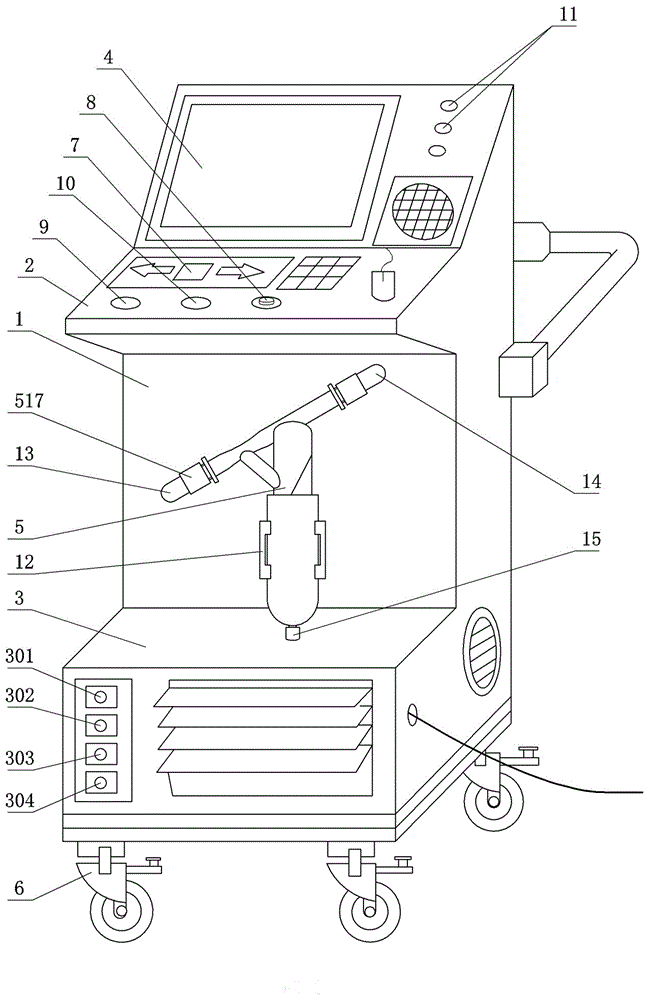

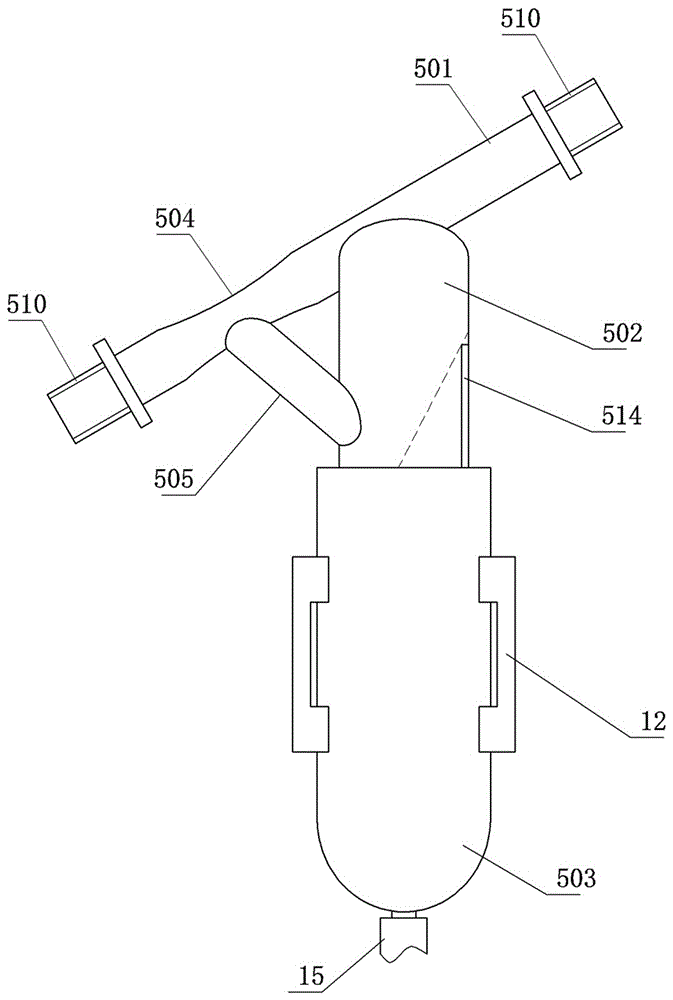

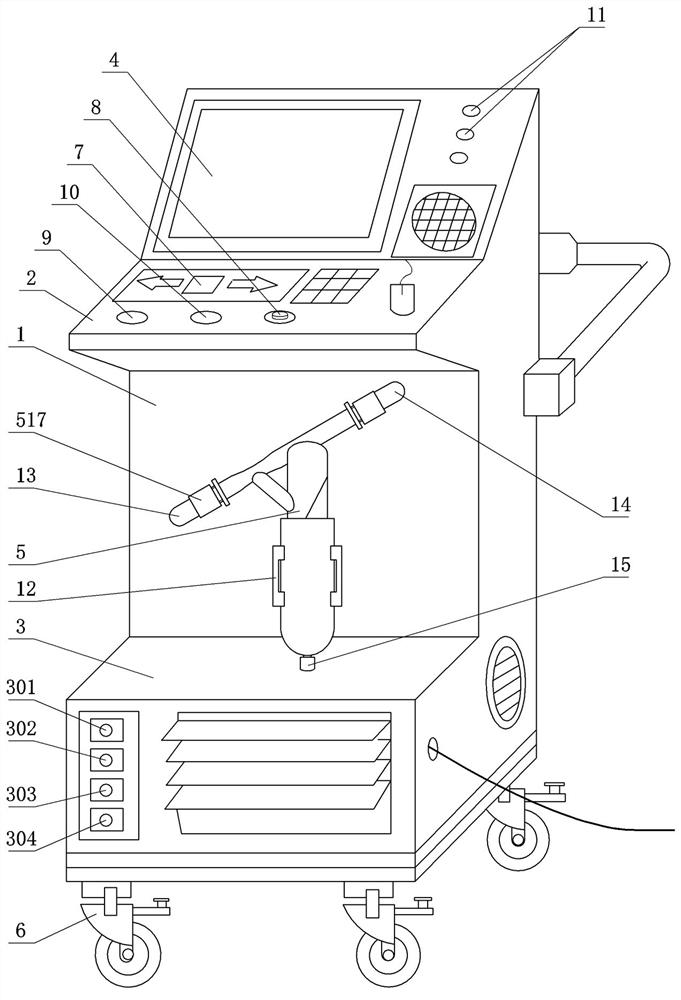

Circulating filtering type gastric-lavage machine for gastroenterology department

ActiveCN105854109AAccelerated settlementImprove filtering effectEnemata/irrigatorsMedical devicesGastric lavageCyclic process

The invention discloses a circulating filtering type gastric-lavage machine for the gastroenterology department. The gastric-lavage machine comprises a gastric-lavage machine body, an operating floor, a working box, a filtering device, a displayer, a keyboard and an indicator lamp. The filtering device is a circulating filtering device and comprises a main tube and a vertical deposit tube which are communicated through a backflow tube. The backflow tube is sequentially communicated with the main tube and the vertical deposit tube and is provided with filter screens so that a circulating loop can be formed and the deposition of wash-out objects can be promoted. Most of solid wash-out objects are blocked on the lower side of the main filter screen so that solid-liquid separation can be achieved and independent detection can be conveniently conducted. In the circulating process, the auxiliary filter screen is arranged, so the filtering effect is further improved, and it is ensured that sand falls into the vertical deposit tube.

Owner:郑州优康药业有限公司

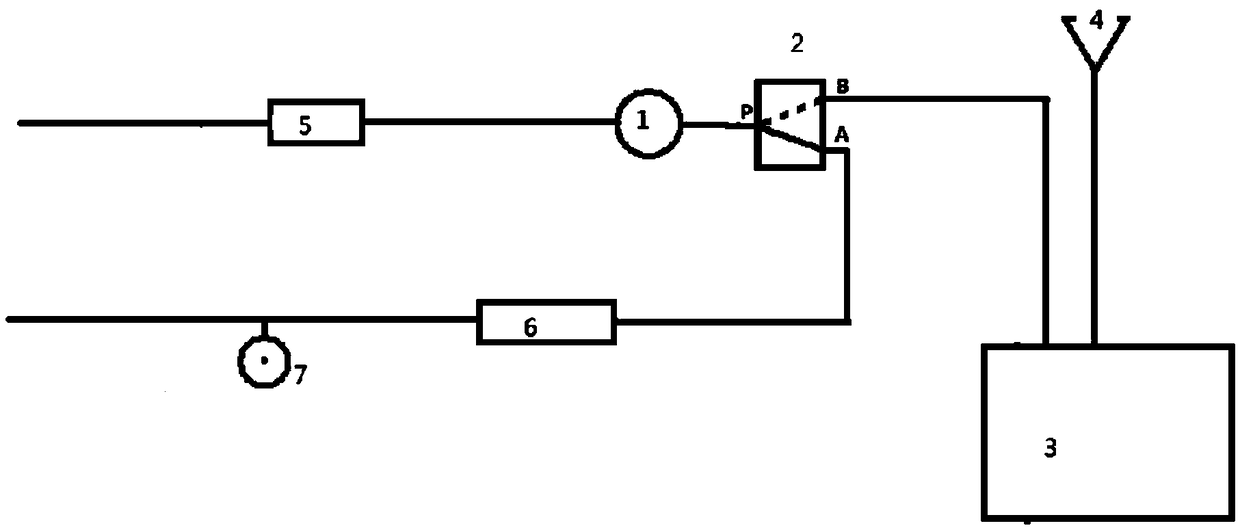

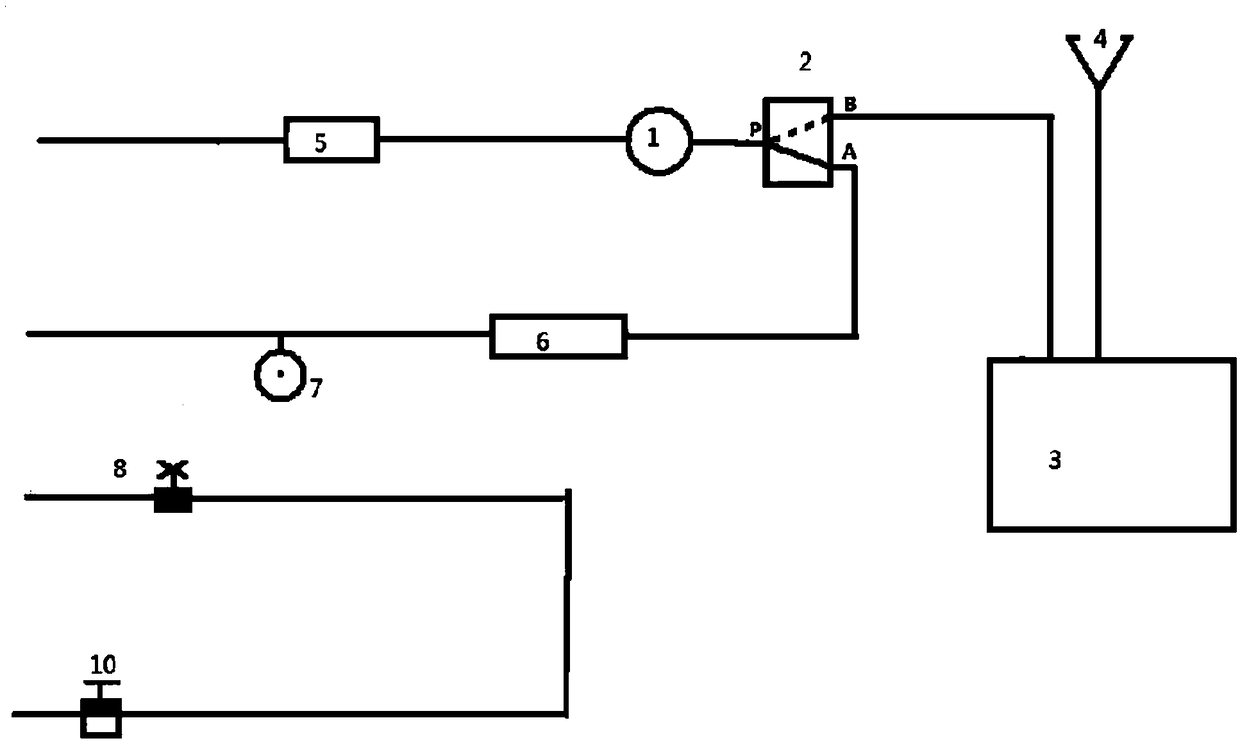

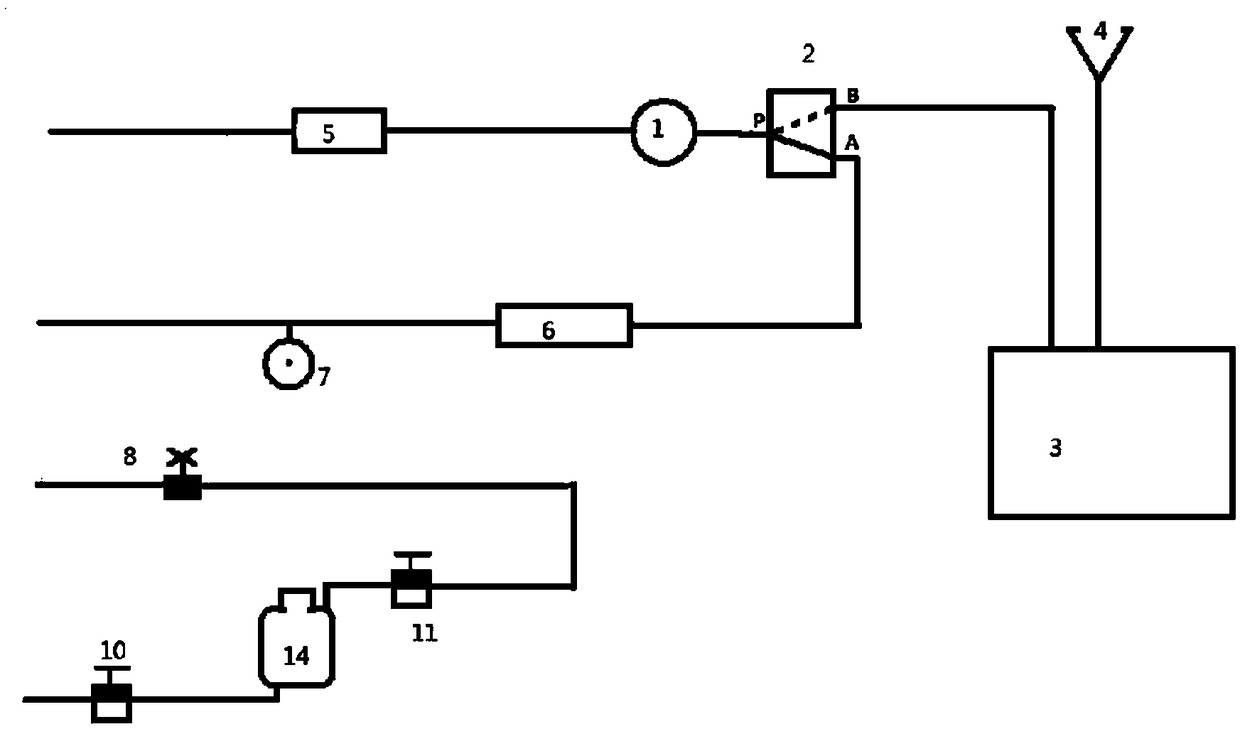

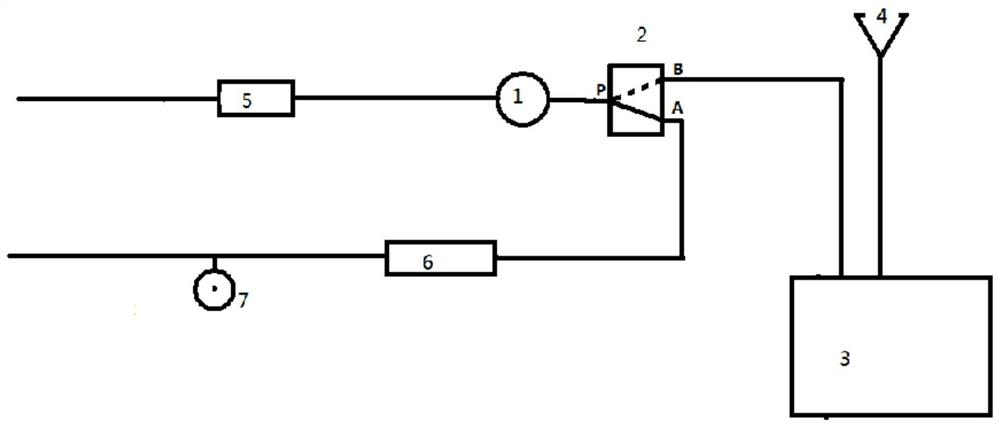

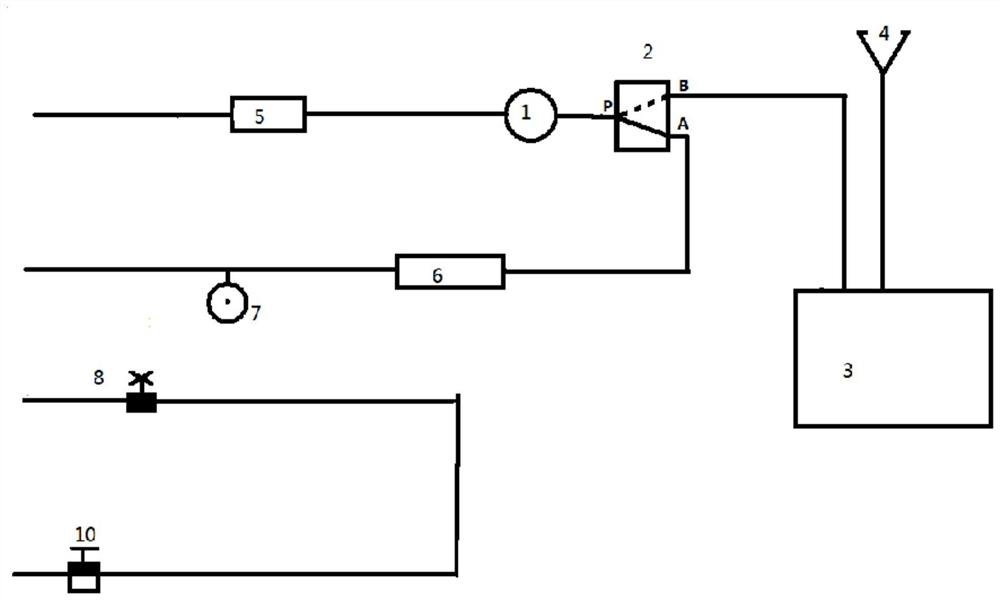

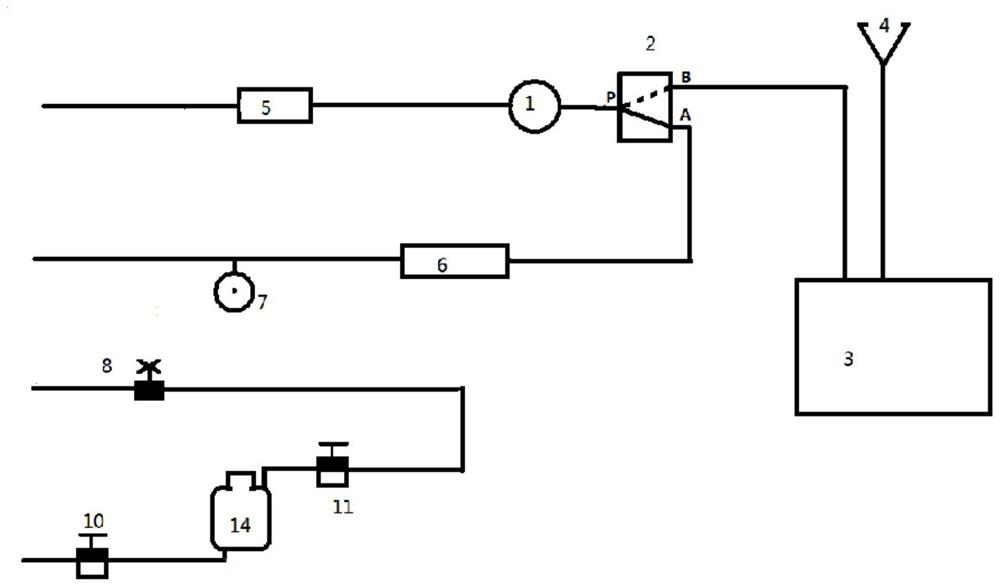

Engine cleaning method and device

ActiveCN109057965AIncrease cycle powerSolve the technical problem of slow circulation flowMachines/enginesEngine componentsHydraulic pumpCleaning methods

The invention provides an engine cleaning method and device and relates to the technical field of vehicle maintenance. The technical problem that cleaning oil flows circularly slowly in the engine when an engine is cleaned is solved. The engine cleaning device comprises a hydraulic pump, a two-position three-way reversing valve, an old oil bucket and a receiving disc. The hydraulic pump is locatedbetween an oil pan of a cleaned vehicle and the two-position three-way reversing valve. When the two-position three-way reversing valve keeps oil way connection of the hydraulic pump and an engine oil tank of the cleaned vehicle, an engine external cleaning loop is formed. The receiving disc and an engine lubricating oil way outlet are connected for receiving waste engine oil flowing out of the engine, and the bottom of the receiving disc communicates with the old oil bucket. The hydraulic pump works to facilitate acceleration circular flowing of the cleaning oil in a vehicle lubricating oilway. The engine cleaning method and device are used for cleaning and maintenance of the vehicle engine.

Owner:北京天元陆兵汽车科技有限公司

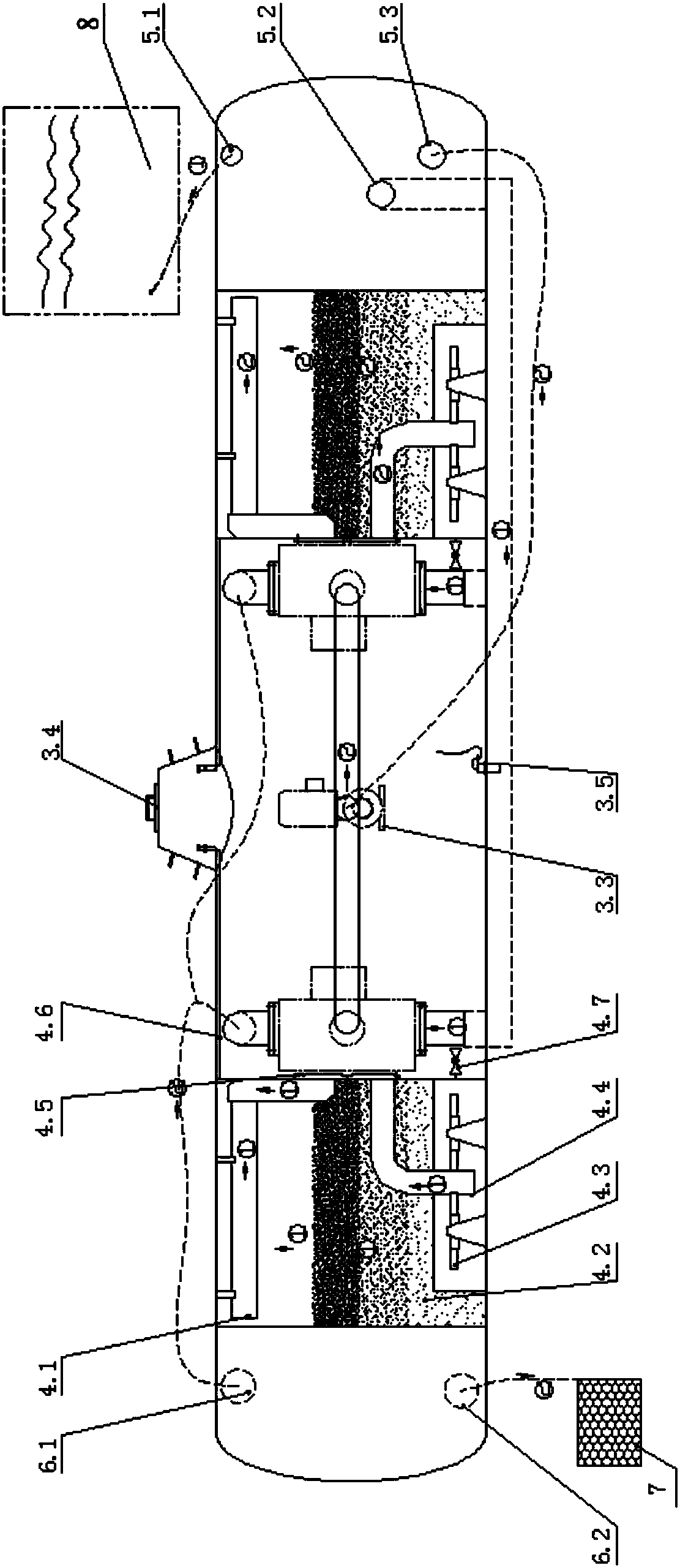

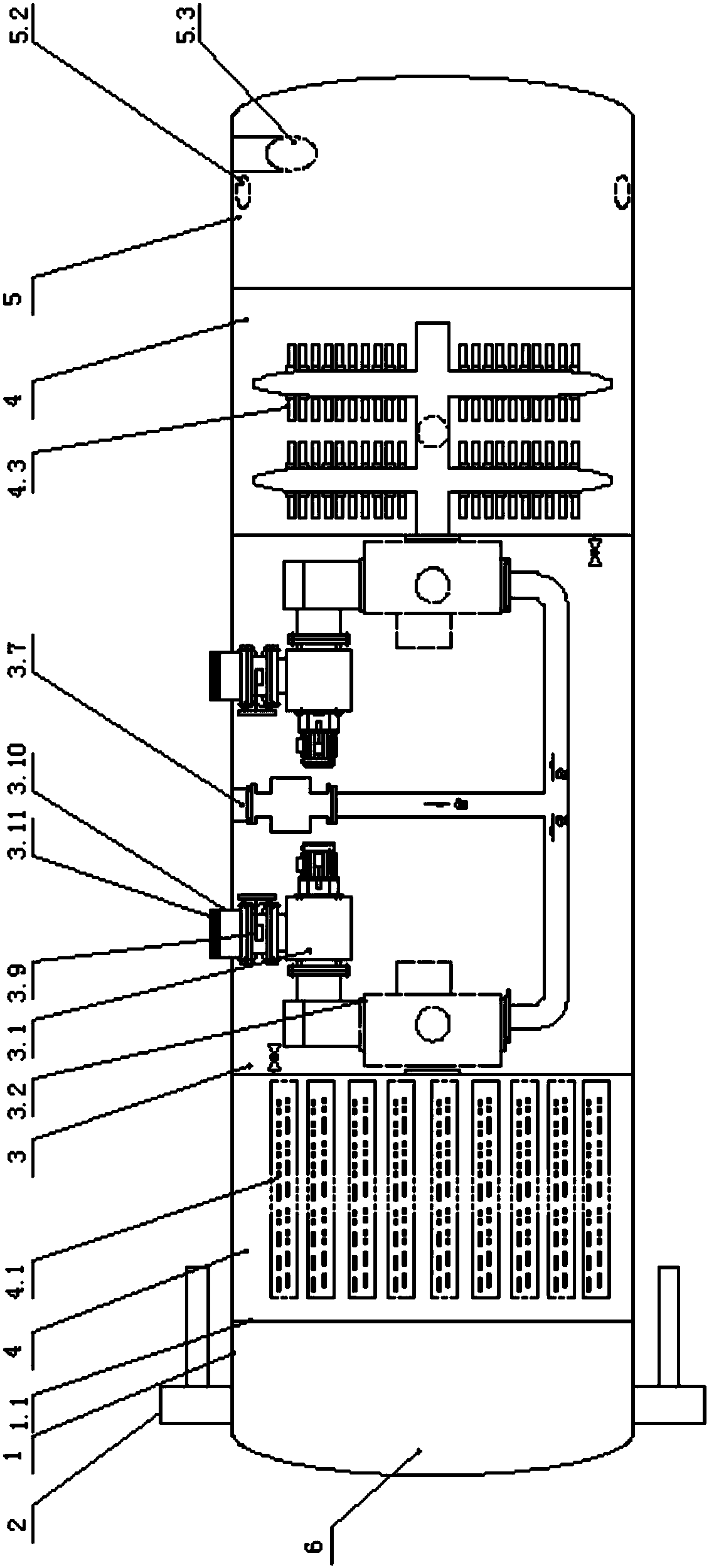

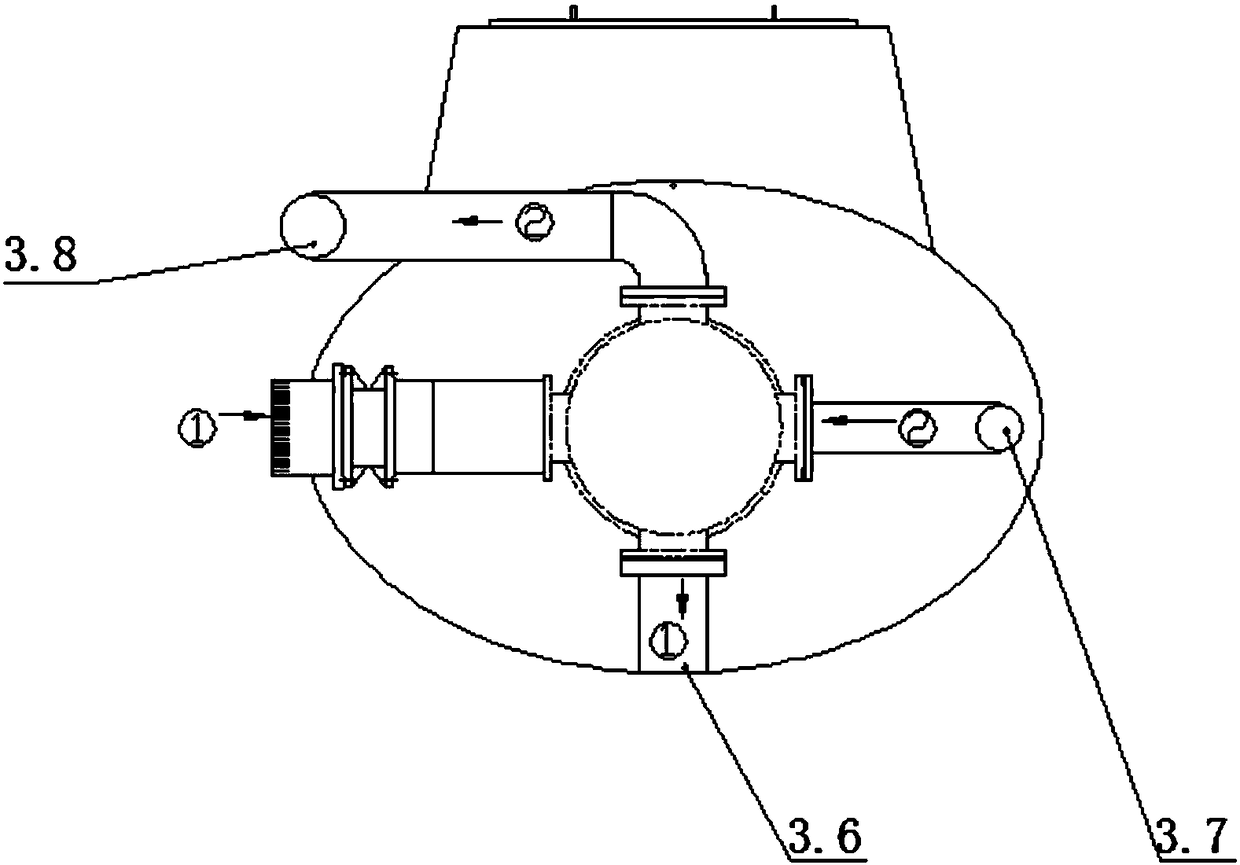

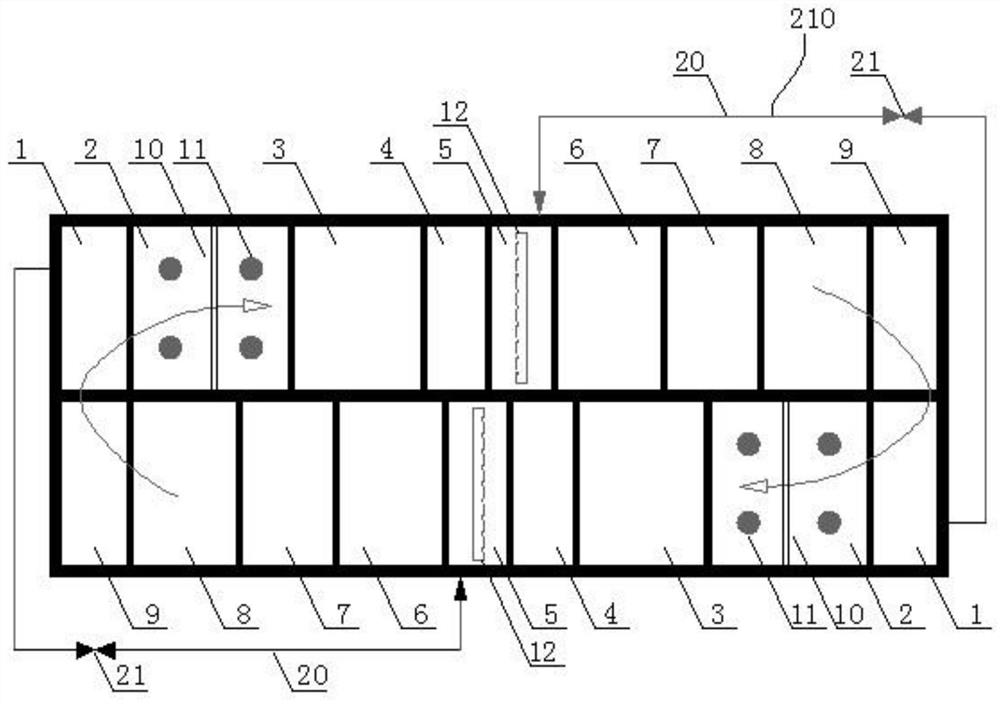

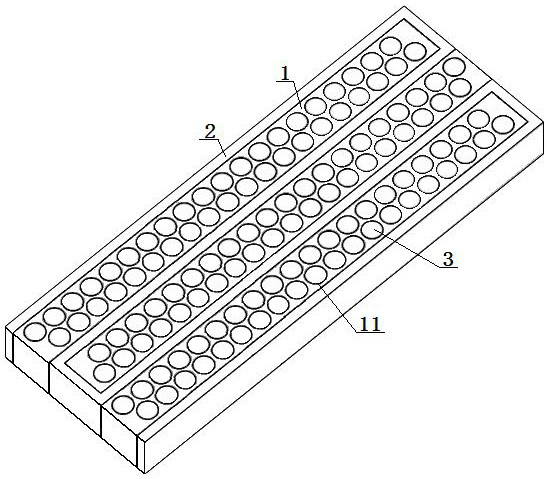

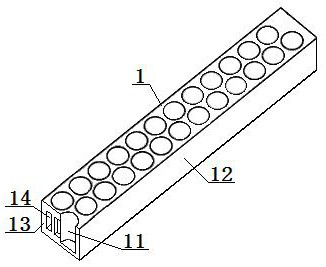

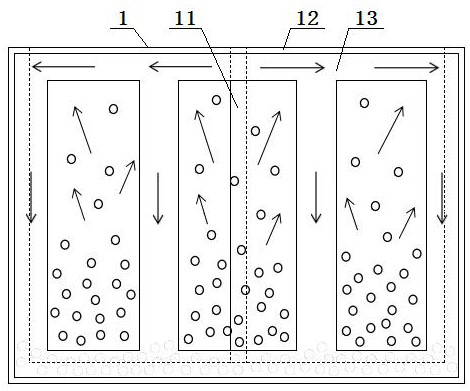

Integrated water treatment device

PendingCN108545894AIncrease cycle powerImprove self-cleaning abilityWater treatment parameter controlTreatment using aerobic processesLow speedWater flow

The invention relates to an integrated water treatment device, which comprises a shell unit, a dissolved oxygen aeration unit, an operation cabin unit, a filtering unit, a clean water tank unit, and asewage collection unit, wherein the shell unit is a shell of the water treatment device, and the aeration unit is used for aerating water near the outside of the water treatment device; the operationcabin unit is an operation control cabin of the water treatment device, and the filtering unit filters the water aerated by the aeration unit; the clean water tank unit is used for storing the waterfiltered by the filtering unit, and the sewage collection unit is used for storing the water backwashed by the filtering unit, wherein the operation cabin unit comprises a wet and dry pump and a waterquality sensor; when the water quality sensor detects that the turbidity of the water to be treated is greater than a set value, the device enters a rapid filtering mode, the dry and wet pump runs ata high speed, so that the water flows into the filtering unit at a high speed; when the water quality sensor detects that the turbidity of the water to be treated is less than the set value, the device enters the slow filtering mode, and the dry and wet pump runs at a low speed, so that the water flows into the filtering unit at a low speed.

Owner:NANJING TIANHESHUI ENVIRONMENT TECH CO LTD

Plant beverage for improving microcirculation and preparation method thereof

PendingCN109820123AAvoid cell damageMaintain health and vitalityFood scienceNervous systemPharmaceutical preservatives

Owner:赛杜恳医药生物科技(上海)有限公司

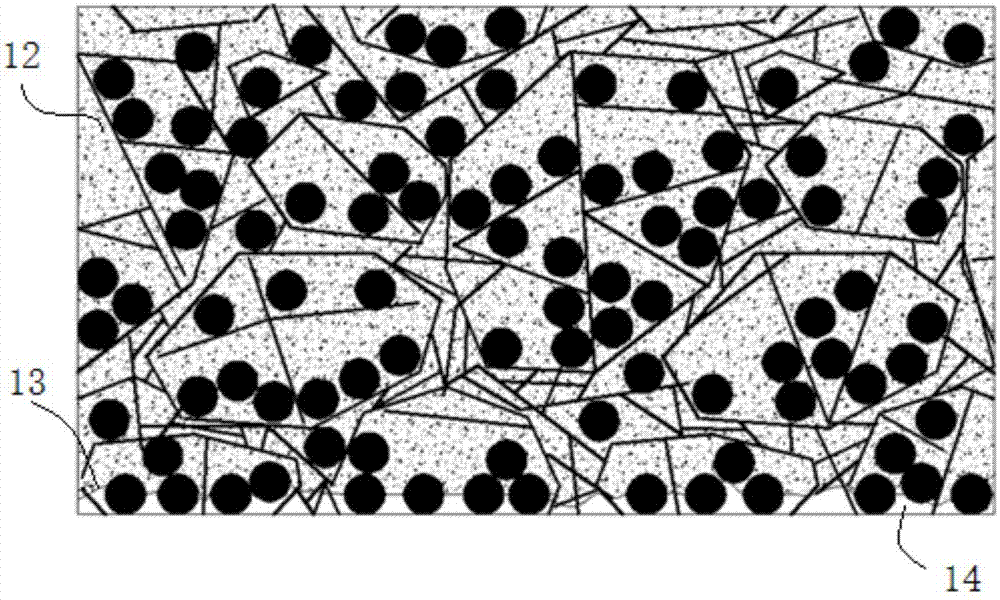

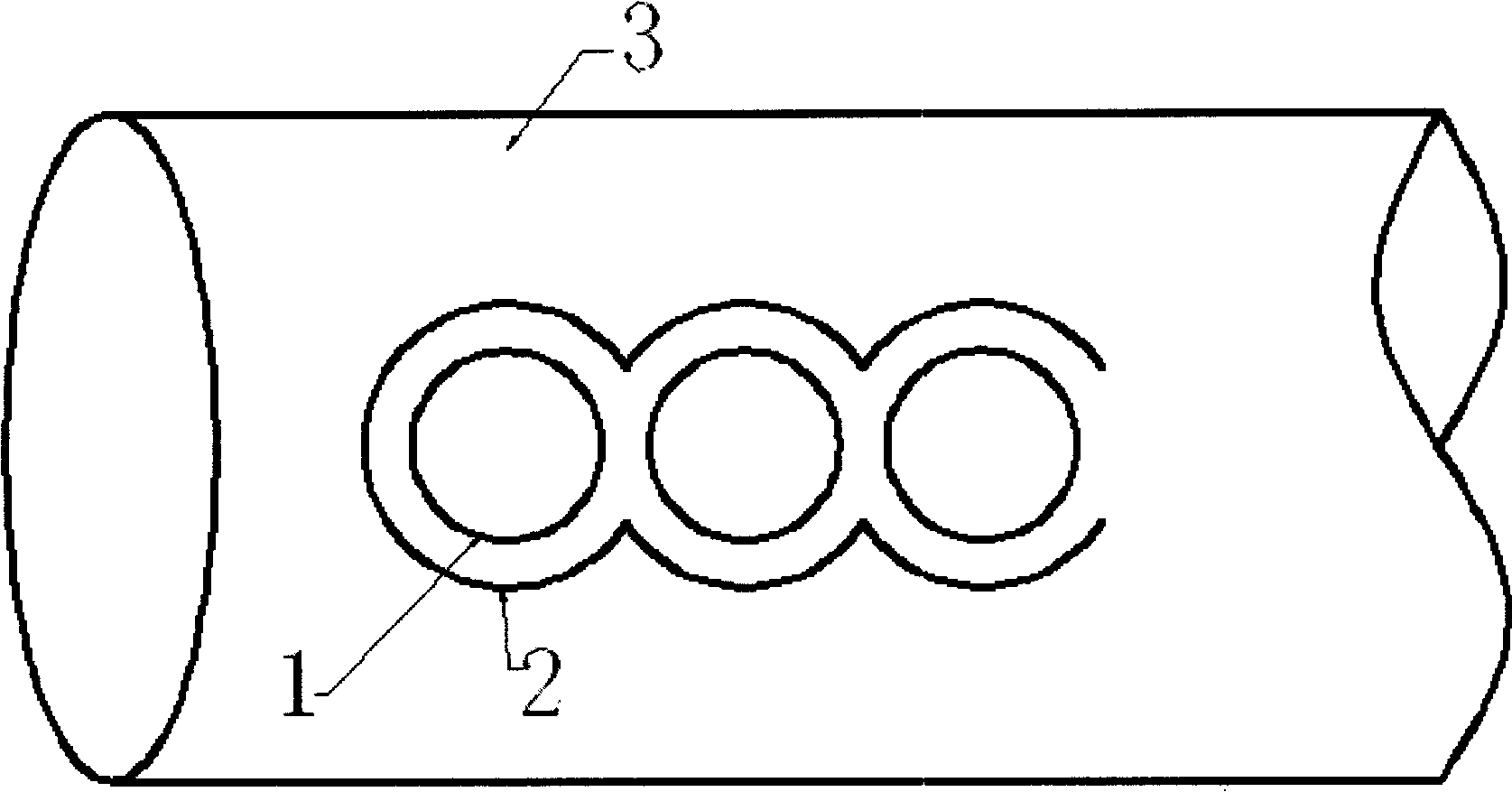

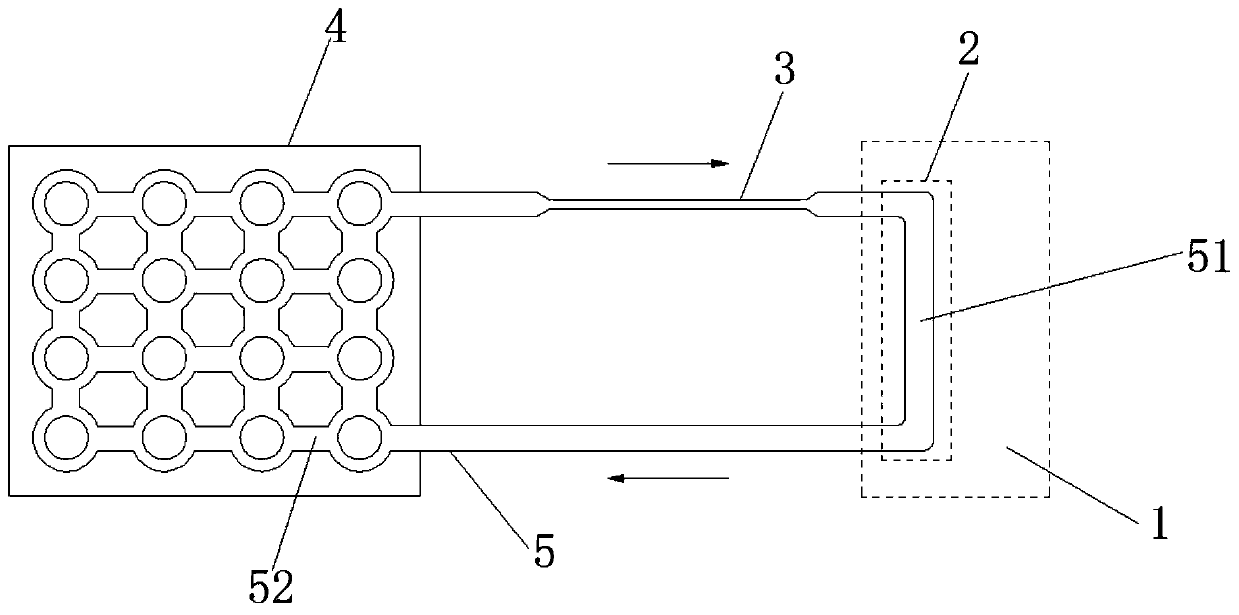

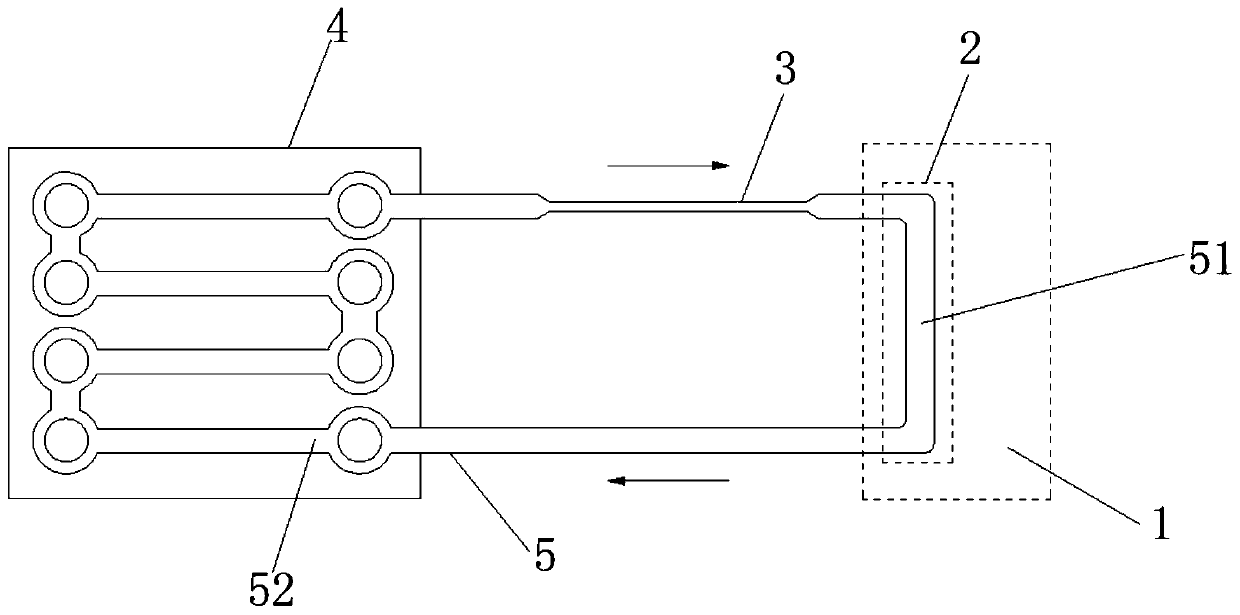

Micro loop heat pipe and method

PendingCN107687783AEasy reunionDoes not significantly deteriorate heat transferIndirect heat exchangersThermodynamicsMicro-loop heat pipe

The invention discloses a micro loop heat pipe and a method. The micro loop heat pipe comprises an evaporation chamber. One end of the evaporation chamber is connected with an inlet of a condensing chamber through a steam pipe. The other end of the evaporation chamber is connected with an outlet of the condensing chamber through a liquid backflow pipe. The interior of the evaporation chamber is partitioned into an evaporation space and a backflow liquid storage space communicating with the evaporation space through a thermal insulating partition plate made of a thermal insulating material. A plurality of layers of capillary cores with different hole diameters are arranged in each of the evaporation space and the backflow liquid storage space. When external heat is input through the wall surface of the evaporation space, a nano fluid working medium in the evaporation space is heated and evaporated to generate steam; and the steam enters the condensing chamber through the steam pipe andis condensed, then flows back to the backflow liquid storage space along the liquid backflow pipe, and then returns to the evaporation space through the bottom of the evaporation chamber, namely a bottom channel of the thermal insulating partition plate; and circulation is achieved in this way.

Owner:SOUTH CHINA UNIV OF TECH

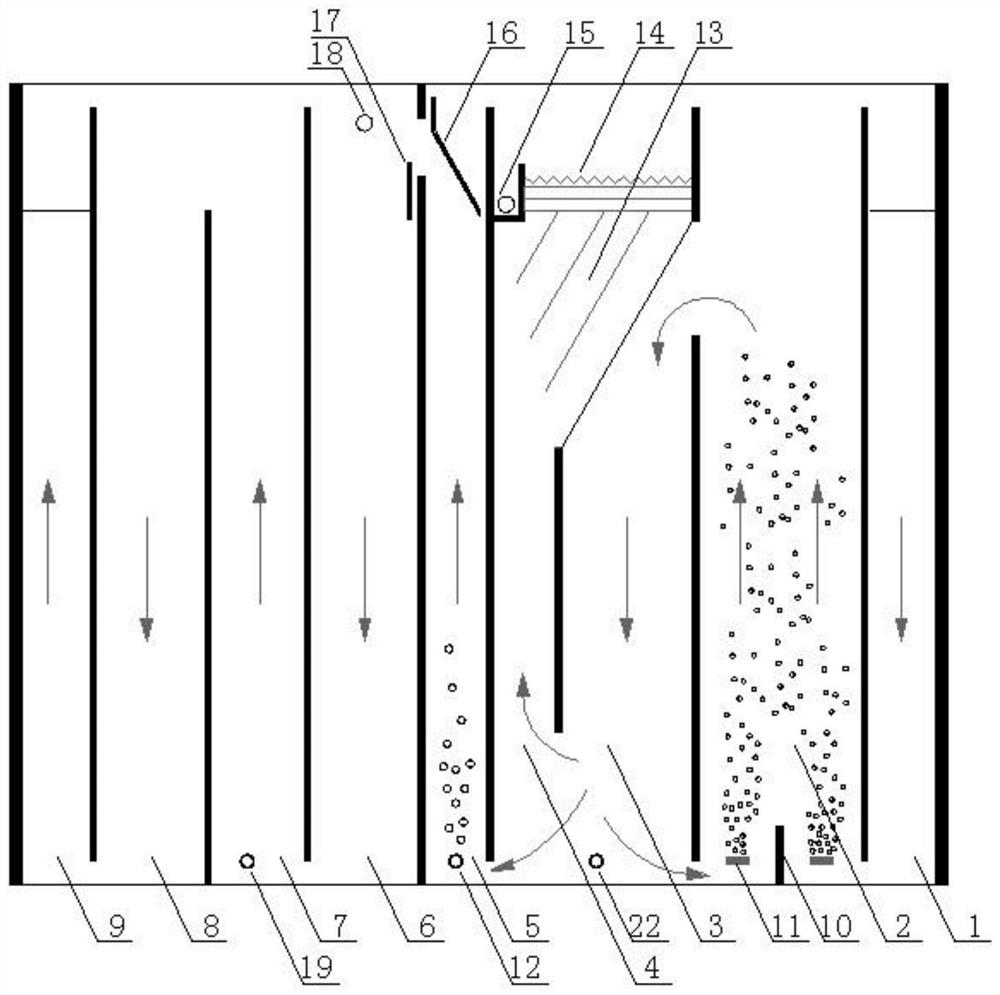

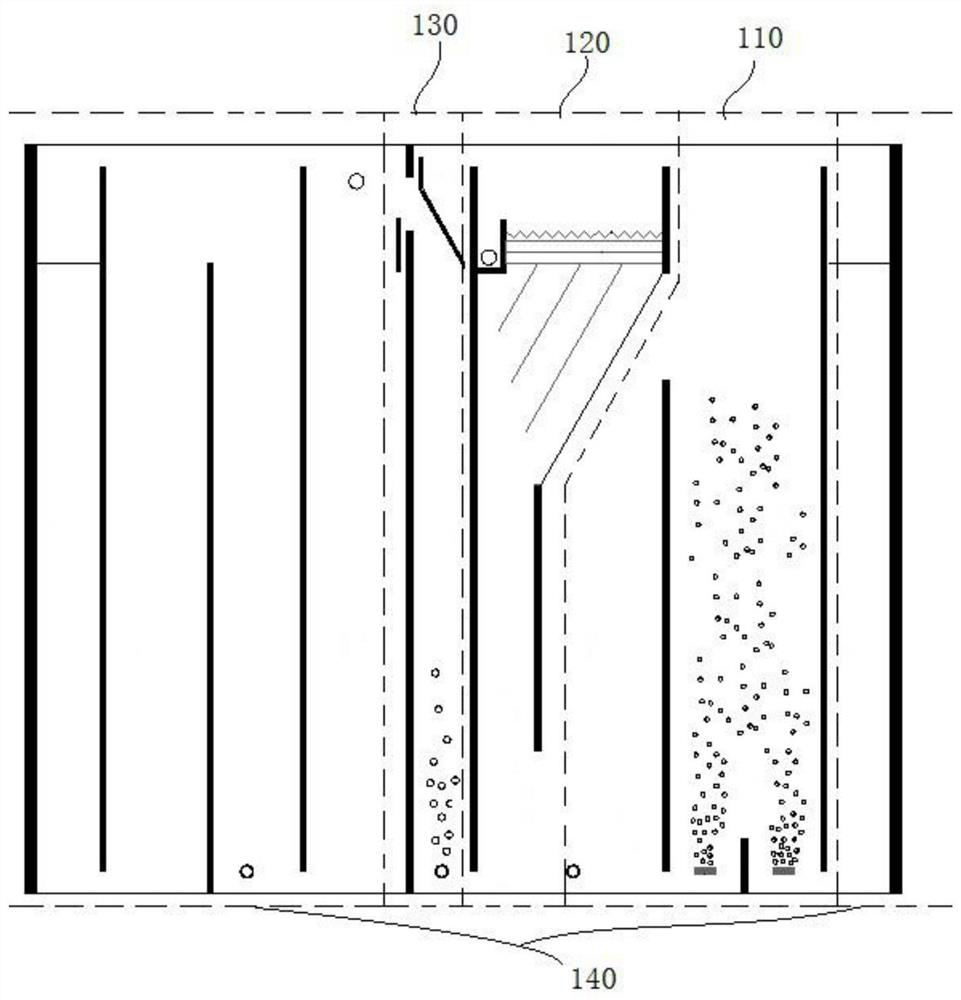

Integrated inclined plate oxidation ditch sewage treatment device

ActiveCN112875849AReduce configurationLow costTreatment with aerobic and anaerobic processesSustainable biological treatmentFluidized bedWater treatment

The invention discloses an integrated inclined plate oxidation ditch sewage treatment device which comprises an aerobic unit, an inclined plate precipitation unit, a steam stripping unit and an anoxic unit based on region division of a reciprocating type circulating water channel in an upper / lower flow direction, the aerobic unit comprises an aeration circulating fluidized bed up-flow zone, an aeration circulating fluidized bed down-flow zone and a steam lift up-flow zone which are communicated in sequence; a microporous aeration disc is arranged at the bottom in the aeration circulating fluidized bed up-flow area to supply oxygen and push the fluidized bed to circulate; the inclined plate precipitation unit comprises an effluent upflow area; an inclined plate settling zone and an effluent overflow weir are arranged at the top of the effluent upflow zone, so that supernate in the inclined plate settling zone overflows and is discharged; the steam stripping unit comprises a perforated aeration pipe arranged at the bottom of the steam lifting flow area, and a steam stripping reinforcing plate and an adjusting weir plate which are arranged at the junction of the steam lifting flow area and the micro-aerobic flow descending area; and the anoxic unit comprises a first anoxic up-flow zone, a first anoxic down-flow zone, a second anoxic up-flow zone and a second anoxic down-flow zone which are communicated in sequence.

Owner:清华苏州环境创新研究院 +1

Application of traditional Chinese medicine composition to preparation of medicine for regulating intestinal flora balance

InactiveCN108310351AReduce diarrheaSignificant improvementDigestive systemAntinoxious agentsRadix AconitiGut flora

The invention provides application of a traditional Chinese medicine composition prepared from processed radix aconiti carmichaeli, rhizoma zingiberis, radix glycyrrhizae preparata, poria cocos, bighead atractylodes rhizome, radix ginseng rubra, white paeony root, fructus corni, fructus amomi, herba ephedrae, herba asari, radix angelicae sinensis, rhizoma cimicifugae and radix puerariae to preparation of medicine for regulating intestinal flora balance. The invention further provides application of traditional Chinese medicine extract, which is prepared by decocting and fermenting the traditional Chinese medicine composition prepared from the processed radix aconiti carmichaeli, the rhizoma zingiberis, the radix glycyrrhizae preparata, the poria cocos, the bighead atractylodes rhizome, theradix ginseng rubra, the white paeony root, the fructus corni, the fructus amomi, the herba ephedrae, the herba asari, the radix angelicae sinensis, the rhizoma cimicifugae and the radix puerariae, to the preparation of the medicine for regulating the intestinal flora balance.

Owner:阮忠宁

Automobile battery liquid cooling heat dissipation device based on steam cavity heat dissipation technology

An automobile battery liquid cooling heat dissipation device based on a steam cavity heat dissipation technology comprises a heat conduction steam cavity, a liquid cooling channel and a plurality of power batteries, the liquid cooling channel is of a return bending structure, the heat conduction steam cavity tightly attached to the liquid cooling channel is arranged between bending areas of the liquid cooling channel, a plurality of battery mounting grooves are formed in the heat conduction steam cavity, and a power battery is fixed in each battery mounting groove. According to the design, the steam cavity structure is adopted for heat transfer, the steam cavity structure is good in heat dissipation performance, flexible, simple and convenient, local heat generated by the battery pack module can be rapidly taken away, high effective heat dissipation of an electric vehicle battery under the high heat flux density is achieved, meanwhile, uniform temperature distribution is kept in the running process, and the service life and the cruising ability of the automobile battery are prolonged.

Owner:WUHAN UNIV OF TECH

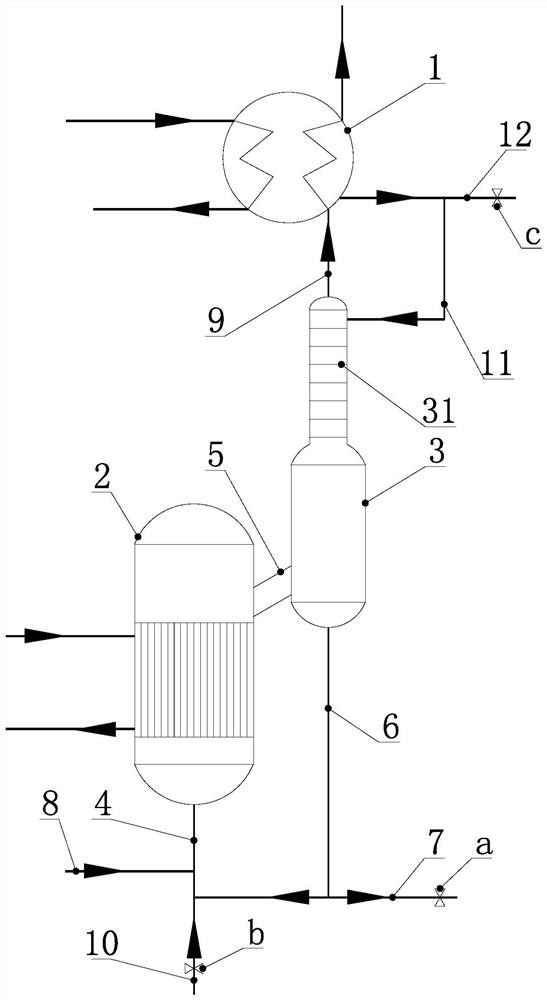

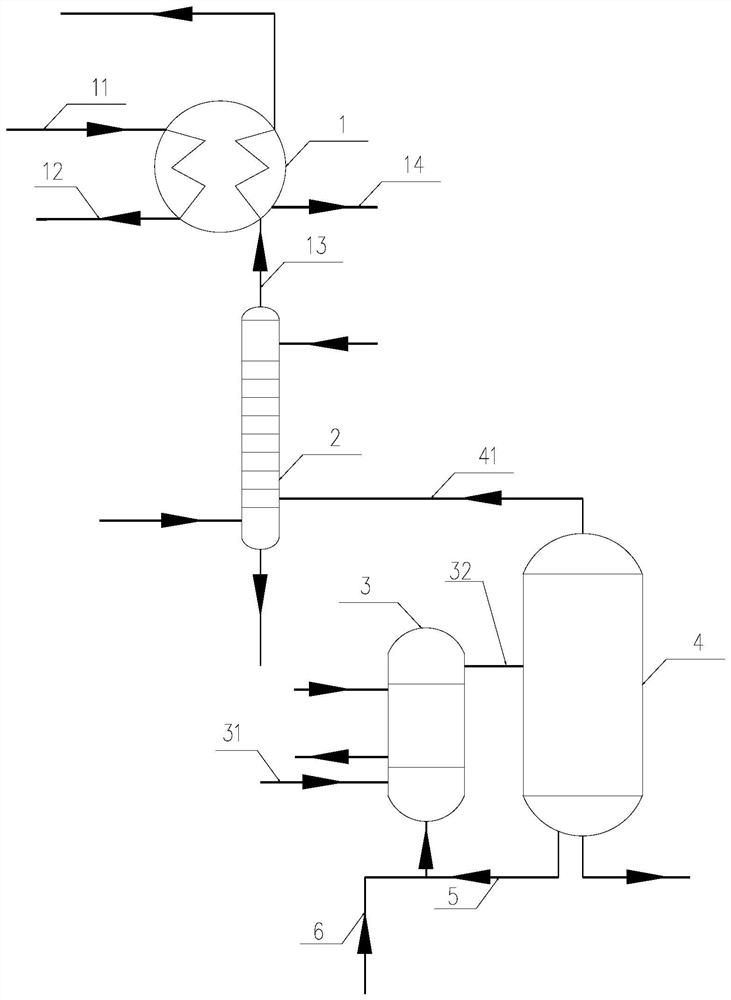

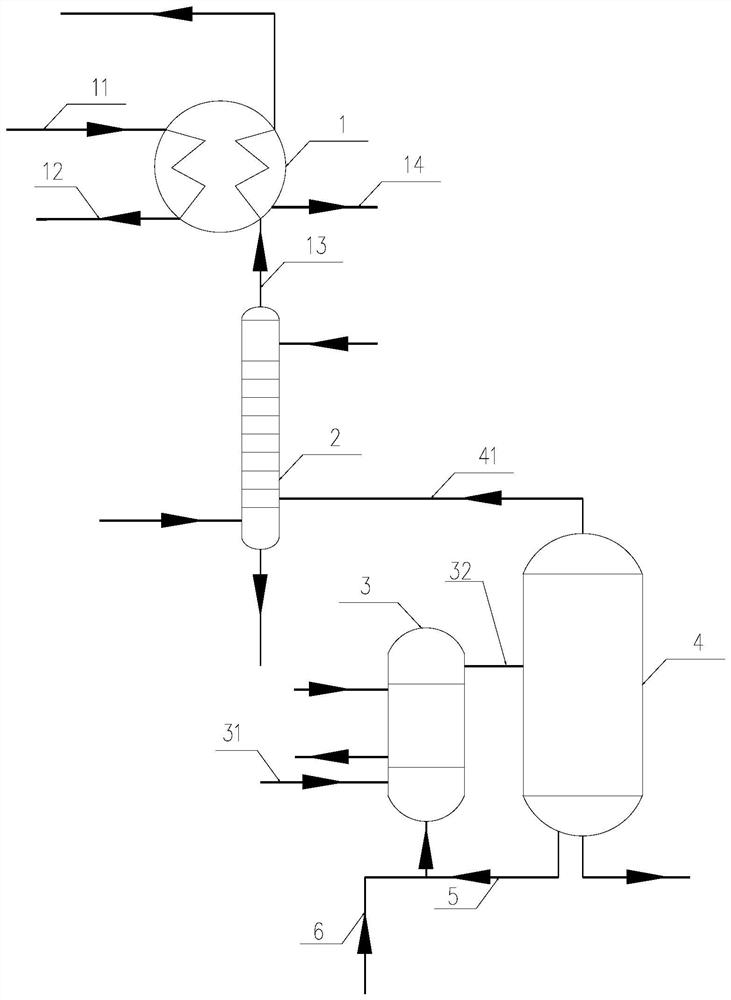

Refined salt continuous concentration system for polyamide

ActiveCN111821714AMeet needsImprove utilization efficiencyEnergy recuperation in distillationSteam distillationThermodynamicsPolyamide

The invention discloses a refined salt continuous concentration system for polyamide. The system comprises a refined salt preheater and a refined salt evaporator, and a refined salt stripping tower, the refined salt stripping tower is positioned below the refined salt preheater and positioned above the refined salt evaporator; a collecting pipe extending downwards is arranged at the bottom of therefined salt evaporator; the lower part of the inner cavity of the refined salt stripping tower is communicated with the upper part of the inner cavity of the refined salt evaporator through a material pipe; the bottom of the refined salt stripping tower is connected with a collecting pipe through a circulating pipe; a concentrated material discharging pipe is further arranged on the circulating pipe, a first valve is arranged to control opening and closing of the circulating pipe, a material outlet of the refined salt preheater is connected with the collecting pipe through a feeding pipe andlocated above the downstream end of the circulating pipe, and a heat medium inlet of the refined salt preheater is connected with the top of the refined salt stripping tower through a steam pipe. Thesystem is simple in structure and convenient to operate, can realize continuous concentration of refined salt for polyamide, reduces the concentration cost of the refined salt, can effectively avoid crystallization and scaling phenomena, and is a guarantee for producing high-quality polyamide.

Owner:华峰集团上海工程有限公司

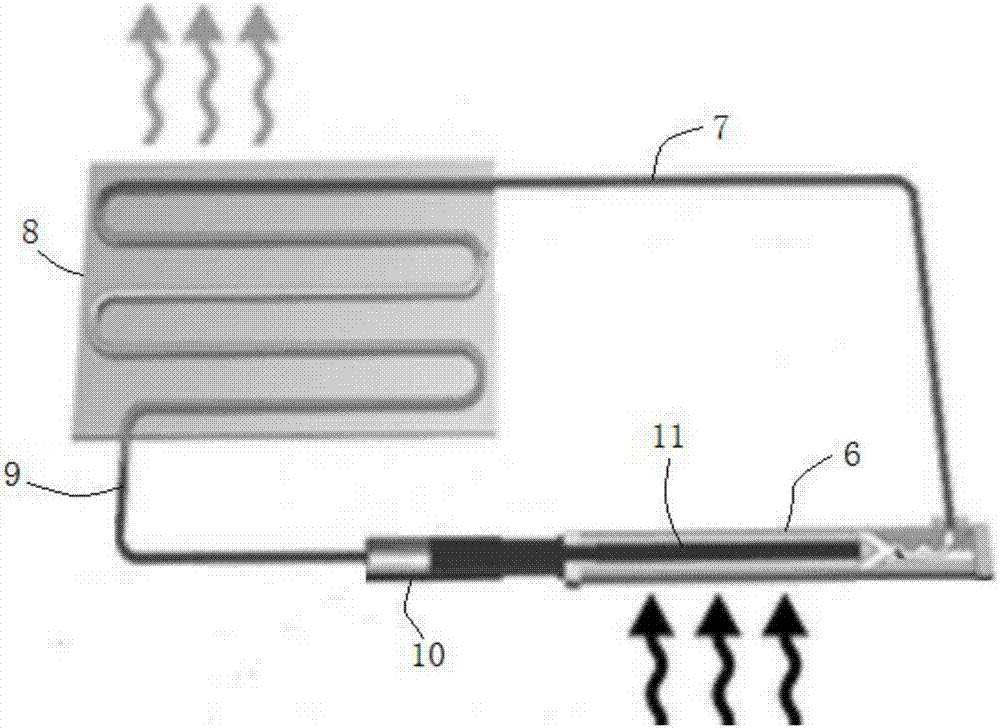

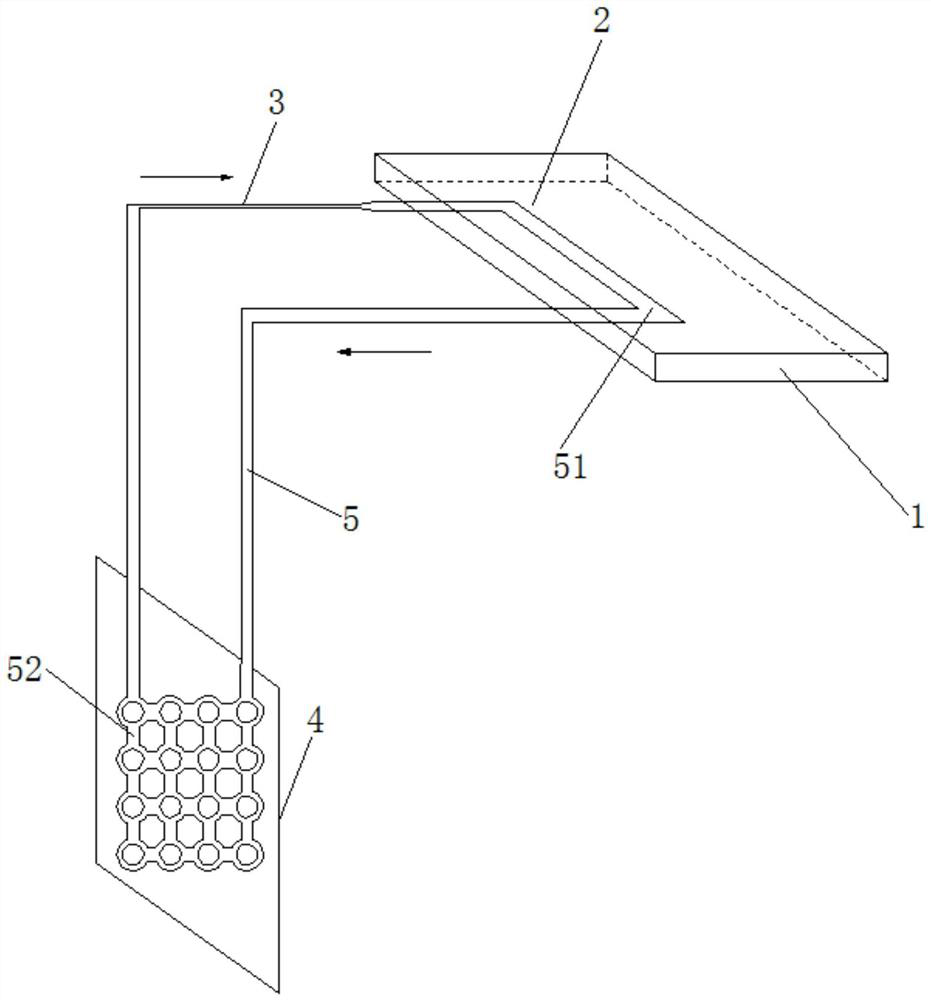

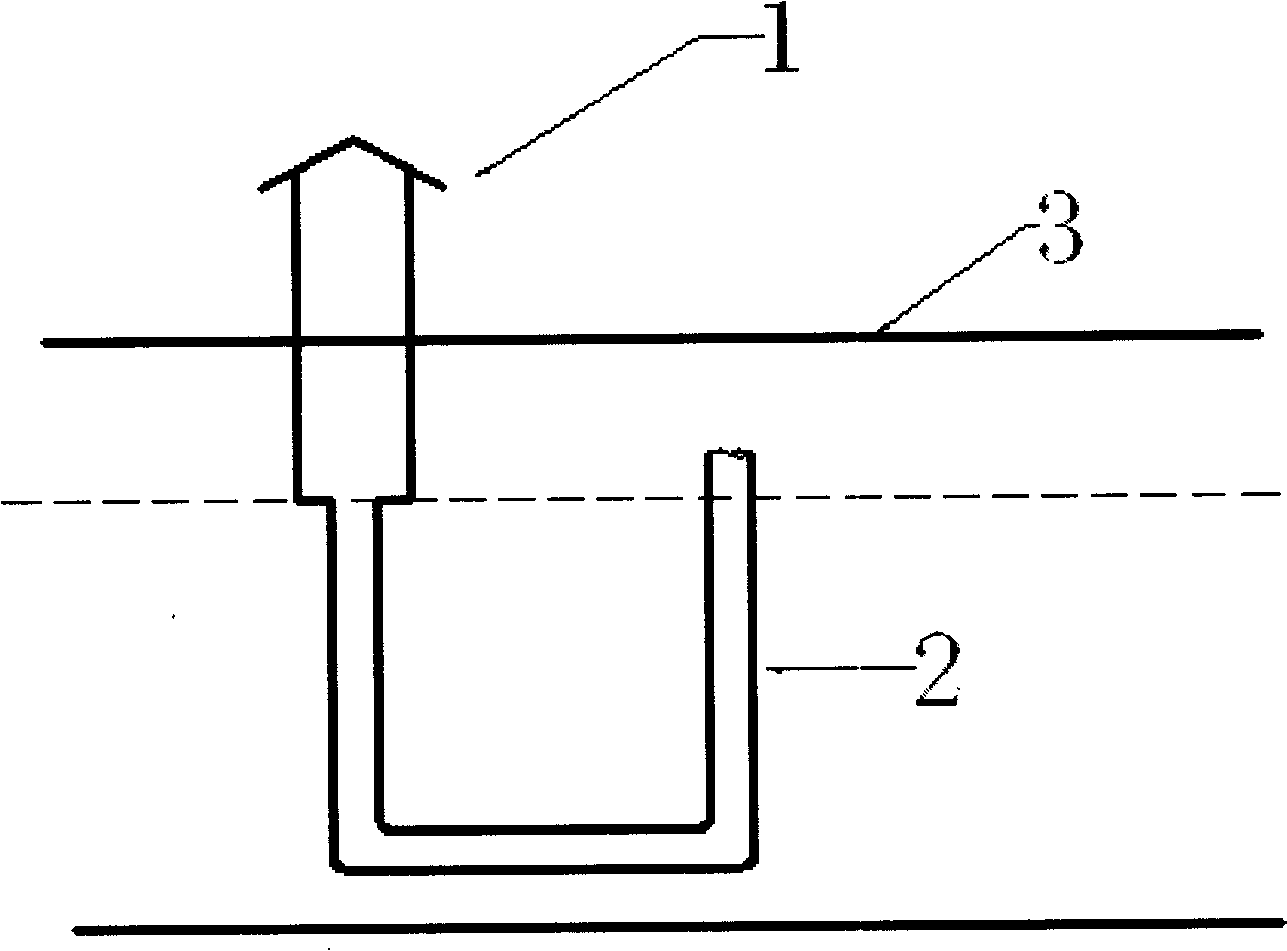

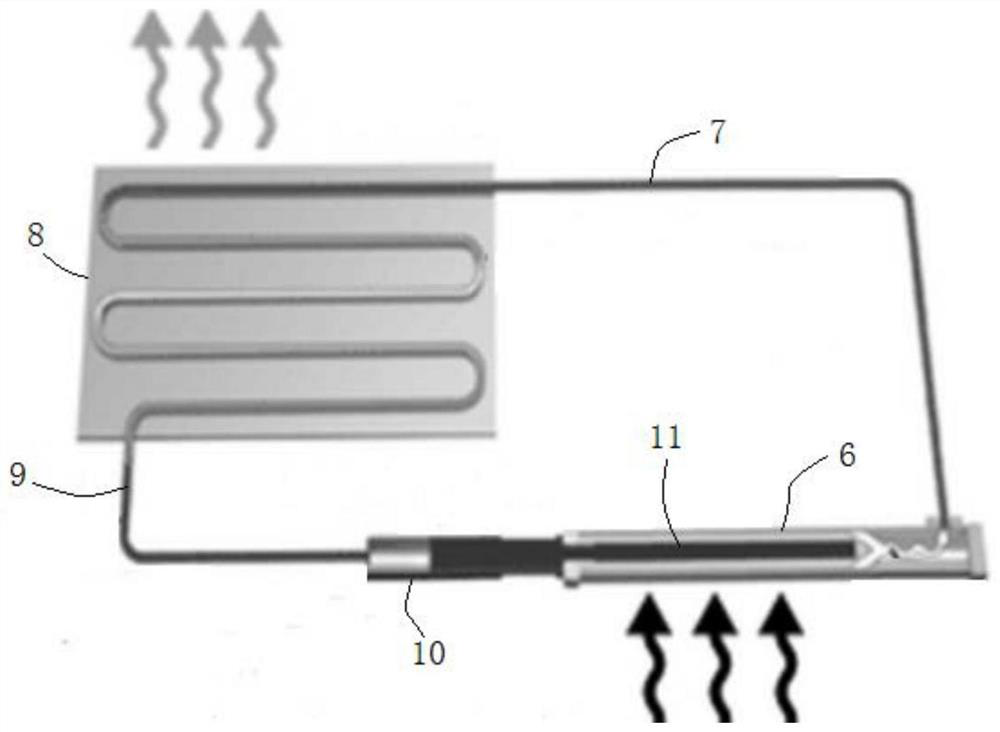

Micro-power cycle balcony wall-mounted solar system

InactiveCN103759426AIncrease cycle powerAvoid restrictionsSolar heat devicesSolar thermal energy generationPower cycleEngineering

The invention discloses a micro-power cycle balcony wall-mounted solar system. The micro-power cycle balcony wall-mounted solar system comprises a control panel, a heat storage water tank, a solar thermal collector and a circulating pump, wherein the solar thermal collector is additionally provided with a photovoltaic cell panel, the circulating pump, the control panel and a power line signal line are integrated to form an integrated power module, the integrated power module is combined with the heat storage water tank, and the integrated power module controls the electric energy obtained by the photovoltaic cell panel through solar irradiation to carry out heat exchange, or utilizes the solar thermal collector to carry out heat exchange or integrates the photovoltaic cell panel and the solar thermal collector through natural selection or artificial selection. According to the micro-power cycle balcony wall-mounted solar system, the circulating pump is added to a circulating pipeline, circulating power is reinforced, sufficiency heat exchange of the system is guaranteed, the performance of the system is more stable, the cost of a forced circulation water heater is largely reduced, the heater is longer in service life, higher in stability and lower in maintenance cost, a connecting pipeline can extend along a wall surface or is buried in the wall and is better combined with a building, and the placement of a water tank and interior decoration are combined perfectly.

Owner:SHANDONG LINUO PARADIGMA

Circulation filter gastroenterology gastric lavage machine

ActiveCN105854109BAccelerated settlementMake sure to fall intoEnemata/irrigatorsMedical devicesGastric lavageDisplay device

The invention discloses a circulating filter type gastric lavage machine for gastroenterology, which comprises a main body of the gastric lavage machine, an operating table, a working box, a filter device, a display, a keyboard, and an indicator light. The filter device is a cycle filter device, including a main pipe and a The vertical deposition pipe is connected with a return pipe between the vertical deposition pipe and the main pipe, and the return pipe is sequentially connected with the main pipe and the vertical deposition pipe, and a filter screen is set to form a circulation loop. Thereby promoting the sedimentation of the eluate. Most of the solid eluate is blocked on the lower side of the main filter to achieve solid-liquid separation for separate detection by the user. In the circulation process, the secondary filter screen can further improve the filtering effect and ensure that the sand falls into the vertical settling pipe.

Owner:郑州优康药业有限公司

Chip heat exchanger and inverter air conditioner

ActiveCN110160383BIncrease heat absorptionImprove the technical shortcomings that cannot be lower than the evaporation sectionMechanical apparatusDigital data processing detailsAir volumeCapillary Tubing

The invention discloses a chip heat exchanger and an inverter air conditioner, which belong to the technical field of chip heat dissipation. The chip heat exchanger includes a heat pipe, and further includes: an expansion plate condenser and a capillary tube; the evaporation section of the heat pipe is arranged in the air conditioner The condensing section of the heat pipe is connected to the evaporating section through the capillary, and the condensing section is connected to the expansion plate condenser, and the expansion plate condenser is connected to the It is bent and arranged below the plane where the evaporation section is located. In this solution, the expansion plate condenser is bent and arranged below the plane where the evaporating section is located, and coincides with the direction of the fan bracket in the outdoor unit of the air conditioner, which does not block the air volume and wind speed of the fan, and can also promote the cooling of the refrigerant in the expansion plate by means of the air volume Condensation heat dissipation improves heat exchange efficiency, reduces chip operating temperature, and solves the problem of slow and difficult cooling frequency increase due to poor heat dissipation of the chip on the computer board of the inverter air conditioner in the high temperature environment in summer, and the control logic is prone to error reporting.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Engine cleaning method and device

ActiveCN109057965BIncrease cycle powerSolve the technical problem of slow circulation flowMachines/enginesEngine componentsHydraulic pumpMechanics

Owner:北京天元陆兵汽车科技有限公司

Shell-and-tube high-temperature waste heat steam boiler with small circulation ratio of partial jet flow

ActiveCN103982886BImprove uniformityLow flow resistanceChemical industryStationary tubular conduit assembliesJet flowFlue gas

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD +1

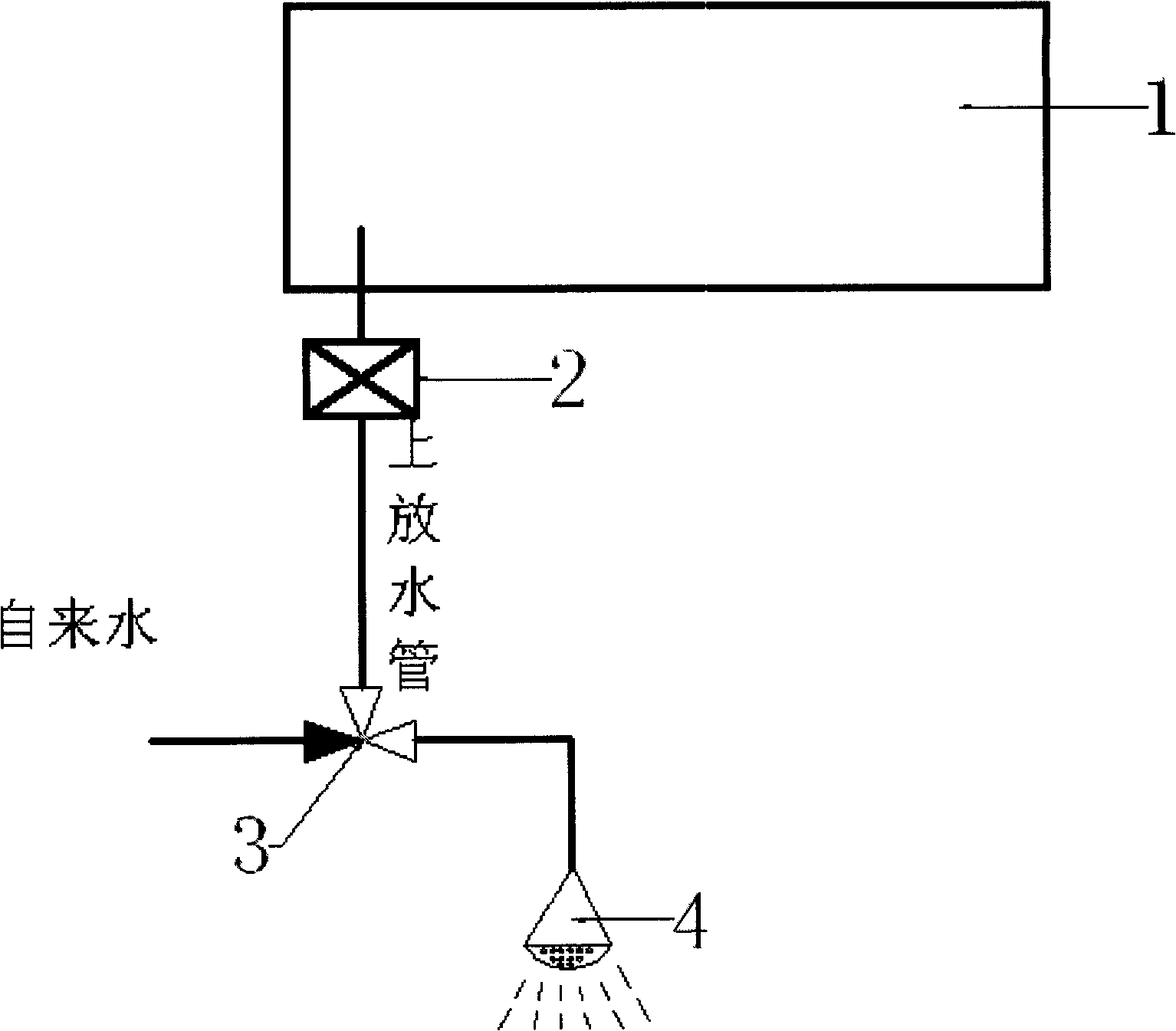

Solid matter self-guiding intermittent exhausting and upper drainage water pipe anti-freezing solar water heater

InactiveCN101285624ASimple control principleEasy to operateSolar heat devicesSpace heating and ventilation detailsSelf guidedWater pipe

By changing the siphonopore space of a vacuum pipe solar hot water heater water tank and the structures of an obturating ring and a dustproof ring, the invention realizes the close packing of the solar water heater vacuum pipe, improves the heat collecting efficiency of the solar water heater, saves the installation space and lowers the construction cost of the vacuum pipe solar water heater. The invention solves the problems that a water release pipe on the solar water heater in northern China is frozen and blocked and the water release is lost when a householder living on a lower floor of a tall building of apartment by adopting a novel water release pipe draining system. By adopting a cold-hot water fluid director inside the vacuum pipe, the invention realizes that naturally circulating ascending water is separated from the descending water inside the vacuum pipe, the hot water is sent to the upper part of a water tank, the cold water is introduced into the lower part of the vacuum pipe, thereby increasing the circulating power, increasing the heat exchange temperature difference between an inner pipe wall of the vacuum pipe and the water and improving the heat absorbing efficiency of the vacuum pipe. The invention reduces the heat dissipation and the vapor and water loss of the atmospheric relief of the solar water heater water tank by adopting the U-shaped pipe upper exhaust steam technique.

Owner:孙庆国 +1

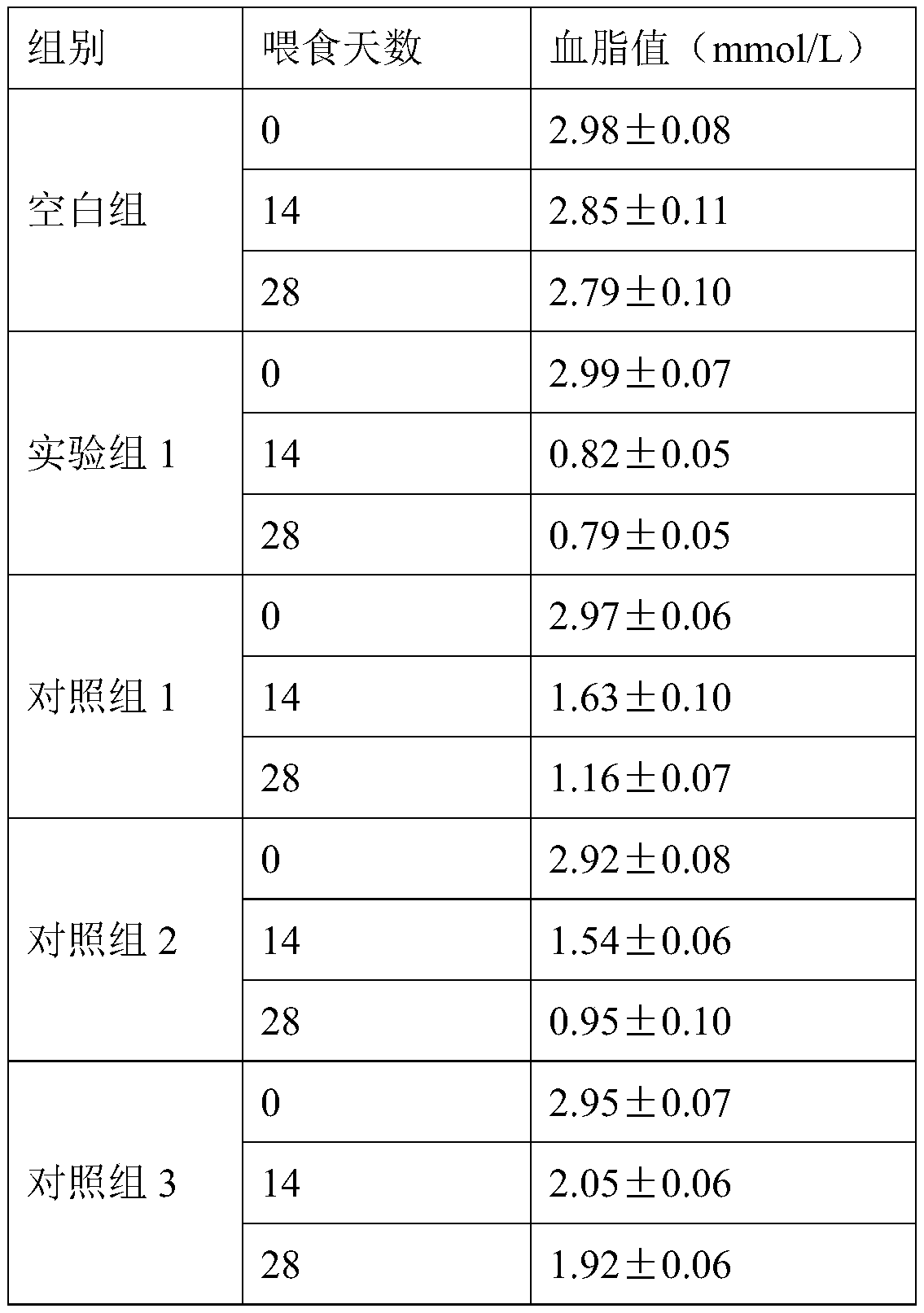

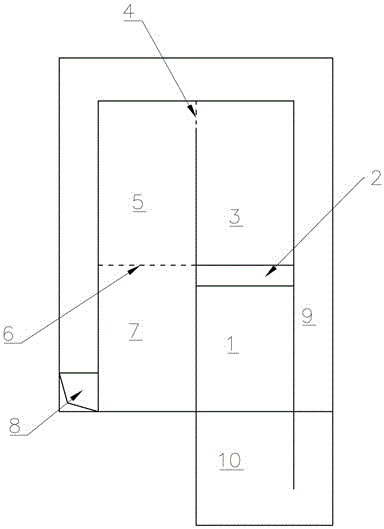

Large-density seawater culture device

InactiveCN105794625ARealize self-circulationIncrease dissolved oxygen content in waterPisciculture and aquariaCultivating equipmentsPlanktonEnvironmental engineering

The invention provides a large-density seawater culture device which is a seawater pond.A main culture unit (3), an omnivore fish unit (5), a pond filter feeding shellfish unit (7), a mud flat filter feeding shellfish unit in a mud flat area (9) and a kelp unit (10) are distributed in the pond in the seawater flow direction.A water and gas mixing device is installed at a water inlet of the main culture unit, and a water inlet of the kelp unit is connected with a mud flat water outlet.Compared with the prior art, various organisms are combined to co-exist in one seawater system, plankton is freely propagated in the system, feed residues, excrement and nutrients such as dissolved N and P are directly digested and absorbed by the cultured organisms or converted by the plankton and then digested and absorbed by the cultured organisms, and thus the seawater system in the culture device is basically purified.Meanwhile, the content of water dissolved oxygen in the water system of the culture device is increased by mixing water and gas.Thus, self-circulation of the water system in the culture device can be achieved, and no solid pollutant is discharged.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

A continuous concentration system for refined salt for polyamide

ActiveCN111821714BMeet needsImprove utilization efficiencyEnergy recuperation in distillationSteam distillationPolyamideProcess engineering

A refined salt continuous concentration system for polyamide, comprising a refined salt preheater, a refined salt evaporator, and a refined salt stripper, the refined salt stripper is located below the refined salt preheater and above the refined salt evaporator, and the refined salt evaporator A collecting pipe extending downward is provided at the bottom of the bottom, the inner space lower part of the refined salt stripper is communicated with the inner space upper part of the refined salt evaporator through the material pipe, and the bottom of the refined salt stripper is connected with the collecting pipe through a circulation pipe, the The circulation pipe is also provided with a concentrated material discharge pipe, and a first valve is set to control the opening and closing. The material outlet of the refined salt preheater is connected with the collection pipe through the feed pipe, and is located above the downstream end of the circulation pipe. The heat medium inlet of the heater is connected with the top of the refined salt stripping tower through a steam pipe. The invention has simple structure and convenient operation, can realize continuous concentration of refined salt for polyamide, reduces the cost of concentration of refined salt, can effectively avoid crystallization and fouling, and is the guarantee for producing high-quality polyamide.

Owner:华峰集团上海工程有限公司

Chip heat exchanger and inverter air conditioner

ActiveCN110160384BIncrease heat absorptionImprove the technical shortcomings that cannot be lower than the evaporation sectionDigital data processing detailsIndirect heat exchangersCapillary TubingRefrigerant

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

A kind of continuous reaction method of polyamide

ActiveCN111647154BReduce reaction energy consumptionEfficient use ofChemical/physical/physico-chemical processesPolymer sciencePolyamide

The invention relates to a continuous reaction process of polyamide. The continuous reaction by using a reaction device comprises the following steps: 1) introducing a heating medium into a shell passof a heating system; 2) enabling the polymerization raw material to pass through a preheating system and a light component removal system, discharging the polymerization raw material into a tube passof a heating system, heating the raw material to 200-250 DEG C until the water content in the polymerization raw material is reduced to be less than or equal to 20%, and carrying out a pre-polymerization reaction; 3) discharging a material obtained by prepolymerization into a reaction system, and carrying out a reaction after prepolymerization to generate process steam; 4) feeding the process steam into a light component removal system, heating the polymerization raw material passing through the light component removal system to 180-240 DEG C and feeding the raw material into a shell pass ofa preheating system, and heating the polymerization raw material passing through the preheating system to 180-230 DEG C; 5) condensing the process steam in the shell pass of the preheating system to serve as reflux liquid, and 6) continuously discharging when the viscosity is 150-300 cp to obtain a polyamide prepolymerization product. The reaction process is simple in process and low in synthesiscost, can effectively guarantee the quality stability of polyamide, and is a guarantee for producing high-end polyamide.

Owner:华峰集团上海工程有限公司

A variable aperture capillary core applied to a loop heat pipe system and its processing method

ActiveCN107462097BQuickly meet suction power requirementsLow flow resistanceIndirect heat exchangersFiberPorous medium

The invention discloses a variable aperture capillary core applied to a loop heat pipe system and a processing method thereof, belonging to the field of porous medium phase change heat transfer and flow. The capillary core of the invention selects powder particles with a higher melting point and fibers with a lower melting point to be mixed and sintered, and the temperature is controlled so that the fibers are completely sintered to form a capillary core skeleton. Aperture; apply the capillary core to the loop heat pipe, automatically adjust the powder particle diameter under different heat loads, adjust the suction force of the capillary core, prevent the phase change interface from going deep into the capillary core, and reduce the heat transfer heat when the capillary core is working At the same time, it can reduce the flow resistance, thereby improving the operating performance of the loop heat pipe.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Continuous reaction process of polyamide

ActiveCN111647154AReduce reaction energy consumptionImprove process steam utilizationChemical/physical/physico-chemical processesChemistryPolyamide

The invention relates to a continuous reaction process of polyamide. The continuous reaction by using a reaction device comprises the following steps: 1) introducing a heating medium into a shell passof a heating system; 2) enabling the polymerization raw material to pass through a preheating system and a light component removal system, discharging the polymerization raw material into a tube passof a heating system, heating the raw material to 200-250 DEG C until the water content in the polymerization raw material is reduced to be less than or equal to 20%, and carrying out a pre-polymerization reaction; 3) discharging a material obtained by prepolymerization into a reaction system, and carrying out a reaction after prepolymerization to generate process steam; 4) feeding the process steam into a light component removal system, heating the polymerization raw material passing through the light component removal system to 180-240 DEG C and feeding the raw material into a shell pass ofa preheating system, and heating the polymerization raw material passing through the preheating system to 180-230 DEG C; 5) condensing the process steam in the shell pass of the preheating system to serve as reflux liquid, and 6) continuously discharging when the viscosity is 150-300 cp to obtain a polyamide prepolymerization product. The reaction process is simple in process and low in synthesiscost, can effectively guarantee the quality stability of polyamide, and is a guarantee for producing high-end polyamide.

Owner:华峰集团上海工程有限公司

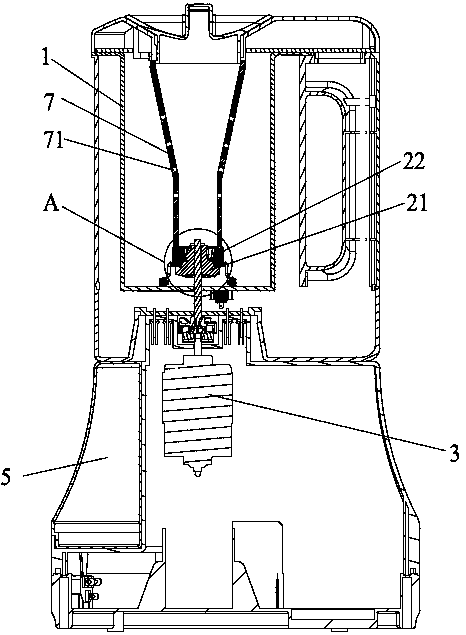

Circular grinding device

ActiveCN102334913BComplete dischargeIncrease cycle powerBeverage vesselsMilk substitutesDrive shaftElectric machinery

The present invention relates to the technical field of soybean milk machine, in particular to a circulating grinding device, which includes a motor, a moving grinding wheel and a static grinding wheel capable of relative rotation, the moving grinding wheel is connected to the motor through a drive shaft, and there is a rotation gap between the moving grinding wheel and the static grinding wheel , the top of the static grinding wheel is provided with a hopper, the hopper is provided with a flow hole, the moving grinding wheel is in sliding connection with the drive shaft, and several blades are provided at the bottom of the moving grinding wheel. The present invention greatly improves the grinding efficiency through the design of the hopper with flow holes combined with the bottom blade of the movable grinding wheel, and the movable grinding wheel that can slide relative to the drive shaft makes the circulating grinding device of the present invention not easy to jam materials and grinds fully.

Owner:MIDEA GRP CO LTD

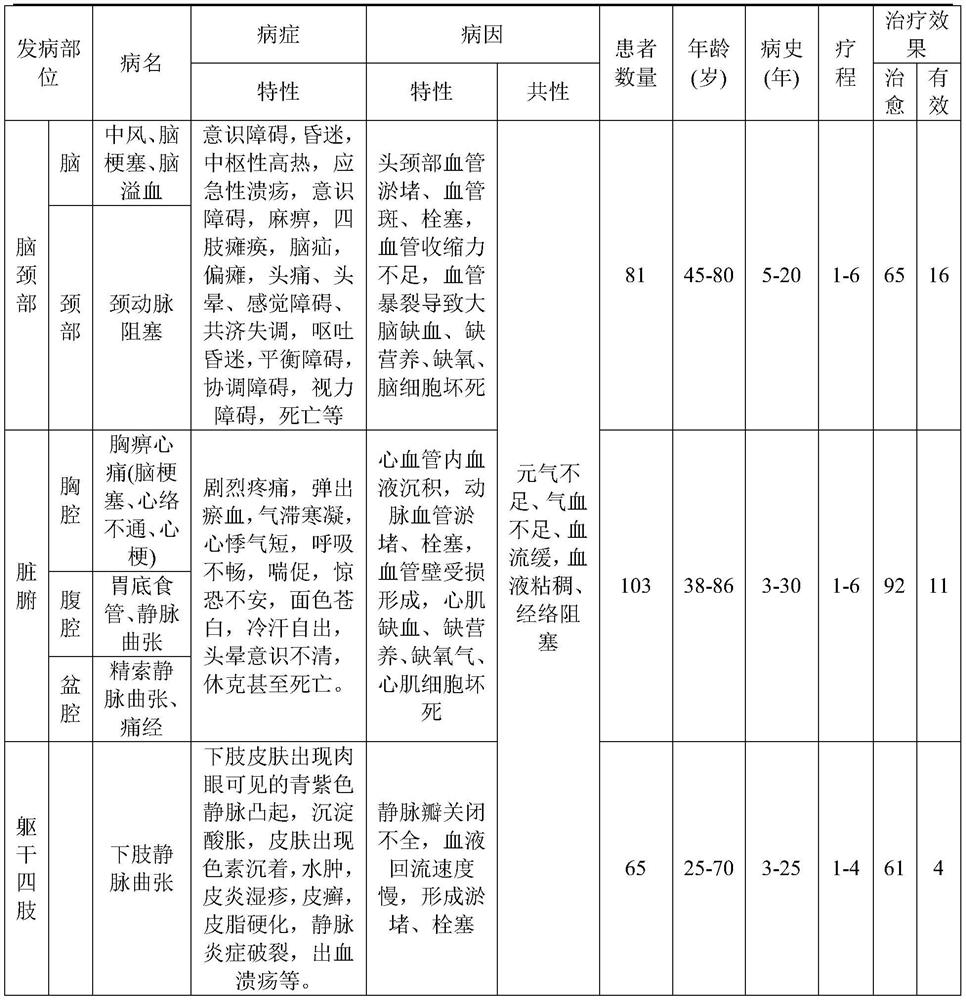

Brain and heart vessel dredging oral liquid

InactiveCN111658749AEliminate resistanceReduce depositionDispersion deliveryMammal material medical ingredientsDiseaseCerebrovascular disorder

The invention discloses a brain and heart vessel dredging oral liquid. The brain and heart vessel dredging oral liquid is prepared by mixing a component A for securing primordial qi by warming middlewarmer and strengthening Ying Wei, a component B for dreging and activating the channels and collaterals, promoting qi circulation and activating blood circulation, a component C for treating blood stasis in brain, a component D used for treating blood stasis in internal organs, a component E for treating blood stasis in body orifices, a component F for calming the liver, calming the nerves, reducing internal heat and arresting convulsion and a component G for reducing blood viscosity and softening blood vessels according to a certain volume ratio. The brain and heart vessel dredging oral liquid disclosed by the invention can promote blood circulation to remove blood stasis, remove thrombus, remove blood vessel plaques and reduce resistance of blood circulation. Waste in the body is discharged while fat is reduced, and blood viscosity is reduced, so that the purpose of treating cardiovascular and cerebrovascular diseases is achieved. The oral liquid is a pure traditional Chinese medicine preparation, does not casue drug dependence, does not have toxic or side effect, and has a good curative effect.

Owner:赵升瑞

A continuous concentration process of refined salt for polyamide

ActiveCN111821715BMeet needsReduce consumptionEnergy recuperation in distillationSteam distillationPhysical chemistryPolyamide

Owner:华峰集团上海工程有限公司

Continuous concentration process of refined salt for polyamide

ActiveCN111821715AMeet needsReduce consumptionEnergy recuperation in distillationSteam distillationThermodynamicsPolyamide

The invention discloses a continuous concentration process of refined salt for polyamide. An adopted concentration system comprises a refined salt preheater, a refined salt evaporator and a refined salt stripping tower, the refined salt stripping tower is positioned below the refined salt preheater and positioned above the refined salt evaporator; the concentration process is as follows: preheating the refined salt solution by a refined salt preheater; feeding into the refined salt evaporator for evaporation through a feeding pipe and a collecting pipe; obtaining vaporous materials, and feeding into the refined salt stripping tower through a material pipe, wherein macromolecular components are intercepted, micromolecular components and water vapor enter the refined salt preheater through asteam pipe, the macromolecular components pass through a circulating pipe, part of the macromolecular components return to the refined salt evaporator under the action of gravity to form circulation,part of the macromolecular components are continuously discharged through a concentrated material discharging pipe, concentrated refined salt is obtained, and the solid content ranges from 60 wt% to90 wt%. The process is simple in process and convenient to operate, is used for continuously concentrating the salt solution for polyamide to obtain refined salt, is low in refined salt concentrationcost, can effectively avoid the phenomena of crystallization and scaling, and is a guarantee for producing high-quality polyamide.

Owner:华峰集团上海工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com