Efficient circulating and filtering device for chemical experiments

A circulating filtration and chemical experiment technology, applied in the direction of filtration circuit, filtration separation, membrane filter, etc., can solve the problems of poor filtration effect and low efficiency, and achieve the effect of easy entry, promotion of solid precipitation, and promotion of water circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

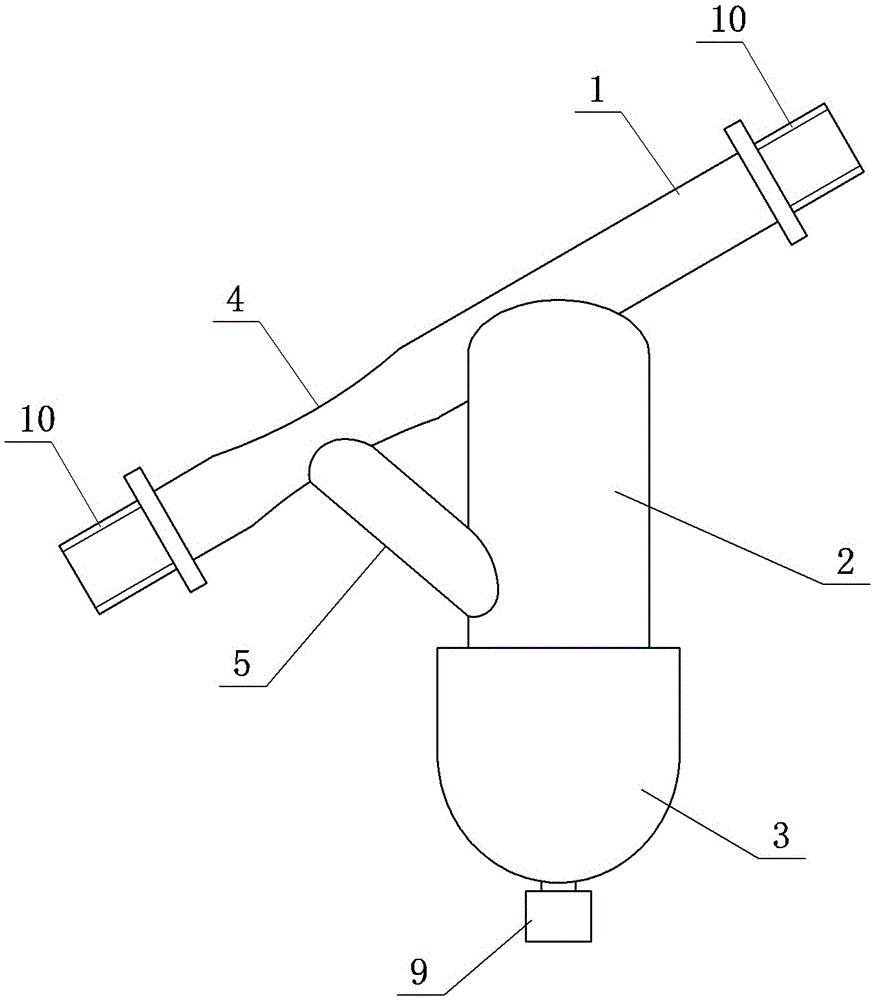

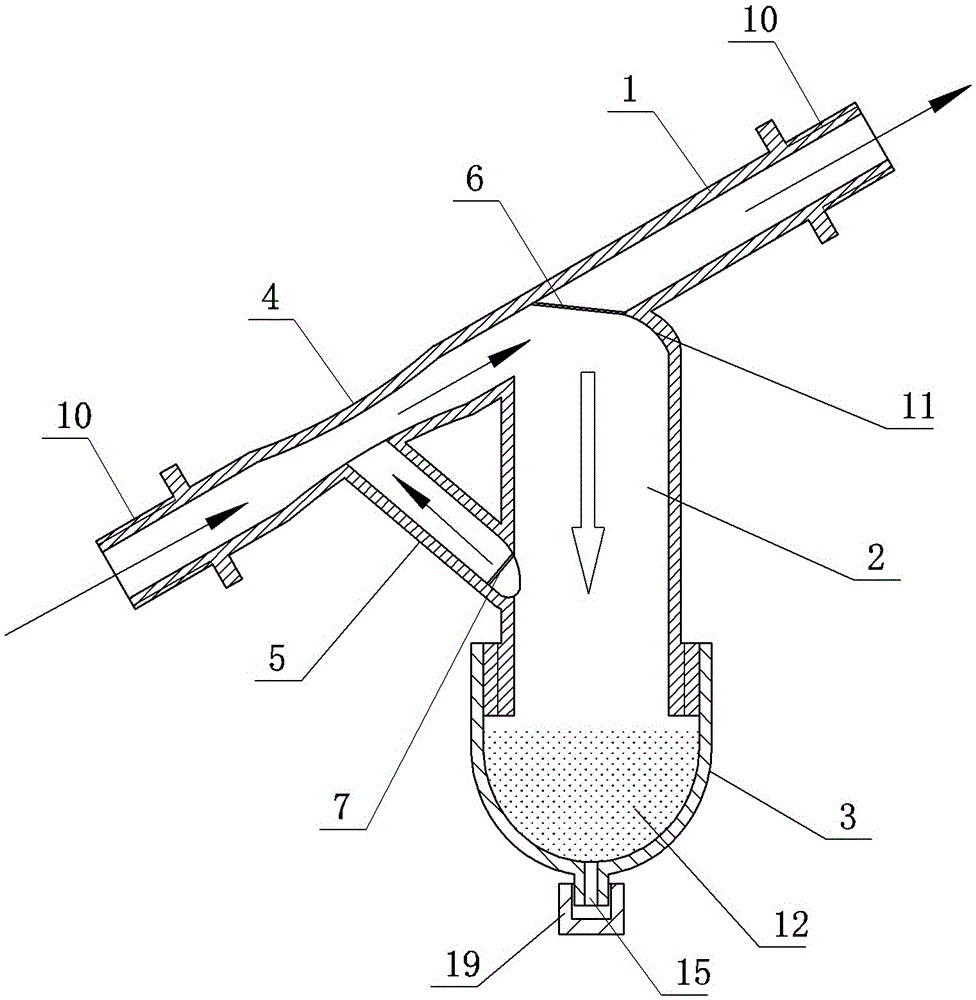

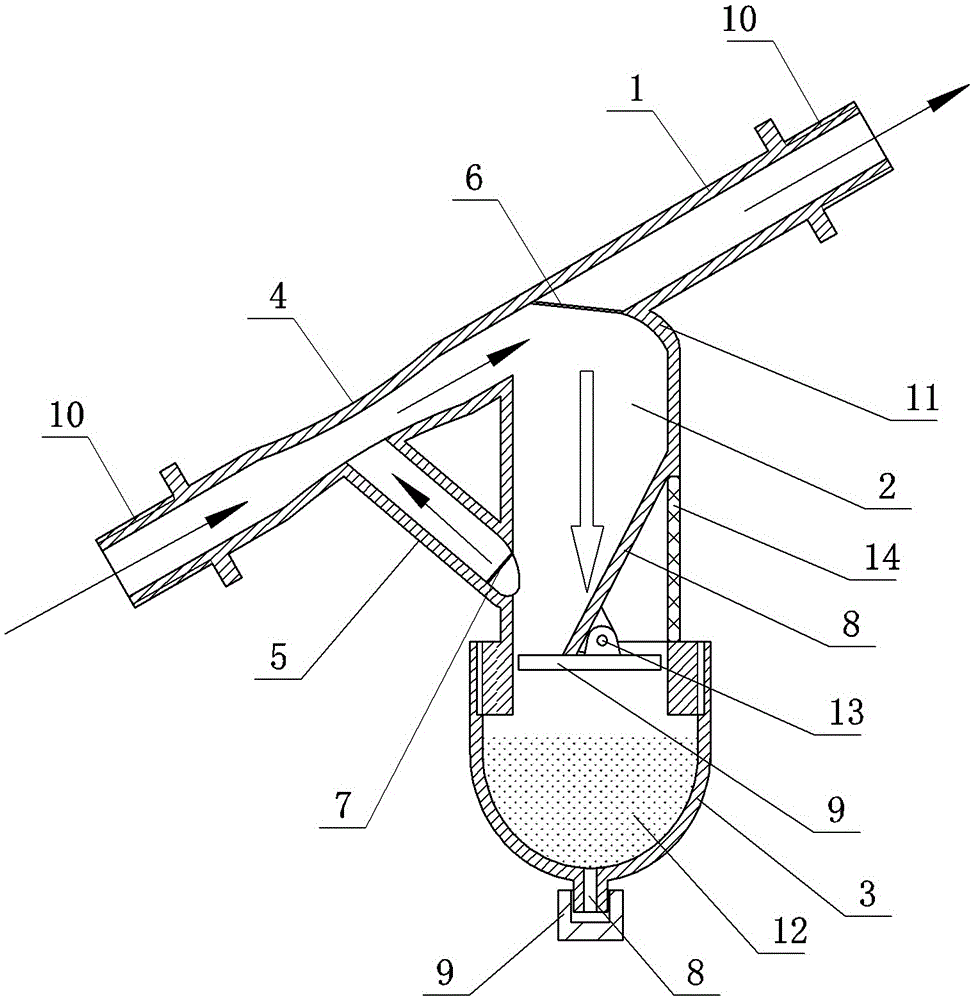

[0014] Embodiment 1: the first kind of high-efficiency circulation filter device for chemical experiment see figure 1 and figure 2 , the main pipe 1 is obliquely connected with the vertical sedimentation pipe 2 and keeps the vertical sedimentation pipe 2 vertically downward, and the water inlet of the main pipe 1 is lower than the water outlet, and the communication port 1 is between the main pipe 1 and the vertical sedimentation pipe 2; There is a return pipe 5 connected between the deposition pipe 2 and the main pipe 1, and the communication port 2 is between the return pipe 5 and the main pipe 1, and the communication port 2 is lower than the communication port 1; the communication port is between the return pipe 5 and the vertical deposition pipe 2 three.

[0015] A main filter screen 6 is provided at the downstream position of the communication port 1, and a secondary filter screen 7 is provided at the downstream position of the communication port 3. A material storage...

Embodiment 2

[0017] Embodiment 2: the second kind of high-efficiency circulation filter device for chemical experiment see figure 1 and figure 2 , On the basis of Embodiment 1, the main pipe 1 is located at the position of the communication port 2 and the converging section 4 is set. The purpose of the convergence section 4 is to promote the internal circulation by means of the negative pressure of the water flow of the main pipe 1, and increase the circulation power for the internal circulation.

Embodiment 3

[0018] Embodiment 3: the third kind of high-efficiency circulation filter device for chemical experiment see figure 1 and image 3 , the vertical sedimentation tube is provided with a guide inclined plate 8, the upper end of the guide inclined plate 8 is away from the secondary filter screen but the lower end is close to the secondary filter screen. Subsidence. A self-adjusting flip plate 9 is arranged at the bottom of the downflow port, and the self-adjusting flip plate 9 is hinged to the back of the sloping guide plate 8 through a pin shaft 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com