Integrated inclined plate oxidation ditch sewage treatment device

A sewage treatment device and oxidation ditch technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of low volume load, large floor area, high energy consumption in operation, and achieve Reduce the cost of pipeline installation, reduce the footprint of the device, and increase the effect of cycle power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

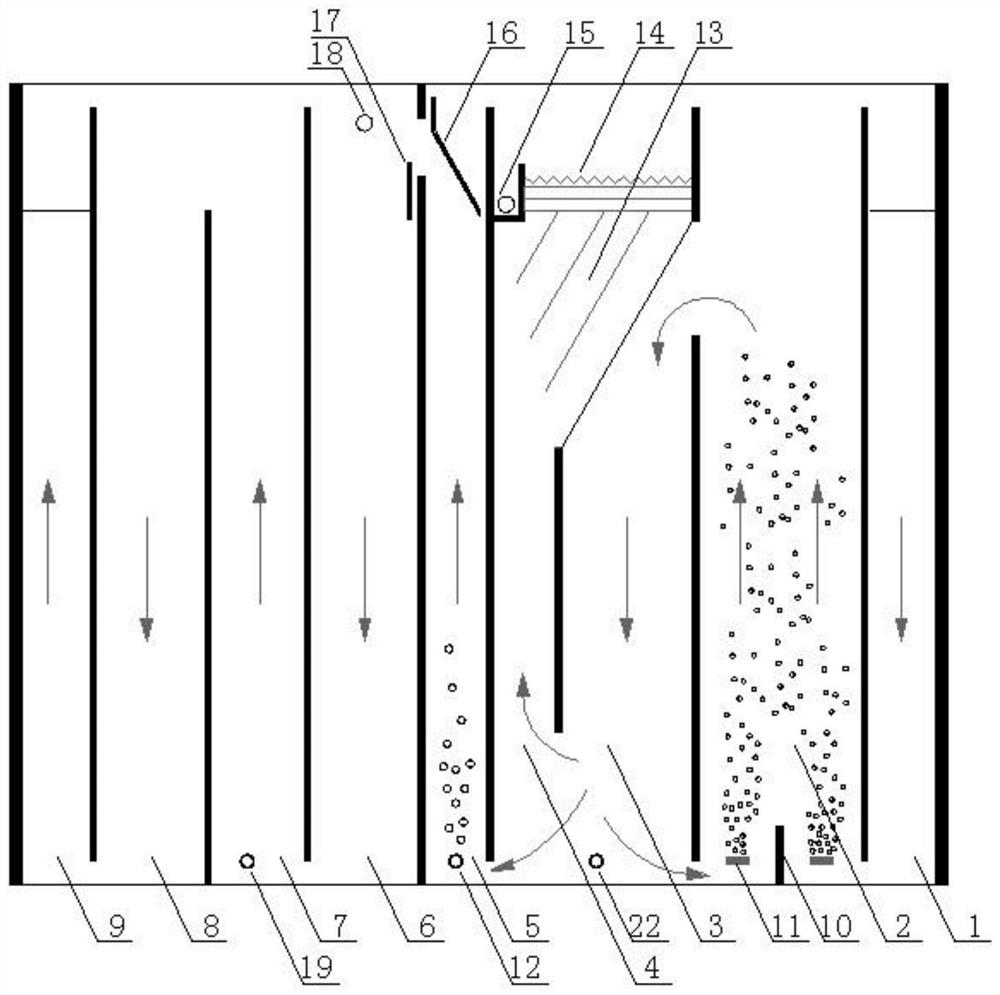

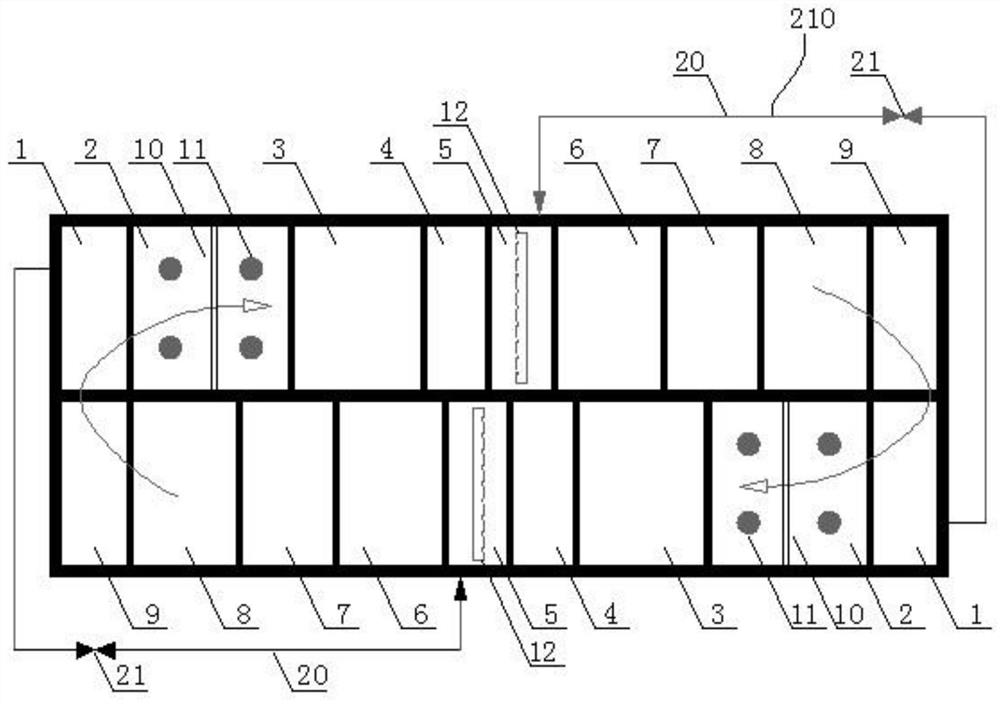

[0033] Such as figure 1 As shown, the plane of the integrated sloping plate oxidation ditch sewage treatment device is a circular structure, and the area of the reciprocating circulating waterway based on the up / down flow direction is divided into: aerobic zone, sloping plate sedimentation zone, stripping zone, micro-oxygen zone, hypoxic zone.

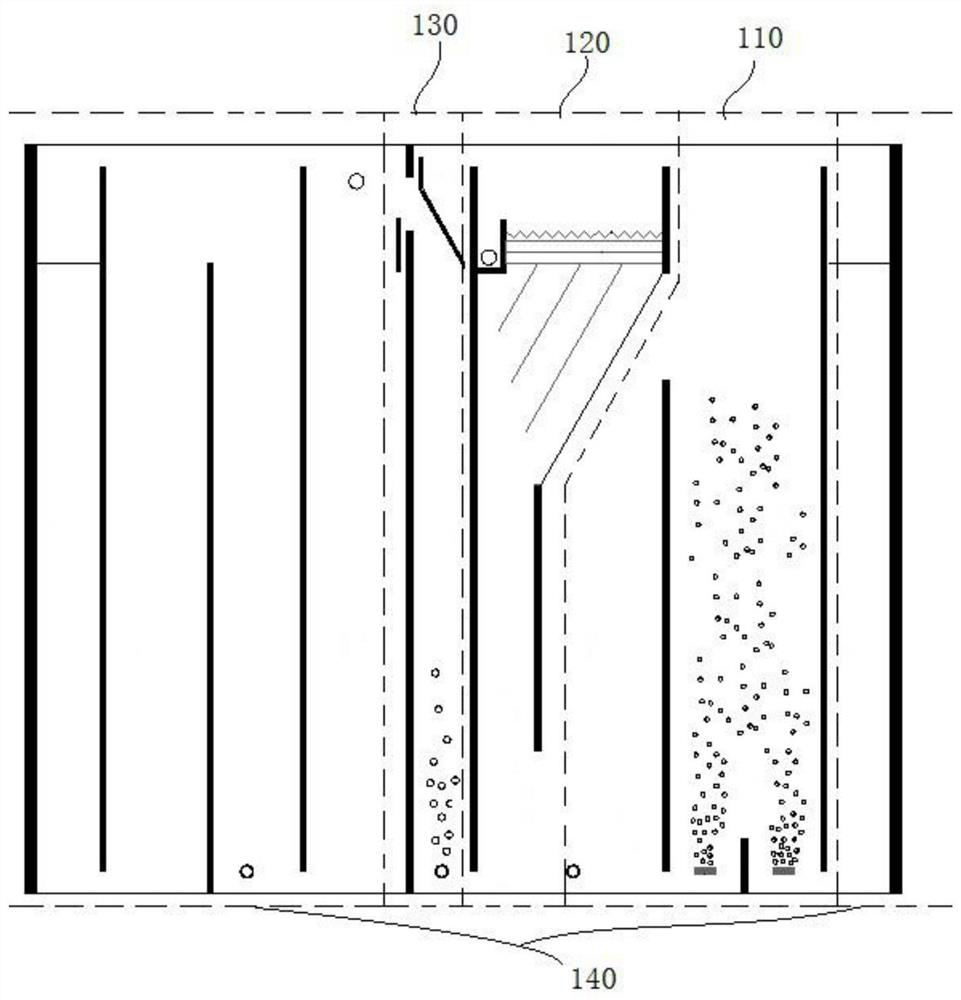

[0034] Such as figure 2 As shown, the plane of the integrated sloping plate oxidation ditch sewage treatment device is a ring structure, and the plane layout is center-point symmetrical. Among them, it specifically includes: aerobic unit 110 , inclined plate sedimentation unit 120 , stripping unit 130 , anoxic unit 140 and anoxic internal circulation unit 210 .

[0035] The aerobic unit 110 is composed of a microporous aeration pan 11 , an aeration circulating fluidized bed upflow zone 2 , an aeration circulating fluidized bed downflow zone 3 and a steam upflow zone 5 .

[0036] The inclined plate sedimentation unit 120 is compos...

Embodiment 2

[0042] Such as figure 1 As shown, the upflow zone 2 of the aerated circulating fluidized bed and the downflow zone 3 of the aerated circulating fluidized bed in the aerobic unit 110 are kept in a circulating fluidized state under the aeration effect of the microporous aeration pan 11. The circulating fluidized state can perform good mixing and agitation on the bottom area of the inclined plate sedimentation unit 120 to prevent sludge deposition. At the same time, the circulating fluidized bed can increase the relative flow velocity of solid and liquid, and improve the mass transfer rate.

[0043] The sloping plate sedimentation unit 120 is provided with a water upflow zone 4, which has a buffering effect and can effectively reduce the disturbance caused by the downflow zone 3 of the aerated circulating fluidized bed to the sloping plate settling zone 13, ensuring that the sloping plate settling zone 13 Good mud-water separation effect.

[0044] The slant plates in the slan...

Embodiment 3

[0052] Wastewater enters the integrated inclined plate oxidation ditch sewage treatment device through the first water inlet 18 or the second water inlet 19, and passes through the first anoxic upflow zone 7, the first anoxic downflow zone 8, the second anoxic downflow zone along the circulation direction of the oxidation ditch. The anoxic upflow zone 9 and the second anoxic downflow zone 1 enter the aerated circulating fluidized bed upflow zone 2 of the aerobic unit 110 .

[0053] The ammonia nitrogen in the wastewater undergoes nitrification reaction in the aerobic unit 110 to generate nitrate nitrogen, and at the same time, some organic pollutants are oxidized and decomposed. Most of the mixed solution flows back to the upflow zone 2 of the aerated circulating fluidized bed through the downflow zone 3 of the aerated circulating fluidized bed to participate in the fluidized bed circulation process, and a part of the mixed solution participates in the oxidation ditch under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com