Solid matter self-guiding intermittent exhausting and upper drainage water pipe anti-freezing solar water heater

A technology for solar water heaters and water discharge pipes, which is applied to solar thermal power generation, solar thermal devices, lighting and heating equipment, etc., can solve the problems affecting the annual use time and sales volume of vacuum tube solar water heaters, and achieve water discharge loss, simple operation, Effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

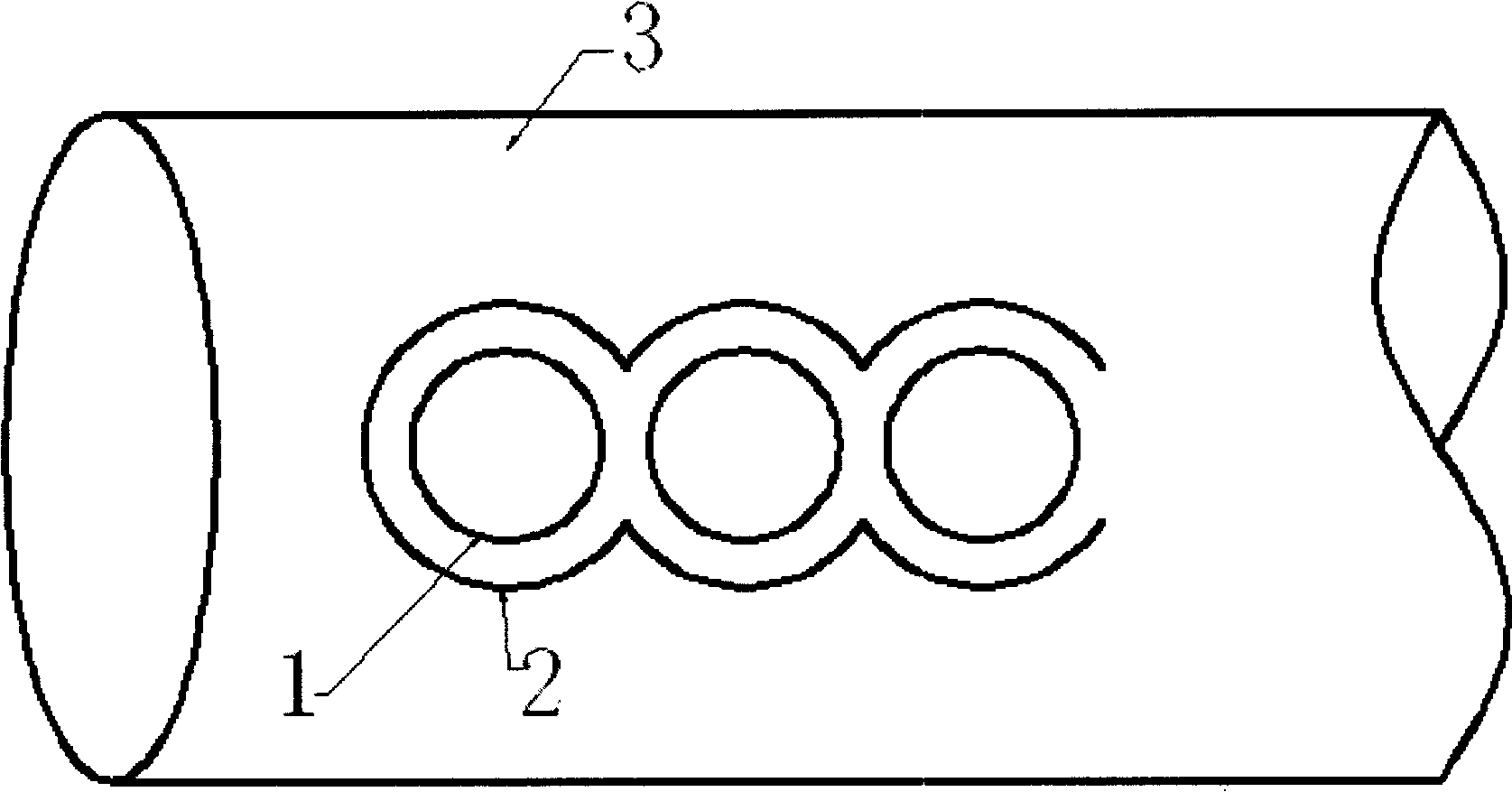

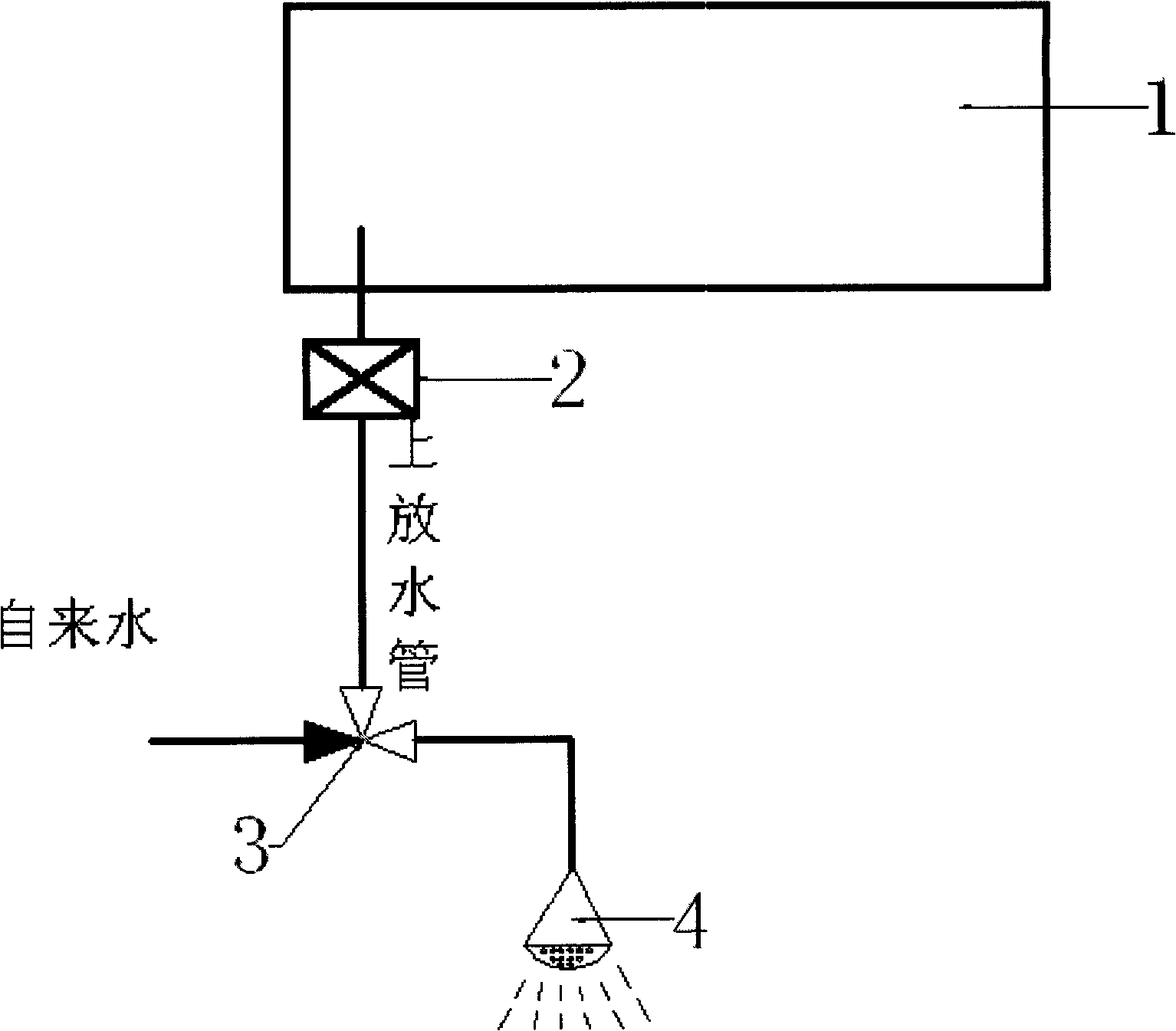

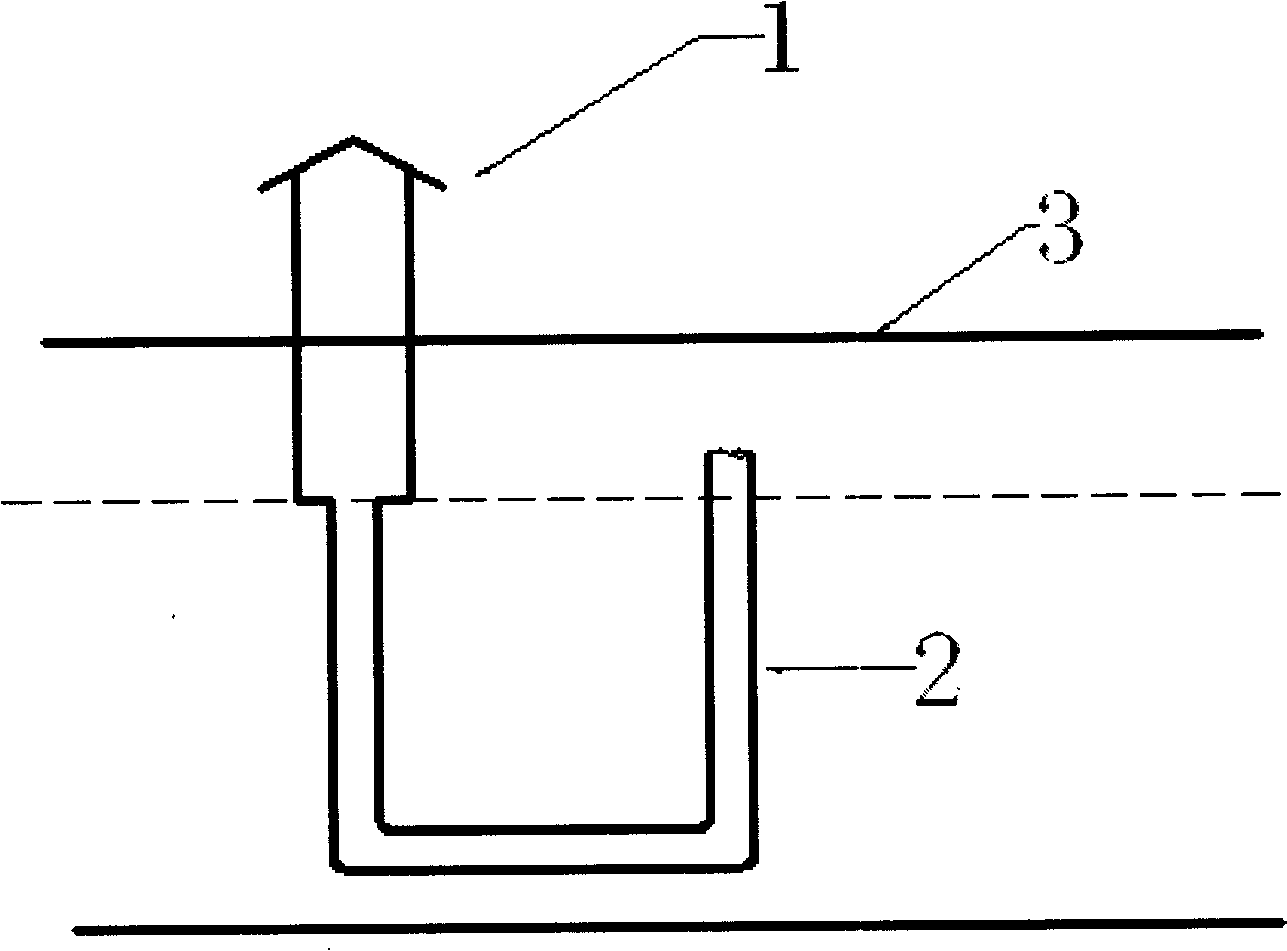

[0019] Reduce the distance between the water tank tube holes of the vacuum tube solar water heater to the desired size according to the requirements, and complete the sealing and dustproofing of the vacuum tube through the one-piece sealing ring and the dustproof ring; insert the hot and cold water deflector into the vacuum tube and keep the side of the semicircular tube Upward, the upward diversion of hot water is realized, thereby improving the natural circulation of water in the pipe; through the coordination and adjustment of the two-position three-way solenoid valve and the two-position three-way manual valve, the water supply, bathing, and drainage of the water heater are realized. Air antifreeze function; through the U-shaped sealed condensate in the U-shaped tube exhaust device on the water tank to realize intermittent exhaust to the air, thereby reducing the loss of heat and water dissipation; when installing the vacuum tube, due to the small tube spacing, this can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com