A continuous concentration process of refined salt for polyamide

A technology for polyamide and refined salt is applied in the field of continuous concentration process of refined salt for polyamide, which can solve the problems of scaling, product quality decline, time-consuming and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

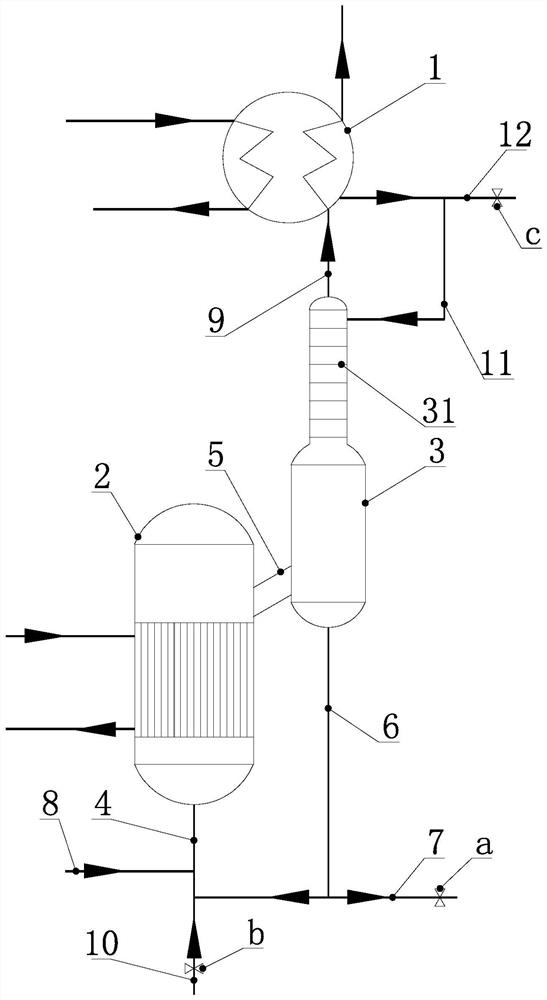

[0034] see figure 1, the concentration system includes a refined salt preheater 1, a refined salt evaporator 2, and a refined salt stripper 3, and the refined salt stripper 3 is located below the refined salt preheater 1 and above the refined salt evaporator 2. The bottom of the refined salt evaporator 2 is provided with a collection pipe 4 extending downwards. Generally, the collection pipe extends vertically downwards, and the extension height of the collection pipe is 1.0-10m. The lower part of the inner space of the refined salt stripper 3 communicates with the upper part of the inner space of the refined salt evaporator 2 through the material pipe 5, and the upper part of the inner space of the refined salt stripper 3 is provided with a tower internal part 31, specifically, the tower internal part 31 is Tray column internals. The bottom of the refined salt stripper 3 is connected to the collecting pipe 4 through the circulation pipe 6, and the concentrated material disch...

Embodiment 2

[0036] Adopt the concentration system of embodiment one to carry out continuous concentration, concrete steps are:

[0037] 1) The refined salt solution mixed with adipic acid and hexamethylenediamine (the total mass content of adipic acid and hexamethylenediamine is 50%) is preheated to 115°C by the refined salt preheater, and enters the refined salt evaporation through the feed pipe and the collecting pipe device, the flow rate is 6t / h;

[0038] 2) The heat medium used in the refined salt evaporator is saturated process steam with a pressure of 0.5-1.5MPaG. The refined salt solution is evaporated in the refined salt evaporator to obtain gaseous materials with a pressure of 0.1-0.5MPa. The gaseous materials enter the refined salt through the material pipe In the stripper;

[0039] 3) The macromolecular components in the gaseous material in the refined salt stripper are intercepted and collected into the lower part of the inner space of the refined salt stripper, and the smal...

Embodiment 3

[0042] Adopt the concentration system of embodiment one to carry out continuous concentration, concrete steps are:

[0043] 1) The refined salt solution mixed with adipic acid and hexamethylenediamine (the total mass content of adipic acid and hexamethylenediamine is 53%) is preheated to 113°C by the refined salt preheater, and enters the refined salt evaporation through the feed pipe and collecting pipe device, the flow rate is 6.5t / h;

[0044] 2) The heat medium used in the refined salt evaporator is saturated process steam with a pressure of 0.5-1.5MPaG. The refined salt solution is evaporated in the refined salt evaporator to obtain gaseous materials with a pressure of 0.1-0.5MPa. The gaseous materials enter the refined salt through the material pipe In the stripper;

[0045] 3) The macromolecular components in the gaseous material in the refined salt stripper are intercepted and collected into the lower part of the inner space of the refined salt stripper, and the small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com