Partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler

A waste heat steam and shell-and-tube technology, which is applied in the field of small-cycle multiplier shell-and-tube high-temperature waste heat steam boilers, can solve the problem of increasing the heat load at the connection between the heat exchange tube bundle and the tube sheet, inducing the deterioration of the heat transfer of the heat exchange tube bundle, and shortening the waste heat equipment. Service life and other issues, to achieve the effect of reducing the floor space and volume, preventing heat transfer deterioration, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

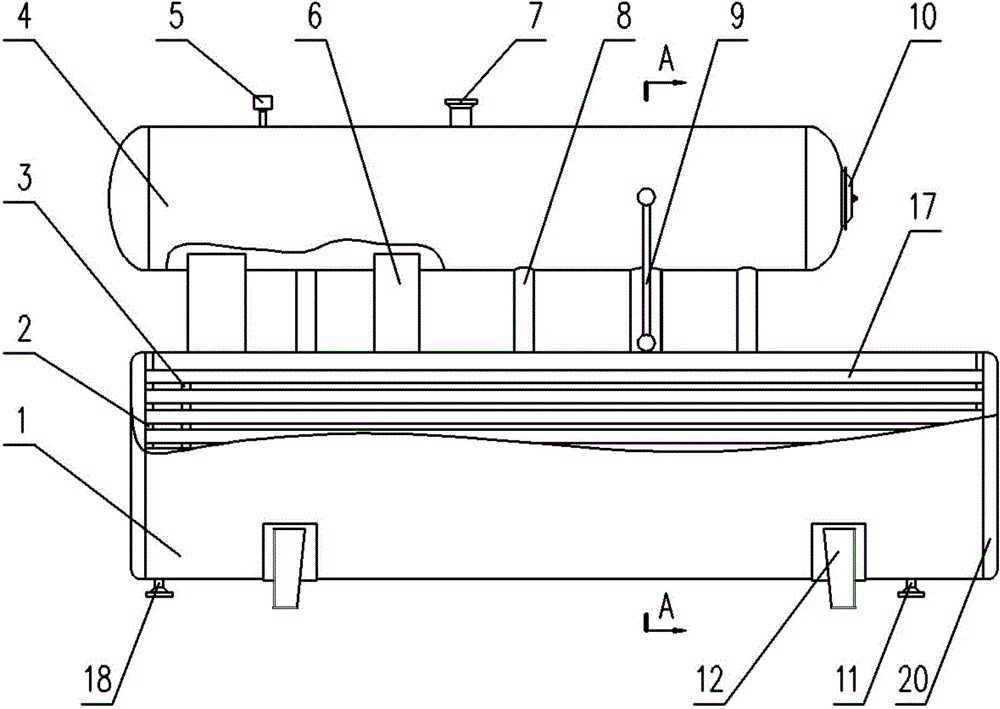

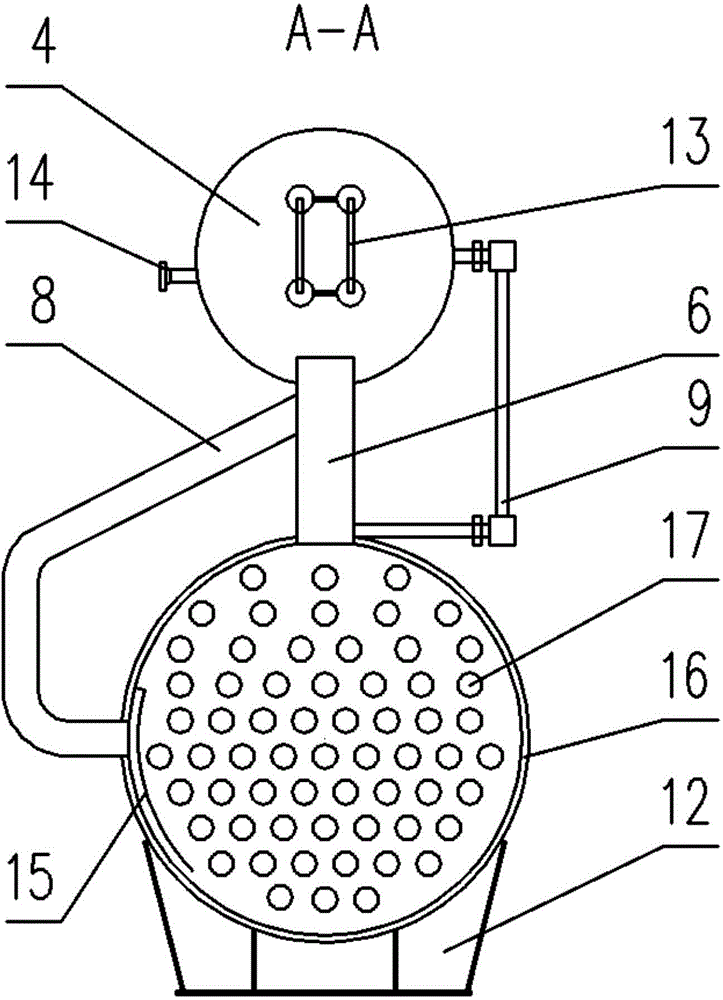

[0034] The shell-and-tube high-temperature waste heat steam boiler with small circulation ratio of local jet flow in the present invention has a structure as follows: figure 1 As shown, it includes a drum 4 and a shell-and-tube evaporation heat exchanger 1 arranged up and down, the drum 4 and the shell-and-tube evaporation heat exchanger 1 are arranged horizontally, and the drum 4 and the shell-and-tube evaporation heat exchanger 1 are arranged horizontally. The heat exchangers 1 are connected through the ascending tube group 6 and the descending tube group 8 respectively, and the drum 4 is connected with the water inlet port 18 on the shell-type evaporative heat exchanger 1 through a high-temperature and high-pressure water pipe, and a high-temperature and high-pressure water pump is installed on the high-pressure water pipe 19.

[0035] Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com