Continuous reaction process of polyamide

A polyamide reaction technology, applied in the continuous reaction process of polyamide, can solve the problems of unstable product quality, high energy consumption of polyamide polymerization, and unusable by-product steam, so as to improve the utilization rate of process steam and avoid Enter the preheating system and reduce the effect of synthesis energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

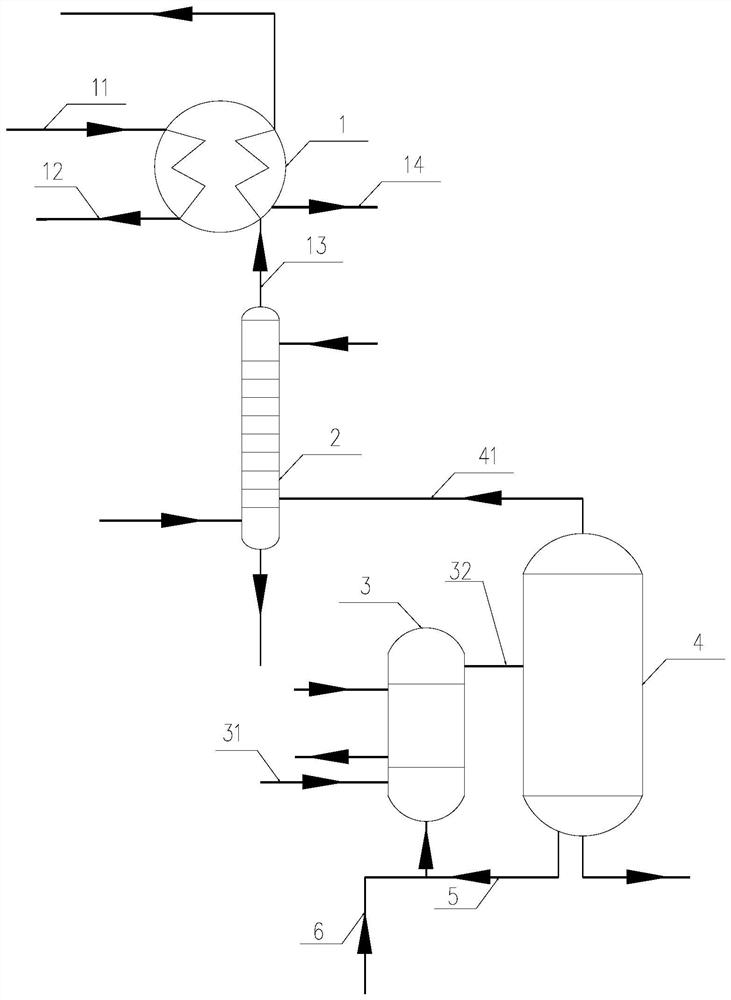

[0034]The reaction device used specifically includes a preheating system 1, a light removal system 2, a heating system 3, and a reaction system 4. Light removal system 2 is located below preheating system 1 and above heating system 3 and reaction system 4 . The tube-side inlet of the preheating system 1 is the polymerization raw material inlet 11 , and the tube-side outlet of the preheating system 1 is the polymerization raw material outlet 12 , which is connected to the feed port of the light removal system 2 . The shell side inlet of the preheating system 1 is the heating medium inlet 13, which is connected with the light components outlet of the light removal system 2. Usually, the shell side outlet of the preheating system 1 outputs uncondensed steam to the outside, and the shell side of the preheating system 1 The process is connected with the return port of the light removal system 2 through the return pipeline 14. Light removal system 2 is a tray tower, and N layers of...

Embodiment 2

[0036] Utilize the reaction device of embodiment one to carry out the continuous reaction of polyamide, specifically:

[0037] 1) 3.8MPa steam is introduced into the shell side of the heating system;

[0038] 2) The polymerization raw material is continuously discharged into the tube side inlet of the preheating system, the feed temperature is 150°C, the composition of the polymerization raw material is dicarboxylic acid and organic diamine with a molar ratio of 1:1.005, and the polymerization raw material passes through the preheating system , Light removal system, enter the tube side of the heating system, raise the temperature to 238°C, evaporate part of the water, reduce the water in the polymerization raw material to 15%, and carry out the pre-polymerization reaction;

[0039] 3) The material obtained by the pre-polymerization reaction is discharged into the reaction system, dehydrated and reacted after pre-polymerization to generate process steam;

[0040] 4) The proces...

Embodiment 3

[0045] Utilize the reaction device of embodiment one to carry out the continuous reaction of polyamide, specifically:

[0046] 1) Biphenyl-biphenyl ether vapor is introduced into the shell side of the heating system;

[0047] 2) The polymerization raw material is continuously discharged into the tube side inlet of the preheating system, the feed temperature is 150°C, the composition of the polymerization raw material is dicarboxylic acid and organic diamine with a molar ratio of 1:1.006, and the polymerization raw material passes through the preheating system , Light removal system, enter the tube side of the heating system, raise the temperature to 230°C, evaporate part of the water, reduce the water in the polymerization raw material to 17.5%, and carry out the pre-polymerization reaction;

[0048] 3) The material obtained by the pre-polymerization reaction is discharged into the reaction system, dehydrated and reacted after pre-polymerization to generate process steam;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com