A variable aperture capillary core applied to a loop heat pipe system and its processing method

A loop heat pipe and processing method technology, applied in aviation thermal control and electronic equipment cooling, porous media phase change and flow fields, can solve the problems of different heat load, poor operating performance, etc., to reduce evaporation thermal resistance and improve operating performance , the effect of stabilizing the phase transition interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

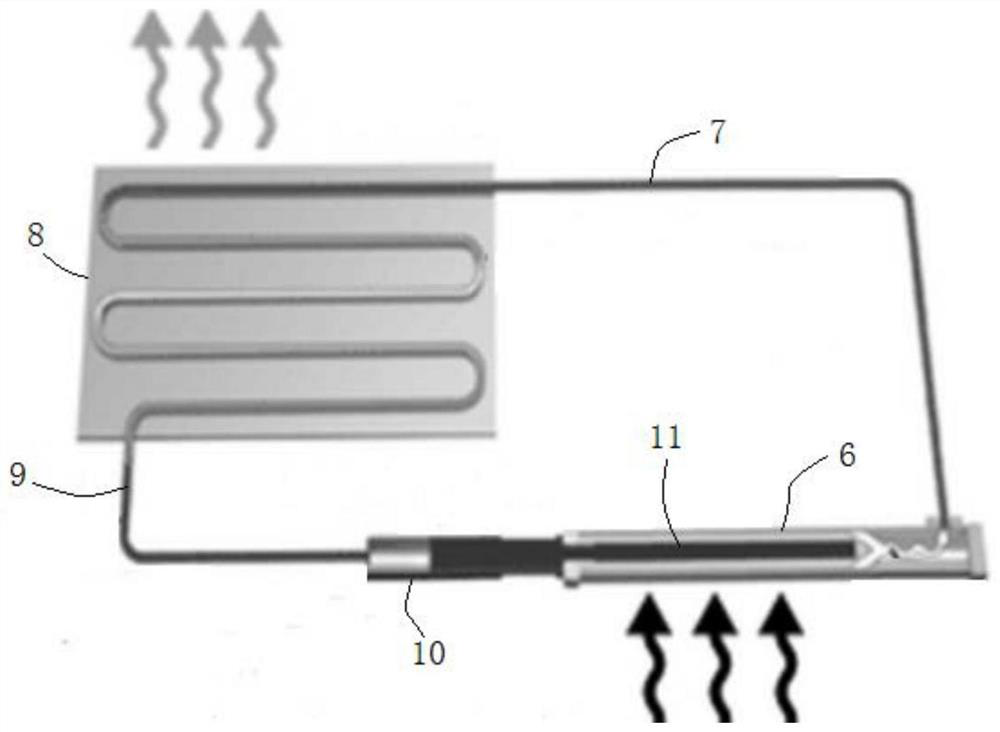

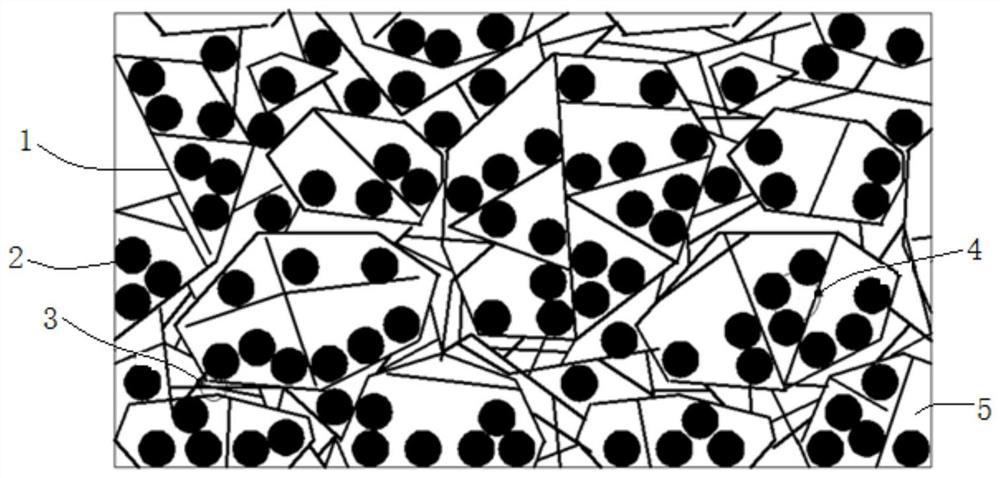

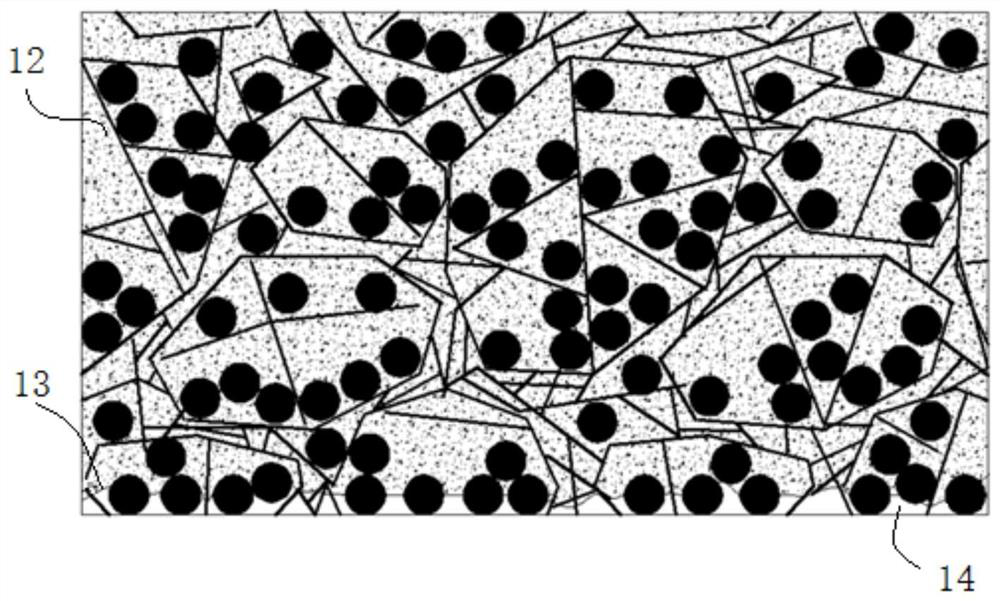

[0039] like figure 2As shown, a variable aperture capillary core applied to a loop heat pipe system in this embodiment includes fibers 1 and powder particles 2, and also includes fiber pores 3, variable powder pores 4 and powder fiber pores 5, wherein the fibers 1. As an internal skeleton, the powder particles 2 are fixed inside the capillary core. The powder particles 2 can move under the meniscus pressure difference caused by the change of thermal load in the skeleton, and the powder pores 4 also change with the movement of the powder particles 2. Thereby, the pore diameter of the capillary core is adjusted to quickly meet the requirements of the stability of the phase change interface 13 in the capillary core, and the movement of the powder pores 4 can change the pumpability and optimize the heat transfer according to the heat load.

[0040] In this embodiment, the capillary core is prepared by using metal raw materials with a large difference in melting point, wherein the...

Embodiment 2

[0051] A variable-aperture capillary core applied to a loop heat pipe system in this embodiment is basically the same as that in Embodiment 1. The difference is that in this embodiment, fiber 1 is a low-melting point metal fiber with a melting point of 1000° C. and powder particles 2 It is a high melting point metal powder particle with a melting point of 1500°C; the filler during mixing and sintering is urea.

Embodiment 3

[0053] A variable-aperture capillary core applied to a loop heat pipe system in this embodiment is basically the same as Embodiment 1, except that in this embodiment, fiber 1 is a low-melting metal fiber with a melting point of 1100° C. and powder particles 2 It is a high melting point metal powder particle with a melting point of 1600°C; the filler during mixing and sintering is NaCl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com