Etching device for manufacturing semiconductor chip and use method thereof

An etching device and semiconductor technology, applied in semiconductor/solid-state device manufacturing, transportation and packaging, conveyor objects, etc., can solve problems such as low work efficiency, achieve the effect of improving yield rate, avoiding excessive etching, and improving reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

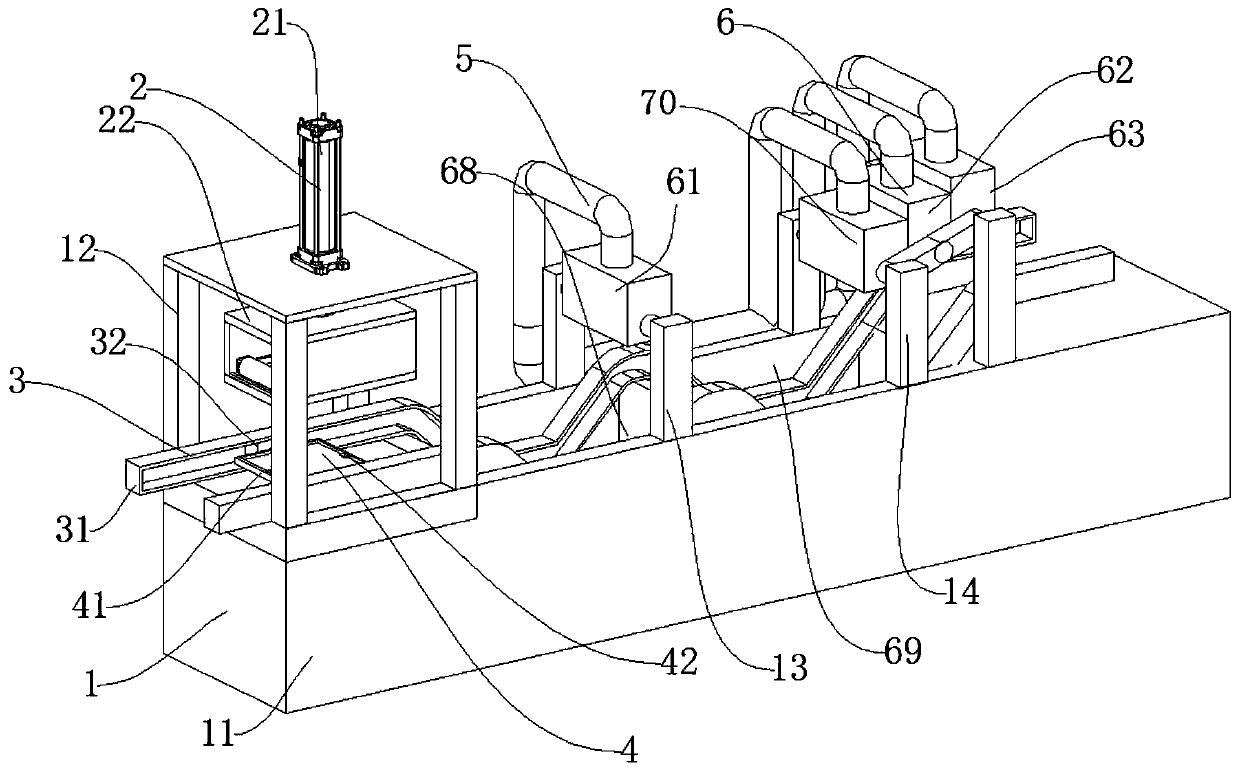

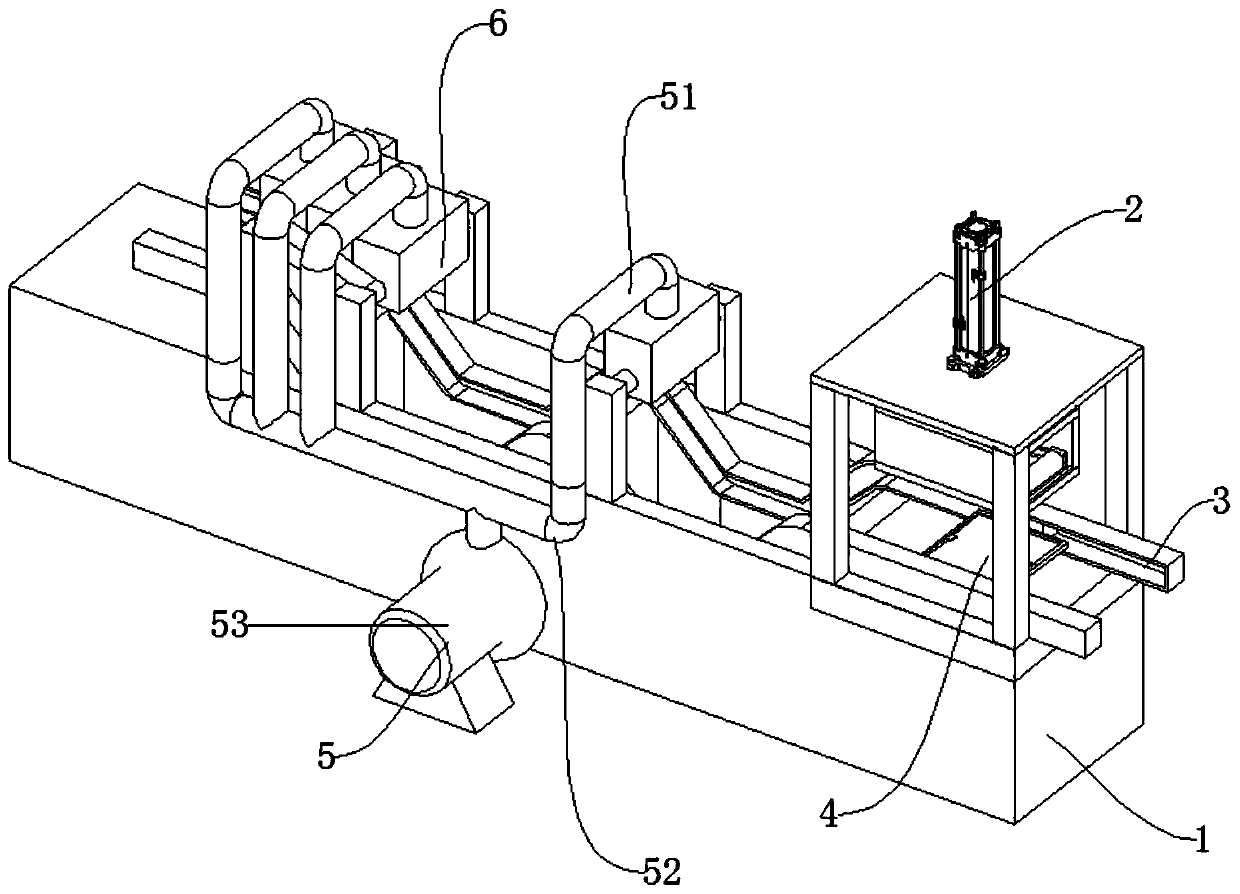

[0040] Embodiments of the present invention provide an etching device for manufacturing semiconductor chips, such as Figure 1-2 As shown, it specifically includes a support mechanism 1, a transport mechanism 3, a printing mechanism 2, an air supply mechanism 5 and a reaction mechanism 6;

[0041] The supporting mechanism 1 plays a supporting role;

[0042] The transport mechanism 3 is connected to the support mechanism 1, and is used to drive the circuit board to be etched to move along a preset track;

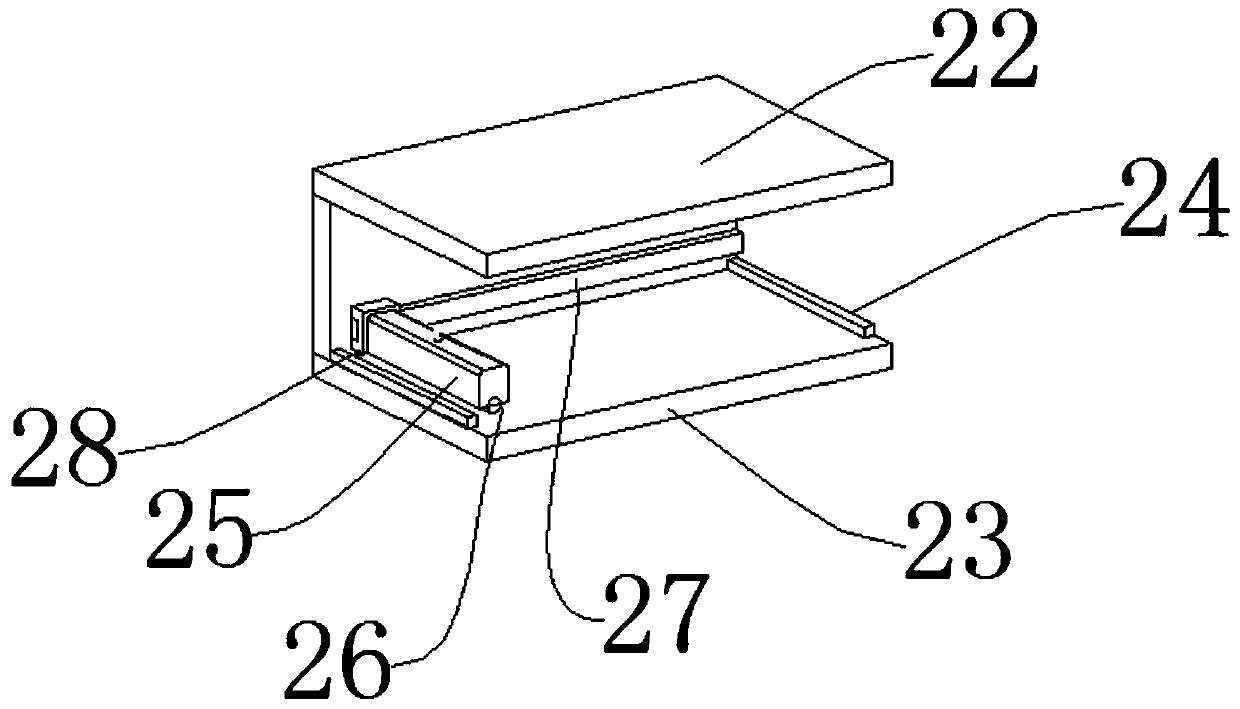

[0043] The printing mechanism 2, the air supply mechanism 5 and the reaction mechanism 6 are arranged in sequence, and all three are arranged above the transportation mechanism 3; the printing mechanism 2 plays a printing role; the air supply mechanism 5 is used to provide air source, the output end of which is connected to the input end of the reaction mechanism 6. When the circuit board moves below the reaction mechanism 6, the gas supply mechanism 5 provides high-pressure...

Embodiment 2

[0061] In the embodiment of the present invention, it is proposed to increase the reaction rate of the whole device by increasing the boiling efficiency of the reaction liquid and the cleaning liquid (water). Based on Embodiment 1, in the embodiment of the present invention, the reaction liquid tank 68 and the water tank 69 Stirring mechanism 7 is arranged inside, and described stirring mechanism 7 comprises stirring motor 71, connecting shaft 72 and stirring seat 73; Described stirring motor 71 links to each other with described stirring seat 73 by described connecting shaft 72, during specific implementation, The connecting shaft 72 is connected to the stirring motor 71 through a coupling, and the effective transmission of force is ensured through the connection of the coupling. For details, see Figure 8 .

Embodiment 3

[0063] An embodiment of the present invention provides a method for using an etching device for semiconductor chip manufacturing, including:

[0064] Place the circuit board to be etched on the transport mechanism 3;

[0065] The transportation mechanism 3 drives the circuit board to be etched to move to the bottom of the printing mechanism 2, and the printing mechanism 2 applies the dressing on the circuit board;

[0066] When the transport mechanism 3 drives the circuit board to move below the reaction mechanism 6, the gas supply mechanism 5 supplies high-pressure gas to the reaction mechanism 6, and the reaction mechanism 6 blows air to the circuit board.

[0067] More specifically, when the method for using the etching device for manufacturing semiconductor chips in this embodiment is applied to the device in Embodiment 1, the following steps are specifically included:

[0068] a, the circuit board that needs to be etched is placed in the groove on the transport plate 41,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com